The unprecedented widespread use of energy storage devices has highlighted the requirement of improved energy density and long-life lithium-ion batteries (LIBs). In terms of next-generation technologies, lithium metal anodes have been observed due to its highest theoretical gravimetric (3,860 mAh g–1) and volumetric (2,061 mAh cm–3) capacity with the lowest potential (–3.04 V, SHE). In this dissertation, I describe brief interpretation of lithium ion batteries, including principles and components of lithium ion batteries in chapter 1.

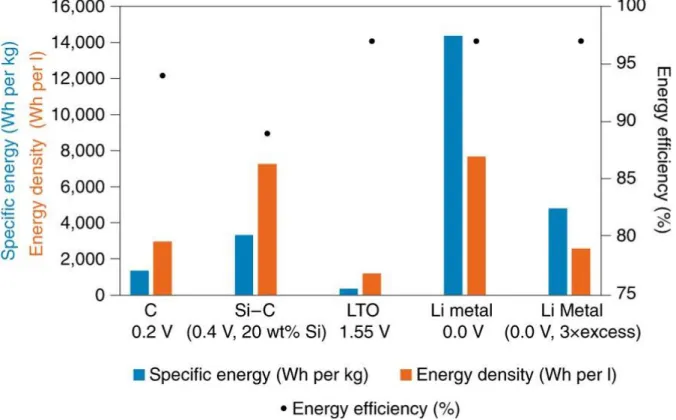

Next, I briefly introduce current and future generation anode materials for high energy density lithium ion batteries; Si-based anodes and Li metal anodes. In Chapter 2, I proposed composite anodes with high gravimetric and volumetric capacity for next-generation lithium-ion batteries. Achieving high electrode density is a particularly important factor in terms of commercial feasibility that the tap density of the active material has been increased to 1.1 g cm-3.

The structure integrity was demonstrated under industrial electrode fabrication with electrode density (1.6 g cm–3), surface capacity (>3.5 mAh cm–2) and electrode composition (additives < 4 wt%). We performed the full-cell evaluation of the 1 Ah pouch at high mass loading and electrode density (~3.75 mAh cm–2 and ~1.65 g cm–3), demonstrating superior cycling stability without rapid capacity drop over 800 cycles .

Introduction of material and chemistry of lithium ion batteries

Introduction

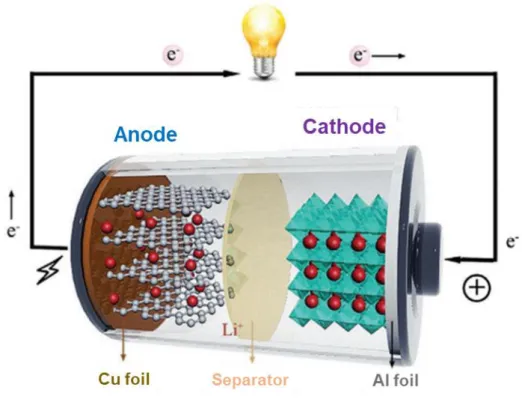

Principle of lithium ion batteries

Current limits and advanced anode materials

Scope and organization of this dissertation

Stress Relief Principle of Micron-sized Anodes with Large Volume Variation for

- Introduction

- Experimental detail

- Results and discussion

- Conclusion

Voltage profile of the reassembled full cell with cycled u-SCM and fresh LCO after 300 cycles on the full cell. dQ/dv discharge plot of the initial and reassembled generation cycle with cycled SCM and fresh Li-foil after 300 cycles on a full cell.

Lithiated Lithiophilic (Li x Si) Layer Induced Li Host Materials for Next Generation

