v ABSTRACT

vi ABSTRAK

vii TABLE OF CONTENTS

CHAPTER INDEX PAGE

DECLARATION ii

DEDICATION iii

ACKNOWLEDGEMENT iv

ABSTRACT v

ABSTRAK vi

TABLE OF CONTENT vii

LIST OF TABLE xi

LIST OF FIGURE xiii

APPENDIX LIST xv

1 INTRODUCTION 1

1.1 BACKGROUND 1

1.2 OBJECTIVE 3

1.3 SCOPE 3

viii

1.5 PLANNING AND EXECUTION 5

2 LITERATURE REVIEW 7

2.1 COMPOSITE 7

2.2 POLYMER MATRIX COMPOSITES 12

2.3 BIOCOMPOSITES 15

2.3.1 Matrix Polymer Material 16

2.3.2 Natural Fibre Reinforcement 18

2.4 PROPERTIES OF BIOCOMPOSITES 22

2.4.1 Mechanical Properties 22

2.4.2 Thermal Properties 23

2.5 PARAMETER EFFECTING PROPERTIES

OF BIOCOMPOSITES 24

2.5.1 Fibre Geometry and Architecture 24

2.6 CONCLUSION 25

3 METHODOLOGY 27

3.1 INTRODUCTION 27

3.2 SAMPLE PREPARATION 30

3.2.1 Raw Materials 26

3.2.2 Chemicals 33

3.3 FABRICATION PROCESS 34

ix Fibre

3.3.2 Composite Preparation 35

3.3.3 Testing Sample Preparation 37

3.4 MECHANICAL TESTING 38

3.4.1 Testing Method 38

3.4.2 Tensile Test 38

3.4.3 Impact Test 41

3.4.4 Flexural Testing 42

3.5 THERMAL ANALYSIS DSC 44

3.7 SURFACE ANALYSIS 45

(MORPHOLOGY STUDY)

4 RESULT AND DISCUSSION 47

4.1 INTRODUCTION 47

4.2 TENSILE TESTING 47

4.2.1 Stress-Strain Curve 48

4.2.2 Tensile Test Result 50

4.2.3 SEM Micrograph for Tensile Test 54

4.3 FLEXURAL TESTING 55

4.4 RESULT IMPACT TEST 60

4.4.1 SEM Micrograph for Impact Test 66

x

5.1 CONCLUSION 68

5.2 RECOMMENDATION 69

REFERENCES 70

xi LIST OF TABLES

NO TITLE PAGE

1.1 Planning and Execution 5

2.1 Advantages and disadvantages of commercial 9

Composites [8]

2.2 Summary of the mechanical properties of hemp fibre 14

Resin composite [15]

3.1 Technical data sheet 6100D fibre melt spinning 31

3.2 Properties of Pineapple leaf fibre 32

4.1 Tensile test result for plain PLA 51

4.2 Tensile test result for PLA+PLAF 51

4.3 Summary of tensile strength 52

4.4 Flexural test result for plain PLA 55

4.5 Flexural test result for plain PLA+PALF 56

4.6 The average flexural testing for experimental and 56

xii

4.7 Summary of flexural result 57

4.8 Plain PLA (0% fibre 100% matrix) 59

4.9 Composite (30% fibre 79% matrix) 60

4.10 The average of experimental and theoretical for impact 61

Properties

xiii LIST OF FIGURE

NO TITLE PAGE

2.1 Fibre glass [9] 10

2.2 Classification of composites [12] 11

2.3 Classification of biopolymer according to origin and 16

Production [4]

