UNIVERSITI TEKNIKAL MALAYSIA MELAKA

EVALUATING RISK FACTORS IN MANUAL MATERIAL

HANDLING TASKS (LIFTING AND LOWERING)

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Manufacturing Management) (Hons.)

by

BAZLI FAIQ BIN ZAINI B051110335

900613-10-5301

DECLARATION

I hereby, declared this report entitled “Evaluating Risk Factors in Manual Material Handling Tasks (Lifting and Lowering)” is the results of my own research except as

cited in the references

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering (Manufacturing Management) with Honours. The member of the supervisory committee is as follow

Pengendalian bahan secara manual seperti mengangkat, menurunkan, menolak, menarik atau memegang memerlukan kekuatan manusia untuk mengendalikannya. Otot atau kekuatan manusia ialah struktur asas dalam pengendalian bahan secara manual. Pengendalian yang salah boleh menyebabkan berlakunya ketidakselesaan otot pada pekerja. Objektif utama kajian ini ialah untuk mendapatkan maklumat tentang faktor risiko yang menyebabkan lesu otot; untuk menganalisis aktiviti otot semasa pengendalian bahan secara manual menggunakan kaedah Rekabentuk Eksperimen dan membina hubungan model antara aktiviti otot dengan peramal iaitu postur badan, jisim beban dan masa pendedahan. Soal selidik digunakan untuk mengumpul maklumat tentang penilaian faktor risiko yang menyumbang kepada ketidakselesaan otot. Data untuk aktiviti otot di RT bisep BR, LT bisep BR, LT Upper Trap, RT Lumbar ES dan LT Lumbar ES dianalisis dengan menggunakan peralatan surface Electromyography (sEMG) semasa subjek melaksanakan pengendalian secara manual dan akhir sekali hubungan antara aktiviti otot dan parameter (postur, jisim beban, masa pendedahan) akan dimodelkan menggunakan analisis varians (ANOVA). Keputusannya, jisim beban menjadi faktor penting yang menyebabkan terjejasnya aktiviti otot semasa eksperimen dan tiada interaksi yang terlibat. Model hubungan pula membuktikan hanya tiga otot (RT Biceps BR, LT Biceps BR dan LT Upper Trap) yang terlibat dalam pembentukan model linear untuk menunjukkan nilai pekali daripada parameter yang boleh menjejaskan aktiviti otot. Kesimpulannya, jisim beban menjadi faktor utama yang menjejaskan aktiviti otot semasa pengendalian manual dalam eksperimen yang boleh menyebabkan lesu otot dan hubungan model membuktikan terdapat tiga otot yang terlibat dalam pembentukkan model iaitu otot RT Biceps BR, LT Biceps BR dan LT Upper Trap.

Manual handling activities such as lifting, lowering, pushing, pulling or holding a load are commonly examples of tasks that requiring human strength. Muscle or human strength is a basis for manual material handling (MMH) job and workplace design. Improper ways of manual handling will cause a muscle fatigue and muscle discomfort at the workers. Manual handling activities at work can result in a wide range of musculoskeletal disorders (MSDs). The main objectives of this study were to evaluate risk factors contributing to muscle fatigue; to analyze muscle activity while performing MMH tasks using Design of Experiments methodology and to model relationship between muscle activity with predictor namely body posture, load mass and exposure time. To assess the risk factor contribute to muscle discomfort, related information were gathered from the questionnaire. Data for muscle activity at RT Biceps BR, LT Biceps BR, LT Upper Trap, RT Lumbar ES and LT Lumbar ES were analyzed using surface electromyography (sEMG) while subject performing manual lifting/lowering task and lastly the relationship between muscle activity and parameter (posture, load mass, exposure time) were modelled using analysis of variance (ANOVA). As a results, load mass become an important factor that affected all muscle activity during the experiments and no interaction involved since all the combination were not significant. From the model relationship, only three muscles (RT Biceps BR, LT Biceps BR and LT Upper Trap) were involved in performing linear model as to show the coefficient value from the parameter that can affected muscle activity. As a conclusion, load mass become a main factor that can contribute to muscle fatigue and model relationship proved that there were three muscles involved were formed at RT Biceps BR, LT Biceps BR and LT Upper Trap muscle.

Dedicated to my beloved parents, Mr. Zaini Bin Ismail and Mrs. Nor Iazan Binti Mohd Ali. Also, to all panels, my family and friends for all the

I am highly indebted to my great supervisor MR. NOR AKRAMIN BIN MOHAMAD for his guidance and constant supervision as well as for providing necessary information regarding the study and also for his support in completing the project.

