*Corresponding author.

Greedy heuristic algorithms for manpower shift planning

A.G. Lagodimos

!

,

*, V. Leopoulos

"

!University of Piraeus, Department of Business Administration, 80 Karaoli and Dimitriou Street, GR-185 34 Piraeus, Greece "National Technical University of Athens, Department of Mechanical Engineering, GR-157 80 Zographou, Athens, Greece

Received 31 March 1998; accepted 24 June 1999

Abstract

Consideration is given to a particular personnel planning problem faced by a food manufacturing company. This problem, referred to herein asmanpower shift planning(MSP), seeks for the minimum workforce needed to work in each available workday shift over a given planning horizon in order to complete predetermined production objectives associated with individual production lines. We formulate MSP as an integer linear program, whose structure allows us to conjecture that it is an NP-Complete problem. We then propose two greedy heuristic algorithms for solving MSP. One for single and another for multiple workday shifts. Using results from a standard ILP optimiser together with a lower bound developed for the MSP solution, we test the performance of the multi-shift heuristic for a variety of operating environments. The results demonstrate very satisfactory performance in terms of both solution time and quality. The paper is concluded with a discussion on the results and proposals for further research. ( 2000 Elsevier Science B.V. All rights reserved.

Keywords: Production planning; Manpower planning; Heuristics

1. Introduction

In several companies, particularly those in the foods and pharmaceuticals industrial sectors, other than some initial processing phases, production largely consists of simple packaging operations. Packaging is accomplished on dedicated packing lines usually requiring one skilled operator and several (practically) unskilled workers. The latter are often hired under short term contracts to work on a particular workday shift (i.e. day, evening or night shift respectively). At the end of their contract, often of one month duration, workers are"red to

be recalled later, if needed. Workers cannot be"red before their contract expires.

In manufacturing environments as the above, total work requirements for a particular month are usually determined by a master production sched-ule, which gives the total production load of each packing line for all the products it produces. How-ever, the production capacity of each packing line directly depends on the number of unskilled workers available. Therefore, a common planning problem faced by management is to decide how many unskilled workers to employ in every daily work-shift of some particular month of the master schedule so as to complete the production load of each packing line, while maximising workforce util-isation. It should be noted that the objective of

maximising workforce utilisation is in most cases equivalent with minimising the total workforce to be employed.

We will refer to this particular personnel and capacity planning problem as the manpower shift planning(MSP) problem. It is with the formulation and the solution of MSP, which to our knowledge has never been formally addressed in the past, that this paper is concerned. In fact, as described here, the MSP problem has been the subject of an indus-trial research project carried out for the Greek a$liate of a multinational company operating in the processed foods and beverages sector.

Since the "rst published work by Dantzig [1], there has been an abundance of research related with personnel planning problems. This traditional paradigm has been primarily concerned with the determination of the workforce to be assigned to each one of a given set of work-time patterns so as to minimise total labour costs, while satisfying given labour requirements associated with each pe-riod of a planning horizon. In its most general form where one practically considers any work-time pat-terns, this problem is known as thetour scheduling

problem. However, other simpler variations of this problem have also been studied. Jarrah et al. [2] provides a recent brief review of these variations, while more comprehensive, but somewhat dated, reviews are given in [3}5].

All variations of tour scheduling have invariably been formulated as integer linear programs. Since these have been shown to be NP-Complete [6], most associated research concentrated in develop-ing e$cient heuristic solutions. Although it is not our intention to provide a comprehensive descrip-tion of the related work, it is worth stating that these heuristics have been based on a wide range of di!erent methodologies such as simulated anneal-ing [7], LP-based approaches [8}10] and goal programming [11].

There are two major di!erences between MSP and the above traditional personnel planning para-digm. Firstly, traditional research is concerned with deriving directly applicable detailed labour sched-ules. In this context, related models attempt to encapsulate all possible work speci"cations and minute details (such as meal breaks, days-o! and part-time work) in order to realistically represent

the respective operating environments. In contrast, MSP e!ectively tackles an aggregate capacity planning problem under general production targets and constraints. Secondly, traditional research as-sumes that workforce requirements for all time periods of the planning horizon are known in advance. In contrast, it is the goal of MSP to determine these workforce requirements for each individual period of the planning horizon so as to ensure that speci"c production objectives (using equipment of given manning needs) are completely satis"ed.

