Papermaking pulps from the fibrous fraction of

Miscanthus x Giganteus

P. Cappelletto

a, F. Mongardini

a, B. Barberi

a, M. Sannibale

a, M. Brizzi

a,*,

V. Pignatelli

baIstituto Poligrafico e Zecca dello Stato,Centro Tecnico Industriale,6ia Salaria,971-00138Rome,Italy bENEA INN BIOAG,C.R.Casaccia,Via Anguillarese301,00060S.M.di Galeria-00060Rome,Italy

Accepted 8 October 1999

Abstract

The use of non-wood raw material could be an effective mean of backing up worldwide wood supply, especially in

countries with insufficient forest resources. An example of such non-wood plants is miscanthus (Miscanthus spp.), a

crop adapted to European growing conditions and that has been extensively investigated as an important source of biomass for energy production, for building materials, geotextiles and substrates in nurseries and greenhouses. This crop is also considered a possible raw material for the paper industry. In Italy, miscanthus biomass productivity

ranges from 15 t ha−1per year to 20 – 30 t ha−1per year. In the present study, the possibility of utilising miscanthus

fibres, as a reinforcing material in paper furnishes based on recycled fibres, was investigated. In order to transform a heterogeneous material into several concentrated and uniform fractions, miscanthus stalks prior to pulping underwent a mechanical cleaning and separation treatment in dry conditions. Two high yield pulping processes (CTMP and TMP) were applied only to the fibrous fraction. Subsequently, the miscanthus pulps were mixed, at different ratio, with wastepaper (old newspapers). Results show that miscanthus pulps, especially CTMP, are suitable to reinforce recycled fibres and to improve the mechanical characteristics of papers containing secondary fibres. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Miscanthus x giganteus; Non-wood fibres; High yield pulping; Paper industry

www.elsevier.com/locate/indcrop

1. Introduction

The use of non-wood raw material could be an effective mean of backing up world-wide wood

supply, especially in countries with insufficient forest resources. Non-wood pulp capacity world-wide was 6.9% of total papermaking pulp capac-ity in 1997 and is estimated to have gone to 11.2% in 1998 (Atchinson, 1998). The non-wood pulp is produced mainly in developing countries but also in Europe; the raw materials most widely used are straw, bagasse and bamboo (Oggiano et al., 1997).

* Corresponding author. Tel.:+39-06-8819707; fax:+ 39-06-88520898.

E-mail address:[email protected] (M. Brizzi)

P.Cappelletto et al./Industrial Crops and Products11 (2000) 205 – 210 206

Among the non-wood crops suitable for paper-making, an interesting one is miscanthus.

The variety Miscanthus sacchariflorus, (the so-called ‘Amur silver grass’), is one of the main papermaking raw materials in the Republic of China, owing to its fast growing cycle, high biomass production, short cooking time and easy pulping (Wu Yi-Ming and Qin Yu, 1988), (Deng Chang-Jiang and Wu Yi-Ming, 1992).

Miscanthus, and particularly its variety Mis

-canthus x giganteus, has been extensively investi-gated also throughout Europe as a possible raw material for energy, building materials, geotextiles and substrates in nurseries and greenhouses. This crop is also considered an important source of biomass for papermaking pulps.

In Italy, a number of productivity trials of miscanthus crop have been performed during the last years, generally on small-scale plots. As an example, under the framework of the R&D Pro-ject ‘Miscanthus Productivity Network’, two four-year agronomic trials for the assessment of miscanthus productivity in Italy were carried out at ENEA Research Centres Brasimone and Tri-saia (respectively located in Northern and South-ern Italy). The results from such trials-as well as from those carried out at different places through-out Italy-indicate that Miscanthus x giganteus is well adapted under different Italian pedoclimatic conditions and yields satisfactorily, its biomass ranging from 15 to 25 – 30 t ha−1 per year. More recently (May 1998), an open-field trial on a 3 ha area has been established at the ENEA Research Centre Brasimone, with the objective of assessing the technical and economic feasibility of cultivat-ing miscanthus on marginal lands and with mini-mal amounts of input. The propagation material has been rhizomes; they were sowed mechanically by using a commercial potato-sowing machine, with a planting density of about 15 000 rhizomes m−2

; no irrigation should be necessary after the phase of plant establishment.

Italy is totally dependent on imports for its needs of virgin papermaking pulps and the raw material supply for the Italian paper industry mainly rely on wastepaper (in 1998 the ratio between wastepaper utilisation and paper and pa-perboard production has been 49.9). In the Italian

situation, miscanthus could be an effective mean of supplying virgin fibres, thanks to its high pro-ductivity, provided that a viable pulping process could be applied to this non-wood plant and a suitable utilisation of its pulps could be found inside the paper manufacturing chain.