I would also like to express my gratitude towards my parents and friends for their kind co-operation and encouragement which help me in completion of this project.

Abstrak i

List Abbreviations, Symbols and Nomenclature xiv

CHAPTER 1: INTRODUCTION 1-7

2.2 Manual Material Handling 9

2.3 Principle of Manual Material Handling 10

2.4 Risk Factor 14

2.4.1 Types of Ergonomic Risk Factor 15 2.4.2 Risk Effect in Manual Material Handling 17 2.5 Summary of Previous Research Work Related To Material

Handling Technique 19

CHAPTER 3: METHODOLOGY 30-48

3.1 Introduction 30

3.2 Planning and Activities 30

3.3 Evaluate the Information on Risk Factor Contributing To Muscle Fatigue and Muscle Discomfort Associated with

Manual Material Handling 33

3.4 Analysis of Muscle Activity While They Are Performing Manual Material Handling Task 35 3.4.1 Subjects for Experiment (sEMG Measurement) 35 3.4.2 Design of Experiment for the Surface Electromyography Measurement 36 3.4.3 Surface Electromyography Signalling and Processing 37 3.4.4 Apparatus 38 3.4.5 Working Procedure 39 3.5 To Model Relationship between Muscle Activity and Load Mass, Task Frequency, Exposure Time and Rest time 41 3.6 Data Collection 43

4.2 Evaluation of Risk Factor Contributing To Muscle Fatigue and

Muscle Discomfort Associated With Manual Material Handling Tasks. 49 4.2.1 Result of Evaluating Risk Factor Based On Manual

Material Handling 49

4.2.2 Result of Evaluating Risk Factor Based On Muscle Discomfort 54 4.2.2.1 Result of Evaluating Risk Assessment Based On

4.2.2.2 Result of Evaluating Risk Assessment Based On

Muscle Discomfort (Standard Deviation) 56 4.2.3 Summary on Evaluating Risk Factors 57 4.3 Interpretation of Muscle Activity Data While Performing Manual

Material Handling Task. 58

4.3.1 First Muscle Activity (RT BICEPS BR) 60 4.3.2 Second Muscle Activity (LT BICEPS BR) 62 4.3.3 Third Muscle Activity (LT UPPER TRAP) 65 4.3.4 Fourth Muscle Activity (RT LUMBAR ES) 67 4.3.5 Fifth Muscle Activity (LT LUMBAR ES) 70 4.3.6 Summary for All Muscle Activity 73 4.4 Model Relationship between Muscle Activities with Body Posture,

Load Mass and Exposure Time using Analysis Of Variance (ANOVA) 74 4.4.1 Hypothesis Testing for RT Biceps BR Muscle 76

4.4.1.1 ANOVA for RT Biceps BR 79

4.4.1.2 Fitted Model for RT Biceps BR 80 4.4.2 Hypothesis Testing for LT Biceps BR Muscle 81

4.4.2.1 ANOVA for LT Biceps BR 84

4.4.2.2 Fitted Model for LT Biceps BR 85 4.4.3 Hypothesis Testing for LT Upper Trap Muscle 86 4.4.3.1 ANOVA for LT Upper Trap 89 4.4.3.2 Fitted Model for LT Upper Trap 90 4.4.4 Hypothesis Testing for RT Lumbar ES Muscle 91

4.4.4.1 ANOVA for RT Lumbar ES 94

4.4.4.2 Fitted Model for RT Lumbar ES 95 4.4.5 Hypothesis Testing for LT Lumbar ES Muscle 96

4.4.5.1 ANOVA for LT Lumbar ES 99

4.4.5.2 Fitted Model for LT Lumbar ES 100 4.4.6 Summary of Model Relationship between Muscle Activities

CHAPTER 5: CONCLUSIONS AND RECOMMENDATIONS 103-106

5.1 Introduction 103

5.2 Research Findings 103

5.2.1 Evaluating Risk Factors 104

5.2.2 Analyzing Muscle Activities Using Design of

Experiments Methodology 104

5.2.3 Model Relationship between Muscle Activities with

Parameter (Body Posture, Load Mass and Exposure Time) 105

5.3 Limitation of Study 105

5.4 Recommendation for Future Study 106

REFERENCES 107

1.1 Organization of Report 6

3.2 Anthropometric Measurement for Participants 35

3.3 The Levels of the Factor 36

3.4 Muscle Activity Experiments 37

3.5 Analysis Procedure for a 2k Design 41 3.6 General ANOVA for Two-Factorial with n Replication

Per Cell 44

3.7 Expected Outcome for This Research 47

4.1 Risk Assessment by the Workers 54 4.2 Risk Factor that Causes Muscle Discomfort 55 4.3 Risk Assessment That Exceed Standard Deviation More