The remainder of the paper is organised as fol-lows. Section 2 provides a formal de"nition of the MSP problem and formulates it as an integer opti-misation program. It also discusses the problem computational complexity in comparison with other known problems and presents a lower bound for its solution. Section 3 presents two heuristic algorithms for solving MSP together with informa-tion concerning their order of convergence. Secinforma-tion 4 describes an example of using one of the algorithms for the solution of a particular application problem. Section 5 reports computational results for testing the performance of the heuristics for a variety of operating conditions. Finally, Section 6 discusses possible MSP extensions and concludes with direc-tions for further research.

2. Problem formulation

In this section, we present a formal statement of the MSP problem and develop the corresponding optimisation model. We also present some initial observations, which help position the MSP prob-lem in the context of previously identi"ed problems and provide comments and conjectures on the problem of computational complexity. We also present a lower bound for the problem solution, which is later used for testing the quality of the proposed heuristics.

2.1. Formal problem dexnition

A machine shop consists ofn independent ma-chines and operatesPshifts per day. Each machine

irequiresa

has a production load of=

ishifts/time periods. The

MSP problem calls for the determination of the minimum number of workers to be employed in each shift in order to complete the production load of each machine within a predetermined time hor-izon of Ddays.

The following operational assumptions are used throughout the analysis:

1. Workforce is #exible and can operate on any machine.

2. Workforce is employed for a particular shift and cannot be moved to another shift.

3. The production load of each machineicovers an integer number of shifts and can be completed within the available time horizon (PD*=

i).

4. There are no precedence or other constraints between machines.

Although these assumptions appear restrictive, it is noted that they are entirely compatible with the operating conditions of the industrial "rm which instigated this research. However, particular pro-posal for relaxing these assumptions are presented in the last section.

2.2. Mathematical model

Based on the formal de"nition given above, the MSP problem is now formulated as an integer linear programming (ILP) model. Without loss of generality, we present this ILP model assuming three daily shifts (i.e.P"3). It is straightforward to adopt the model for cases where the number of daily shiftsPtakes the value of any positive integer.

Let >

i be the number of workers employed in

shiftiand letX

tjbe an indicator variable where

X tj"

G

1 if machinejoperates in periodt,

0 otherwise.

The period index t indicates a particular day and shift combination under the following convention:

0(t)Dfor the day shift,

D(t)2Dfor the evening shift,

2D(t)3Dfor the night shift.

The workforce needed for the operation of machine

jin periodtwill bea

jXtj. Since the total workforce

at any period cannot exceed that available for the respective shift,

Clearly, in order to complete its targeted produc-tion load, each machine j needs to operate for exactly=

jperiods (possibly spread over all three

shifts). Hence:

3D+

t/1 X

tj"=jfor allj.

The above completes the problem formulation. In brief

Minimise Z">

1#>2#>3

Note that, in order to model the MSP problem for values of PO3, we simply need to change the number of variables entering the objective function and the number of constraints accordingly.

2.3. Initial observations

Given the structure of the proposed MSP model, we now proceed with some initial observations and conjectures with respect to its solution. In fact, the development of the solution algorithms presented in this paper were strongly in#uenced by these observations.

As MSP has been formulated, each term>

iof the

Therefore, the di!erences represented by the con-straint sets in Eqs. (1)}(3) practically correspond to the non-utilised workforce in each period of the corresponding shift. Clearly, if it was possible to

equalise workforcebetween all periods in each shift at the minimum level possible, while satisfying the production targets given by constraints (4), we would have achieved an ideal solution with full workforce utilisation. Obviously, due to the inte-grality of the manning needs of each machine as well as constraints (4)}(5), this is not always a feas-ible solution to the problem (see below).

Based on the above and concentrating on the single shift problem (i.e. forP"1), there appears to be a strong similarity between the MSP problem and the well-known problem of scheduling parallel unrelated machines so as to minimise the total makespan. In the latter problem, an ideal solution (again not always feasible) is obtained by schedules which equalise the production load allocated to each parallel machine. In fact, the usual formula-tion of the parallel machines scheduling problem (e.g. [12]) involves an ILP model very similar to the one developed here for the single-shift MSP prob-lem. The di!erence is that in the model for parallel machines scheduling the left-hand side of con-straints (4) always equals to one. In this respect, the parallel machines scheduling problem is simpler than the MSP problem. We have used, however, the strong similarity between these two problems to develop the heuristic algorithms presented here.

It is worth stating that, even in its simplest form, the parallel machines scheduling problem is known to be an NP-Complete [13]. Based on the sim-ilarity of this problem with MSP and considering the extra structural complexities of the latter, we may safely conjecture that the MSP problem pre-sented here is also NP-Complete. Although this remains to be formally proven, in the following we seek to develop e$cient heuristic algorithms for its solution.

