Application of Al

2O

3Nanofluid on Sintered Copper-powder Vapor

Chamber for Electronic Cooling

Nandy Putra, Wayan Nata Septiadi, Ranggi Sahmura, Cahya Tri Anggara

Heat Transfer Laboratory, Department of Mechanical Engineering Universitas Indonesia

Kampus UI, Depok 16424

nandyputra@eng.ui.ac.id

Keywords: vapor chamber; nanofluid; sintered copper-powder; CPU cooling

Abstract. The development of electronic devices pushes manufacturers to create smaller microchips with higher performance than ever before. Microchip with higher working load produces more heat. This leads to the need of cooling system that able to dissipate high heat flux. Vapor chamber is one of highly effective heat spreading device. Its ability to dissipate high heat flux density in limited space made it potential for electronic cooling application, like Central Processing Unit (CPU) cooling system. The purpose of this paper is to study the application of Al2O3 Nanofluid as working fluid for

vapor chamber. Vapor chamber performance was measured in real CPU working condition. Al2O3

Nanofluid with concentration of 0.1%, 0.3%, 0.5%, 1%, 2% and 3% as working fluid of the vapor chamber were tested and compared with its base fluid, water. Al2O3 nanofluid shows better thermal

performance than its base fluid due to the interaction of particle enhancing the thermal conductivity. The result showed that the effect of working fluid is significant to the performance of vapor chamber at high heat load, and the application of Al2O3 nanofluid as working fluid would enhance thermal

performance of vapor chamber, compared to other conventional working fluid being used before.

Introduction

The amount of transistor in single microchips keeps doubling every two years, creating small and high performance Central Processing Unit (CPU) [1]. As the number of transistor rises, the amount of heat that is produced also rises [2]. Meanwhile the trend of computer and gadget development goes to the miniaturization of the product. It made smaller yet with high performance. [3]. These leads to the need of a compact cooling system that is able to dissipate high heat flux.

Vapor chamber basically is a two phase heat spreading device. Similar to heat pipe, it has excellent ability of dissipating heat through the working fluid phase change, with advantages over cylindrical heat pipe as geometry adaptation and ability for much localized heat dissipation. Its flat shape made vapor chamber ready to be applied as Central Processing Unit (CPU) cooling system [4-6]. Numerous investigations about vapor chamber with the variation of wick (using sintered copper powder, grooved and screen mesh) and working fluid (using water, water with surfactant, methanol, acetone, and refrigerant) have been conducted [7-15].

Meanwhile by the author’s knowledge there are only a few publication studied the use of Al2O3

nanofluid with different concentration as the working fluid of sintered copper-powder vapor chamber. Nanofluid is fluid consist of base fluid and nanometer-sized particle [16]. Its thermal performance over the base fluid and its application on several heat exchanging devices like thermosyphon and heat pipe has already been studied. Suresh et al. [17] studied the heat transfer characteristics of Al2O3-Cu/water nanofluid. The study revealed that the nanofluid added friction factor to the fluid and

enhanced the convective heat transfer by increasing Nusselt number. The nanofluid application for heat pipe has been studied [18-22], showing the potential use of it as working fluid.

Advanced Materials Research Vol. 789 (2013) pp 423-428 Online available since 2013/Sep/04 at www.scientific.net

© (2013) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/AMR.789.423

This study evaluated the effect of Al2O3-water nanofluid to the thermal performance of sintered

copper-powder wick vapor chamber. The nanofluid were charged at different volume fraction concentration and the inclination effect of vapor chamber were also tested.

Methods

Preparation of nanofluids and vapor chamber

Al2O3 nanoparticles were dispersed in the base fluid of distilled water by ultrasonicating for 30

minutes in ultrasonic processor. The volume fraction concentration of nanoparticle in nanofluid is calculated by using equation (1):

% volume fraction = (Wnp/ρnp)/ (Wnp/ρnp + Wbf/ρbf) (1)

where Wnp and ρnp are the weight and the density of nanoparticle, and Wbf and ρbf are the weight and

the density of base fluid respectively.