Introduction

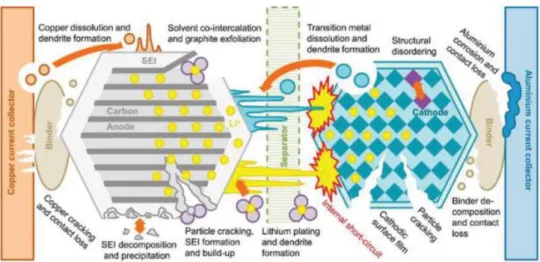

Li-metal has been inspired again as the next-generation prominent promising anode materials because extensive research on high-energy silicon anodes to commercialize it was insufficient to replace graphite in terms of cycle stability.103-107 Li-metal enables extremely high specific capacity (3860 mAh/ g) and the lowest electrochemical potential (−3.04 V) that it has its high power and energy density.108-110 However, the use of lithium metal batteries (LMB) was prevented due to serious safety concerns related to volume expansion from non-uniform deposition, uncontrollable dendrite growth and crack-induced repeated SEI formation. 111-114 The above causes cause electrolyte consumption, low Coulombic efficiency, resulting in capacity degradation and more serious internal short circuits and explosion. 115, 116 Regulation of Li plating and suppression of Li dendrites should be realized to solve the problems. The density of the electrodes inevitably shows low value, which leads to reduced volumetric capacity. This will contribute to the polarization of the electrode and hinder the uniform electrode response.

Extreme volume changes also accompany Li metal electrodes during charge and discharge, leading to unstable SEI formation.123-127 The above fetal issues are related to safety concerns. For these reasons, tremendous studies have been attempted to advance the Li metal electrodes in terms of the stability. Several effective strategies have recently been proposed over Li metal anodes via improved experimental approaches.

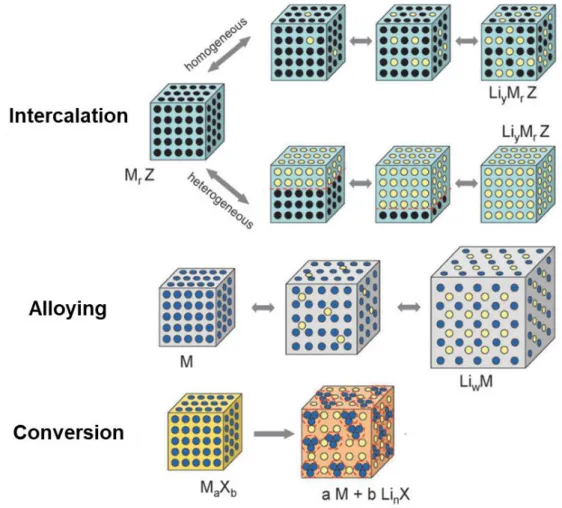

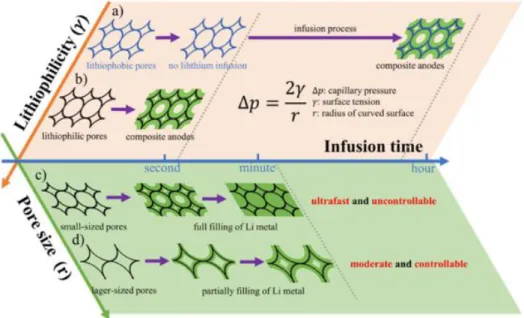

Typical strategy including Li storage materials can reversibly store the plated Li within the sufficient void space (Figure 3-4).128 Lithiophilic characteristic materials applied electrodes are widely researched with the effective Li deposition at the lithiophilic site with low polarization (Figure however, despite these fervent studies to overcome the limit, Li metal anodes are still insufficient for practical battery application. Herein, this study proposes a strategy of Li storage materials that meet the commercialization conditions. This carbon material has a hyperporous structure , and as a result, the density of the material is extremely low and exhibits high porosity characteristics.

Because these pores exist in an interconnected structure, they have an advantage in the diffusion of Li through the electrolyte. Lithophilic Si was added to the conductive carbon framework to increase the ease of Li deposition due to its lithiophilicity. The volume expansion of the electrode at the lithiated state of 3 mAh cm-2 was only 30% from 27 μm to 35 μm due to the corresponding pore volume.

Key challenges and key parameters in next-generation metal batteries; sulfur cathode, oxygen cathode and solid state battery. Design scheme of Li metal nanocapsules for selective Li deposition by focusing on the lithiophilic agent. Molecular dynamics calculation results and Li-ion coating and stripping behaviors on lithiated Si surface.