Another issue concerns the MSP problem solu-tion space. This is important since it corresponds to the number of feasible variables combinations to be searched by an (explicit or implicit) enumeration algorithm (such as branch and bound) in order to locate the optimal solution. Based on the MSP model and particularly considering constraints set

(4), it is not hard to see that the maximum number of feasible variables combinations (and so candi-date solutions) can be calculated by the expression

n

<

i/1

A

PD=

i

B

. (6)

Clearly, even for moderate values of the problem variables, the solution space may grow into very large numbers. An example of this is given in Sec-tion 4, when describing a particular case study in detail.

We close this section by presenting a lower bound for the optimal solution of the MSP prob-lem. This bound is given by the following expres-sion (which is valid for any number of shifts):

B"+n

i/1 a

i=i/D. (7)

The above gives the total workforce-periods neces-sary to meet all production targets averaged over the days in the planning horizon. It physically rep-resents the minimum (optimal) workforce needed to be employed daily (in all shifts), if workforce could be equalised between the periods of each individual shift (i.e. the ideal MSP solution). Since this ideal solution is not attainable (thus feasible) for any problem setting, the actual optimum for a given problem can exceed the value given by (7). Note that an analogous expression is also used as a lower bound for the optimal solution in the parallel ma-chines scheduling problem discussed earlier [14,15]. We used the bound in (7), when testing the performance of one of the heuristic algorithms we propose.

3. Heuristic solution algorithms

single-shift heuristic can be used to tackle the multi-shift MSP problem.

Throughout the presentation of the heuristic algorithms, we have deliberately chosen to sacri"ce some mathematical rigour (particularly on detailed data-management activities for the heuris-tic implementation) in favour of the underlying logic clarity.

3.1. Single-shift algorithm

The basis for developing the heuristic for the single-shift operation (with P"1) has been the excellent performance of the so calledgreedy heuris-tic for the parallel machines scheduling problem discussed earlier (see Baker [15] for a description of the greedy heuristic in the context of this problem). The similarity between the two problems allowed as to adopt the greedy heuristic for solving the single-shift MSP as follows:

Step 1: List all machines in decreasing manning requirements.

Step 2: List all periods in the planning horizon.

Step 3: Select (and consider) the "rst machine in the list.

Step 4: Find the period with least-assigned work-force so far and reserve it for the operation of this machine.

Erase the reserved period from periods list.

Step 5: Repeat from Step 4 until the periods re-served for the operation of the machine exactly equals its production load. Erase the machine from the machine list.

Step 6: Repeat from Step 2 until the machine list is empty.

Considering one machine at a time, the heuristic reserves time periods (by allocating the respective workforce) for the operation of a machine until all time periods needed for the production of its re-spective load has been covered. The justi"cation for the greedy characterisation of the heuristic stems from the fact that machines are considered in de-creasing order of manning. Hence, machines with high manning needs are given priority (that is time periods for their operation are reserved"rst), con-sidering machines with less manning later in order

to even-out workforce allocation between periods (i.e."ne tuning).

Throughout the heuristic, the main criterion for selecting a particular time period for the operation of a machine is the least-assigned workforce so far. In this respect, the heuristic attempts to combine the operation of machines at particular periods so as to e!ectively equalise workforce between all peri-ods of the planning horizon. Clearly, when this is achieved, the solution becomes equal to the lower bound in (7) and corresponds to an optimal solu-tion for the single-shift MSP problem.

A "nal point worth making is that the above heuristic is single-pass. As a result, decisions con-cerning the allocation of periods to particular ma-chines are made once and these are not revised (or altered) as the application of the heuristic develops. The implications of this logic on the speed of the heuristic are discussed in Section 3.3.

3.2. Multi-shift algorithm

The problem with directly applying the above heuristic to multi-shift operating environments arises from the fact that it is practically insensitive to any qualitative segmentation of the planning horizon (that is into di!erent shifts). However, since workforce is practically allocated to shifts, the my-opic choice of the period with the least-assigned workforce so far cannot guarantee to be the best available choice and may actually lead to a de-crease in overall workforce utilisation"gures.