4.7 One-way ANOVA and Two Sample T-test for Exposure

Time 78

4.8 ANOVA for RT Biceps BR Muscle 79 4.9 Estimated Effects and the Coefficient for Muscle Activity

RT Biceps BR 80 4.14 Estimated Effects and the Coefficient for Muscle Activity

LT Biceps BR 85 4.19 Estimated Effects and the Coefficient for Muscle Activity

LT Upper Trap 90 4.24 Estimated Effects and the Coefficient for Muscle Activity,

RT Lumbar ES 95

4.25 One-way ANOVA and Two Sample T-Test for Body

Posture 96

4.27 One-way ANOVA and Two Sample T-test for Exposure

Time 98

4.28 ANOVA for LT Lumbar ES Muscle 99 4.29 Estimated Effects and the Coefficient for Muscle Activity,

LT Lumbar ES 100

4.30 Summary Table on The Hypothesis Testing, P-value

and Model Relationship 101

1.1 MSD Most Common Work-Related Problem 4

3.2 Electromyography Electrode Placements 38 3.3 Symmetric Lifting and Lowering 38 3.4 Asymmetric Lifting and Lowering 39 3.5 Flow Processes for Experimental Procedures 40

3.6 Minitab User Interface 42

3.7 Process Flow for Model Relationship between

Muscles Activities with Factors Involves 42

4.1 Common Posture for Load Lifting 50 4.2 Most Comfortable Posture for Load Lifting 50

ANOVA - Analysis of Variance

APDF - Amplitude Probability Distribution Function

BLS - Bureau of Labour Statistics

ILO - International Labour Organization

INC - Inclinometer

NIOSH - National Institute of Occupational Safety and Health

OSHA - Occupational Safety and Health Act

PLBDR - Probability of Low Back Disorder Risk

LIST OF ABBREVIATIONS, SYMBOLS AND

PSM 1 - Projek Sarjana Muda 1

PSM 2 - Projek Sarjana Muda 2

RA - Reverse Arrangement

RT - Right

RMS - Root Mean Square

SS - Sums of Square

SEMG - Surface Electromyography

TRAP - Trapezius

WBV - Whole Body Vibration

WHO - World Health Organization

1.1 Introduction

This research centers on problems related to issues on muscle activity while carrying a manual material handling task. Specifically, the purpose of this research is to identify the risk factor, and investigate the muscle activity that affected from the specific manual material handling tasks.

This chapter begins with a background study and then discusses and presents the problem statement, objectives and scope involves. Finally, the organization of the whole research is presented.

1.2 Background of Study

In contempt of the widely use of robots in industrial jobs such as assembling parts and Material Licensing Tracking System (MLTs), there are still several tasks in industry that require humans to perform it manually. These tasks consist of lifting, holding, carrying, or moving loads in the work area. They often cause musculoskeletal injuries to that worker (Jozef Zurada, 2012; Shengli Niu, 2010;). Although the majority of jobs becomes automated, human strength is still used in many industrial activities. Other researchers also agreed that manual material

handling (MMH) tasks such as lifting, lowering, pushing, pulling or carrying loads are common tasks that require human strength (Min K.Chung & San H. Kim, 1996).

There is a risk of injury if such tasks are not carried out properly and safely and researcher shows an important correlation between manual handling and musculoskeletal injury (Widanarko et al, 2011). Manual lifting exists as a significant problem even with more frequently developed industrial activities and technologies that lead to musculoskeletal injury (Kim et al. 2011). Over one third of reported injuries in the UK resulting in 3 days or more absence are cause by manual handling incidents at work (Health Safety Executive, 2010b).

