www.serd.ait.ac.th/reric

Effects the Strength of Electromagnetic Field and

Temperature on the Inherent Moisture of Brown Coal

in Electrothermal Dewatering Brown Coal (EDBC)

Process

Muhammad D. Bustan*1 and Triana Prihatin+

Abstract – The most utilization of coal low rank which is the reservoir is abundant is as mixture with other high qualified coal. Then, there is a consideration to use it as fuel at power plants to ensure the world’s energy security. But the inherent moisture contents inside the coal make it become less economical. It has encouraged experts to find the technology to eliminate the moisture contents. This work used a new technology termed as Electromagnetic Dewatering Brown Coal (EDBC). The objective of this work is to study the effects of the strength of electromagnetic field and the temperature for the enhancement of coal product qualities. The indication is there will be the reduction of the inherent moisture contents and the increase of the value heating. The operating conditions are varying the voltage of 0, 4, 8, and 12, and the temperature of 50 oC, 60 oC, and 70 oC. The results of this study show the increasing of heating value from 6,477 kcal/kg to 7,902 kcal/kg and the reduction of the inherent moisture content from 12.09 % (adb) to 2.64 % (adb).

Keywords – Electrothermal dewatering brown coal technology, inherent moisture content, electromagnetic field.

1. INTRODUCTION

Since era of industry revolution, the demand of energy has increased rapidly. Human depends on primary energy such as crude oil, coal, and natural gas. Among those fossil fuels, coal is the most abundant and affordable to cover world’s energy. Now, coal is the one important factor for energy security. The Energy Information Administration (EIA) estimated the reserves of recoverable coal at over 1083 billion short tons as of January 1, 2001 [1]. Furthermore, the International Energy Agency (IEA) [2] projects that energy demand will increase by almost 85% over the next 30 years. Currently, coal plays an important rule as energy resources worldwide that supplies almost 40% for world’s electricity. For centuries, coal not only generates electricity but also as fuel for steel, cement, and other industries. In the contrary, these conditions face the coal’s demand more fluctuate and unpredictable because its price depends on its supplies and crude oil’s prices. Besides that, the quality of coal also influences the coal prices. Most of coal is classified as low rank or lignite which contains water. The water content is unbeneficial because can reduce its heating value.

In spite of the high cost of transportation, the high water content in lignite will reduce the combustion

*

Department of Chemical Engineering, Graduate School, University of Sriwijaya, Padang Selasa Street No.524, Bukit Besar, Palembang, South Sumatera, 30139, Indonesia.

+

Department of Chemical Engineering, Graduate School, University of Sriwijaya, Padang Selasa Street No.524, Bukit Besar, Palembang, South Sumatera, 30139, Indonesia.

E-mail: [email protected]

1

Corresponding author;

Tel: + 62711352132 ext 112, Fax: + 62711320310 E-mail: [email protected]

efficiency such as at power plant. It is because some of heat which resulting from coal combustion is used to vaporizing the coal water contents, latent or sensible heat. As results, heat latent can not be utilized either for turbine movement or for heating process at high temperature. It means necessary to enhance the coal quality.

The purpose of coal quality enhancement is also to reduce the gas emission of CO

2 and CO from coal combustion. The higher the coal rank, the higher the efficiency combustion. Generally, steam power plant using high coal rank will produce less pollution. Other side, if a power plant uses low type, it will increase the pollution because of the uncompleted combustion and the release of pollutant such as sulphur and volatile matter.

Many countries have investigated the technology of coal enhancement to optimize it as energy resources and to raise its selling price. Besides solid phase, gasification and liquefaction technology have been developed. There is also Upgrading Brown Coal (UBC) technology which is proposed to reduce the water content approximately 90%, as in [3].

at certain temperature altering the formation of coal composition. The coal heating occurred at 200-350 oC in free of oxygen resulting in the composition and properties which are varied depend on the heating temperature. Hydrothermal dewatering process technology [5] was a drying process which is took place at 200-340 oC and above 70 atm using water as medium. Temperature must be appropriate enough to cut the functional groups of carboxyl and hydroxyl. In principle, the inherent water contents will be pushed out through coal drop and then collected with steam. The release of water contents is caused by the difference of coal expand thermal coefficient. Upgrading brown coal combined with dehydration technology [6] were developed based on porosity, adsorption, and reaction which involved coal chemical compounds.

