DEVELOPMENT OF THE BIOMASS STOVE WITH AN AIR

CONVECTION FOR HOUSEHOLD USING IN RURAL AREA

Daddy Budiman

1*), Agung Kurniawan

1), Rivanol Chadry

1), Menhendry

1)1)

Mechanical Engineering Department, Padang State Polytechnics, Padang

Limau Manis Campus

–

Padang

*email :

daddy.budiman@polinpdg.ac.id

1)and daddy.budiman@gmail.com

Abstract

The energy crisis can be solved by the substitution energy from biomass that can easily be found around the rural area which surrounded the small and medium city. To convert the inner energy of biomass, we need a stuff that called a biomass stove. It can burn the unused biological material such as straw, leaves, twigs, wood, and rice husk and gives heat which can be used to household usage. The problem for burning the biomass is not simple to use and complicated in preparing the existing stove. This paper tries to develop the new biomass stove that has a good performance of thermal efficiency. Theoretically it can be achieved by increasing the supply of oxygen into the burning chamber. The stove is also easy to build by using the simple design and used the oil sheet metal drum that can easily be found.

The performance of the stove is measured by Water Boiling Testing (WTB). The result shows that the stove has a moderate thermal efficiency performance (26.88%) and easy to use as long as the air supply is available.

Keyword: biomass, stove, burning performance, combustion chamber

Kata kunci : Biomass, Stove, Burning Performance, Combustion Chamber, Efficiency, Air Convection

1. Introduction

Energy availability is the important sectors for the stabilization of a nation. Indonesia needs to manage this energy sector wisely because local the oil and gas production do not meet the requirement of the oil and gas consumption. To solve the problem, the government should import that since 2003. To ensure the people can buy the oil and gas, the government already spent Rp 274,743 Trilyun in APBN 2014 (BPS 2014)

The subsidizing of oil and gas is used for transportation, household usage in form of kerosene, gasoline,

diesel fuel, and LPG. For household’s usage, kerosene is replaced by LPG in 3 Kg package. Number of

household in Indonesia is around 6.477.160.000 (BPS 2014). 46 % of the households is stay in the villages and 54% live in the city. 40% of the cities households stay in the suburb around the city.

One way to solve the subsidized oil and gas by the government is to find alternative energy other than oil and gas. In household scale, the alternative energy is using biomass. Biomass is available around houses in suburban areas, villages and in rural areas. Potential household which can use biomass is 4,378,560,160 households

Energy conversion that needed for the household is in formed of heat to cook. The stuff to convert the biomass to heat is stove. Many kind of stove are available such as anglo in Indonesia, oorja in India, NISP in China (Thurber et al. 2014; Xu et al. 2016).

2. Theoretical Framework

One of the methods to convert the biomass into energy is by burn it. Burning process makes the chemical bonds of the biomass converted into heat and energy. The ability to produce the energy depends on the type of biomass, combustion method, and the scale of usage (Chen et al. 2016)

There are three kind of methods to convert the biomass become a heat. They are: Grate Firing (GF), Fluidised Bed (FB), and Pulverized (PF). Grate Firing is chipping the biomass in the grate and feed it into the combustion chamber. Fluidized bed let the biomass particles suspended in a hot, bubbling fluidity bed which blows the jets of air to provide the oxygen needed for combustion or gasification processes. Pulverized is a method of powdering the biomass than blow it into hot combustion chamber (Rosendahl 2013)

The principle of combustion follow the equation below:

∑ ∑ note:

Vi = Mass of the object i Ri = Reactant of the object i Vi = Mass of the object j Pj = Product of the object J

The value of the combustion can be calculated:

kJ or

kJ (Eugne L 2000)

The types of stove are varied depend on the availability of the materials, the condition of a location, and also the culture of a region (Grimsby et al. 2016). Some stove use a simple design without using chimney, while others use a compact design with a chimney. For the small industry the stove design is more complicated with semi-gasified technology (Tryner et al. 2014)

The biomass or known as the solid fuels are also varies depending on the potential that exists in the region that uses the stove (Motghare et al. 2016) (Johnson et al. 2013). In the villages, rural area, and suburb, there are many biomass resources } that can be found such as: twigs, wood branches, sawdust, rice husk and coconut shell.

