RFID+ Exam Gram

By OTA Training , Eva Zeisel, Robert Sabella

... Publisher: Que

Pub Date: May 16, 2006

Print ISBN-10: 0-7897-3504-0

Print ISBN-13: 978-0-7897-3504-1

Pages: 336

Table of Contents | Index

Studying for the new RFID+ exam? The RFID+ Certification Exam Cram is the

perfect study companion. It features relevant Exam Notes that will help you score better on the exam, more than 300 exam prep questions, tips, acronyms, memory joggers, and the ever popular "Cram Sheet" tearcard, which is great for last-minute studying. There is also a CD-ROM based testing engine included, providing for realistic exam preparation and readiness feedback. Plus, the RFID+ Certification Exam Cram has the CompTIA Authorized Quality Curriculum (CAQC) seal of approval!

RFID+ Exam Gram

By OTA Training , Eva Zeisel, Robert Sabella

... Publisher: Que

Pub Date: May 16, 2006

Print ISBN-10: 0-7897-3504-0

Print ISBN-13: 978-0-7897-3504-1

Pages: 336

Table of Contents | Index

Copyright

About the Authors Acknowledgments

We Want to Hear from You! Introduction

Self-Assessment

Chapter 1. RFID+ Certification Exam

CompTIA's RFID+ and Other Certifications About the RFID+ Exam

Signing Up to Take the Exam Scheduling the RFID+ Exam Taking the Test

Chapter 2. RFID Tags Basic Tag Anatomy

Passive Communication Methods Tag Frequencies

Tag Construction Methods EPC Classes

Tag Selection and Placement Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Types of RFID Interrogators Interrogator Installation

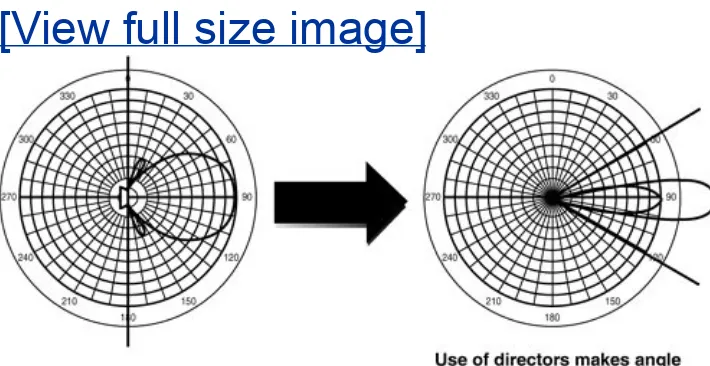

Interrogation Zone Considerations RFID Antennas

Antenna Field Calculations Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Chapter 4. Peripherals RFID Printer/Encoder Printer Installation Chapter 5. Site Analysis Initial Site Survey Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Chapter 6. Design Selection Frequency Selection

Tag Type Selection Dwell Time

Antenna Selection Cabling Considerations

Equipment Selection and Protection Triggering Devices

Interfaces

Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Chapter 7. Installation Equipment Testing Placement Evaluation Connections Testing Grounding

Equipment Configuration After Installation Testing Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Tag Failures

Hardware and Software Diagnosis

Component Replacement and Documentation Firmware Upgrades

Exam Prep Questions

Answers to Exam Prep Questions Need to Know More?

Chapter 9. Standards and Regulations Air Interface Protocol

Tag Data Standards

International Standards and Regulations Standards and Regulations by Region Safety Regulations

Exam Prep Practice Questions Answers to Exam Prep Questions Need to Know More?

Chapter 10. Practice Exam 1

Chapter 11. Practice Exam 1 Answer Key Chapter 12. Practice Exam 2

Chapter 13. Practice Exam 2: Answer Key

Appendix A. CD Contents and Installation Instructions Multiple Test Modes

Random Questions and Order of Answers

Detailed Explanations of Correct and Incorrect Answers Attention to Exam Objectives

Installing the CD Technical Support Appendix B. Glossary

Copyright

RFID+ Exam Cram

Copyright © 2006 by Que Publishing

All rights reserved. No part of this book shall be reproduced, stored in a retrieval system, or transmitted by any means, electronic, mechanical, photocopying, recording, or otherwise, without written permission from the publisher. No patent

liability is assumed with respect to the use of the information contained herein. Although every precaution has been taken in the preparation of this book, the publisher and author assume no responsibility for errors or omissions. Nor is any liability assumed for damages resulting from the use of the information contained herein.

Library of Congress Catalog Card Number: 2005934730

Printed in the United States of America

First Printing: January 2006

08 07 06 05 4 3 2 1

Trademarks

All terms mentioned in this book that are known to be trademarks or service marks have been appropriately

capitalized. Que Publishing cannot attest to the accuracy of this information. Use of a term in this book should not be regarded as affecting the validity of any trademark or service mark.

Every effort has been made to make this book as complete and as accurate as possible, but no warranty or fitness is implied. The information provided is on an "as is" basis. The authors and the publisher shall have neither liability nor responsibility to any person or entity with respect to any loss or damages arising from the information contained in this book or from the use of the CD or programs accompanying it.

Bulk Sales

Que Publishing offers excellent discounts on this book when ordered in quantity for bulk purchases or special sales. For more information, please contact

U.S. Corporate and Government Sales

1-800-382-3419

For sales outside the U.S., please contact

International Sales

Publisher

Paul Boger

Executive Editor

Jeff Riley

Development Editor

Steve Rowe

Managing Editor

Project Editor

Andy Beaster

Copy Editor

Chuck Hutchinson

Indexer

Aaron Black

Proofreader

Heather Arle

Contributing Authors

Mark Brown Mickey Kamer

Technical Editors

Greg Dixon Chris Zimmardi Tom O'Boyle Vern Peeler Chris Zeisel Steve Lazar Denis Bishop John Baker Jason Brewer

Publishing Coordinator

Cindy Teeters

Multimedia Developer

Dan Scherf

Interior Designer

Cover Designer

Anne Jones

Dedication

Thank you to Mark Brown for his expertise, dedication, and ability to always make me smile; and Rob Sabella for his never-ending energy, great attention to detail, and encouragement to make me go all the way with this book. Also thanks to my husband, who tolerated my late nights and weekends at the computer. Love to him, my

wonderful parents, and my whole family in the Czech Republic.

Eva Zeisel

I would like to dedicate this book to my mother and father, Marie and Charles Sabella, who both encouraged me and gave me the ability to dream. To Boston College for developing in me the ability to achieve my dreams. And most of all, to my loving wife, Beth, and beautiful daughter, Sofia, who stood by me despite all the time I spent away from them building OTA and writing this book. Their love and devotion have once again proved to me that despite all my ambition, it is they who really are my dreams come true. AMDG.

About the Authors

Eva Zeisel is the Director of Training and Certification for OTA

Training. She is responsible for instructional design and development of course content and onsite delivery of OTA's RFID courses. Prior to joining OTA, Eva led the Wal-Mart One Store RFID Tagging Pilot Project and performed troubleshooting of RFID equipment in Wal-Mart stores across the southern

United States. Before coming to the United States, Eva gained a broad range of experience in RFID, management, marketing, and business in Europe and the Middle East. Eva holds a

master's degree in economics and management and is working on her second master's in management of information systems.