Previous researches on miscanthus (Cappelletto et al., 1998) and other non-wood plants (Cappel-letto and Mongardini, 1997) showed that a pre-liminary mechanical treatment is necessary in order to separate the raw material into uniform fractions, concentrate the fibrous material, and eliminate foreign matter (together with leaves and pith), thus decreasing chemical consumption and reducing pollution loads in wastewater. Therefore, the pre-treatment system was designed to perform the following operations:

compaction of stalks (if they had not already been conditioned during field harvesting); cutting of raw material (usually delivered as

round-bales) by means of a blade mill; transport of cut material by means of fans;

separation of light fractions by means of a cyclone;

separation of heavy fines; this fraction includes the material that have been reduced to powder during the compression, the cutting and the pneumatic transport operations.

With these operations the resulting material will be formed by a higher percentage of fibres, since it will lose most of the foreign matter (dust, sand, pebbles) and useless material (leaves, pith, epithe-lial and parenchyma cells of stalks).

Table 1

Brasimone Centre, pedoclimatic conditions

ENEA Brasimone Centre 40035 Castiglione Location

dei Pe´poli-Bologna, Italy 44° 07%N

Latitude

11° 07%E Longitude

870–980 m above sea level Altitude

Rainy climate, cold winters Climate

Loam-clay, high potassium contents (218 Soil type

ppm)

For the pulping trials, a processing technique that includes a preliminary dry-mechanical treat-ment, a high yield pulping process and one perox-ide bleaching sequence, has been applied.

In the preliminary treatment, the miscanthus stalks were compressed (simulating the condition-ing operation in the field), then chipped by means of a ‘Caravaggi Bio 350’ blade mill equipped with a 50 mm mesh and finally separated (stalks, leaves, dust) by means of a rotating screen equipped with a 3 mm mesh.

Papermaking fibres are concentrated in the stalks, therefore the pulping treatment was ap-plied only to this fraction, formed by cleaned and uniform fibrids 5 – 7 cm long.

Two different pulping processes were tested: TMP and CTMP. Both are high yield processes and require low chemical and energy inputs. Af-terwards the CTM pulps alone have been bleached by one stage peroxide sequence.

The pulping process was carried out in two stages (wet pre-treatment and defiberizing) for the TMP and three stages (wet pre-treatment, cooking and defiberizing) for the CTMP. Wet pre-treat-ment took place in an open vessel, while the cooking took place in an electric heated, 16-l rotating boiler. Then the pulp stock was squeezed by means of an elicoidal press. Defiberizing was carried out in an 8¦Bauer disc refiner, where two steam injections were applied in order to reach the best fibre elementarization at the lignin melting temperature. Both pulps were screened in a Werverk sorter and refined in a Hollander Valley apparatus.

Utilising as raw material only the fibrous frac-tion of miscanthus plants, the objectives of the present study were: (a) to investigate the feasibil-ity of obtaining papermaking pulps with soft and low input pulping processes, (b) to evaluate the differences between a miscanthus TMP (thermo-mechanical pulp) and a miscanthus CTMP (chemi-thermo-mechanical pulp), (c) to determine the possibility of utilising these pulps as a rein-forcing material in paper furnishes based on recy-cled fibres.

2. Material and methods

Miscanthus stalks from a three years crop, es-tablished at the above mentioned ENEA Brasi-mone Centre, were utilised as raw material for the papermaking trials that had been carried out at the Centro Tecnico Industriale of Istituto Poli-grafico e Zecca dello Stato. Table 1 shows the pedoclimatic conditions of the Brasimone site.

Table 2

Miscabhus x giganteus: pulping and bleaching conditions

CTMP TMP

Pulping

Wet pre- Open vessel, 60°C for 30 min, 1% H2O2 Open vessel, 60°C for 20 min, 1% NaOH treatment

Cooking NO 16 litres boiler, 120°C for 30 min, solid/liquid ratio: 1/7; chemicals: NaOH (5%); H2O2 (1%), EDTA (0.2%) 8¦Bauer disc refiner, 3000 rpm, 8¦Bauer disc refiner, 3000 rpm, 2 steam injections Defiberizing

2 steam injections NO

P.Cappelletto et al./Industrial Crops and Products11 (2000) 205 – 210 208

Table 3

Miscanthus x giganteus: results of dry-mechanical treatment before pulping and stalks fraction chemical analysis, as%

Treatment

Miscanthus fractions (%) Chemical analysis (after treatment) (%) yield (%)

After Ex in Ashes Lignin Holo-cellulose Cellulose As it is

resistant benzole+H2O

treatment

93.4 68.6 9.4

Stalks 75.9 1.5 27.4 60.3 38.1

4.5 3.3

Table 2 shows the pulping and bleaching conditions.