2.4 Properties of five commercial materials [21] 17

2.5 Categories of natural fibre [4] 18

2.6 Various type of natural fibre [5] 19

3.1 Flowchart for final year project 1 28

3.2 Overview of research methodology 29

3.3 Polylactide (PLA) [7] 31

3.4 Pineapple leaf fibre [21] 33

3.5 Flow of the fabrication process 34

3.6 Mould 36

3.7 Graph of temperature versus time for the fabrication 36

Process

3.8 PALF/PLA composite plate after compressed via hot 37

Press machine

3.9 Tensile test specimen 38

3.10 The dimension of the specimens for tensile test 40

3.11 Apparatus for impact testing of materials [36] 42

3.12 The dimension of the specimen for impact test 42

xiv

3.14 Graph for sample DSC of PLA 44

3.15 Scanning Electron Microscope (SEM) [21] 46

4.1 Graph stress-strain for unreinforced PLA 49

4.2 Graph stress-strain for PALF reinforced PLA 49

4.3 Graph of plain PLA vs PLA+PALF 52

4.4 Graph of Experimental vs References for Fibre Size of 53 PLA+PALF

4.5 Graph of Experimental vs References for Fibre Type 53

Of PLA+PALF

4.6 Sample plain PLA from tensile test was use to test for 54

SEM

4.7 Sample plain PLA+PALF from tensile test was use to 55

Test for SEM

4.8 Graph of Plain PLA vs PLA+PALF for Flexural 58

Strength

4.9 Graph of Plain PLA vs PLA+PALF for Flexural 59

Modulus

4.10 Graph of Experimental vs References for the size of fibre 59

4.11 Graph of Experimental vs References for the type of fibre 60

4.12 Graph of Experimental vs References for Fibre Size. 65

4.13 Graph of Experimental vs References for Fibre Type. 65

4.14 Sample plain PLA from the impact test was use to test 66

for SEM.

4.15 Sample plain PLA + PLAF from the impact test was 63

1 CHAPTER 1

INTRODUCTION

1.1 BACKGROUND

2 The use of natural fibers as a reinforcement in fiber-reinforced plastic (FRP) is a good choice because of their advantages. The natural fibre may be obtained either from plants or animals [4]. Plants based fibre consists of kenaf, hemp, flax, bamboo, pineapple and sisal. While for animal, the fibre obtained from silk and wool. Natural fibers have many application in the automotive industry, aerospace, marine and infrastructure primarily in non structure parts. The advantages of using the natural fiber than the other reinforcing materials are their low cost, low density, high mechanical strength, high toughness, size ability, flame retardancy and corrosion resistance, non abrasive, non-toxic, acceptable specific strength properties enhanced energy recovery, and biodegradability [2].

There are many different polymers of renewable materials such as polylactic acid polymers (PLA), cellulose esters, poly hydroxyl butyrates, starch and lignin based plastic. Among these polymers, polylactide has been introduced commercially for product where biodegradability is wanted. Polylactide acid (PLA) is a versatile polymer and it‟s made from renewable agriculture raw materials where is then fermented to lactic acid. Polylactide polymers have good stiffness and brittle materials and it is necessary to used plasticizers to improve the elongation and impact properties. The polylactide (PLA) is full biodegradable [5].

3 1.2 OBJECTIVE

The objectives of this project are listed below:

i. To produce biocomposites with good mechanical and physical properties.

ii. To study the effect of chemical treatment on the bonding mechanism present

in the polymer composites.

iii. To access the tensile and impact properties of the polymer composites.

1.3 SCOPE

The scopes of this project are listed as below:

i. Selection of fibre material and chemical treatment process in producing

biocomposites.

ii. To fabricate the biocomposites test panel.

iii. To conduct a series of mechanical testing to identify the mechanical properties of

the biocomposite.

iv. To conduct a physical testing.

4 1.4 PROBLEM STATEMENTS

With growing production and mass volume use, the disposal of non-biodegradable composites after their intended useful life has become an important and expensive issue [4]. Besides that, composites cannot be easily recycled and reused because the combine with two dissimilar materials and the released gases might also bring new pollution [4]. The advantages of using the fossil resources not only difficult to recycling, it also induces the problem of waste plastic and petroleum products and can cause an increased in carbon dioxide linking to global warming because of the incineration. This phenomenon also leads to greenhouse effect and world climatic changes [2].