Robert Sabella is President and Founder of OTA Training.

Bringing more than 15 years of entrepreneurial experience to OTA, Rob is considered one of the most innovative leaders in developing and bringing new technologies to market and training a work force capable of supporting these new

technologies. Rob founded OTA with the belief that in order for RFID implementations to be successful, people must be given the right skills to enable that success. Rob saw that first hand when he co-founded OTA Solutions, Inc., a leading RFID

placement company that focuses on the development and

placement of RFID-trained resources. Rob's OTA Training is one of the Founding Members of the CompTIA RFID+ Cornerstone Committee. Rob holds a Juris Doctor, a master's degree in philosophy, and a bachelor's degree from Boston College.

About the Technical Editors

A special thanks to our incredible team of technical editors. They are the most talented people in the RFID industry today, and we were honored to have them contribute to this book:

Instruments; Tom O'Boyle, Miles Technologies; Vern Peeler, International Paper; Steve Lazar, Texas Instruments; Denis

Bishop, Lowry; John Baker, Venture Research; Chris Zeisel,

Acknowledgments

We would like to acknowledge the contributions of the following people without whose efforts OTA Training and this book would not be possible. Many thanks to contributing authors Mark

Brown and Mickey Kamer for all the help they gave us to get

past the finish line.

Thanks to our incredible team of technical editors. They are the most talented people in the RFID industry today, and we were honored to have them contribute to this book.

Thanks to our industry friends that have taken the time to review the book and offer their suggestions: Ron Rose, Mark Colborn, Brad Wikholm, Randy Smith, Dave Ferguson, Tom Wojcik, and Bryan Albers.

Thanks to Neil Spinner, Bob Gessel, Matt Arnold, Brad Eck, Phillip Hubbell, Randy Denney, Clark Ferguson, Bobbie

Martin, Wayne Carlisle, Joe Zentner, and Ron Ogan.

Thanks to the RFID Young Turks: Chris Hanebeck, Jerrold

Prothero, and David Shaw, who gave us so much weekly

support in all of our endeavors.

Thanks to all of our partners,; Kevin Ellison and James Reed

at Sun Microsystems; Tony Sabetti, Bill Allen, Tammy

Stewart, Kelly Stark at Texas Instruments; Jay Bojan at

Miles Technologies; Mark Roberti at RFID Journal; John

Baker at Venture Research; Jeff Polly and Denis Bishop at

Lowry; Paul Pisano at Tagsys, Lou Sirico at AWID, Eitan Avni at KSW Microtec, Manoj Kutty and Sanjaya Sharma at TIS,

John McGinnis at Avid Wireless; Doug Chaney at DC

Thanks to Gary Roden and Pedro Aguirre, Maria Smith,

Sheila Bellinger, Mark Frederiksen, Bart Pacifico and Sabi

Avramescu, Marco Marchetti, and Matt Galley.

Thanks to Jeff Riley and the folks at Que Publishing for keeping us on track and for all of their support.

Thanks to Dave Sommer, Tammy Borgens, Bala

Swaminathan, and all the folks at CompTIA who, through all

of their hard work, have made the RFID+ certification a reality. And to all of the many members of the RFID+ Cornerstone Committee members who have been a real joy to work with, especially Bob Berg from DHL, Dan Mullen and Bert Moore

from AIM, Stephen Schwartz and Jeff Reynolds from

Intermec, Dennis O'Neil from IBM, Dave Shuping from FCBS,

and Patrick Sweeney from ODIN Technologies.

Thanks also to AIM Global, Association for Automatic

We Want to Hear from You!

As the reader of this book, you are our most important critic and commentator. We value your opinion and want to know what we're doing right, what we could do better, what areas you'd like to see us publish in, and any other words of wisdom you're willing to pass our way.

As an executive editor for Que Publishing, I welcome your comments. You can email or write me directly to let me know what you did or didn't like about this bookas well as what we can do to make our books better.

Please note that I cannot help you with technical problems related to the topic of this book. We do have a User Services group, however, where I will forward specific technical

questions related to the book.

When you write, please be sure to include this book's title and author as well as your name, email address, and phone number. I will carefully review your comments and share them with the author and editors who worked on the book.

Email: [email protected]

Mail: Jeff Riley

Executive Editor Que Publishing

800 East 96th Street

Indianapolis, IN 46240 USA

For more information about this book or another Que

Introduction

Welcome to RFID+ Exam Cram. Whether this is the first Exam Cram book you have ever read, or whether you have used our test preparation resources before, you will find that this book provides important information, critical insights, and valuable suggestions and is intended to prepare you to take and pass the CompTIA RFID+ exam, as administered by VUE testing

organizations and VUE-certified third-party vendors such as OTA Training.

This introduction explains CompTIA's RFID+ certification program in general and describes how the Exam Cram series can help you prepare for the certification exam.

Who Is This Book For?

This book is for you if

You are an RFID professional who is already familiar with RFID system design and installation concepts and who has a good working knowledge of RFID terms, concepts, tools, and technologies.

You are interested in moving into RFID specialization while having extensive experience in IT, bar-coding, supply chain management, or automatic data collection and are seeking a good place to start your training and learning

experiences.

This book is not for you if

experience with RFID systems and applications, or with RFID terms, concepts, tools, and technologies.

You are curious about this suddenly popular RFID

technology and want to find out what the fuss is about.

If you fall into the category that indicates this book is not for you, you should start your RFID+ certification path with in-class training for beginners that introduces you to the basics of the technology as well as terms, concepts, and techniques that you need to know or by reading basic RFID publications, including industry magazines.

About This Book

Exam Cram books help you understand and appreciate the subjects and materials you need to pass certification exams. Exam Cram books are aimed strictly at test preparation and review. They do not teach you everything you need to know about a topic. Instead, the series presents and dissects the questions and problems that you are likely to encounter on a test. The aim of the Exam Cram series is to bring together as much information as possible about the certification exams that are its primary focus.

Nevertheless, if you want to completely prepare yourself for any test, we recommend that you begin by taking the

Self-Assessment immediately following this introduction. This tool will help you evaluate your knowledge base against the

requirements for the CompTIA RFID+ exam under both ideal and real circumstances.

some time installing, configuring, and working with RFID interrogators, antennas, printers, and other RFID-related

devices, as well as learning about the RFID systems deployed in real environments, best practices, and ideas used for these

deployments, because the RFID+ exam is focused on such activities and the knowledge and skills gained by these activities.

You might also decide to start working immediately with the material in this book. Whenever you are ready to take that step, Chapter 1 starts with everything you need to know about the examhow to apply for it; how to prepare for it; and what to expect before, during, and after the actual test. Although we try to provide you with the most accurate information, the

conditions of the exam may change, so please refer to www.comptia.org for updates.

Chapter 2, 3, and 4 give you the knowledge of RFID hardware such as RFID tags, interrogators, antennas, and peripheral devices; their function and working principles; as well as underlying RF physics explanations including necessary calculations. Chapters 5, 6, 7, and 8 take you through the process of deploying an RFID solution. You start with site analysis, continue with designing and installing the solution, and then perform necessary testing and troubleshooting.

