Analysis of Indentation Size Effect of Vickers Hardness Tests of Steels

Nyoman Budiarsa, Andrew Norbury, Xiaoxiang Su, Gareth Bradley

and Xuejun Ren

School of Engineering, Liverpool John Moores University, L3 3AF, UK

Keywords: Vickers hardness, indentation size effect, H/E.

Abstract. In this work, the indentation size effect (ISE) in Vickers hardness tests of steel with selected heat treatments (annealed or tempered) has been investigated and analysed. Systematical hardness tests were performed within a commonly used micro-load range. The experimental data was analysed according to the Meyer power-law and the proportional specimen resistance (PSR) models and the link between ISE and material properties was discussed. The results showed that the experimental data fitted well with the Mayers power-law (P = A.dn) and the PSR (P/d = al + a2d)

models. The ISE index (n) showed a good correlation with the hardness-elastic modulus ratio (H/E), which potentially could be used to predict the relative contributions of the elastic and plastic deformation contact area under indentation load and to normalize the hardness values for inverse material properties .

Introduction

Vickers microhardness testing is widely used in testing different types of materials. It requires only a small amount of material and is convenient to use. In some cases, the property distributions over a wide area can be mapped, which is particularly useful for situations such as welded joints, surface integrities of machined surfaces or gradient materials. Recent developments in inverse FE modelling could potentially extend the use of hardness tests to a new area of predicting the constitutive plastic properties (e.g. yield strength and work hardening coefficients). This is particular appealing to situations such as heat treatments of steels where hardness tests are routinely used for process developments and/or quality control. However, the results of a hardness test can be influenced by many factors, among which ISE, i.e. observation of the phenomena that the hardness is dependent on the applied load [1], is the most significant issue. ISE could directly influence the analysis of hardness results, in particular when comparing data from different sources. This has to be investigated to be able to accurately predict/compare the material properties from hardness tests.

ISE has been studied extensively for indenters of various shapes including both sharp (conical or pyramidal) and spherical indenters over different material groups [2-5]. The source of ISE is still a subject of study, which has been attributed to a number of phenomena and mechanisms, including: elastic recovery, work hardening during indentation and strain gradients associated with dislocations [5-8]. The scale of ISE has been correlated to different material properties such as elastic modules, dislocation density, etc. [2, 5-7]. Previous work by Ren et al [3] on Knoop hardness tests of single crystal ceramics showed the ISE coefficients exhibited a good correlation with the hardness to modulus ratio (H/E) of the materials. It is of interest to extend the work to steels with different teat treatments due to their widespread applications.

In this work, the ISE of steels with selected heat treatments (annealed or tempered) has been investigated and analysed. Systematical hardness tests were performed within a commonly used micro-load range. The experimental data was analysed according to the Meyer power-law and the PSR models and the link between ISE to material properties is explored.

Advanced Materials Research Vols. 652-654 (2013) pp 1307-1310 Online available since 2013/Jan/25 at www.scientific.net

© (2013) Trans Tech Publications, Switzerland doi:10.4028/www.scientific.net/AMR.652-654.1307

Materials and Experimental

The sample material used was a medium carbon steel with 0.54 % C (0.54 C; 0.9 Mn, 0.055 P, 0.014 S, 0.19 Si, 0.014Ni) in the form of steel rods (5 mm in diameter). The hardnesses of samples under annealed or quenched and tempered (200°C, 400°C and 600°C) conditions were compared to establish the ISE over a load range commonly used in testing heat-treated components. The samples were sectioned, mounted in resin before being polished with diamond paste. The hardness tests were undertaken carried out on a Duramin Vickers microhardness tester and the experimental data analysed utilising the power law and PSR models.