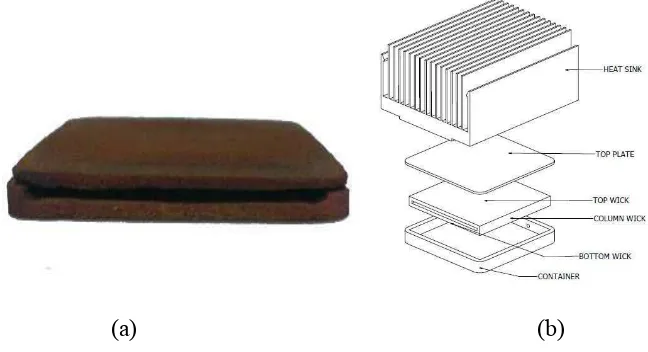

Vapor chamber designed for this experiment made from copper with total dimension of 60 mm x 60 mm x 8 mm, assembled of bottom container, top plate and wick structure as can be seen in fig. 1(a) The evaporator and condenser thickness were 1.2 mm with 2 mm sintered copper-powder wick on the inner side of both, creating the bottom and the top wick. The sintered copper-powder made from copper-powder with the mesh of 300 µm. The bottom and the top wick were connected by column wick, as can be seen in fig. 1(b), providing path for the liquid to flow back from the evaporator to the condenser. The bottom container and the top plate were welded together, then attached to a standard heat sink fan. The heat sink was grooved so the vapor chamber can fit in snugly. The working fluid injected to the vapor chamber has charge volume ratio of 60%.

(a) (b)

Figure 1. (a) Sintered copper-powder as the wick of vapor chamber ; (b) Vapor chamber assembly for the experiment

Experimental Setup

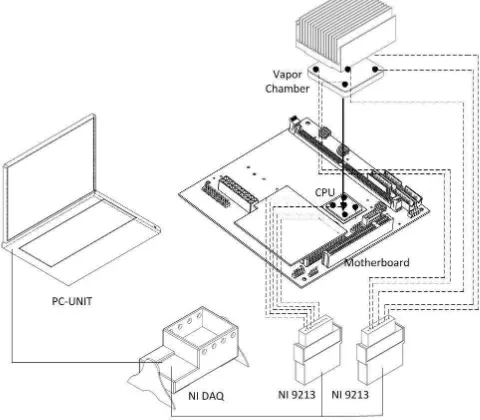

The evaluation of vapor chamber thermal performance was conducted by arranging the experimental setup as shown in fig. 2. At the evaporator of the vapor chamber, central processing unit (CPU) of Intel® Pentium 4 socket 478 2.4GHz were placed as the heat source. Having 13.1 Watt at the idle condition and 48.3 Watt at the maximum load condition, the CPU was being loaded by running software Prime95. The thermocouples being used were the type K thermocouple, and all the thermocouples were connected to the high precision NI 9213 data acquisition module. The ambience temperature is being kept at 25 ± 0.5 oC.

The variations of nanofluid volume fraction concentration were 0.1 %, 0.3%, 0.5%, 1%, 2% and 3% to see the effect of concentration to the enhancement of thermal performance. The inclination angles being used are 0o or horizontal position, 45o and 90o or the vertical position.

Figure 2. Experimental Setup

Result and Discussion

Effect of working fluid to the thermal performance

Firstly, vapor chamber without working fluid was tested at CPU with no load for 10 min, continued with full load condition for 20 min and back to the no load condition for 10 min. Then, water and Al2O3-water nanofluid were tested with the same loading condition. The result then compared with

cooling performance of conventional heat sink without vapor chamber. The result is presented in Fig. 3(a).

It can be observed that vapor chambers vividly have better thermal performance than conventional cooling system heat sink fan, shown by the lower CPU temperature with ∆T around 3oC at no load condition. But it can be seen that the effect of working fluid has not significantly give impact to the thermal performance of vapor chamber at no load condition. At this level of load, the heat from the CPU was not enough to ignite the boiling phenomenon inside the vapor chamber. Thus, the heat transfer was being conducted mostly by conduction and, in the small amount, by free convection, so the effect of working fluid becomes less impactful. This also validated by the fact that nanofluid-charged vapor chamber did not yield better performance than water-charged vapor chamber.

While at the full load CPU operating condition, the effect of working fluid was greatly impact the thermal performance of vapor chamber. At this loading condition, it can be seen that vapor chamber without working fluid shows worse thermal performance than the vapor chamber with working fluid shown by high CPU temperature. The average CPU temperature for empty vapor chamber and water charged vapor chamber is 61.36 oC and 59.12 oC respectively. At this loading condition, the heat from the CPU intensifies the boiling phenomenon inside the vapor chamber, making the heat transfer at the fluid-charged vapor chamber undergone efficiently. While at the empty vapor chamber, the heat transfer depended only on conduction, increasing the thermal resistance. It also can be observed that nanofluid-charged vapor chamber shows better thermal performance than water-charged vapor chamber at this loading condition, producing average CPU temperature of 57.52 oC. This indicates that the enhancement of thermal characteristics of nanofluid affected the thermal performance of vapor chamber at a greater amount on high heat load condition, rather than at low heat load condition. As the enhancement of thermal conductivity only affected the performance at the small amount, the other improvement of the nanofluid over its base fluid should be analyzed.