Chapter 9 is dedicated to various standards and regulations that affect the RFID industry, which give you a necessary overview of different organizations and standards you have to watch for when working in RFID.

At the end of the book, we provide you with two complete

practice RFID+ exams, as well as answer keys and explanations about why each choice isor is notthe best possible response.

tightly focused reference that you can use in your future studies or in the field as well.

Chapter Formats

Each Exam Cram chapter follows a regular structure, along with graphical cues about especially important or useful material. The structure of a typical chapter is as follows:

Hotlists Each chapter begins with lists of the terms you

need to understand and the techniques and concepts you need to master before you can be fully conversant with the chapter's subject matter. We follow these "hotlists" with a few introductory paragraphs, setting the stage for the rest of the chapter.

Topical Coverage After the opening hotlists, each chapter

covers the topics related to the chapter's subject.

Exam Alerts Throughout the topical coverage section, we

highlight material most likely to appear on the exam by using a special Exam Alert layout that looks like this:

Alert

This is what an Exam Alert looks like. An Exam Alert stresses concepts, terms, or activities that will most likely appear in one or more exam questions. For that reason, we think any

Even if material is not flagged as an Exam Alert, all the content in this book is associated in some way with test-related material. What appears in the chapter content is critical knowledge. The Exam Alert also usually points at a section or concept that is especially important and is

explained in detail before or after the alert.

Notes Where a body of knowledge is deeper than the scope

of the book, we use notes to indicate areas of concern,

specialty training, or direction to places where you may find the information. The following is an example of a note:

Note

Each RFID application is different. Choosing between a tethered and a wireless interrogator depends on your application objective and the particular environment in which you are

deploying. While you gain mobility by using a wireless interrogator, you trade off power consumption. All of these issues need to be addressed and resolved before you can select the appropriate equipment needed for a

particular application.

Tips We provide tips that help you to build a better

foundation of knowledge or to focus your attention on an important concept that reappears later in the book. Tips provide a helpful way to remind you of the context

surrounding a particular area of a topic under discussion. The following shows you what a tip looks like:

This is what a tip looks like. The intent of tip elements is to provide you with alternative ways to approach duties RFID professionals perform in the real world. These may be quicker ways of doing tasks or new methods that are not as well known. These elements help bring real-world RFID content into the boundaries of an exam prep book too!

Exam Prep Questions This section presents a short list of

test questions related to the specific chapter topic.

Following each question is an explanation of both correct and incorrect answers. The practice questions are designed to reinforce your knowledge of the material.

Details and Resources Every chapter ends with a section

titled "Need to Know More?" that provides direct pointers to the RFID resources that offer more details on the chapter's subject. If you find a resource you like in this collection, use it, but do not feel compelled to use all the resources. On the other hand, we recommend only those resources we

ourselves use regularly, so none of our recommendations will waste your time or money.

The bulk of the book follows this chapter structure, but we would like to point out a few other elements:

Practice Exams The sample tests, which appear in

Chapters 10 and 12 (with answer keys in Chapters 11 and 13), are designed to reinforce your knowledge of the

Answer Keys These chapters provide the answers to the practice exams, complete with explanations of both the correct and incorrect responses.

CD Installation and Contents (Appendix A).

Glossary This is an extensive glossary of important terms

used in this book and includes the terms that you are likely to encounter on the exam. This glossary will make an

excellent reference tool to aid you in your RFID implementations.

Index You can use the index to track down terms as they

appear in the text.

Cram Sheet This is a tear-away sheet, inside the front

cover of this Exam Cram book. It is a valuable tool that represents a collection of the most difficult-to-remember facts and formulas we think you should memorize before taking the test. Remember, you can dump this information out of your head onto the margins of your test booklet or scratch paper as soon as you enter the testing room. These are usually facts that we have found require brute-force memorization. You need to remember this information only long enough to write it down when you walk into the test room. You might want to look at the Cram Sheet in your car or in the lobby just before you walk into the testing center. The Cram Sheet is divided under headings, so you can review the appropriate parts just before each test.

How to Use This Book

The order of chapters is what we consider to be a logical

the exam. If you feel that you are already up to speed on

certain topics, you may elect to skip the chapter or chapters in which those topics are covered. In any case, you should try all the questions in the chapters and the sample tests in Chapters 10 and 12. If you find errors, sections that could be worded more clearly, or questions that seem deceptive, feel free to let us know by email at [email protected].

Good Luck!

Thank you for choosing the Exam Cram as your preparation tool for the RFID+ exam. We hope you enjoy the book. We would wish you luck on the exam, but we know that if you read all the chapters and work with the sample exams, you will not need luck. You will do well on the strength of your knowledge, skills, and your ability to apply those skills to real-life workplace

Self-Assessment

The reason for including a self-assessment in this Exam Cram book is to help you evaluate your preparedness to achieve CompTIA RFID+ certification. It should also help you

understand what you need to know to master the topic of this book, namely RFID. Before you start with the self-assessment, however, the following sections address concerns you might face when pursuing the RFID+ certification, as well as what an ideal RFID+ candidate might look like.

RFID Professionals in the Real World

The following section describes an ideal RFID+ candidate, but only a few candidates meet this ideal description because only a few people have extensive experience in RFID. However, if you invest the effort and time, you will be able to succeed in this certification. In fact, we have designed this Exam Cram book to make it as easy as possible to prepare for the exam.

The RFID+ Candidate Qualifications

The ideal candidate for the certification exam can, with little or no supervision, design and implement a complex RFID system using in-depth knowledge of RF communication; RFID hardware functions; installation and configuration including interrogators, antennas, printers/encoders, and other ancillary devices; RFID tags; RFID middleware; connectivity; networking; and

The borderline qualified candidate is able, with some

supervision, to implement an RFID system using knowledge of RF communication; RFID hardware functions; installation and configuration including interrogators, antennas,

printers/encoders, and other ancillary devices; RFID tags; connectivity; networking; and automatic data collection

technologies. This candidate should have an understanding of networking basics, serial communication, engineering concepts, bar-code technology, and business process analysis.

The candidate that is not yet qualified to become RFID+

certified is someone who is only familiar with RFID concepts at a high level and knows some of the RFID buzzwords, but has no relevant experience in the field.

After finishing the self-assessment, you will have a clear idea about what you already know and what you need to learn.

Put Yourself to the Test

The following questions and observations are designed to help you figure out how much work you must do to pursue RFID+ certification and what kinds of resources you might consult. There are no right or wrong answers, only steps along the path to certification. Only you can decide where you really belong in the broad spectrum of aspiring candidates.

Educational Background

To assess your educational background, answer the following questions:

If yes, proceed to question 2; if no, proceed to question 4.

2. Have you ever learned about RF physics? [Yes or No]

If yes, you probably can handle discussions about RF waves and their behavior, RF frequencies, communication

techniques, antenna field characteristics, and calculations.

If no, consider some basic reading or research in this area. You can find a lot of information on the Internet; for

example, see www.answers.com. We recommend a book titled Radio Frequency Principles and Applications, by Albert A. Smith, Jr. (IEEE Press, 1998, ISBN 0-7803-3431-0);

however, you can find other books on this topic in your favorite online bookstore.

