In this study, the degradation and mechanical properties of the biowaste composites will be investigated. The increase in weight percent of WR powder from 10% to 20% used correlates with a more exponential increase in the amount of moisture absorbed over a 24 hour period. The composite immersed in seawater absorbs more moisture than the same composite immersed in tap water up to the 48 hour mark.

In addition, the author would like to sincerely thank his supervisor Dr. Norlin Nosby for all her patience, guidance and help throughout the completion of this final annual project over the past 8 months. The author would also like to thank his mother, Yasothi K. R. Gopal, for all the moral support and help she provided during the completion of the Final Year Project (FYP). Finally, the author would also like to thank the laboratory assistants and friends who helped to complete this project.

In the present age, the impact of our human activities on the earth has never been more widespread. Agamuthu, Malaysia's landfills are almost full, which in turn causes many illegal landfills to develop, which are often unsanitary and cause more damage due to improper handling of the waste[4]. 2 | P a g e Therefore, it is crucial that we as inhabitants of the planet take big steps to reduce our waste production footprint on the earth.

This waste crisis has prompted scientists to pay attention to polymer composites from bio-waste. By using otherwise discarded waste, scientists have not only been able to combat existing waste problems, but have been able to produce materials that far exceed the capabilities of existing materials.

Problem Statement

Methods such as the 3Rs (Reduce, Reuse, Recycle) and the production of biodegradable materials were proposed and implemented. Governments around the world have carried out various activities to control the amount of waste produced by their population. Efforts such as providing trash cans throughout cities and incentives for people who recycle are very common in this day and age.

Scope of Study

LITERATURE REVIEW

Overview

5 | Page This means that the oxygen content of the water will drop to dangerously low levels and if this toxic water reaches the lakes, it can cause the death of all river life. In terms of air pollution, rotting waste in landfills produces a gas called landfill gas (LFG). Methane is a potent greenhouse gas that is 28 to 36 times more effective than CO2 in trapping heat in the atmosphere over a 100-year period [16].

A natural source and rich in non-essential amino acid citrulline, WR (a common agricultural by-product) contains abundant carboxylic acid and amino groups [18]. The characteristic of WR is studies that have shown that WR consists of pectin, cellulose, proteins and carotenoids [19]. WR is used as biowaste material in this study due to its wide consumption.

There are many different types of plastic, the most prominent being acrylic or polymethyl methacrylate (PMMA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PETE or PET), polyvinyl chloride (PVC ) and Acrylonitrile-Butadiene-Styrene (ABS) [22]. Yarns made from PP are often used in the manufacture of clothing, a moisture barrier used for packaging items, and as plastic for Tupperware and such. One of the reasons PP is widely used is that it is readily available and relatively inexpensive when compared to other similar plastics.

PP is also known as a very tough material, as it has a high ability to plastically deform without breaking. PP is also commonly used in electrical components due to its high resistance to electricity. PP has a melting point of 160 to 166 °C, due to this high temperature it can be used for various applications in contact with heat.

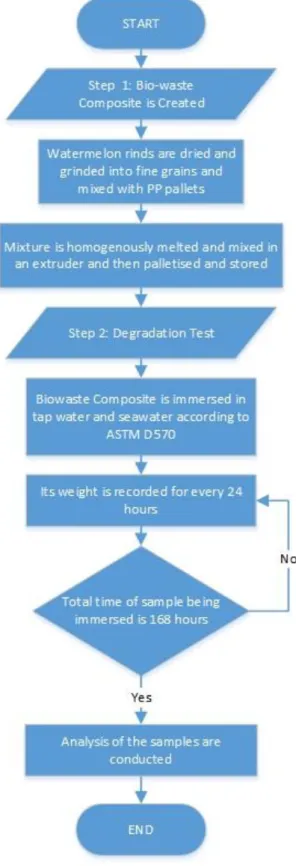

To produce the bio-waste composite, the WR must first be dried to remove all moisture. The moisture absorbing properties of the sample after the immersion at specified time will be analyzed and discussed [25]. The bio-waste composite will also be subjected to degradation test to show the degradation properties of the composite.