Effect of nanofluid concentration

The volume fraction concentration of 0.1%, 0.3%, 0.5%, 1%, 2% and 3% were tested under the same CPU loading condition. The result is presented in Fig. 3(b). It can be observed that at no load condition, increment of volume fraction concentration of Al2O3-water nanofluid from 0.1% up to 1%

did not give significant effect on vapor chamber thermal performance as the temperature of CPU scattered randomly at the temperature range of 29.8 oC – 31.5 oC. But at the volume fraction concentration of 2% and 3%, significant improvement of thermal performance was noted as CPU temperature fell below 29 oC. At the concentration of 2% and 3%, there were denser formations of nanoparticles at the evaporator so the thermal conductivity were greatly increased, reduce the thermal resistance. This help the heat transfer and reduce the average CPU temperature.

At the full load condition, it can be observed that along with the increment of volume fraction concentration of nanofluid, the thermal performance increased. The 3% nanofluid concentration yields the best thermal performance, producing average CPU temperature of 54.64 oC.

(a) (b)

Figure3. (a) Effect of working fluid and (b) Effect of Al2O3-water nanofluid concentration to the thermal performance of vapor chamber at no load, and full load condition

The lower nanofluid concentration produces higher average CPU temperature, which is 57.31 oC, 57.52 oC, and 57.94 oC for 2%, 1% and 0.5% volume fraction concentration. The 0.3% and 0.1% nanofluid concentration produced no significant improvement of thermal performance, showed by the slight difference in average CPU temperature compared to water as working fluid.

The enhancement brought by the nanofluid were explained by the improvement of boiling phenomenon at evaporator. As discussed by Qu et al. [19], the nanoparticles suspended at base fluid can enhance and stabilize the nucleation at the evaporator and increase the bubble release frequency, decreasing the thermal resistance of evaporator. This phenomenon increased as the concentration of nanofluid increased. This explained the higher thermal performance showed by the higher nanofluid concentration.

Effect of Inclination Angle

The investigation conducted by testing vapor chamber with two different nanofluid concentration at three different inclination angles. The result is presented in Fig. 4.

The result shows that for both concentrations, inclination angle brought similar effect on the thermal performance of vapor chamber. For 2% nanofluid concentration, inclination angle of 45o only brought slight increase at the average CPU temperature over the horizontal position. Average temperature of CPU at horizontal position and at 45o inclination angle is 56.06 oC and 56.34 respectively. While at the vertical position or 90o inclination angle, vapor chamber produce significantly higher average CPU temperature as much as 57.32 oC. The same trend happened for the 3% nanofluid concentration. This is due to the different amount of working fluid available at the evaporator at different inclination

angles. At horizontal position, evaporator is flooded with working fluid, ensuring the availability of fluid which absorbs heat and doing the phase change process. This made the heat transfer undergone efficiently and prevented dry-out. At 45o inclination angle, the working fluid of the evaporator decreased due to gravity, hamper the ability of wick to pump liquid. The phenomenon is getting worse for the 0o inclination angle since the gravitational force become larger. At this vertical position, there was very little amount of working fluid left at the evaporator side, letting the heat transfer dominated by conduction and increasing the thermal resistance.

Figure 4. Effect of inclination angle on thermal performance of vapor chamber

Conclusion

The effect of working fluid on the vapor chamber was investigated. It was revealed that at a lower heat load, effects of working fluid are small due to the domination of conduction in vapor chamber heat transfer process. The effects become more and more significant as the higher heat load applied. The higher heat load intensifies the boiling process and made the heat transfer process undergone efficiently. The effects of nanofluid concentrations were also observed. It was discussed that higher concentration of nanofluid enhance the thermal performance of vapor chamber due to the nanoparticles suspended at the working fluid enhancing and stabilizing the nucleation process, increasing the bubble release frequency and improving boiling phenomenon at the evaporator. This reduce thermal resistance and increase the thermal performance of vapor chamber. The inclination angle was also observed that the effect of gravitational force made the horizontal position as the best working position for vapor chamber.

Acknowledgment

The Author would like to thank DRPM Universitas Indonesia for the financial support in doing this research through Hibah Riset Utama 2012 Scheme.

References

[1] R.R.Schaller. Moore’s law: past, present and future Spectrum, IEEE Vol 36 (2002) 52-59 [2] L.B. Kish. End of Moore’s law: thermal (noise) death of integration in micro and nano

electronics. Physics Letters A 305 (2002) 144-149

[3] R. Godwin-Jones. Emerging Technologies Mobile-Computing Trends: Lighter, Faster, Smarter.

