221

SOMASUNDARAM & SRINIVASAN: DESIGN OPTIMIZATION OF DOSA MAKING WORKSTATION Journal of Scientific & Industrial Research

Vol. 69, March 2010, pp. 221-224

*Author for correspondence E-mail: somas789@yahoo.com

Design optimization of dosa making workstation for smooth

ergonomic interface

A Somasundaram1* and P S S Srinivasan2

1Department of Mechanical Engineering, Kongu Engineering College, Perundurai, Erode 638 052, India 2K S Rangasamy College of Technology, Tiruchengode 637 209, India

Received 12 August 2008; revised 21 December 2009; accepted 08 January 2010

This study presents design optimization of Dosa making workstation (DMW) used in preparation of South Indian food,

dosa. Anthropometry of South Indian user population is considered in ergonomic interface analysis. Design of Experiments (DOE) was used for optimization of DMW. Four control parameters (shoulder height, arm length of worker, table width and table height of DMW) were considered in design optimization. Proposed parameters (height, 1150 mm; width, 750 mm) reduced risk of musculoskeletal disorder for users and enhanced quality of work at DMW.

Keywords: Design of Experiments, Dosa Making Workstation, Ergonomics, Musculoskeletal disorder

Introduction

Dosa making workstation (DMW) is highly engaged to prepare dosa - a South Indian food item. Ergonomic studies identified risk factors and reduced musculoskeletal disorder (MSD) in task specific applications. Attwood1 indicated that particular type of

discomfort could be linked to specific aspects of workstation design. Fogleman et al2 identified risk

factors associated with self reported MSD in a population of visual display terminals operators. Sarma et al3 studied

height of workstation of tyre-changer considering anthropometry of user groups. Gallagher et al4 observed

that repetitive works can increase stresses on spine. Bernard5 found that MSD is associated with perceptions

of intensified work load, monotonous work, limited job control, low job clarity, and low social support.

This study on Indian hotel kitchen ergonomics enhances safety and comfort for workers.

Experimental

A preliminary survey was conducted to identify problems in hotel kitchen environment (HKE) by interviewing 350 persons working in HKE in Erode and Coimbatore districts of Tamilnadu, India. Dosa making section in South Indian hotel kitchen contributes 20-27%

of total sales in middle class hotels. User’s perception of existence of discomfort in HKE reflect poor interface between men in work and HKE (Fig. 1). Workers average dissatisfaction was recorded using a ten point scale. Dosa

making has been found to involve repetitive arm and wrist rotation, trunk bending, arm stretching and prolonged standing; all of these ergonomic risk factors lead to discomfort and MSD for workers.

Work Schedule and Capacity Utilization

Each worker prepares 350-500 dosa in average. In semi urban hotels, only one worker is made to work the whole day with a rest of about 6 h in between shifts. Peak hour load leads to MSD because of repetitive arm motion and improper interface between workers in DMW.

222 J SCI IND RES VOL 69 MARCH 2010

Height, length, breadth of workstation, shoulder height, arm length and heat inside kitchen were factors leading to MSD. Based on variations in workstation parameters, workstation is broadly classified into model 1, model 2 and model 3 (Table 2). Among 30 kitchens surveyed, dosa workstation used models as follows: model 1, 60%; model 2, 25%; and model 3, 15%. Average temperature around workplace of a DMW was 36°C.

Solution Methodology

Risk factors causing MSD were observed mainly due to anthropometry and work posture. Shoulder height and arm length of cook engaged in dosa making largely influenced arm reach over dosa plate in preparing dosa. Also, width and height of work surface of DMW had large impact on arm reach. All four parameters were considered as critical input parameters in design optimization of DMW. Arm reach over surface of dosa

plate in preparing dosa was output of experiment. Design Optimization using Design of Experiments (DOE)

Any change in height and width of DMW affects worker’s efficiency. Any change in table length

negligibly affected worker’s efficiency as worker can move along the length of DMW. Increase in height of DMW leads to raised arms during dosa making and this increased risk of MSD. Increase in width of DMW made worker to lean forward while reaching outermost edges. Trunk angle (> 15-20° leads to lower back disorder, a type of MSD.

Selection of Variation Levels

Anthropometry data follows normal distribution for a given population. Three levels of shoulder height and arm length of users (for 5th, 50th and 95th percentile) data

was considered. Also, three levels of DMW’s width and height were considered. These four parameters highly influenced response or arm reach (R) of worker over DMW (Table 3).

Orthogonal Array

Orthogonal array was used for ergonomic interface analysis. For four control parameters with three levels of variation (with no noise factors), minimum number of conventional experiments required was 34 *1=81. Using

Taguchi’s DOE technique, number of experiments was calculated using degrees of freedom approach. An

Table 1— Risk factor perceptions surveyed from HKE

S.No Factors Range Average

1 Neck pain 1-5 4

2 Shoulder pain 2-4 3

3 Wrist/hand pain 3-5 4

4 Low back pain 2-4 3

5 Low leg pain 2-5 4

6 Finger pain 2-4 3

7 Elbow/ forearm 1-3 2

8 Eye strain 1-3 2

9 Skin dryness 2-4 3

10 Body dehydration 2-4 3

(5-Very high, 4-High, 3-Moderate, 2-Low, 1-None)

Table 2—Dimensions of DMW grouped from actual observations Model Height, mm Length, mm Breadth, mm