3. Have you ever learned about wireless technologies? [Yes or No]

4. Have you ever learned or worked with automatic data collection systems? [Yes or No]

5. Have you ever learned or worked in supply chain management? [Yes or No]

6. Have you ever learned or gained some experience in networks? [Yes or No]

7. Have you ever learned or worked with bar codes? [Yes or No]

You should have answered Yes to most of the questions. The knowledge you have gained in these areas will be very helpful to you in your preparation for the RFID+ certification.

An important key to success with taking the RFID+ exam lies in obtaining hands-on experience with various RFID equipment, as well as participating in the design of an RFID system and its deployment.

To assess your level of hands-on experience, answer the following questions:

1. Have you ever installed and/or configured an RFID interrogation zone? [Yes or No]

2. Have you ever installed and/or configured an RFID peripheral or ancillary device? [Yes or No]

3. Have you ever worked with RFID tags? [Yes or No]

4. Have you ever seen, designed, or deployed a working RFID solution?[Yes or No]

If you answered no to any of these questions, we recommend that you at least participate in a hands-on training session to gain some minimum amount of experience with hardware installation and configuration.

Testing Your Exam Readiness

Whether you attend a formal class on a specific topic to get ready for an exam or use written materials to study on your own, some preparation for the RFID+ exam is essential to your success. We have included two practice exams in this book, so if you do not score well on the first test, you can study more and then try the second test.

big difference in the information and knowledge you are able to gain. For information about RFID+ classes, enter a string such as "RFID+ certification" or "RFID training" in your favorite search engine.

Assessing Readiness for the RFID+ Exam

In addition to assessing your general exam readiness, you can do several things to prepare for the RFID+ exam. As you are getting ready for the exam, visit the websites at

www.examcram.com and www.cramsession.com. You can sign up for "Question of the Day" services for this exam; join

ongoing discussion groups; and look for pointers to exam resources, study materials, and related tips.

Ready to Take the Exam?

After you have

Assessed your readiness

Completed the right background studies

Obtained the hands-on experience that will help you to understand the equipment and technologies that RFID uses

Reviewed sources of information to help you prepare for the test

Chapter 1. RFID+ Certification Exam

Terms you need to understand:

Radio button

Check box

Multiple-choice options

Multiple responses

Scenario-based questions

Techniques and concepts you need to master:

Signing up to take an exam

Scheduling the exam

Preparing to take a certification exam

Practicing to take a certification exam

Making the best use of the testing software

Process of elimination

Budgeting your time

CompTIA's RFID+ and Other Certifications

The Computing Technology Industry Association

(www.comptia.org) offers numerous IT certifications, primarily aimed at entry- and intermediate-level IT professionals.

CompTIA has developed a completely new certification for

radio-frequency identification (RFID) professionals titled RFID+.

CompTIA exams are all vendor and platform neutral, which means that they primarily test on general skills and overall

knowledge instead of focusing on a particular vendor or product specifics. As such, the CompTIA exams offer certification

candidates a chance to demonstrate the necessary general abilities that will be relevant in most workplaces. This explains why employers view CompTIA exams and certifications

favorably.

According to a recent research study commissioned by

CompTIA and conducted by Frost & Sullivan, a global leader in strategic growth consulting, RFID implementations are expected to grow over the next few years. A survey of more than 500 companies in North America found that just over 50% of the companies have completed either RFID implementations or plan to do so within the next 12 months. However, a worldwide lack of skilled integrators who have the facilities, education, and expertise to design, deploy, and manage RFID networks has the potential to hinder the adoption of RFID technology in all

countries and industries.

About the RFID+ Exam

The CompTIA RFID+ candidate will have fundamental RFID knowledge, typically has 624 months of experience in the RFID industry, and performs the following tasks as part of his or her job:

Installation, configuration, and maintenance of RFID hardware and device software

Site surveys/site analysis

Tag selection, placement, and testing

What is Tested?

The following list shows the domains tested by this examination and the approximate extent to which they are represented in the exam:

1. Interrogation Zone Basics: 13%

2. Testing and Troubleshooting: 13%

3. Standards and Regulations: 12%

4. Tag Knowledge: 11%

5. Design Selection: 11%

6. Installation: 11%

8. RF Physics: 11%

Signing Up to Take the Exam

After you have studied this book, have taken the sample test, and feel confident to tackle the real exam, you can sign up to take the exam either at Virtual University Enterprises (VUE) or as a part of the OTA Training's RFID+ Certification Course. The RFID+ exam at VUE costs approximately $225; you can locate the exact price at www.vue.com/comptia/ or www.comptia.org.

Signing Up with VUE

You can contact VUE to locate a nearby testing center that administers the test and to make an appointment. The sign-up web page address for the exam itself is www.vue.com/comptia/. You can also use this web page (click the Contact button, click the View Telephone Directory by Sponsor link, and then click CompTIA) to obtain a telephone number for the company, if you cannot or do not want to sign up for the exam on the web page.

Signing Up with OTA

You can contact OTA Training through its website at

Scheduling the RFID+ Exam

To schedule an exam, call at least one day in advance, but do not count on getting an early appointment. In some areas of the United States, tests are fully booked for weeks in advance. To cancel or reschedule an exam, you must call at least 12 hours before the scheduled test time (or you may be charged). When calling VUE, be sure to have the following information ready for the telesales staffer who handles your call:

Your name, organization, and mailing address.

A unique test ID. For most U.S. citizens, this is your Social Security number. Citizens of other nations can use their taxpayer IDs or make other arrangements with the order taker.

The name and number of the exam you want to take.

Taking the Test

When you come to take your exam, be sure you bring two forms of identification that have your signature on them, including one with a photograph. You are not allowed to take any printed material into the testing environment, but you can study the Cram Sheet from the front of this book while you are waiting. Try to arrive at least 15 minutes before the scheduled time slot.

When taking an exam, you are not permitted to take anything with you into the testing area, but you are furnished with a blank sheet of paper and a pen. We suggest that you

immediately write down on that sheet of paper any of the information from the Cram Sheet you have had a hard time remembering.

You have some time to compose yourself, to record memorized information, and even to take a sample orientation exam before you begin the real thing. We suggest you take the orientation test before taking your first exam, but because the exams are all more or less identical in layout, behavior, and controls, you probably will not need to do this more than once.

Typically, the test room is equipped with one to several

computers, and each of them is separated from the others by dividers to keep anyone from seeing what is going on at other workstation screens.

All CompTIA certification exams allow a predetermined

questions. You have up to 90 minutes to complete the exam.

After you have completed the exam, the software tells you

whether you have passed or failed. Your results are broken into several topic areas. Even if you fail, you should ask for a

detailed report that the proctor can print for you. You can use this report to help prepare for retaking the exam. If you need to retake the exam, you must schedule it with the appropriate

organizations again. CompTIA has a retake policy, which you can find on its website.

Note

Keep in mind that questions for each exam are randomly chosen from a pool; therefore, on your next exam, you most likely will encounter all new questions.

Response Limits

You select from four or more response options, the options that best complete the statement or answer the question. The exam can also contain "distracters" or wrong answers as a response option that examinees with incomplete knowledge or skill would likely choose but that are generally plausible responses fitting into the content area. Test item formats used in this

examination are multiple choices with a single answer, multiple choices with more than one answer, and scenario-based

questions.