Language Learning & Technology Volume 12, Number 3 (2008) 3-9

[4] S.C. Wong, K.C. Hsieh, J.D. Wu, W.L. Han. A novel vapor chamber and its performance. International Journal of Heat and Mass Transfer 53 (2010) 2377 – 2384

[5] Y.S. Chen, et al. Numerical simulation of a heat sink embedded with a vapor chamber and calculation of effective thermal conductivity of a vapor chamber. Applied Thermal Engineering 29 (2009) 2655-2664

[6] Y. Wang, K. Vafai. Transient characterization of flat plate heat pipes during startup and shut down operations. International Journal of Heat and Mass Transfer 43 (2000) 2641-2655

[7] A.A. Attia, B. El-Assal. Experimental investigation of vapor chamber with different working fluids at different charge ratios. Ain Shams Engineering Journal 3 (2012) 289-297

[8] J.S. Go. Quantitative thermal performance evaluation of a cost-effective vapor chamber heat sink containing a metal-etched microwick structure for advance microprocessor cooling. Sensors and Actuators A 121 (2005) 549-556

[9] Y.T. Chen, S.W. Kang, Y.H. Hung, C.H. Huang, K.C. Chien. Feasibility study of an aluminum vapor chamber with radial grooved and sintered powders wick structures. Applied Thermal Engineering 51 (2013) 864-870

[10] S.C. Wong, K.C. Hsieh, J.D. Wu, W.L. Han. A novel vapor chamber and its performance.

International Journal of Heat and Mass Transfer 53 (2010) 2377-2384

[11] X. Ji, J. Xu, A.M. Abanda. Copper foam based vapor chamber for high heat flux dissipation. [12] P. Naphon, S. Wiriyasart. Study on the vapor chamber with refrigerant R-141b as working fluid

for HDD cooling. International Communications in Heat and Mass Transfer 39 (2012) 1449-1452

[13] H.Y. Li, M.H. Chinang, C.I. Lee, W.J. Yang. Thermal performance of plate-fin vapor chamber heat sinks. International Communication in Heat and Mass Transfer 37 (2010) 731-738

[14] S.C. Wong, S.F. Huang, K.C. Hsieh. Performance tests on a novel vapor chamber. Applied Thermal Engineering (2011) 1757-1762

[15] P. Naphon, S. Wongwises, S. Wiriyasart. On the thermal cooling of central processing unit of the PCs with vapor chamber. International Communications in Heat and Mass Transfer 39 (2012) 1165-1168

[16] Z.H. Liu, Y.Y. Li. A new frontier of nanofluid research – Application of nanofluid in heat pipes.

International Journal of Heat and Mass Transfer 55 (2012) 6786-6797

[17] S. Suresh, K.P. Venkitaraj, P Selvakumar, M. Chandrasekar. Effect of Al3O3-Cu/water hybrid nanofluid in heat transfer. Experimental Thermal and Fluid Science 38 (2012) 54-60

[18] Y.H. Huang, T.P. Teng, B.G. Lin. Evaluation of the thermal performance of a heat pipe using alumina nanofluid. Experimental Thermal and Fluid Science 44 (2013) 504-511

[19] J. Qu, H.Y. Wu, P. Cheng. Thermal performance of an oscillating heat pipe with Al2O3-water nanofluid. International Communications in Heat and Mass Transfer 37 (2010) 111-115

[20] T.P. Teng, H.G. Hsu, H.E. Mo, C.C. Chen. Thermal efficiency of heat pipe with alumina nanofluid. Journal of Alloys and Compounds 5045 (2010) 5380-5384

[21] R. Saleh, N. Putra, S.P. Prakoso, W.N. Septiadi. Experimental investigation of thermal conductivity and heat pipe thermal performance of ZnO nanofluid. International Journal of Thermal Science 63 (2013) 125-132

[22] N. Putra, W.N. Septiadi, H. Rahman, R. Irwansyah. Thermal performance of screen mesh wick heat pipes with nanofluid Experimental Thermal and Fluid Science 40 (2012) 10-17

Advances in Materials, Processing and Manufacturing

10.4028/www.scientific.net/AMR.789

Application of Al2O3 Nanofluid on Sintered Copper-Powder Vapor Chamber for Electronic Cooling

10.4028/www.scientific.net/AMR.789.423

DOI References

[4] S.C. Wong, K.C. Hsieh, J.D. Wu, W.L. Han. A novel vapor chamber and its performance. International Journal of Heat and Mass Transfer 53 (2010) 2377 – 2384.

http://dx.doi.org/10.1016/j.ijheatmasstransfer.2010.02.001

[10] S.C. Wong, K.C. Hsieh, J.D. Wu, W.L. Han. A novel vapor chamber and its performance. International Journal of Heat and Mass Transfer 53 (2010) 2377-2384.