This may happen, for example, when the said period belongs to some shift with an even work-force distribution among its periods (which corres-ponds to a high utilisation "gure). An allocation decision to this period could a!ect the workforce distribution, resulting in a net increase of the work-force planned for this shift (and consequently a de-crease of workforce utilisation). This could have possibly been avoided if we had chosen a period perhaps with more-assigned workforce so far, but belonging to a shift with a workforce distribution that can accommodate this allocation without an overall workforce increase for this shift.

account the e!ects that the choice of a particular period may have on the total workforce utilisation. Among the possible ways to achieve this, we have chosen one which was introduced into the multi-shift MSP heuristic algorithm described be-low. We stress that the particular multi-shift algo-rithm is an extension of the single-shift heuristic, obtained by incorporating a speci"c shift selection criterion into its operational logic (this is described below).

Although we have tried to avoid most math-ematical formalism, the following additional nota-tion is necessary for presenting the multi-shift heuristic:

f

t workforce assigned so far to periodt Z

i workforceZ assigned so far to shift i;

i"max(i~1)DxtxiDMftN

¸

t non-utilised workforce so far in periodshifti); ¸ t (of

t"Zi!ft

S

i total non-utilised workforce-periods so far inshifti; + (i~1)DxtxiD¸t

Since we are considering one machine at a time, in the presentation of the heuristic all machine indices are suppressed. Hence, production load = and

manningaalways correspond to the machine cur-rently under consideration.

Step 1: List all machines in decreasing order of manning requirements.

Step 2: List all periods in the planning horizon (keeping respective shift information).

Step 3: Select (and consider)"rst machine in the list.

SetN"=.

Step 4: Locate all¹periods for which¸

t*a.

Use single-shift heuristic logic to reserve

min(N,¹) of these periods for operation of

selected machine.

Erase reserved periods from the periods list.

SetNPN!min(N,¹).

IfN"0 continue from Step 7.

Step 5: Locate the remaining K

i free periods in

each shifti.

Considering each shift separately, use single-shift heuristic logic to reserve min

(N,K

i) periods for the operation of

se-lected machine.

Evaluate total non-utilised workforce in each shiftS

i resulting from above

alloca-tion.

Step 6: Keep the allocation for the shiftiHwhich has the minimumS

i.

Erase all periods of shiftiHfrom the peri-ods list.

SetNPN!KH

i andKHiP0.

Step 7: Repeat from Step 5 until the periods re-served for the operation of the machine exactly equal its production load (i.e.

N"0).

Erase the machine from the machines list.

Step 8: Repeat from Step 2 until the machine list is empty.

As the single-shift heuristic, the multi-shift algo-rithm gradually constructs a solution by consider-ing machines in decreasconsider-ing mannconsider-ing order (thus it is also a greedy heuristic). First the heuristic re-serves (in Step 4) all possible periods which can accommodate the operation of the selected ma-chinewithoutany workforce increase (i.e. the peri-ods for which¸

t*a). It then starts reserving all the

available periods of individual shifts, considering each shift separately in a predetermined sequence. By reserving as many periods in a shift as possible, the heuristic attempts to avoid any unnecessary splitting of a machine operation between di!erent shifts, something that could simultaneously in-crease workforce in several shifts (Steps 5}7). To do this, a criterion is needed for deciding shift priori-ties (that is, the order in which shifts are selected for consideration).

The particular shift priorities selection criterion incorporated into the heuristic (Step 6) is to select the shift for which the allocation of the machine under consideration provides the least non-utilised workforce periods so far (that is, select the shift with minimumS

i). Clearly, since we ignore the

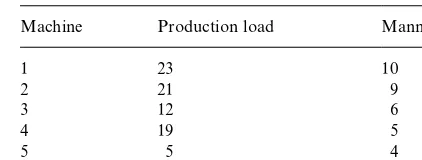

Table 1

Data used for application example

Machine Production load Manning

1 23 10

2 21 9

3 12 6

4 19 5

5 5 4

3.3. Algorithmic convergence

We now turn to determine the rate according to which the proposed heuristic algorithms converge to a"nal solution. Although the analysis presented here is strictly valid for the single-shift algorithm, it approximately holds for the multi-shift heuristic also.

As described in the previous section, both algo-rithms mainly consist of a series of sorting opera-tions (one sorting operation for each available machine) followed by some subsequent decisions taken on the basis of the sorted data. It is well known that the operation of sorting kobjects ac-cording to a given criterion may be e!ectively car-ried out at a rate kln(k) (see, for example, [14]). Introducingk"PD(for the total number of time periods in all shifts) and considering all available machines n, we can easily determine the conver-gence rate of the heuristics to be of the order:

Order of Convergence"O[nPDln(PD)].

The above logarithmic order of convergence clearly demonstrates that the proposed algorithms can reach a solution practically very fast. Therefore, they may be expected to be successfully applied for the solution of large MSP problems. Some further comments concerning the computational time re-quired for running the multi-shift heuristic are given in Section 5.