Results and Discussions

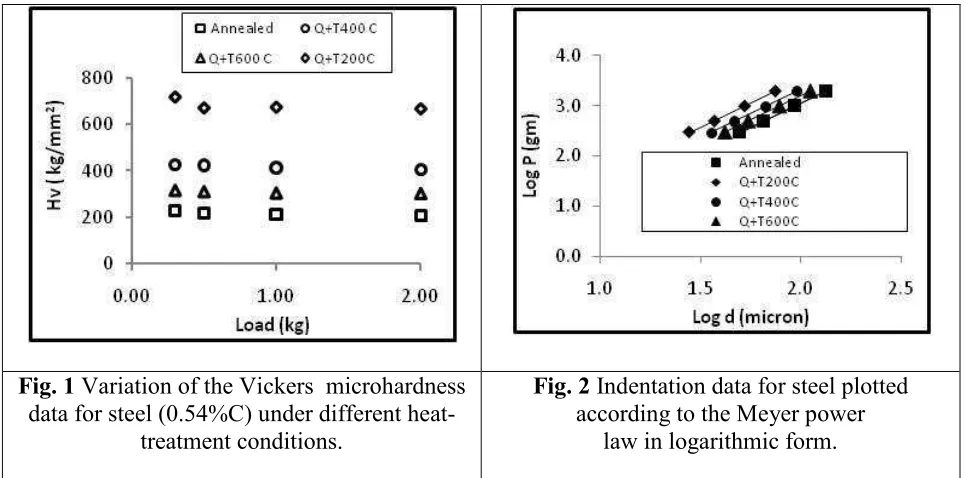

Fig. 1 shows the variation in the Vickers hardness of the materials with respect to applied load. Each data point represents the mean value of six measurements. As shown in the figure, there is a clear variation in the ISE of the Vickers hardness on steel with different heat-treatment conditions. The hardness of the annealed sample is much lower than the other tempered samples, with the hardness value decreasing with increasing tempering temperature. In all the cases, within the testing load used, the data clearly showed that increasing the applied load resulted in decreased hardness values. As the tempering temperature increased, the variations of hardness with respect to load became less significant.

Fig. 1 Variation of the Vickers microhardness data for steel (0.54%C) under different heat-

treatment conditions.

Fig. 2 Indentation data for steel plotted according to the Meyer power

law in logarithmic form.

The ISE has traditionally been described in terms of the Meyer power law and the proportional specimen resistance model [6-7]. The power law described relationships between the applied load (P), and the resulting indentation size (d):

P = A d (1)

Log P = log A + n log d (2)

where P is the applied load, d is the diagonal length and, A and n are constants. The exponent n, is a measure of the ISE behaviour, which has been experimentally observed between 1.5 and 2.0 [5-6]. When n > 2, there is reverse ISE behaviour, whilst when n=2, the hardness is independent of the applied test load, and is given by Kick’s law:

P = A d (3)

Where A0 is geometric conversion factor for the indenter used.

Fig. 2 plots the indentation data according to the Meyer power law in logarithmic form. It is evident from the figure, that this equation describes the data well for all samples. The slope, which represents the ISE index n, was higher for the tempered condition than the annealed condition and exhibited an increasing trend with increasing tempering temperature indicating less significant ISE over the load range used. This suggested that ISE increased with increasing nominal hardness values.

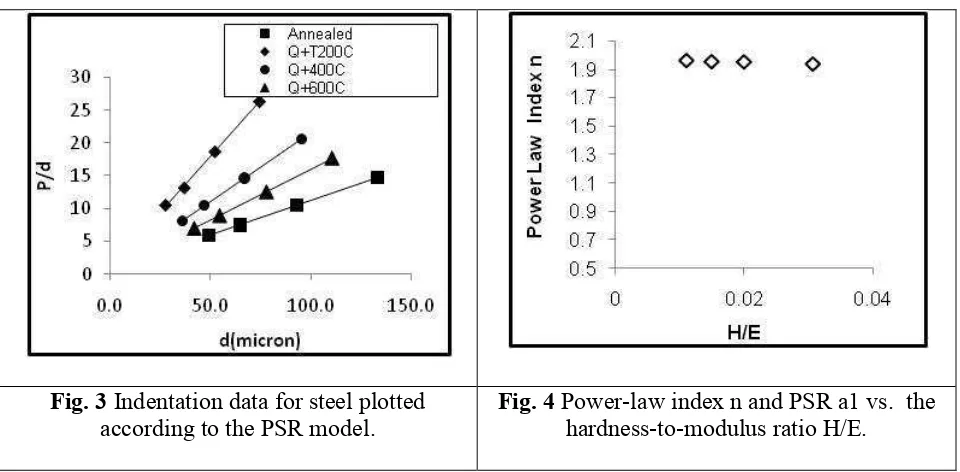

Proportional specimen resistance (PSR) approaches resulted in a relationship between the applied load (P) and the resulting indentation size d (µm) with which, the normal ISE behaviour could be described by the relation [6]:

P = a d + a d (4)

= a + a d (5)

Where the parameter a1 characterises the load dependence of hardness and a2 is a load-independent

constant. a1 represents the energy consumed in creating new surface and a2 represents the work of

permanent deformation or the volume energy of deformation. Equation (5) could be used to describe the measured data as depicted in Fig. 3. The correlation coefficients were again greater than 0.99 in all cases. There was a clear difference between the slope of data for the annealed condition and the tempered conditions, which increased as the hardness of the samples increased.

Fig. 3 Indentation data for steel plotted according to the PSR model.

Fig. 4 Power-law index n and PSR a1 vs. the hardness-to-modulus ratio H/E.

The hardness test results showed that in all the cases, there was a clear ISE in the heat-treated steel samples tested. Both power law and PSR model could accurately depict the ISE observed. Previous work has linked the ISE to the Young’s modulus, but it is commonly accepted that the Young’s modulus of steels does not vary significantly with heat treatments, so elastic resistance could not be the main cause of ISE observed over the load range employed. Fig. 4 depicts the power-law index n against the hardness-to-modulus ratio H/E. It is clearly shown that the ISE parameters exhibited a reasonable agreement with the H/E values. This suggests, similar to the Knoop hardness in single crystals of ceramics [6], that the ISE could be linked to the hardness-Elastic modulus. This potentially could provide a method to normalise ISE in order to inversely predict the plastic material parameters of metals with different heat treatment conditions. Further work is required to study this trend with a more comprehensive set of data.

