Table of contents

Periodical:

Applied Mechanics and Materials

Volume: 776 (2015)

Recent Decisions in Technologies for Sustainable Development

Papers published in this volume: Preface

Sustainable Development of Concrete Using GGBS: Effect of Curing Temperatures on the Strength Development of Concrete

Gidion Turu'allo

p.3

Properties of Sand Sheet Asphalt Mixture Incorporating Waste Plastic

I. Nyoman Arya Thanaya, I. Gusti Raka Purbanto, I.G. Wikarga

p.9

Asphalt Pavement Temperature Profile for Tropical Climate in Indonesia

I. Made Agus Ariawan, B.S. Subagio, B.H. Setiadji

p.17

The Development of Slurry Seal Design with Ordinary Portland Cement Replacement by Low Calcium Fly Ash

Ary Setyawan, D. Sarwono, M.S. Adnan

p.24

The Structural Properties Assessment of Thin Hot Mixture Asphalt for Pavement Preservation

Ary Setyawan, Abdul Hakim Mustafa Elshawesh, Sholihin As'ad

p.30

Mechanical Strength of Hydraulic Binder Made by Blending Type I Portland Cement and Pozzolan

I. Made Alit Karyawan Salain

p.36

Laboratory Tests on Failure of Retaining Walls Caused by Sinusoidal Load

Anissa Maria Hidayati, R.W. Sri Prabandiyani, I. Wayan Redana

p.41

Deformation Behavior of Concrete due to the Influence of the Steel Ring Width Variations as the External Confinement

Endah Safitri, Iswandi Imran, Nuroji, Sholihin Asa'ad

p.47

Evaluation of High Grade Recycled Coarse Aggregate Concrete Quality Using Non-Destructive Testing Technique

Ni Nyoman Kencanawati, Jauhar Fajrin, Buan Anshari, Akmaluddin, Mitsuhiro Shigeishi

Mechanical Strength of Hydraulic Binder

Made By Blending Type I Portland Cement and Pozzolan

I Made Alit Karyawan Salain

1,a1Civil EngineeringDepartment, Udayana University, Bali, Indonesia aimaksalain@yahoo.com

Keywords: portland cement, pozzolan, flexural tensile strength, compressive strength

Abstract.The mechanical strength of hydraulic binder made by blending type I Portland

cement(PC) and pozzolan has been examined at the age of 3, 7, 14, 28 and 90 days.The mechanical strength test was realized by using mortar specimens measuring 40x40x160 mm according to NF EN 196-1. The mix proportion of mortarwas 0.5 water :1.0 hydraulic binder : 3.0 sand, by weight.The hydraulic binder was a mixture of 80% PC and 20% pozzolan. Five types of pozzolan were used in this study: two natural pozzolan and three artificial pozzolan. As a control, it was made a mortar havingthe same proportion except that the hydraulic binder was 100% PC. The test result showsthat all of pozzolan present a good pozzolanic reactivity. At 3 days,the strength of the mortar with blended binder (MBB) is lower than the strength of the control mortar(CTM). At that time, the flexural tensile strength and the compressive strength of the MBB rangerespectively from 5.23 to 6.81 MPa and from 13.61 to 18.37 MPa, whereas the CTM strength has reached 7.30 MPa and 27.92 MPa. The MBB strength increasesand it canachieve or even exceed the CTM strengthwith increasing age of hydration. In fact, at 90 days, the flexural tensile strength and the compressive strength ofMBB can reach about 10.08 to 11.06 MPa and 49.69 to 54.17 MPa respectively. In this period of hydration, the flexural tensile strength and the compressive strength of CTM are only 10.13 MPa and 49.00 MPa. The different development of the mechanical strength of MBB could be stronglyrelated to the chemical content of the pozzolan used, especially, reactive silica and reactive alumina.

Introduction

Portland cement is the main component in concrete technology that serves as a hydraulic binder to unify aggregates into a solid mass. Various types of Portland cement have been developed in accordance with the requirements of the type of building and the environment in which the concrete will be used. One type of Portland cements which is developed as an effort to reduce production cost as well as environmental problems is the Portlandpozzolan cement (PPC). This type of cement is made by grinding together a mixture of Portland cement clinker and material havingcharacteristics of pozzolan [1].

Pozzolan is a mineral containing mainly of silica and alumina which when in finely divided form and in the presence of water, at normal temperatures, will react with lime to form calcium silicate hydrates(C-S-H) and calcium aluminate hydrates (C-A-H) compounds, similar to the compounds produced in the hydration process of Portland cement. It is well known that, the main mineral of Portland cement, C3S and C2S, willreact with water to produce C-S-H and free lime Ca(OH)2. Free

lime less contributes to the strength and even tends to be detrimental in terms of durability, when in the course of time, the free lime reacts with the aggressive elements such as sulfate [2-4]. By grinding a mixture, in certain proportion, of Portland cement clinker and pozzolan, it will obtain a type of cement,named PPC, which has characteristics such as lower heat of hydration and better workability, strength and resistance to sulfate attacks when compared withtype I Portland cement [2-4].

Pozzolan used in the manufacture of PPC can be derived from natural such as pumice or from industrial wastes such as fly ash. However, the characteristics of each pozzolan may vary from one type to the others, as pozzolan is not a fabrication product. Therefore, an examination is necessary

Applied Mechanics and Materials Vol 776 (2015) pp 36-40 Submitted: 2015-02-19 © (2015) Trans Tech Publications, Switzerland Accepted: 2015-04-10 doi:10.4028/www.scientific.net/AMM.776.36

to determine whether a pozzolan can be used as a material in the production of PPC. This can be realized by examining the reactivity of the pozzolan by blending it with Portland cement, hydrating the blend and then measuring the mechanical strength of the hydrated blend.