4. Application example

We now present and discuss an application example demonstrating the actual use of the multi-shift heuristic algorithm. Most data came out of the industrial case study which instigated this research and concerns the Greek subsidiary of a multina-tional foods and beverages producer. Table 1 shows the data concerning the production load targets and the manning needs for each machine used in the example. We wish to determine the minimum work-force required to accomplish the given targets in an environment operating three daily shifts for a plann-ing horizon of 10 days (i.e.P"3 andD"10).

Before demonstrating the application of the multi-shift heuristic, some initial comments related

to the structure of the problem under consideration are granted. Despite its apparently fairly limited size, the solution space of the problem is very large. In fact, using expression (6), we can determine the number of feasible parameter combinations to be circa 3.27]1033, which clearly demonstrates the

need for an e$cient solution heuristic. We can also determine a lower bound for the expected solution. Using expression (7) for the data of this problem, we obtain: B"606/10"60.6P61 workers per day. Recall that we do not really know whether this is a feasible solution.

Table 2 shows the results obtained by applying the multi-shift heuristic algorithm. As it has been constructed, each line of the table represents a par-ticular allocation decision for the operation of the corresponding machine. Table entries represent the workforce allocated in each period, presented in the order in which the relevant decisions were made. The last column of the table gives the exact step of the multi-shift heuristic during which the particular decision was made. The "nal rows of the table present the solution, giving the workforce allocated in each period (by summing all corresponding column entries) and each shift (the maximum workforce allocated in all periods of the shift) respectively.

Tab

not been able to locate (by using extensive local neighbourhood search) any better solution than the above, something that might indicate that the heu-ristic solution is actually optimal in this case.

We also solved the above problem using the LINGO optimisation package (which employs a branch and bound implicit enumeration algo-rithm) and the single-shift heuristic algorithm. The best solution we arrived at with the LINGO pack-age was Z"64 (using a PC-586 at 90 MHz), obtained after consideration of circa 2.15]108

distinct solution nodes during 238 hours of com-puter run-time as de"ned by the LINGO optimiser [16]. Note that, when applied to this problem, the single-shift heuristic provided a solution Z"65, marginally worse than the LINGO solution, but obtained faster (at a speed slightly higher than that of the multi-shift heuristic).

In order to apply the single-shift algorithm to this multi-shift problem, we have initially ignored any correspondence between time periods and shifts and applied directly the single-shift heuristic to solve the resulting transformed single-shift prob-lem (i.e.P"1 andD"30). Based on the conven-tional correspondence between periods and shifts introduced in Section 2.2, we have then grouped individual periods into three groups (of ten peri-ods), each representing a particular shift. From then on, we evaluated the workforce to be em-ployed in every shift (and in total) in exactly the same manner as with the multi-shift algorithm out-lined earlier in this section.

5. Computational results

Numerical computations were performed in order to test the performance of the multi-shift heuristic algorithm. In the absence of a de"nite knowledge of the optimal solution, the heuristic results were tested against two di!erent surrogate measures of e$ciency; namely, the lower bound in expression (7) and the results provided by the LINGO optimizer.

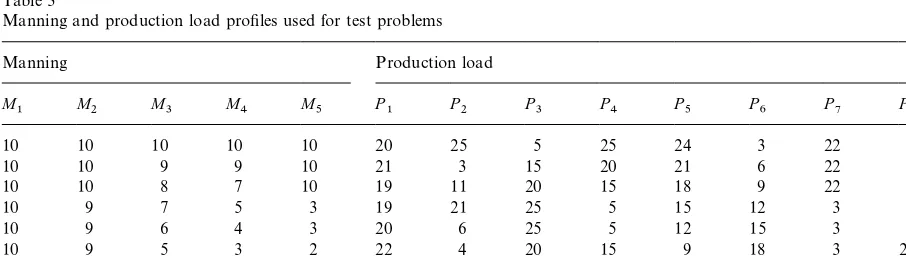

Table 3

Manning and production load pro"les used for test problems

Manning Production load

M

1 M2 M3 M4 M5 P1 P2 P3 P4 P5 P6 P7 P8

10 10 10 10 10 20 25 5 25 24 3 22 3

10 10 9 9 10 21 3 15 20 21 6 22 3

10 10 8 7 10 19 11 20 15 18 9 22 3

10 9 7 5 3 19 21 25 5 15 12 3 3

10 9 6 4 3 20 6 25 5 12 15 3 3

10 9 5 3 2 22 4 20 15 9 18 3 22

10 9 4 2 1 21 13 15 20 6 21 3 22

10 8 3 1 1 19 15 5 25 3 24 3 22

standard setting of the package, with a stopping limit for ending the branch and bound search set at 106 solution nodes (which corresponds to circa 65 min computer run-time as indicated by the package).