Experimental detail

Results and discussion

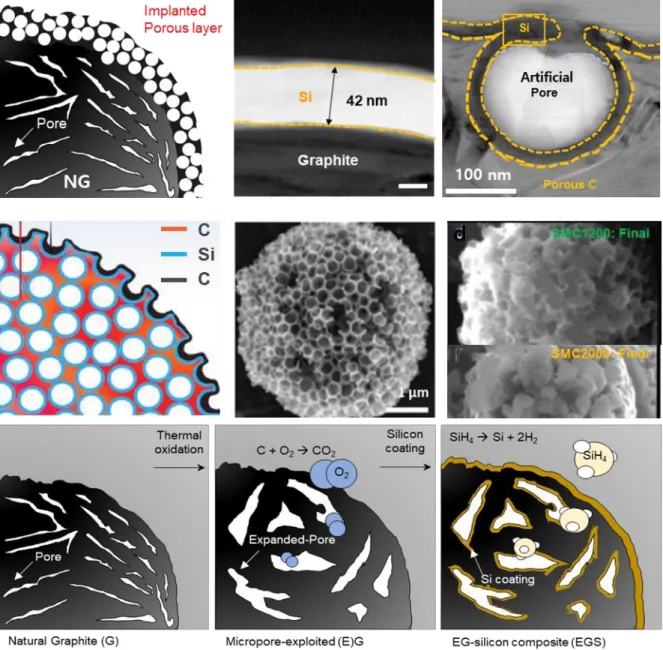

Sequential schematic illustration during PC-S operation (coating and stripping) with structural features of the formed material. On the surface of the inner pore, the thickness of Si was confirmed to be about 3.2 nm, and it was confirmed that it was formed very uniformly on the PC surface. The distribution of the blue-tuned Si component showed a clear band shape on the pore surface, which could prove a rationally deposited Si layer on the PC surface.

After the fabrication of PC-S, we performed the pore characterization analysis at the electrode level. As the volume of the Si layer increases during the lithiation process, the remaining space is further reduced. Cross-sectional STEM images of (a) low magnification, (b) high magnification with structural components, and (c) uniform PC-deposited Si layer on the inner surface of the pores.

For this electrode, when charged at 3 mAh cm-2, the electrode thickness increased to 64 μm (Figure 3-17b). A new material 2 μm thick is deposited on the surface of each particle and the interior of the particle is generally empty. Most of the Li was not deposited on the inner pore surface, while a significant portion of Li was deposited on the outside of the PC particles.

The cross-section of the lithiated electrode with the same areal capacity (3 mAh cm-2) is shown in Figure 3-19b. In addition, the results for 500 PC without Si deposition were also presented to compare the effect of the Si layer (Figure 3-20). Nevertheless, the excess Li was deposited on the surface of the electrode, staining the Li dendrite.

In contrast, Li dendrite was not found on the electrode surface to which 500 PC-S particles were applied. Because Li deposition is preferred on the copper current collector surface due to its higher lithophilicity. The results of the uniform lithophilic layer with a thickness of several nanometers have not been reported.

Conclusion

Green, scalable and controllable fabrication of nanoporous silicon from commercial alloy precursors for high-energy lithium-ion batteries. An all-integrated anode via interconnected chemical bonding between double-shell yolk-structured silicon and binder for lithium-ion batteries. A Comparative Study of Commercial Lithium Ion Battery Cycle Life in Electric Vehicle: Capacity Loss Estimation.

Coral-like silicon-based network anodes for ultrafast charging for high energy and power density lithium-ion batteries. 30 Subramanian Natarajan and Vanchiappan Aravindan, Burgeoning Prospects of Pent Lithium-Ion Batteries in Multifarious Applications, Adv. Investigating critical factors affecting stress distribution in silicon-based 1D nanostructures for lithium-ion battery anodes.

Confronting Issues in the Practical Implementation of Si Anode in High-Energy Lithium-Ion Batteries. Mesoporous silicon sponge as anti-pulverization structure for high-performance lithium-ion battery anodes. Scalable production of Si nanoparticles directly from low-grade sources for lithium-ion battery anode.

Rational design of void-involved Si@TiO2 nanospheres as high-performance anode material for lithium-ion batteries. Face-to-face contact and Open-Void Coinvolved Si/C Nanohybrids Lithium-Ion battery anodes with extremely long life. Surface Coating Limitation Induced Anisotropic Swelling of Silicon in Si-Void@SiO x Nanowire Anode for Lithium-Ion Batteries.

Micro-sized Si-C composite with interconnected nanoscale building blocks as high-performance anodes for practical use in lithium-ion batteries. Dual conductive network-activated graphene/Si-C composite anode with high areal capacity for lithium-ion batteries. Surface coating limitation induced self-discharge of silicon nanoparticles as anodes for lithium ion batteries.