For questions with multiple choices, you select one option that best answers the question or completes a statement. The option can be embedded in a graphic where you point and click on

your selection choice to complete the test item.

The question that requires you to select only a single answer has radio buttons. Following is an example of such a question:

1.

Which part of an RFID tag can be made with conductive ink?

A. Substrate

B. Overlay

C. Antenna

D. ASIC

A1:

The correct answer is C. Antennas can be printed using conductive inks. The

substrate is made of plastic, paper, and so on; therefore, answer A is incorrect. The overlay is usually made of adhesives or plastic; therefore, answer B is also

incorrect. The ASIC is typically made of silicon; therefore, answer D is also incorrect.

This example corresponds closely with CompTIA RFID+

certification format; the only difference is that the question is not followed by an answer key.

Multiple Responses

answer, you will be told how many answers to select. Following is an example of a multiple-response question:

2.

Which of the following are RFID tag classifications? (Choose three)

A. Active

B. Passive

C. Hyper Active

D. Semi-passive

A1:Answers A, B, and D are correct. Answer C is incorrect because RFID tags are not

classified as Hyper Active.

For this type of question, more than one answer is required, and you are requested to check multiple check boxes. Such questions are scored wrong unless you choose all the required selections. A partially correct answer does not result in partial credit.

Scenario-Based Questions

Scenario-based questions involve exhibits and use charts or diagrams to document a scenario that you are asked to design, configure, or troubleshoot. The solutions are numbered and you are required to chose a correct number in a multiple-choice answer. Careful attention to such exhibits is the key to

Using CompTIA's Exam Software Effectively

A well-known exam aid to use when taking exams is to first read over the entire exam from start to finish; during this time, answer only the questions you are sure you can answer with the correct option. After that, you will have an idea about how many questions you have left and can divide your time more efficiently for the remaining questions.

The CompTIA software makes this approach possible by

including a check box at each question that permits you to mark the question for later review.

If you are running out of time or do not know the answers for the rest of the questions, you can try the last resort option: Guess.

Tip

Chapter 2. RFID Tags

Terms you need to understand:

RFID tag

Application Specific Integrated Circuit (ASIC)

Smart label

Tag antenna

Inductor/induction coil

Modulation circuitry

Control circuitry

Processor memory

Power source

Active tags

Passive tags

Semi-passive tags

Substrate

Inlay or inlet

High Frequency

Ultra High Frequency

Super High Frequency (Microwave)

EPC classes

Gen 1

Gen 2

Single dipole

Dual dipole

Techniques and concepts you need to master:

Read-only

Read/write

Write Once/Read Many (WORM)

Tag size ratio equation: Antenna versus range/frequency

Copper etching

Foil stamping

Screen printing

Modulation

Inductive/magnetic coupling

Electromagnetic coupling

Chip to tag/flip-chip

Strap to tag

Fluidic Self Assembly

Impedance

Interrogation tunnels

Tag polarization

Shadowing

Static test

Dynamic test

All radio-frequency identification (RFID) systems consist of three main components:

An RFID tag

An RFID reader

Basic Tag Anatomy

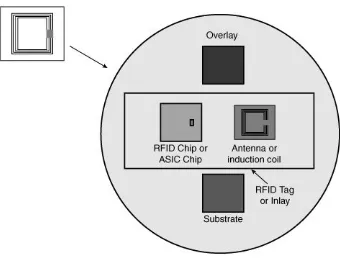

An RFID tag is composed of an RFID chip (also called an Application Specific Integrated Circuit or ASIC), an antenna (sometimes called an inductor), and a power source. The RFID chip consists of modulation circuitry, control circuitry, memory, and a processor. Functionality of each of these elements

depends on the kind of tag as well as the presence or absence of a power source. The following list highlights these items further:

Antenna/Inductor The antenna, or inductor, receives a

signal from the reader and radiates a response back to the reader. Whether the tag uses an induction coil or an

antenna is a function of the frequency at which the tag is designed to operate:

Low Frequency and High Frequency tags normally use induction coils.

Ultra High Frequency and microwave frequency tags have antennas.

In Figure 2.1, you can see the design difference between an induction coil and an antenna.

Modulation Circuitry Modulation circuitry changes the signal received from the reader to include data that will be transmitted back to the reader.

Control Circuitry The internal functions under the command of the processor are controlled by control circuitry.

Processor The processor interprets the signal received from the reader and controls memory storage and retrieval.

Memory The memory element serves as writable and nonwritable data storage. Tags can be programmed to be read-only or read/write. Tag programming can take place either at the manufacturing level or at the application level, and this depends on the kind of tag.

Note

Information on whether the tags are read-only or write once, read many is included in the

specifications for each of the tag classes.

The power source provides electrical power to the other tag elements. A tag can harvest power from the signal received from the reader, or it can have its own internal power source (battery). The way the tag gets its power generally determines the category of the tag.

These categories include

Active tags

Semi-passive (battery-assisted) tags

Passive tags

Note

Active, semi-passive, and passive tags differ not only by their power source but also by their

communication techniques.

Active RFID Tags

Active tags can also support larger memory and processing functions because they have their own power source. Those capabilities are dependent on a particular tag type. Active tags can, for example, carry various sensors to monitor

environmental conditions, such as temperature, humidity, or motion, and report this information to a back-end system and/or store it in their memory. They can also communicate with each other as well as with readers in the system.

Depending on type, an active tag can transmit its ID and other data without being interrogated by a certain reader and

independently of the position of a reader. It has an improved signal-to-noise ratio because it can utilize broadband and spread spectrum communication to enhance its performance against background noise and interference.

Active tags can have read ranges up to several miles since they are limited only by their transmit circuit and power.

Passive RFID Tags

Passive tags have no internal power source. They draw their power from the reader that sends out electromagnetic waves, inducing a current in the RFID tag's antenna. Because they rely on RF electromagnetic energy from the reader for both power and communication, they are restricted in their read/write range.

The read range of passive tags is much smaller in comparison to active tags (the read range of passive tags is around 10 feet, but can be up to 30 feet; the read range of active tags can be up to several miles).

type of tag. These principles are further explained in the following section on Passive Communication Methods.

Semi-passive RFID Tags

Semi-passive tags use a battery to run the microchip's circuitry but communicate by drawing power from the reader. This

design reduces time for a tag to respond and can increase its read range. Thanks to the power source, semi-passive tags can utilize a larger memory capacity and include processing

capabilities.

Active and semi-passive tags are useful for tracking high-value goods that need to be scanned over long ranges, but these types of tags are usually too expensive to place on low-cost items.

Alert

It is important to know the differences between

active, passive, and semi-passive tag characteristics, communication techniques, and possible

Passive Communication Methods

The communication between a passive tag and a reader

consists of energy transfer as well as data transfer. Energy is transferred using coupling, which refers to the connection between devices. RFID uses electrical coupling via

electromagnetic fields. An electromagnetic field, as the name implies, has an electric component and a magnetic component. RFID tags use either the electric field or the magnetic field

(using inductive coupling) or both to receive energy from the reader. There are various methods of transferring the data to a reader but passive tags usually use passive backscatter or

inductive coupling.