In fact, all UBC’s technology mentioned above still can not lead the efficient technology because the processes is occurred at high temperature and pressure above 100 oC and 1 atm. Because of that the aim of this work is to develop the UBC’s technology at low temperature and pressure by applying an electromagnetic field and varying the process temperature. The enhancement of upgrading products can be identified from the reduction of inherent moisture contents and the increase of heating value.

2. THEORETICAL BACKGROUND

The parameter of coal quality describes physic and chemistry properties as main factor for coal treatment, such as water contents, volatile matter, ash, fixed carbon, heating value, and sulphur contents [7]. For UBC’s technology, the inherent moisture contents and heating value are the most dominant factor.

Water occurs in coals in three ways, as inherent moisture in the internal pores of the coal substance including water associated with the mineral impurities, as surface moisture wetting the external surfaces of the coal particles in which adsorption may play a small part, and as free water held by capillary porous in the interstices between the coal particles. Water contents consist of inherent moisture and free moisture. Water which is bounded physically at coal pores and has vapour pressure lower than normal termed as the inherent moisture. It is occurred at coalification process. The higher the inherent water contents, the lower the coal rank. On the other hand, free moisture is water which is absorbed at coal surface because of external factor. It is mixed inside of the coal capillary. Total moisture shows the large amount of water containing in the coal which is bounded either because of chemically or external influence. Total water contents are considered as impurities because not only causes handling difficulties, increases handling and transportation costs but also reduces its heating value.

The heating value of coal is the heat total resulting from the combustion of coal components which are easy be burned, such as carbon, hydrogen, and sulphur. It is related to the coal substances directly. The coal rank will increase as if coal heating value increases.

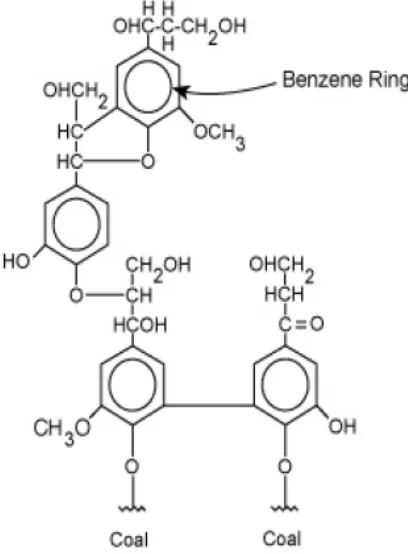

The lignite chemical structure is predicted by W.H Orem as Figure 1 [8]. Coal particles contain oxygen functional groups such as hydroxyl, carbonyl and

carboxyl, and mineral matter that contribute the surface hydrophilicity. More than 70% of the oxygen in the lignite was in hydroxyl and ether groups, and the others were ester and carbonyl groups. Those functional groups affect the heating value of lignite because its hydrophilicity can increase the inherent moisture of lignite.

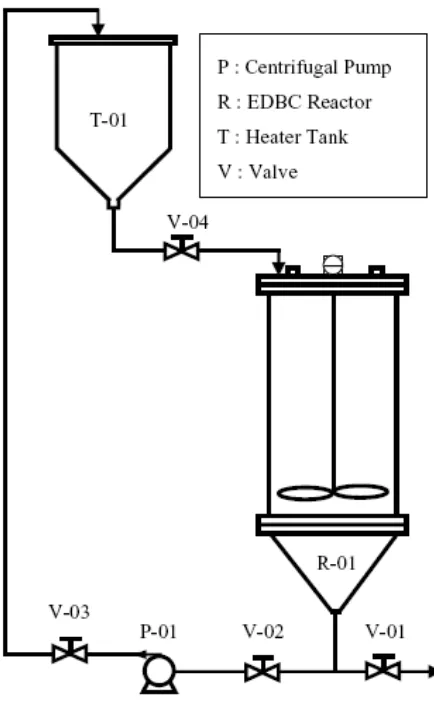

Water which is trapped in coal is bounded chemically with coal compound is showed in Figure 2 [9]. If the bond between coal compound, hydroxyl, and water are broken, the heating value of coal will enhance. It needs free ions to disturb the bonds by attracting hydroxyl group from coal compound. An effort to get free ions is by using electromagnetic. To substitute water that is trapped in coal compound, fuel is used to penetrate to the coal pores and the most potential is kerosene because its density is light enough.