Improved thermal efficiency of the stove have become an attention of some experts. Some researcher focus on the thermal insulation (Phusrimuang and Wongwuttanasatian 2016), while others did research on the design of the chimney (Accinelli and Gozal 2015). The burner design (Sharma et al. 2016), and air distribution(Wang et al. 2014) are also related to the thermal efficiency. Many expert put more effort in medium and big scale of combustion efficiency related to air distribution but less researcher did in the small scale like household stove.

3. Methods

The method to build the stove is started from solving the national energy problem by find the solution to substitute the LPG stove in rural and suburb area based on the flowchart below:

Figure 1. Flow Chart of Stove Development

The requirement of the stove:

1. The raw material is available and easy to get. 2. The size of the stove is not to big nor to small.

3. The development of the stove doesnt need the special skill. 4. Can burn vaiety of biomass solid fuel.

The design of the stove can be seen in the picture 2 below:

Figure 2 Stove Design

caption: 1. Cover 2. Pot Holders 3. Air distributor 4. Exhaust of the smoke 5. Casing

6. Intake manifold 7. Fan

Stove Manufacturing

Conclusion Energy Problem

Data Collecting and

Literature Study LPG subtitution

Design Variable

Meet the Design Variable, Research

Purposes Basic Design

Testing the Stove Performance No

Yes

4. Result and Discuss

The dimension from the design is develop become the real stuff with the detailed dimension: 1. Air distributor part 1 ( height 28cm and diameter 28cm).

2. Air distributor part 1(height 28cm and diameter 25cm). 3. Stove Casing (height 28cm and diameter 30cm). 4. Intake manifold (W,H,L8x8x15cm).

The air distributor divides the air from the fan so it can be diverge in order to spread the oxygen evenly.

Figure 3, Air Distributor part 1

The second one air distributor serve to keep the solid fuel keep blowed by air flow and keep the combustion process sustain The air distributor part 2 also serve as a collector of the solid fuel.

Figure 4. Air Distributor Part 2

Figure 5. Casing of the Stove.

Figure 6. Intake Manifold with Fan.

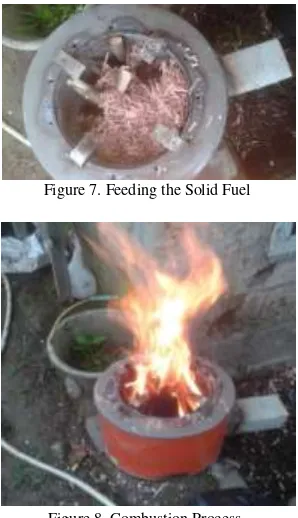

The solid fuel which is used in this stove could be dry twig and chooped wood. The solid fuel put into the combustion chamber and triggered by the starting fire like can be seen in figure 7 and 8.

Figure 7. Feeding the Solid Fuel

Figure 8. Combustion Process.

Water boiling testing did with boil 1 liter of water with solid fuel as many as 0.4 Kg as cab be seen in figure 9 below:

Figure 9. Water Boiling Testing Process.

Efficiency of the stove can be calculated as:

From the water boiling testing the efficiency of the stove is 26.88%. It is a good enough in term of thermal efficiency and the design of the stove quite simple that can be built the member of the house holds

5. Conclusion

The development of the stove with air convection has moderate efficiency. The dimension of the stove is compact and simple and could be made by the regular person. The stove uses the sheet metal that available from the used oil drum.

The air intake need the fan with small electricity needed, This could be the chance for the next research.