5.1. Test problems

The multi-shift heuristic was tested using 40 dis-tinct test problems, representing a variety of di! er-ent operating environmer-ents. For all problems, we kept the same number of machines, daily shifts and the planning horizon (i.e.n"8,P"3 andD"10) and varied the respective machine manning and production load. The reason for this was that (as some preliminary results have indicated) these are the main parameters which in#uence the quality of the problem solution.

All 40 di!erent problems were constructed as the result of combining 5 machine manning with 8 pro-duction load pro"les. These pro"les are shown in Table 3. Machine manning pro"les vary in the range (1, 10) and were chosen to represent several di!erent operating environments. In this context, pro"les M

1 and M2 represent cases with nearly

even manning needs for all machines, while pro"les

M

3}M6allow for more extreme manning

distribu-tions. In the same way, load pro"les vary in the range (3, 25) and include approximately even (P

1),

entirely random (P

2), parabolic (P3}P4) and

skewed pro"les (P

6}P8). Observe that load pro"le

pairsP

6}P5andP7}P8are reversed images of each

other.

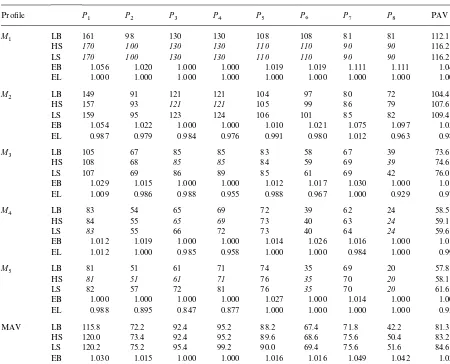

5.2. Numerical results

The results for all test problems are presented in Table 4. Except for the cells in the last column and row of the table which give corresponding averages over all production load (PAV) and manning (MAV) pro"les respectively, each other cell of the table corresponds to a speci"c test problem (in-dicated as the particular pro"les combination). In each cell we show the following results: the heuristic solution (HS), the lower boundB(rounded to the closest larger integer) from (7), the LINGO solution (LS), the e$ciency of the heuristic relatively to lower bound (EB) and the LINGO solution (EL) (obtained as the ratio of the heuristic solution over

Band LS respectively).

Observe that some results of the table are italicised. These indicate values we know with certainty they represent optimal solutions for particular test problems. In most problems, we identi"ed this optimal solution when the result ob-tained by either the heuristic or LINGO equalled the lower bound. For a few test problems, however, the optimal solution was identi"ed even when this did not occur (observe rowM