The unbleached CTM pulp was bleached apply-ing a hydrogen peroxide process (Table 2 gives bleaching parameters).

The two high yield miscanthus pulps were utilised to prepare papers containing different ra-tios of miscanthus pulps and wastepaper (these secondary fibres originated from old newspapers): 30% miscanthus+70% wastepaper;

50% miscanthus+50% wastepaper;

70% miscanthus+30% wastepaper;

100% miscanthus;

100% wastepaper.

Handsheets for evaluation of physico-mechani-cal properties were prepared according to TAPPI T 205 om-88. Physico-mechanical characteristics of the handsheets — tensile, burst and tear in-dexes — were determined according to ISO 192/

2-1985, ISO 2578-1093 and ISO 1974-1990 methods, respectively. Optical properties, includ-ing opacity and brightness, were estimated ac-cording to UNI 7623 method.

3. Results and discussion

Results of the fractionation treatment are shown in Table 3. The dry mechanical treatment not only allowed obtaining three different uni-form fractions of material, but also changed the ratio between these fractions. The percentage of the fibrous fraction over the total increased from 75.9 to 93.4. The total yield of the treatment was 73.5%; leaves and pith were the substances mostly removed.

The chemical analysis of the stalk fraction confirms its fibrous constitution, as shown by the quite high cellulose content (Table 3). The lignin content is in the range of the normal values expected for a graminaceous plant, while the ashes content is very low even for a non-wood species (wheat straw has an average ash content of 10%).

Results of pulping yield are shown in Table 4. As expected, the TM process gave a much higher yield than the CTMP. In fact the CTMP includes a chemical attack to the lignin and to other non-cellulosic substances. Furthermore the CTMP pulps were bleached and also the bleach-ing process reduces the total pulp yield. Anyway the 66.5% yield still allows including this pulp into the high yield category and should not be consid-ered too low. In fact, the pulp yield has been determined on a screened pulp where the 160-mesh screen in the sorter had eliminated some of the parenchyma cells and medullar rays. For the bleached CTM pulp, the COD (Chemical Oxygen

Table 4

Miscanthus x giganteus. Pulping yield and fibres composition of TM and CTM pulps (%)

200 mesh 6.1 12.4

Cappelletto

et

al

.

/

Industrial

Crops

and

Products

11

(2000)

205

–

210

209

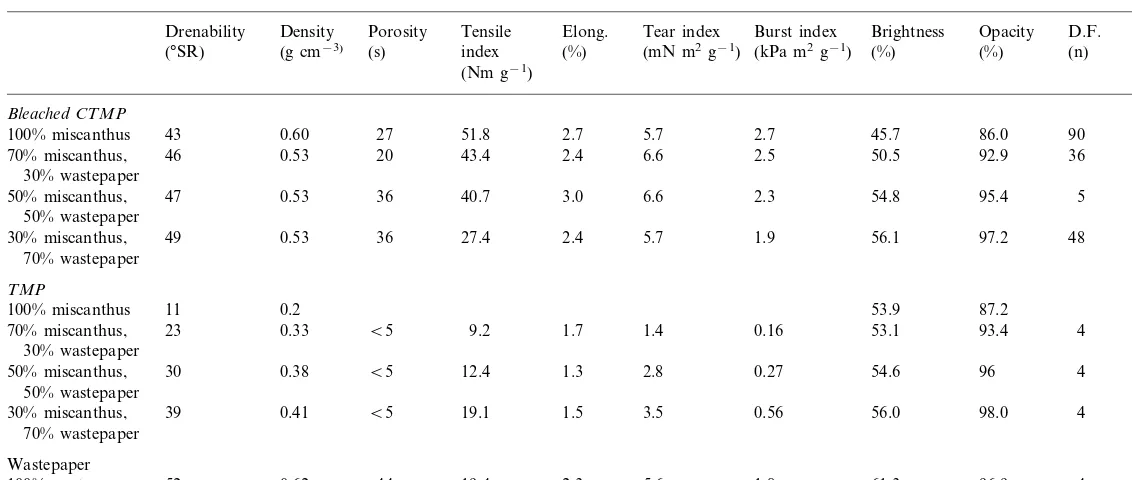

Miscanthus x giganteus. Papermaking properties of papers containing different percentage of miscanthus pulps and wastepaper