Passive Backscatter

Passive tags communicate with a reader using passive

backscatter (also called modulated backscatter). How does this work? The reader transmits a continuous-wave RF signal into the reading environment. When a tag appears in the area, it receives the reader's signal and demodulates it (or breaks it up) into patterns of ones and zeros. This data is used as commands to inform the tag what operation to perform. By detuning and tuning its antenna very rapidly the tag modulates the signal and reflects it in a pattern of ones and zeros back to the reader.

Figure 2.2 shows the passive backscatter principle in graphic form.

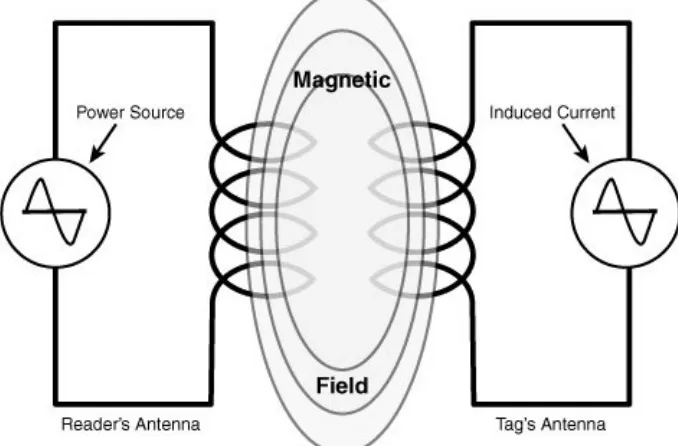

Inductive Coupling (Magnetic Coupling)

The electrical current flow through a conductor generates a magnetic field around the conductor. Although that is true,

there is a second part to this phenomenon. When a conductor is exposed to a magnetic field, the magnetic field causes a current to flow in the conductor. This is known as inductive coupling, because a current is generated by the influence of the magnetic field. Figure 2.3 demonstrates this principle further.

This is the communications process used by Low Frequency (LF) and High Frequency (HF) band RFID devices. The RFID reader's antenna uses current to generate the magnetic field. The

antenna on the RFID tag (in this case an induction coil), when exposed to the magnetic field generated by the reader's

antenna, generates the current in the tag that powers the tag's circuitry. Circuitry on the RFID tag switches the impedance loading of the tag's antenna, in accordance to a data stream, causing a modulation of the magnetic field joining the reader and tag. The modulation is demodulated by circuitry in the RFID reader, and the data is transmitted to the user.

Alert

You must know the principles of passive backscatter and electromagnetic coupling.

Electromagnetic Coupling

Ultra High Frequency tags and Microwave tags usually use electromagnetic coupling. They can utilize the electric field as well as the magnetic field for energy. Because of the nature of a magnetic field, it can be utilized only in short distances from the source. That is why LF and HF tags, which primarily use the magnetic field, have short read ranges. In instances, where UHF and microwave tags are in near proximity to the radiating

source (antenna), they can also use the magnetic field if their antenna design allows it. For longer read ranges (over

frequency band.

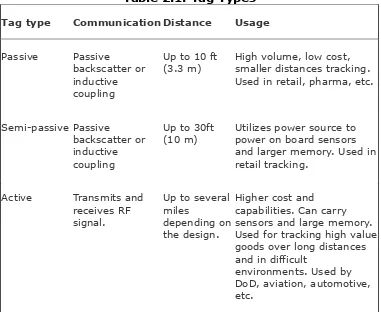

Table 2.1 gives you a summary of different tag types, their communication methods, distance, and where they are used.

Table 2.1. Tag Types

Tag type Communication Distance Usage

Passive Passive

backscatter or inductive coupling

Up to 10 ft (3.3 m)

High volume, low cost, smaller distances tracking. Used in retail, pharma, etc.

Semi-passive Passive

backscatter or inductive coupling

Up to 30ft

(10 m) Utilizes power source topower on board sensors and larger memory. Used in retail tracking.

Active Transmits and receives RF signal.

Up to several miles

depending on the design.

Higher cost and capabilities. Can carry sensors and large memory. Used for tracking high value goods over long distances and in difficult

Tag Frequencies

The four primary frequency bands for RFID tags are

Low Frequency or LF (120140 KHz)

High Frequency or HF (13.56 MHz)

Ultra High Frequency or UHF (860960 MHz)

Super High Frequency/Microwave (2.45 GHz and above)

The following list highlights each of these tag frequencies in more depth:

Low Frequency (LF) Tags These tags operate at 120140 KHz. They are generally passive and use near field inductive coupling; therefore, they are well suited for applications requiring reading small amounts of data at relatively slow speeds and at short distances. Their read range varies from 1' to 36' (1 meter), typically below 18' (0.5 meter). LF tags do not support simultaneous tag reads; therefore, there are no collision issues. LF tags are also relatively costly because they require a longer, more expensive copper antenna. They penetrate materials such as water, tissue, wood, aluminum, and so on, and their common applications are in animal identification, automobile security, Electronic Article Surveillance (EAS), commerce, and other areas.

than LF tags; and have lower costs due to simpler antenna design. HF tags enable higher transfer data rates than LF tags, and their read range varies from 1' to 30', typically under 36' (1 meter). HF tags are used in "smart shelf" applications, smart cards, libraries, baggage handling

(currently not in the United States), and other applications. High Frequency applications are currently most used around the world due to absence of restrictions on the use of this radio frequency and the wide adoption of smart card

systems.

Ultra High Frequency (UHF) Tags UHF active and passive tags can operate at different frequencies. UHF active tags usually operate at 433 MHz, and UHF passive tags usually operate at 860960 MHz. Generally, passive UHF tags are not very effective around metals and water. They perform well for distances greater than 36' (1 meter). UHF passive tags usually reach to about 30 feet (10 meters). UHF tags have good non-line-of-sight communication, have a high data range, and can carry relatively large amounts of data. Generation 2 allows for simultaneous read attempts up to 1,500 tags per second under ideal conditions, however, in real world environment the number of actual acquisitions can be about five to ten times smaller.

Tip

There are now UHF tags, which are designed for near-field communication utilizing the magnetic field. This gives them the advantage over

traditional passive UHF tags (that use only the electromagnetic field), which were not effective around water, metals and dense materials. These UHF tags can now be applied on products that used to be tagged only with HF tags. These tags have improved performance on products

transfer rates but short read ranges.

Super High Frequency/Microwave (µWave) Tags

These tags operate at frequencies of 2.45 GHz and above (also 5.8 GHz) and can be either active or passive. Their characteristics are similar to UHF tags; however, they have faster read rates and are less effective around metals and liquids than tags of lower frequencies. These tags can be smaller in size compared to LF, HF, and UHF tags and are used for electronic toll collection as well as for tracking of ISO cargo containers, trains, commercial vehicles, parking, etc. The read range varies from 1 to 3 feet (0.3 to 1 meter) for passive tags and is very dependent on design. Active systems also use microwave frequency.

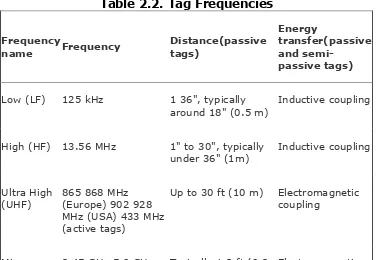

Table 2.2 summarizes characteristics of different frequencies.