1 1250 1300 750

2 1150 1200 600

3 900 1100 500

Table 3—Three levels of variation in critical parameters

Parameter Dimension, mm

L1 L2 L3

Shoulder height (A) 1320 1430 1540

Arm length (B) 670 750 840

Table width (C) 680 750 830

Table height (D) 950 1050 1150

2

223

SOMASUNDARAM & SRINIVASAN: DESIGN OPTIMIZATION OF DOSA MAKING WORKSTATION

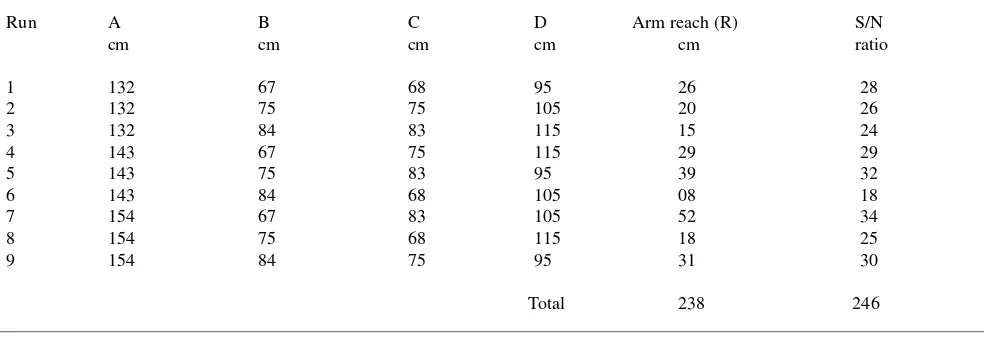

orthogonal array (L9) for three levels, four control parameter and no noise level along with response factors and S/N (signal to noise) ratio is tabulated (Table 4). Theoretical response (arm reach, R) was calculated as Theoretical response, R (mm)= [C+150]-[B2-(A-D) 2]

…(1) Eq. (1) was used in interfacing of human body dimensions with DMW parameters. Preferred clearance between worker and workstation was found to be 150 mm. R is maximum distance that worker stretches his arm to reach outer edge of DMW. Worker bends his trunk forward while reaching edges, when engaged in dosa

preparation. Eq. (1) may be suitably modified for other application also depending on variables considered in interface.

Even though there were no noise parameters, S/N ratio were calculated in order to identify optimum design parameters and variation of control parameter as

S/N Ratio=10 log [(1/n) R2] …(2)

where, n, number of levels (assumed to be 1); R, response

Results and Discussion

Results

Experimental output values (R over width of table and S/N ratio) under nine experiments for four critical input parameters (shoulder height, arm length of worker engaged in dosa making, dosa plate surface width and table height of DMW) were calculated (Fig.2, Table 4). Calculation of Variation and Sum of Least Squares of Control Parameters

Sum of squares (SS) value and variation were obtained as

SS= [(A12/3) + (A 2

2/3) + (A 3

2/3)] – (R 2/9) …(3)

Variation (%) = SSB/SS …(4) where A, summation of responses of each parameter for various level; SSB, summation of squares of corresponding control parameters; SS, summation of squares.

Table 5—Sum of squares (SS), variation and optimum design values for “nominal the best”

Factor Dimension, cm SS Variation Optimum design values for

% “nominal the best”

L1 L2 L3 Optimum Value

level mm

A 78 79 89 25 13 2 1430

B 92 83 71 70 37 2 750

C 72 85 90 60 33 2 750

D 90 78 78 32 17 2,3 1150

SS 187

Table 4-—L9 Orthogonal array indicating dimensions of critical parameters, reach and S/N ratio

Run A B C D Arm reach (R) S/N

cm cm cm cm cm ratio

1 132 67 68 95 26 28

2 132 75 75 105 20 26

3 132 84 83 115 15 24

4 143 67 75 115 29 29

5 143 75 83 95 39 32

6 143 84 68 105 08 18

7 154 67 83 105 52 34

8 154 75 68 115 18 25

9 154 84 75 95 31 30

224 J SCI IND RES VOL 69 MARCH 2010

Optimization settings for each of control parameters (Table 5) indicated holds good for 50th percentile

population (level 2). Optimum parameter values were: shoulder height, 1430 mm; arm length, 750 mm; dosa

plate width, 750 mm; and table height, 1150 mm. Discussion

Arm length and table width contributed more to the performance. Table height had significant influence over performance. “Nominal the best” - Level 2 parameters holds good for 50th percentile population to reduce

discomfort and enhance safety. 95th percentile user group

also found level 2 parameters suitable but 5th percentile

user group did not find it suitable. So “Nominal the best” parameters considered for new design of DMW that suit most users. However, 5th percentile users may be advised

to stand on a platform (height, up to 100 mm) to make use of same workstation.

Conclusions

From ergonomic interface analysis using DOE, 50th

and 95th percentile workers were recommended to use a

workstation (height, 1150 mm; width, 750 mm). 5th

percentile anthropometry workers were advised to use

dosa maker of height 1050 mm. Worker’s productivity was enhanced from 38 dosa/h to 42 dosa/h, due to relief

in physical stresses for optimum design values of DMW. Back pain, shoulder pain and neck pain rating have gone down to 3, 2, and 2 respectively from previously respective reported levels of 3, 3, and 4, indicating improvement.

Acknowledgement

Authors thank DST for funding research work (DST reference No. SP/WS/066/2006).

References

1 Attwood D, Comparison of discomfort experienced at CADD, word processing and traditional drafting workstations, Int J Ind Ergon, 4 (1989) 39-50.

2 Fogleman M & Guimaraes L, Factors associated with self reported musculoskeletal discomforts in vedio display terminal (VDT) users, Int J Ind Ergon, 29 (2002) 311-318.

3 Sarma D V & Panneerselvam S, Ergonomics in redesign of Tyre-Changer, Int Ergon J, 27 (2) (1998) 6-11.

4 Gallagher S, Marras W S, Litsky A & Burr D, Torso flexion loads and the fatigue failure of human lumbosacral motion segments, Spine, 30 (2005) 2265-2273.