In a bad scenario, the effect of musculoskeletal injuries may result in performance decrement for industrialized countries. World Health Organization came out with the result that musculoskeletal injuries or musculoskeletal disorder (MSDs) are the leading cause of workplace disability in developed countries (WHO, 2003). Representing one-third of work injuries, they have affected some criteria such as:

i. Significant economic and social consequences (Punnett and Wegman, 2004)

ii. High cost for company due to reduced of quality and productivity (Eklund, 1997)

iii. Overburden the health system (Badley et al., 1994)

1.3 Problem Statement

The Department of Occupational Safety and Health Malaysia stated that there are almost 700 occupational musculoskeletal diseases happen in 2014 and make the number increase from the previous year 2013 (SOCSO Annual Report, 2014). Besides that, in the same period there were a report stated that the fatal injuries occurred for every 3.2 cases out of every 100,000 full-time workers (Bureau of Labor Statistic, 2012). Ergonomics problems at the work area and bad organization of work are among of the reasons that contribute to risk factor as mentioned by occupational safety and health problem (Shengli Niu, 2010). Among situation that contribute to the raising magnitude of musculoskeletal disorders (MSDs) suffered by the workers are caused by postural stress from prolonged standing, sitting, and awkward posture. In addition, the psychosocial factors including psychological stress, job stress and job dissatisfaction are the factor that related to ergonomics problem. Most of the ergonomics problems are related to the risk factor affected to the workers (Frymoyer & Mooney, 1986).

Work related MSDs may occur even the workers are exposed to an occupational risk factor at the workplace on an occasional basis for only 25% or less as stated by previous exposure-response data. (Punnet, 2000). Risk factor can cause several visual effects such as eye strain, fatigue, MSDs such as low back pain, neck pain, shoulder pain, repetitive motion injuries and tensions (Punnett & Wegman, 2004). According to Bureau of Labor Statistic, there are 387, 820 MSD cases accounted for rate of 33% worker injury and illness in 2011. (OSHA 2012).

Previous researcher stated that the number of musculoskeletal accidents during lifting is up to 52%, pushing and pulling 13%, holding loads 10%, repetitive movement is about 13% and 12% is for others manual material handling activities. (Abdillah, 2013).

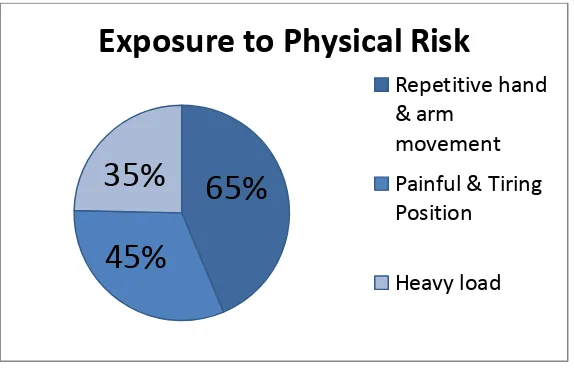

65% report a repetitive hand and arm movement as a problem, 45% of working in painful and tiring position and 35% are required to working with excessive heavy loads (Shengli Niu, 2010).

Figure 1.1: MSD Most Common Work-Related Problem

Figure 1.2: Exposure to Physical Risk

1.4 Project Objective

The specific objectives of this study are elaborated as follows:

1. To evaluate the information of risk factor contributing to muscle fatigue and muscle discomfort associated with manual material handling tasks. The physiological factors of workers such as working postures are determined and analyzed using ergonomics assessment tools to regulate the effect of identifying occupational risk factors on worker’s health. Examples of such activities include working posture, repetitive motion, forceful exertion, contact stress or vibration where the related risk factors are involved.

2. To analyze muscle activities of workers while they are performing manual material handling task by using Design of Experiments (DOE) methodology.

The purpose of this activity is to analyze and evaluate the muscle activity recorded using surface electromyography (sEMG) and muscle discomfort within specific time of manual material handling task.

3. To model relationship between muscle activities with posture, load mass and exposure time.

1.5 Scope and Limitation of Study

This section is intended to describe the scope and limitations of carried out study. This study will be focusing on the real situation such as human (subject), work load, manual handling tasks, exposure time and rest time. Risk factor that contributed to muscle fatigue and discomfort associated with manual material handling were observed and identified. Muscle activities that are related to the participants will be identified based on the parameter namely body posture, load mass and exposure time from the experiments.

These experiments were focused only on three samples from the same population due to the time constraint and limited electromyography equipment. The analysis of muscle activity will be conducted in real experiment situation. Data from muscle activity will be analyzes using computer software and ANOVA method were used to model the relationship between muscle activity and parameters involved.

1.6 Organization of Report