Table 2.2. Tag Frequencies

Frequency

name Frequency Distance(passivetags)

Energy

transfer(passive and

semi-passive tags)

Low (LF) 125 kHz 1 36", typically

around 18" (0.5 m) Inductive coupling

High (HF) 13.56 MHz 1" to 30", typically

under 36" (1m) Inductive coupling

Ultra High

(UHF) 865 868 MHz(Europe) 902 928 MHz (USA) 433 MHz (active tags)

Up to 30 ft (10 m) Electromagnetic coupling

(µW) 1 m) coupling

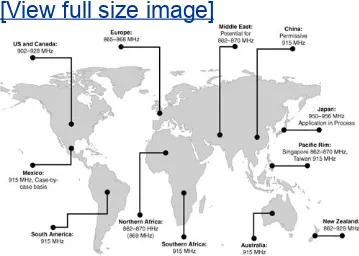

Figure 2.4 identifies the different frequencies in UHF band specific to various regions around the world.

Figure 2.4. Frequencies for UHF RFID operation

around the world.

[View full size image]

Alert

Tag Construction Methods

RFID tags are composed of an antenna and an RFID chip. Such a tag is technically called an inlay. Inlays need to be integrated into packaging for application use. The principle is shown in Figure 2.5

The antenna, chip, and packaging are made of a range of materials using various methods of manufacturing, which we discuss next.

Figure 2.5. RFID tag construction.

Various methods and materials are used for antenna construction. The principle methods are

Etching (using copper, aluminum, or silver)

Foil stamping

Screen printing

Etching

The etching process works as follows:

1. A mask is used to "burn" an image into the photopolymer layer.

2. The substrate, metal film, and photo resist are subjected to a chemical solution that removes all of the metal except where the image was burned.

3. A different chemical solution is used to remove the "burned" photo resist.

4. The finished antenna goes through additional processes to protect the metal surface from oxidation.

Foil Stamping

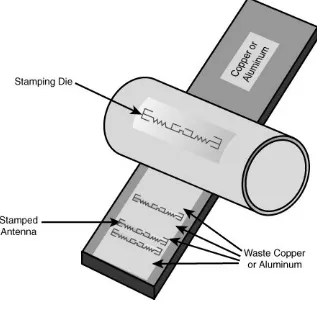

The foil stamping process, illustrated in Figure 2.6, works as follows:

1. A die is used to "stamp" out the shape of an antenna.

3. Newly stamped antennas then advance to have the chip attached.

Figure 2.6. Foil stamping process.

Screen Printing

The screen printing process, illustrated in Figure 2.7, works as follows:

1. An open image of an antenna is created on a meshed screen.

"squeezed" through the open mesh onto a substrate.

3. The nonimage area is sealed so the ink is not transferred.

Figure 2.7. Screen printing process.

Performance Differences

What are the differences between the antennas produced by these three construction methods?

Frequency radio waves, the antenna is subjected to alternating current (AC), not direct current (DC). Design of printed

antennas can be changed to perform almost as well as a copper antenna.

Evaluation of performance and cost for copper versus high-speed printed UHF antennas has indicated the following:

Depending on the design, printed antennas showed a 93% to 96% radiation efficiency compared to copper antennas, and the cost of printed antennas varied between 24% to 44% of copper antennas.

Chip Placement Approaches

The two major methods of placing an RFID chip on the tag are

Flip-chip or chip to tag

Strap to tag

Flip-chip Technique

The flip-chip (or chip to tag) technique involves a robotized hand that uses a precise vacuum nozzle to pick up an individual silicon chip cut from a 6- to 8-inch wide wafer. This chip is then carried to a transfer station, where it is flipped over so its two electrical contact points face down. Another vacuum nozzle sets the chip down, matching contact points to the pads of the

chip is difficult to handle, and this technique is tough to integrate with packaging and label lines.

Strap to Tag Technique

The strap to tag technique mounts the 1mm-square chip on a larger strap to make the handling easier. The strap with the chip is then attached to an antenna. The advantages of this

approach are not only the greater handling ability and

possibility to use very small chips, but also the possibility of higher volume production compared to the flip-chip method.

Q Factor

All antennas in tags are designed to operate within the

bandwidth of their intended use (for example in the US within 902 928 MHz for UHF tags). The antenna is designed to

resonate in the intended band by modifying the magnetic and electric components of the antenna's field to create a tuned circuit in the band. The sharpness (effectiveness) of the tuned antenna when resonating at a specific frequency is its Q factor. The amount of transferred energy is proportional to the size of the transmitting and receiving antennas as well as the tag ability to operate at the resonance frequency.

The resonance frequency is a state with minimum impedance that allows for maximum current flow in the circuit. The

resonance frequency is a function of the inductance and capacitance of the tag circuit. The higher the Q factor, the higher the amount of energy transfer. Although higher energy transfer is desirable, the higher Q factor results in reduced bandwidth.

Where fc is a resonant frequency (center frequency).

Calculation of a Q factor in a tuned radio frequency receiver is following:

Where R is resonance, L is inductance, and C is capacitance.

Tag Packaging

The following types of RFID tag packaging are the most common:

Label (or smart label) A type of tag that is a flat, thin, flexible form using usually paper or very thin plastic. This type of packaging is used in RFID printers and applicators.

Ticket A flat, thin, flexible tag that is printed on paper

without adhesive.

Card A flat, thin tag embedded in tough plastic for long life.

Glass bead A small tag in a cylindrical glass bead, used for

Integrated A tag integrated into the object it is tagging rather than applied as a separate label. For example, it is molded into the object.

Wristband A tag inserted into a plastic wrist strap.

Button A small tag encapsulated in a rugged, rigid housing.

EPC Classes

EPC classes are specified in the EPCglobal standards and are the product of the collaborative efforts of EPCglobal subscribers

from many industries. To be considered an EPCglobal standard, a specification must be ratified by the EPCglobal Board of

Governors for release and implementation. There are currently two ratified standards:

EPC Tag Data Standard Version 1.1 rev 1.27 This

EPCglobal standard identifies the specific encoding schemes for a serialized version of the EAN.UCC Global Trade Item Number (GTIN), the EAN.UCC Serial Shipping Container Code (SSCC), the EAN.UCC Global Location Number (GLN), the EAN.UCC Global Returnable Asset Identifier (GRAI), the EAN.UCC Global Individual Asset Identifier (GIAI), and a General Identifier (GID). The latest revision adds the Department of Defense construct header and the

hexadecimal expression for raw Uniform Resource Identifier (URI) representation.

Class 1 Generation 2 UHF Air Interface Protocol

Standard Version 1.0.9 This standard defines the physical

and logical requirements for a passive-backscatter,

interrogator-talks-first (ITF), radio-frequency identification (RFID) system operating in the 860960 MHz frequency band. The system includes the interrogators (readers) and the tags (labels).

EPC Tag Classes Capabilities

the preceding class. Each higher class maintains the preceding class's characteristics and adds new capabilities over its

predecessor.