Fibre provides strength and stiffness and act as reinforcement in fibre-reinforced composite materials [7]. Natural fibre reinforce composites are finding increasing use in spectrum of applications. Natural fibre can be obtained from plant and animal. Natural fibre that consist of plant have gained commercial success in automotive applications , while natural fibre from animal are also used as reinforcing agents [4]. To date, limited studies have focused on understanding the effect of fibre type, size and architecture on the mechanical properties of polymer biocomposites. One of the important aspects to enhance the mechanical properties of these materials is by improving the adhesion between the matrix and the fibre, at the interface.

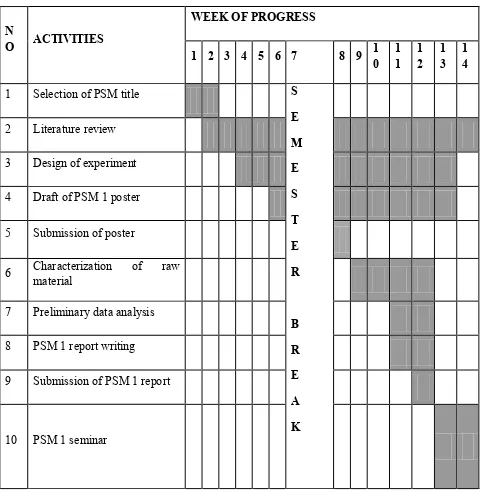

5 1.5 PLANNING AND EXECUTION

Table 1.1: Gantt chart for PSM 1

N

O ACTIVITIES

WEEK OF PROGRESS

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1 Selection of PSM title S

E M E S T E R B R E A K

2 Literature review

3 Design of experiment

4 Draft of PSM 1 poster

5 Submission of poster

6 Characterization material of raw

7 Preliminary data analysis

8 PSM 1 report writing

9 Submission of PSM 1 report

7 CHAPTER 2

LITERATURE REVIEW

2.1 COMPOSITES

8 phosphate and a soft and flexible material called collagen which is a protein [9]. Collagen also has in hair and finger nails. When it combines with hydroxyapatite it can give bone the properties that needed to support the body [9].

Natural composites exist in both animal and plants. Wood for instance, which is made from long cellulose fibre. Cellulose is also found in cotton, but when it does not bind it together with lignin, it become much weaker. When the two weak substances lignin and cellulose combine together, it will become a much stronger one [9]. For many thousands of years, people have been making a composite. Exodus speaks of using straw to reinforce mud in brick making, without which the bricks would have no strength [10]. Mud can be dried out to make a brick shape to give a building material. It has a good compressive strength but it will break easily if apply a bending force because it has a poor tensile strength. For the ancient society to imitating the nature, they will use this approach as well by mixing mud ad straw together it is possible to make bricks that are resistant to both squeezing and tearing and make excellent building blocks [9, 10].

9 Table 2.1: Advantages and Disadvantages of Commercial Composite [8].

ADVANTAGES DISADVANTAGES

Lighter weight. High raw material cost and usually

high fabrication and assembly cost. The ability to tailor the layup for

optimum strength and stiffness.

Adverse effects of both temperature and moisture.

Improve fatigue life. Poor strength in the out of plane

direction where the matrix carries the primary load.

Corrosion resistance. Susceptibility to impact damage

and delaminating or ply

separations.

Good design practice. Greater difficulty in repairing them

compared to metallic structure. Reduced assembly costs due to

fewer details part and fasteners.

Matrix degrades.

The biggest benefits of modern composites materials are they are light and strong. A new material can be made that exactly from the requirements of a particular application, when choosing the right and appropriate combination of matrix and reinforcement material. Besides that, composites also can provide the flexibility design because many of them can be molded into complex shapes. Although the resulting product is more sufficient, the raw materials are often expensive.

![Table 2.1: Advantages and Disadvantages of Commercial Composite [8].](https://thumb-ap.123doks.com/thumbv2/123dok/504592.56886/24.612.107.551.98.419/table-advantages-disadvantages-commercial-composite.webp)