Summary

In this work, the indentation size effect (ISE) in hardness tests of steel with selected heat treatments (annealed or tempered) was investigated and analysed. Systematical hardness tests were performed within a commonly used micro-load range. The experimental data was analysed according to the Meyer power-law and the proportional specimen resistance (PSR) models and the link between ISE to material properties was also discussed. The results showed that the experimental data fitted well with the Mayers power-law (P = A.dn) and the PSR (P/d = al + a2d) models. The Mayers index (n)

showed a good correlation with hardness-elastic modulus ratio (H/E), which potentially could be used to predict the relative contributions of elastic and plastic deformation contact area under indentation load. Further work, with a more comprehensive set of data, is required to study this trend and establish a procedure to normalize the data in order to predict the constitutive materials properties inversely from hardness tests.

References

[1] X. Kong, Q. Yang , B. Li , G. Rothwell, R. English and X.J. Ren: Materials & Design Vol 29(8) (2008), p.1554.

[2] M. Atkinson: Journal Mech. Sci. Vol. 33 (1991), p.843.

[3] X.J. Ren, R.M. Hooper, C. Griffiths, J.L. Henshall: J Materials science Vol. 22 (2003), p.1105. [4] Y.V. Milman, A.A. Golubenko, S.N. Dub: Acta Materialia Vol.59 (2011), p.7480.

[5] G.M. Pharr, E.G. Herbert, and Y.F. Gao: Annu. Rev. Mater. Res. Vol. 40 (2010), p.271.

[6] X.J. Ren, R.M. Hooper, C. Griffiths, J.L. Henshall: Philosophical Mag. A. Vol. 10 (2002), p.2113. [7] H. Li, A. Ghoshs, Y.H. Han and R.C. Bradt: Journal of Materials Research Vol. 8 (1993), p.1028.

[8] W.D. Nix and H. Gao: J Mech Phys Solids Vol.46(1998), p.411.

Advances in Materials and Materials Processing 10.4028/www.scientific.net/AMR.652-654

Analysis of Indentation Size

Effect of Vickers Hardness

Tests of Steels

by

I Nyoman Budiarsa

FILE

TIME SUBMITTED 06-JUN-2015 02:11PM

SUBMISSION ID 548514909

WORD COUNT 1771

CHARACTER COUNT 9222

18

%

SIMILARITY INDEX

9

%

INTERNET SOURCES

18

%

PUBLICATIONS

3

%

STUDENT PAPERS

1

5

%

2

3

%

3

2

%

4

2

%

5

1

%

6

1

%

Analysis of Indentation Size Effect of Vickers Hardness

Tests of Steels

ORIGINALITY REPORT

PRIMARY SOURCES

N. K. Mukhopadhyay. "Micro- and

nanoindentation techniques for mechanical

characterisation of materials", International

Materials Reviews, 08/01/2006

Publication

st.sdhykx.cn

Internet Source

Sangwal, K.. "Analysis of the indentation size

effect in the microhardness measurement of

some cobalt-based alloys", Materials

Chemistry & Physics, 20030115

Publication

www.crystalresearch.com

Internet Source

Gong, J.. "Analysis of the indentation size

effect on the apparent hardness for

ceramics", Materials Letters, 199902

Publication

7

1

%

8

1

%

9

1

%

10

1

%

11

<

1

%

12

<

1

%

Werkstofftechnik, 03/2011

Publication

Riscob, B., Mohd Shakir, N. Vijayan, K. K.

Maurya, M. A. Wahab, and G.

Bhagavannarayana. "Unidirectional crystal

growth and crystalline perfection of

L-arginine phosphate monohydrate", Journal of

Applied Crystallography, 2012.

Publication

A. Abu El-Fadl. "Influence of x-irradiation on

indentation size effect and formation of

cracks for [Ky(NH4)1-y]2ZnCl4 mixed

crystals", Crystal Research and Technology,

04/2007

Publication

Ryou, H.. "Nanoscopic dynamic mechanical

properties of intertubular and peritubular

dentin", Journal of the Mechanical Behavior

of Biomedical Materials, 201203

Publication

www.eng.livjm.ac.uk

Internet Source

P. Sayan. "Effect of Various Impurities on the

Hardness of NaCl Crystals", Crystal Research

and Technology, 11/2001

Publication

bcc-13

<

1

%

14

<

1

%

EXCLUDE QUOTES OFF

EXCLUDE

BIBLIOGRAPHY ON

EXCLUDE MATCHES OFF

metals – indentation size effect and strain

rate sensitivity", Philosophical Magazine,

2014.

Publication

Ebisu, T.. "Analysis of the indentation size

effect in brittle materials from

nanoindentation load-displacement curve",

Journal of the European Ceramic Society,

201009

Publication

Elkut, F.. "Numerical study of the mechanics

of indentation bending tests of thin

membranes and inverse materials

parameters prediction", Computational

Materials Science, 201202