EPC classes for passive tags include the following:

EPC Class 0

EPC Class 1 (Generation 1 and 2, also called Gen 1 and 2)

The read/write characteristics of each class are

Class 0 tags are Write Once, Read Many (WORM). This class of tags is factory programmed and not field programmable.

Class 0+ tags are also rewritable. Class 0+ is not an official tag class. It was originally developed by Matrics, Inc. (now Symbol Technologies, Inc.), and its characteristics are

based on Class 0 with added capacity including the ability to be field programmable.

Originally, Class 1 tags were WORM as well and could be read by readers from other companies. In reality Class 1 tags are Read Many Write Many.

Class 1 Generation 1 tags evolved into Class 1 Generation 2 tags and are commonly referred to as Gen 2 tags. These tags have the following advantages over their predecessors:

Gen 2 has better tag identification, which allows for elimination of duplicate reads during multiple tag scans.

Gen 2 tags were tested for reliability, and the results

showed extremely high read rates on tags (close to 100%). These tags also provide for much faster reads, up to 10 times faster than Gen 1.

Tags can be accessed, locked, and killed by a reader, giving more options to users for securing their tags against illicit use.

The memory and password are stored together. The chip has a 256-bit memory, where the 96-bit part is allocated for the EPC number, with the possibility to support up to 256 bits of EPC information and a total of 496 bits of memory. The memory also stores passwords and other data. For a retail store, these tags offer more storage capacity and security against in-store chip-hacking.

Tag Selection and Placement

To identify the best tag for the RFID system and product as well as its proper placement on the product, it is important to test the tags in conjunction with a product, system, and

environment.

Testing

You can test which is the right tag for a specific product and which is the best placement of the tag on that item, package, or pallet in several ways:

Purchase and use customized or out of the box software.

Use a test facility.

Out of the Box/Customized Software

Today, you can find companies that develop software to help you determine the optimal placement for tags on boxes as well as identify the right tag that will be the most successful with a given product. Although these software packages certainly save time, they can be very expensive.

Certain companies charge a one-time fee for this software package; others are per SKU pricing. The product testing and calibration methods vary as dramatically as do the prices of the software. Some measure minimum effective power needed to power a tag for a given spot on the box. Some perform

including three-dimensional graphics to show you in living color the right spot to place your tag.

Tip

The costs of these platforms are fairly high, but you have to balance the costs against the time they can save you and then make the choice that is right for your situation.

Product Testing Facilities

A growing number of testing facilities sell their services for tag placement compliance testing. Test lab capabilities vary

dramatically, and knowing specifically what you are testing, and who it is for, will help you determine if this is the right place for you. Some facilities perform a complete scientific analysis and RF study of your package in a clean room, giving you the

ultimate hotspot analysis. Other facilities test in "dirty"

scenarios, looking for the best placement of the tag under the worst conditions, in an RF-rich environment with varying levels of interference to simulate diverse real-world conditions. Some testing centers offer the best of both worlds, which is the

mixture of clean room and "dirty" testing. Depending on your interrogation zone conditions, you determine whether this level of testing is right for you.

Distance Test (Static Test)

a reader with an antenna on one end. Static testing requires a controlled environment.

Attach a tag on the box (avoid the bar codes, holes, places where the box will be cut open) and move the box toward the reader. Capture the distance that records solid read rates. Repeat this test for different tag locations on the box, kinds of tags, readers, and antennas.

At the end of testing, the data should give you an idea which tag performed the best with your product. Select a few of the best-performing tags and perform the tag location test.

Tag Location Test (Dynamic Test)

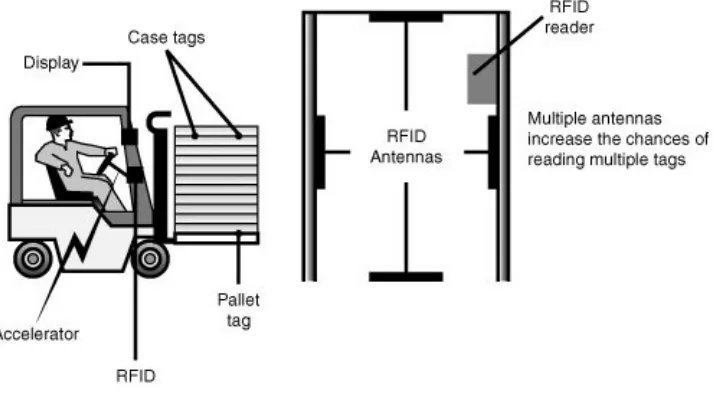

The tag location test is very important for fulfilling mandate-compliance requirements and is performed usually on a high-speed conveyor with readers and antennas attached

(interrogation tunnels).

Draw a grid on your box with fields that can fit the tags you selected in the distance test. Remember that a denser grid is required for challenging products that contain liquids or metals either in the product itself or in its packaging. Finding the best tag location on these boxes may be more difficult.

Place the selected tag into a selected grid on a box and run it a certain number of times on a high-speed conveyor. Capture the number of successful reads for each individual lap and for all laps combined. Repeat this test for every grid that has the potential to be the right placement for the tag and also every tag you selected from your distance test. The results give you an idea which tag on which location performed the best.

Note

EPCglobal is developing standards for static and dynamic tag testing (using conveyor, dock door, forklift, etc.) including tag testing and applied tag testing.

Tag Orientation/Polarization

Different tags are built to different specifications. Understanding how these tags work in relation to the RF field is critical to the success of your project.

In the early days of RFID, tags were single dipole. This means that there is essentially one antenna aligned on a single axis. The resulting correlation of the tag to the field is this: For a field with specific polarization, these types of tags must be aligned so that they are parallel with the read field. For example, if linear antennas are used, and they are aligned horizontally, the tags must be horizontally aligned and facing the antenna to read successfully. These tags work well in manufacturing lines where orientation and position can be assured due to the

process of manufacturing. When using a reader with circular antennas, the readability of single dipole tags improves.

As tags developed, more thought was given to this issue. As a result, dual-dipole tags were developed. Originally, they were made with the orientation of the dipoles set 90 degrees apart. Today, however, multiple variations of this type of tag are

turned so they are perpendicular to the antenna. This is critical for retail applications where many boxes are being read, and orientation cannot be assured.

Alert

You must know what the issues are surrounding tag orientation and how to distinguish tags with different polarizations.

Shadowing

Another consideration of the tag placement process is

shadowing. For instance, when the tags are placed on products and then assembled to a pallet, the tags may be placed right behind each other, and the RF signal produced by the reader's antenna is used by the first tag to generate a response, while the second tag gets minimal or no signal and has no chance to respond to interrogation. This is called shadowing. The second tag is "in the shadow" of the first tag.

Tag Selection for Specific Products

When selecting a tag for a certain product, you must consider the materials that the product and its packaging are made of and then choose the tag that will perform the best under those circumstances.

Different materials affect the tag's performance when the tag is in its applied state, or attached to the product. Metals reflect RF energy, and if they are too close in proximity to the tag, metals can detune the tag so that it cannot be read by the interrogator. Liquids absorb and reflect RF energy, and other dense material can also have such negative effects on your tag's performance. Knowing this can help you understand where to look for optimal tag performance.

Every type of tag performs differently in the presence o