RESEARCH METHODOLOGY

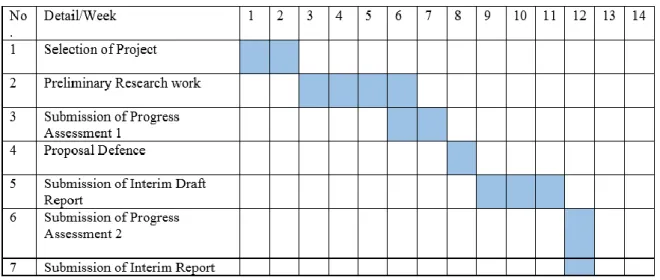

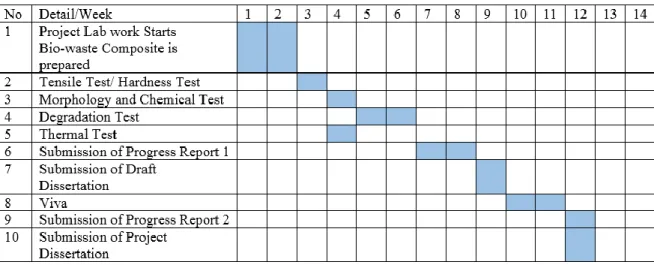

Gantt chart

- Properties of PP

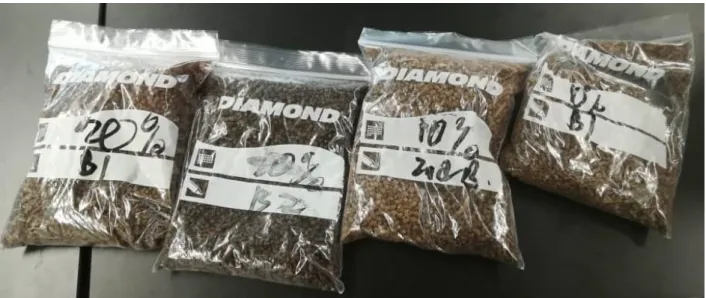

- Preparation of Watermelon Rind (WR)/PP composite

This material is actually composed of WR biowaste and plastic. The percentage of WR used for WR and PP was calculated using Equation 3.1. 9 | P a g e After measuring and mixing the correct proportion of WR and PP to be used, the mixture is extruded using a Leistritz extruder as shown in Figure 3.1.

Testing of the Bio-waste composite .1 Degradation test

The weight average of the 20WR/80PP composites is calculated using Eq.3.2, where W1, W2 and W3 are the weight of each of the sample and W is the average weight of each of the sample. Then the percentage of moisture absorbed is calculated using Eq.3.3, where W* is the average weight of the sample on a particular day and W is the original weight of the sample.

RESULTS AND DISCUSSION

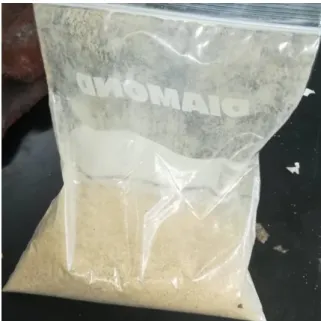

Preparation of Watermelon Rind (WR)

13 | P a g e The fruits were then dried for 18 hours in a drying oven below 60˚c to remove all moisture inside the WRs. After the drying process was completed, the watermelon rind was ground with a mortar mill and sieved into fine particles.

Degradation test

- Diffusion coefficient (D)

After that, the bonded squares with different concentrations of WRs are immersed in two solutions, namely the sea water solution and the tap water. The weight values of the three 10WR/90PP samples immersed in tap and sea water are averaged for each time interval as shown in Table 4.2. The percentage of absorbed moisture increases faster with the 20WR/80PP than with the 10WR/90PP in both tap water and seawater.

For example, after 24 hours, the percentage of moisture absorbed was higher in the 20WR/80PP composite, both seawater and tap water. 20WR/80PP absorbed 1.7% more moisture in tap water and 3.3% more moisture in seawater compared to 10WR/90PP composite. The rate of moisture absorbed occurs faster in seawater as opposed to tap water for both composites up to 48 hours.

For example, after 48 hours, the amount of moisture absorbed by the 10WR/90PP immersed in seawater is 5% higher than the same composite immersed in tap water. The 20WR/80PP composite immersed in seawater is 1.7% higher than the same composite immersed in tap water after 48 hours. 19 | Page The highest final average moisture absorption was recorded in the 10WR/90PP immersed in the tap water, followed by the 20WR/80PP immersed in the seawater, and finally the 10WR/90PP immersed in the seawater and the 20WR/80PP immersed in the tap water determined was at 48.35%.

Based on the values obtained from Table 4.4, 20WR/80PP immersed in seawater recorded the highest value of diffusion coefficient, followed by 20WR/80PP immersed in tap water, 10WR/90PP immersed in seawater, and finally 10WR/ 90PP immersed in tap water. Therefore, water diffusion is most favorable in seawater compared to tap water, while it is also greater at 20WR/80PP compared to 10WR/90PP. In the initial phase of immersion, the Na+ and Cl- ions present in seawater accelerate the absorption of water through cracks and voids.

Therefore, the diffusion coefficient of samples immersed in seawater is higher than that of distilled water [31]. This is highlighted in Figure 4.10 above, where the final percentage of moisture is absorbed by both the 10WR/90PP and 10WR/90PP. 20 | Page 20WR/80PP composites with a minimum of 48.35% also significantly eclipse the moisture absorbed by the virgin PP material, which recorded a maximum percentage of 4% after 168 hours.

Therefore, it shows that the higher the concentration of WR in the composite, the higher the moisture absorbency of the material. Finally, it causes the diffusion coefficient in 20WR/80PP to be higher than in 10WR/90PP in seawater and tap water.

CONCLUSION AND RECOMMENDATION

Conclusion

Recommendation

12] Greenpeace International, “New research uncovers a crisis in the global trade of recyclable plastics,” Greenpeace International, Apr, 2019. Available: https://www.bloomberg.com/news/articles trash-in-philippines-to - being-returned-to-Canada-Hongkong-Korea. 16] United States Environmental Protection Agency, "Basic Information on Landfill Gas." United States Environmental Protection Agency, April, 2018.

Hongyu, "China Leads World in Watermelon Production and Consumption - People's Daily Online," People's Daily Online, para. Li et al., "Biochar derived from watermelon rinds as a renewable adsorbent for efficient removal of thallium(I) from wastewater," Process Safety and Environmental Protection, vol. Peijs, "Water absorption in all polypropylene composites and its effect on mechanical properties", Composites, Part B: Engineering, vol.

Raji, "Evaluation of some empirical models for predicting water uptake in seeds of African breadfruit (Treculia Africana), International Journal of Food Properties, vol.