Fig. 1. The Chemical Structure of Lignite

3. EXPERIMENTAL

The technology developed by this work was a modification of previous methods by adding electrolyses at main process. This technology, named as Electrothermal Dewatering Brown Coal process, also considered the energy savings, hence can minimize the energy needs to obtain the optimal process. Figure 3 described the simplified schematic of EDBC process.

was varied at 1:10, 1:20, and 1:40. Coal was pulverized in sizing 50 mesh and mixed with kerosene resulting in slurry in the mixing tank which was completed with the heater. Then, the mixture was flowed into reactor where the electrolyses equipment and the stirring systems were fixed inside it. The physical bond of water inside the pores coal will be unstable because of the electromagnetic field, hence the water inside of the coal pores will be removed and substituted by kerosene compounds. The circulation of mixture and electromagnetic were occurred in 15 minutes. Solvents and coal particles then were separated so the coal product of EDBC process will be obtained in wet condition. Next, the wet coal was dried in the oven and the dry coal was analyzed in laboratory while kerosene was recycled into reactor.

Fig. 2. Water Bonded in Coal Compounds

Fig. 3. The Experimental Set-up

4. RESULTS AND DISCUSSION

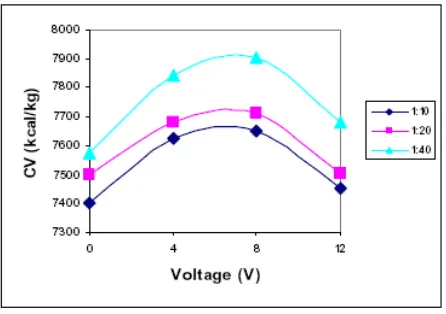

Figures 4 and 5 show there were similar phenomena for the process at the difference of coal-kerosene ratio. The decreasing of inherent moisture contents is maximum at 70 oC while the increasing of heating value is minimum at 50 oC for voltages 8 Volt and ratio of coal and kerosene 1:40, respectively. The graphic is in sinusoidal pattern as an electrical wave from electromagnetic sources. This phenomenon is caused by the voltages effects. The percentages of inherent moisture contents were different for each coal ratio because of the electrons supply from the electromagnetic process. The amount of electron that is supplied by electromagnetic is affected by the process temperature and kerosene.

REFERENCES

Fig. 5. Effects of process temperature to the increasing of heating value at 50 °C

[1] Energy Information Administration (EIA). 2003. International Energy Annual 2001. Washington DC: U.S. Department of Energy.

[2] World Coal Institute. 2006. Coal : Meeting Global Challenges. London : World Coal Institute.

[3] Deguchi, T., Shigehisa, T., and Shimasaki K. 1999. Study on Upgrading Brown Coal Process for Indonesian Low Rank Coal. In Proceedings of the tenth ICCS. Japan : Kobe Steel, Ltd.

[4] Sugita, S., Deguchi, T., Shigehisa, T., and Makino, E. 2004. Demonstration of UBC Process in Indonesia-Upgrading of Low Rank Coal. Coal and

Safety Journal, 24, 54-60. Japan Coal Energy

Centre.

[5] Sasongko, D. 2000. Effect of Particle Size in Hydrothermal Dewatering of Kalimantan Selatan

Subbituminous Coal. In Proceedings of

International Conference and Exhibition on Low Rank Coal Utilization. Jakarta.

5. CONCLUSION

The electromagnetic process gives significant effect to the decrease of inherent moisture contents and the increase of coal heating value. The highest decrease of inherent moisture content is at coal-kerosene ratio of 1: 40, temperature at 70 oC and the voltages at 8 volts while the highest increase of heating value is at

coal-kerosene ratio of 1: 40, temperature at 50 oC and the voltages at 8 volts. There was the increase of heating value from 6,477 kcal/kg to 7,902 kcal/kg and the reduction of inherent moisture content from 12.09 % (adb) to 2.64 % (adb).

[6] Ochs, Thomas L., and Summers, C. 2000.

Upgrading Low-Rank Coal by dehydration. In Proceedings of International Conference and Exhibition on Low Rank Coal Utilization. Jakarta. [7] Speight, James G. 1994. The Chemistry and

Technology of Coal. 2nd Edition. New York: Marcel Dekker, Inc.

[8] Levine, Duane G., Richard H., et al. 1981.

Understanding the Chemistry and Physics of Coal

Structure (A Review). New Jersey: Exxon Research

and Engineering Company.