1). In fact, for these

Table 4

Results obtained for all test problems

Pro"le P

1 P2 P3 P4 P5 P6 P7 P8 PAV

M

1 LBHS 161170 98100 130130 130130 108110 108110 9081 9081 112.1116.2

LS 170 100 130 130 110 110 90 90 116.2

EB 1.056 1.020 1.000 1.000 1.019 1.019 1.111 1.111 1.042

EL 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000

M

2 LB 149 91 121 121 104 97 80 72 104.4

HS 157 93 121 121 105 99 86 79 107.6

LS 159 95 123 124 106 101 85 82 109.4

EB 1.054 1.022 1.000 1.000 1.010 1.021 1.075 1.097 1.035

EL 0.987 0.979 0.984 0.976 0.991 0.980 1.012 0.963 0.984

M

3 LBHS 105108 6768 85 85 83 58 67 39 73.6

85 85 84 59 69 39 74.6

LS 107 69 86 89 85 61 69 42 76.0

EB 1.029 1.015 1.000 1.000 1.012 1.017 1.030 1.000 1.013

EL 1.009 0.986 0.988 0.955 0.988 0.967 1.000 0.929 0.978

M

4 LBHS 8384 5455 6565 6969 7273 3940 6362 2424 58.559.1

LS 83 55 66 72 73 40 64 24 59.6

EB 1.012 1.019 1.000 1.000 1.014 1.026 1.016 1.000 1.011

EL 1.012 1.000 0.985 0.958 1.000 1.000 0.984 1.000 0.992

M

5 LB 81 51 61 71 74 35 69 20 57.8

HS 81 51 61 71 76 35 70 20 58.1

LS 82 57 72 81 76 35 70 20 61.6

EB 1.000 1.000 1.000 1.000 1.027 1.000 1.014 1.000 1.005

EL 0.988 0.895 0.847 0.877 1.000 1.000 1.000 1.000 0.951

MAV LB 115.8 72.2 92.4 95.2 88.2 67.4 71.8 42.2 81.3

HS 120.0 73.4 92.4 95.2 89.6 68.6 75.6 50.4 83.2

LS 120.2 75.2 95.4 99.2 90.0 69.4 75.6 51.6 84.6

EB 1.030 1.015 1.000 1.000 1.016 1.016 1.049 1.042 1.021

EL 0.999 0.972 0.961 0.953 0.996 0.989 0.999 0.978 0.981

From Table 4, we observe that the heuristic has found a known optimal solution for 22 problem settings (55% of test problems). More important, however, is the fact that, other than the 4 problems for which the heuristic solution di!ers more (but always less than 10%), for all other problems (90% of test problems) the heuristic solution deviated less than 3% from the lower bound. Given the nature of the bound, this indicates a very satisfactory overall quality of the heuristic solution at least for the problems set tested.

Turning to the e!ects of the parameters setting on the heuristic solution quality, these are not en-tirely uniform for all cases. Although a more

de-tailed investigation of this issue may be granted, it appears that (as expected) the form of the manning and load pro"les may be factors a!ecting the solu-tion quality. In general, solusolu-tion quality improves when the manning pro"les used allow for the com-bined machines operation in particular periods. Observe the increased optimal solution occurren-ces for such pro"les (asM

1andM5). Similar e!ects,

appear for the load pro"les (as P

3andP4).

How-ever, by not knowing the actual optimal solution for all problems, these are just initial observations which need further study.

in most cases. In particular, of a total of 23 prob-lems for which the two approaches gave di!erent solutions, the proposed heuristic solution was bet-ter in 20 problems (that is for 87% of these problems and 50% of all problems). Moreover, LINGO gave a known optimal solution for only 12 test problems (30% of all problems compared with 55% for the heuristic). Note, however, that other than a few problems where LINGO solutions were indeed very poor (see cases M5}P3 and M5}P4), these did not di!er dramatically from the heuristic ones. Additionally, it is possible that the LINGO solutions could improve if the stopping condition set for the branch and bound search were relaxed. A "nal issue concerns the computer run-time required for arriving at a heuristic solution. In all test problems the solution time varied between 12 and 16 seconds computer run-time. This is con-sidered as extremely fast, given that the implemen-tation software used is not dedicated for the solution of such combinatorial problems. We can further support this statement by comparison with the solution time required by the LINGO opti-miser. In fact, other than the few cases where LINGO reached a known optimal solution (which took circa 2 minutes run-time) in all other cases the solution was obtained after the stopping condition was activated at circa 65 minutes computer run-time.

6. Discussion and conclusions

This paper has dealt with the formulation and the heuristic solution of a not previously studied personnel planning problem, we code-named MSP. The problem arises naturally during the aggregate production planning stages of particular types of industries where the available production capacity strongly depends on the workforce employed. In fact, one of the heuristics developed has now been integrated as a regular computerised decision sup-port tool within the planning procedures of a manufacturing company.

We formulated MSP as an ILP model and dem-onstrated its strong resemblance to the well known parallel independent machines scheduling problem for minimising makespan. Although it still remains

to be formally established, on the basis of the struc-tural similarity between the two models we conjec-tured that MSP (even in its simplest single-shift variation) is an NP-Complete problem. We also proposed an expression for evaluating a lower bound of the MSP solution and developed heuristic algorithms for tackling single and multi-shift prob-lems. The multi-shift algorithm e!ectively extends the single-shift algorithm by incorporating a par-ticular shift priorities selection criterion in its oper-ating logic.

Both heuristics, which may be classi"ed as greedy algorithms, construct the solution gradually by considering one machine at a time in one single pass. This operating logic makes both heuristics extremely fast (having logarithmic order of conver-gence), something that allowed industrial imple-mentation using standard commercial software and hardware tools. Moreover, as demonstrated by computational results for multi-shift environments, the heuristic solutions quality is very satisfactory. Heuristic solutions were better than those obtained by the LINGO optimiser in 50% of all test prob-lems and deviated not more than 3% from the lower bound in most cases examined. This is not surprising considering the good performance gen-erally reported for greedy algorithms in relation with various machine scheduling problems [14,17]. Since this is the"rst formal study of the MSP problem, there is still much ground for further research with respect to both the problem formula-tion per se and the re"nement of the heuristic algorithms. Considering"rst the MSP formulation, we may attempt its generalisation by relaxing the underlying assumptions. In this context, extra fea-tures could be incorporated such as the use of less