Refferenced

Accinelli, R. A., and D. Gozal. 2015. Biomass Pollution, Chimney Stove Interventions, and Discrepant Outcomes. Chest 148 (5):e163-e164.

BPS. 2016. 2014 [cited Agustus 2016]. Available from https://www.bps.go.id/linkTabelStatis/view/id/1178. Chen, L., P. Song, W. Zeng, J. Zhang, C. Feng, and H. Ma. 2016. Exhaust emission characteristics of gaseous

low-temperature biomass fuel in spark-ignition engine. Applied Thermal Engineering 108:1-10. Eugne L, K. 2000. Applied Combustion. 2nds ed. Vol. 2. Ohio: Ohio State University Press.

Johnson, M. A., V. Pilco, R. Torres, S. Joshi, R. M. Shrestha, M. Yagnaraman, N. L. Lam, B. Doroski, J. Mitchell, E. Canuz, and D. Pennise. 2013. Impacts on household fuel consumption from biomass stove programs in India, Nepal, and Peru. Energy for Sustainable Development 17 (5):403-411. Motghare, K. A., A. P. Rathod, K. L. Wasewar, and N. K. Labhsetwar. 2016. Comparative study of different

waste biomass for energy application. Waste Management 47, Part A:40-45.

Phusrimuang, J., and T. Wongwuttanasatian. 2016. Improvements on thermal efficiency of a biomass stove for a steaming process in Thailand. Applied Thermal Engineering 98:196-202.

Rosendahl, L. 2013. Biomass Combustion Science, Technology and Engineering: Woodhead Publishing. Sharma, M., S. C. Mishra, and P. Mahanta. 2016. Effect of burner configuration and operating parameters on

the performance of kerosene pressure stove with submerged porous medium combustion. Applied Thermal Engineering 107:516-523.

Thurber, M. C., H. Phadke, S. Nagavarapu, G. Shrimali, and H. Zerriffi. 2014. ‘Oorja’ in India: Assessing a large-scale commercial distribution of advanced biomass stoves to households. Energy for Sustainable Development 19:138-150.

Tryner, J., B. D. Willson, and A. J. Marchese. 2014. The effects of fuel type and stove design on emissions and efficiency of natural-draft semi-gasifier biomass cookstoves. Energy for Sustainable Development 23:99-109.

Wang, X., B. Niu, S. Deng, Y. Liu, and H. Tan. 2014. Optimization Study on Air Distribution of an Actual Agriculture Up-draft Biomass Gasification Stove. Energy Procedia 61:2335-2338.

Xu, Y., Y. Wang, Y. Chen, C. Tian, Y. Feng, J. Li, and G. Zhang. 2016. Characterization of fine and carbonaceous particles emissions from pelletized biomass-coal blends combustion: Implications on residential crop residue utilization in China. Atmospheric Environment 141:312-319.

Biodata Penulis

[1] Daddy Budiman, memperoleh gelar Sarjana Teknik (ST), Program Studi Teknik Mesin Fakultas Teknik

[Universitas Andalas], lulus tahun 1996. Tahun 2005 memperoleh gelar Master of Engineering (M.Eng) dari Program Ilmu Manufaktur [University of South Australia]. Saat ini sebagai Staf pada Jurusan/Prodi Teknik Mesin [Politeknik Negeri Padang].

[2] Agung Kurniawan, memperoleh gelar Ahli Madya (Amd), Program Studi Teknik Mesin [Politeknik Negeri

Padang, lulus tahun 2015. Saat ini menekuni wirausaha di kota Solok

[3] Rivanol Chadry, memperoleh Master Teknik dari Universitas Indonesia pada tahun 2008. Saat ini menjadi tenaga

pengajar tetap di Jurusan Teknik Mesin Politeknik Negeri Padang

[4] Menhendry, memperoleh Master of Engineering dari University of South Australia pada tahun 2007. Saat ini aktif

mengajar pada Jurusan Teknik Mesin Politeknik Negeri Padang