Drenability Density Porosity Tensile Elong. Tear index Burst index Brightness Opacity D.F. Stiff-(mN m2g−1)

(s) (kPa m2g−1)

(g cm−3) (%)

(°SR) index (%) (%) (n) ness

(mN) (Nm g−1)

Bleached CTMP

0.60 27 51.8 2.7 5.7

43 2.7

100% miscanthus 45.7 86.0 90 5.6

46 0.53 20 43.4 2.4 6.6

70% miscanthus, 2.5 50.5 92.9 36 4.7

30% wastepaper

47 0.53 36 40.7 3.0

50% miscanthus, 6.6 2.3 54.8 95.4 5 6.2

50% wastepaper

49 0.53 36 27.4 2.4 5.7 1.9 56.1

30% miscanthus, 97.2 48 3.2

70% wastepaper

TMP

0.2

100% miscanthus 11 53.9 87.2

23 0.33 B5 9.2 1.7 1.4 0.16

70% miscanthus, 53.1 93.4 4 3.5

30% wastepaper

30 0.38 B5 12.4 1.3

50% miscanthus, 2.8 0.27 54.6 96 4 2.8

50% wastepaper

39 0.41 B5 19.1 1.5 3.5

30% miscanthus, 0.56 56.0 98.0 4 2.8

70% wastepaper

Wastepaper

0.62 44 19.4 2.3 5.6 1.8

52 61.3

P.Cappelletto et al./Industrial Crops and Products11 (2000) 205 – 210 210

demand) of the pre-treatment and cooking wastewater has been determined. The two values of 2850 ppm and 70 200 ppm, respectively, corre-late well with the calcucorre-lated pulp yield.

In the two high yield pulps also the fibre distri-bution is different; the percentage of the longest fibres (those retained at the 28-mesh screen) is 34.3% for the bleached CTMP and 28.8% for the TMP. In fact the decreased flexibility of fibres after a thermo-mechanical process, reduces fibre length during the refining (Table 4).

Table 5 shows the papermaking properties of the different types of handsheets that were pre-pared. As a general observation, when miscanthus bleached CTMP are added to a furnish based on secondary fibres, the papermaking properties of the paper increase, while the miscanthus TMP, as expected, has no such positive effects. In some blends (50% miscanthus CTMP+50% wastepa-per and 70% miscanthus CTMP+30% wastepa-per) we noted a possible synergetic effect, i.e. the mixture shows higher values than the papers pre-pared with the single components; the phe-nomenon certainly deserves further investigation. The optical properties (brightness and opacity) did not show any improvement neither when CTMP were added nor TMP.

4. Conclusions

The study confirms the feasibility of applying a high yield pulping process to miscanthus, pro-vided that a dry-mechanical treatment is previ-ously carried out on raw material.

The CTMP pulps improved the strength prop-erties of paper based on recycled fibres originating from old newspapers.

It’s necessary to find an alternative utilisation for the pith and the leaves that have been re-moved by the dry-mechanical treatment, in order to exploit the whole biomass and make the mis-canthus chain more profitable.

In the future, the promising results obtained from this work, as well as those from productivity trials in the field, have to be exploited by realising a demonstration scale ‘whole-chain’ test, in order to assess the technical and economic feasibility of the Miscanthus crop.

References

Atchinson, J., 1998. Progress in the global use of non-wood plant fibers and prospects for their greater use in the future, Inpaper Intl. April – June, 21 – 30.

Cappelletto, P., Mongardini, F., 1997. Industrial systems for preparation of cellulose fibers: IPZS experience. Proceed-ings of the Flax and other bast plants Symposium. Non-Textile Applications, 30 September – 1 October 1997, Poznan, Poland.

Cappelletto, P., Mongardini, F., Bilancini, L., 1998. Nonwood fibers: Miscanthus sinensis. Industria della Carta 2, 56 – 60. Deng Chang-Jiang, Wu Yi-Ming, 1992. Study of the chemical structure of hemicellulose extracted from Amur Silver grass. Proceedings of the Shanghai Conference, 6 – 9 April, 1992, Shanghai, China.

Oggiano, N., Angelini, L.G., Cappelletto, P., 1997. Pulping and paper properties of some fibre crops. Ind. Crops Prod. 7, 59 – 67.

Wu Yi-Ming, Qin Yu, 1988. The characteristics of Miscanthus sacchariflorus kraft cooking and using of process control. Proceedings of the Beijing Conference, 11 – 24 July, 1988, Beijing, China.