#exible workforce, limits to the workforce em-ployed in each shift, constraints restricting particu-lar machines to operate simultaneously or daily shifts di!ering in duration. Moreover, we might introduce a cost structure which would allow to di!erentiate workforce costs per shift.

for the solution of generalised versions of MSP such as those discussed above. Noticeably, due to their simple operating logic, the heuristics proposed may be easily adapted to deal with most of these vari-ations. It remains, however, to be seen whether the heuristic performance will still remain satisfactory when dealing with these more complex problems.

A"nal related issue concerns the comparison of the proposed heuristic algorithms with other ap-proaches. As review papers indicate [18,19], several researchers have proposed heuristics for dealing with particular aspects of the parallel machines scheduling problem with the objective of minimis-ing makespan. Others, in the context of di!erent applications, have proposed heuristics for dealing with problems e!ectively identical to parallel ma-chines scheduling (see, for example, [20,21] in rela-tion with the modi"ed bin-packing problem). Due to the strong similarity between these problems and MSP, it seems that with minor modi"cations some of these heuristics could be easily adapted for the solution of MSP. It would be interesting, therefore,

"rst to extend some of these heuristics to cover MSP and then to compare their performance with that of the heuristics we have proposed in this paper.

Acknowledgements

This research was partially supported by the Greek Development Ministry under research grant PABE-96-BE140.

References

[1] G. Dantzig, A comment on Edie's tra$c delays at toll booths, Operations Research 2 (1954) 339}341.

[2] A.I.Z. Jarrah, J.F. Bard, A.H. de Silva, Solving large-scale tour scheduling problems, Management Science 40 (1994) 1125}1144.

[3] K. Baker, Workforce allocation in cyclical scheduling problems: A survey, Operational Research Quarterly 27 (1976) 155}167.

[4] J. Tien, A. Kamiyama, On manpower scheduling algo-rithms, SIAM Review 24 (1982) 275}287.

[5] S. Betchhold, M. Brusco, M. Showalter, A comparative evaluation of labour tour scheduling methods, Decision Sciences 19 (1991) 353}373.

[6] J. Bartholdi, A guaranteed-accuracy round-o!algorithm for cyclic scheduling and set covering, Operations Re-search 29 (1981) 501}510.

[7] M.J. Brusco, L.W. Jacobs, A simulated annealing ap-proach to the solution of#exible labour scheduling prob-lems, Journal of the Operational Research Society 44 (1993) 1191}1200.

[8] L. Krajewski, L. Ritzman, J. McKenzie, Shift scheduling in a banking operation: A case application, Interfaces 10 (1980) 1}8.

[9] J. Morris, M. Showalter, Simple approaches to shift, days-o!and tour scheduling problems, Management Science 8 (1983) 942}950.

[10] F.F. Easton, D.F. Rossin, Su$cient working subsets for the tour scheduling problem, Management Science 37 (1991) 1441}1451.

[11] J.S. Loucks, F.R. Jacobs, Tour scheduling and task assign-ment of heterogeneous work force: A heuristic approach, Decision Sciences 22 (1991) 700}718.

[12] N. Piersma, H.E. Romeijn, Parallel machine scheduling: A probabilistic analysis, Naval Research Logistics 43 (1996) 897}916.

[13] R.M. Garey, D.C. Johnson, Computers and Intractability, Freeman and Company, New York, 1979.

[14] E.J. Anderson, The Management of Manufacturing: Mod-els and Analysis, Addison-Wesley, Wokingham, 1995. [15] K. Baker, Introduction to Sequencing and Scheduling,

Wiley, New York, 1974.

[16] Anonymous, LINGO: The Modeling Language and Opti-mizer, LINDO Systems Inc., Chicago, 1995.

[17] A.G. Lagodimos, A. Charalambopoulos, A. Kavgalaki, Computer-aided packing shop scheduling in a manufac-turing plant, International Journal of Production Econ-omics 47 (1996) 621}630.

[18] S.C. Graves, A review of production scheduling, Opera-tions Research 29 (1981) 646}674.

[19] T.C.E. Cheng, C.C.S. Sin, A state-of-the-art review of par-allel-machine scheduling research, European Journal of Operational Research 47 (1990) 271}292.

[20] R.L. Rao, S.S. Iyengar, Bin-packing by simulated anneal-ing, Computers in Mathematical Applications 27 (1994) 71}82.