Materials and Experimental Method

[image:3.595.153.441.251.360.2]It was used type I Portland cement (PC), natural and also artificialpozzolan as the ingredient of the hydraulic binder.Two natural pozzolan: pumice 1 (P1) and pumice 2 (P2) and three artificial pozzolan: fly ash (FA), bottom ash (BA) and waste of tile fragments (WT) were used in this study. All of pozzolan, except FA, were grounded so that their grains passed through sieve No. 200 (75 µm). The content of some chemical elements of PC and pozzolan is shown in Table 1.

Table 1 Chemical composition of type I Portland cement and pozzolan Oxide

[%] PC P1 P2 Pozzolan FA BA WT Al2O3 5.22 0.44 15.25 2.96 1.37 1.33

CaO 56.76 0.43 0.27 1.84 1.64 0.36 SiO2 25.97 75.93 68.84 66.62 82.15 81.58

Fe2O3 4.03 0.32 5.28 2.72 5.50 2.70

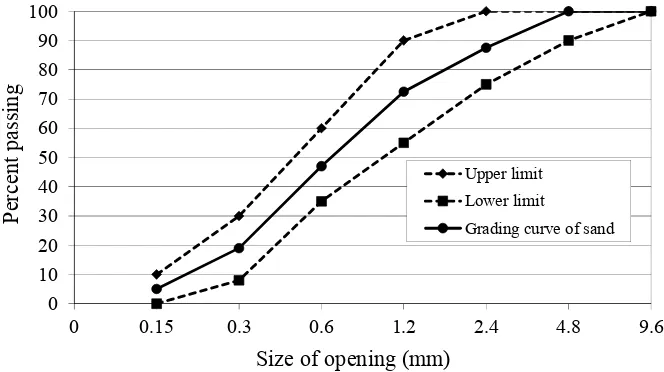

Natural sand was used as fine aggregate. The grain distribution of fine aggregate was designed to meet grading zone 2 according to SNI 03-2834-2000[5]. The fineness modulus of this fine aggregate was 2.69.The grain distribution of the sand is presented in Fig. 1.

Fig. 1. Grading curve for sand with SNI 03-2834-2000zone 2 grading limits

Five types of mortar were produced by mixing water, hydraulic binder and sand. The mix proportion of each mortar was 0.5 water : 1.0 hydraulic binder : 3.0 sand,by weight.The hydraulic binder was a mixture of 80% PC and 20% pozzolan. As a control, it was made a mortar havingthe same proportion except that the hydraulic binder was 100% PC. The characteristics of each mortar are given in Table 2.

0 10 20 30 40 50 60 70 80 90 100

0 0.15 0.3 0.6 1.2 2.4 4.8 9.6

Pe rc en t p as si ng

Size of opening (mm)

Upper limit Lower limit

Grading curve of sand

[image:3.595.132.464.435.621.2]Table 2. Characteristics of mortar

Mortar Hydraulic Binder Water: Hydraulic Binder: Sand M1 80% PC + 20% P1 0.5:1.0:3.0

M2 80% PC+ 20% P2 0.5:1.0:3.0 M3 80% PC+ 20% FA 0.5:1.0:3.0 M4 80% PC+ 20% BA 0.5:1.0:3.0 M5 80% PC+ 20% WT 0.5:1.0:3.0

M6 100% PC 0.5:1.0:3.0

Specimens that have been casted, in the form of prisms sizing 40x40x160 mm, were left in the mould for 24 hours and thenwere released from the mould for curing. The curing was carried out by immersing the specimens in water up to the time specified for the test: 3, 7, 14, 28 and 90 days.

The mechanical strength test concerning flexural tensile strength and compressive strength was realized according to NF EN 196-1 [6] by using 3 specimens for each type of mortar. First, the flexural tensile strength test was conductedby giving a load at the centre span of the specimen which was free supported at two ends, until the specimen was fracture. And then, the compressive strength test was realized by using eachfracture of this specimen. The mechanical strength test equipment and the prismatic specimens sample are shown in Fig. 2.

Fig. 2 Mechanical strength test equipment and prismatic specimens 40x40x160mm

Results and Discussion

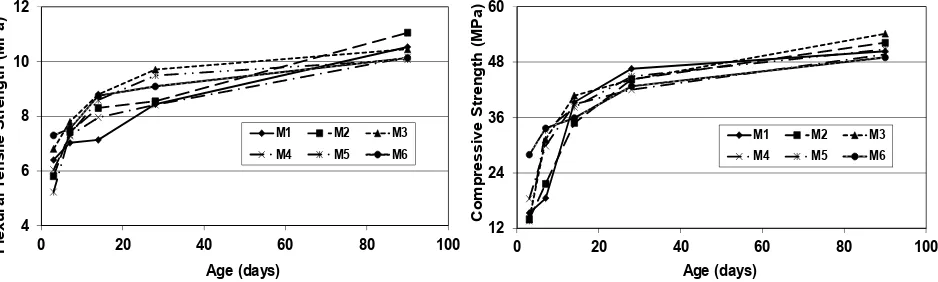

Results. The development of flexural tensile strength and compressive strength of each mortar based on hydration time is given in Fig. 3.It is clearly observed that the strength development is strongly influenced by the type of pozzolan used in the blended binder.

At the age of 3 days, it appears that the strength of the mortar with blended binder (MBB) is lower than the strength of the control mortar (CTM). At that time, flexural tensile strength and compressive strength of the MBB range respectively from 5.23 to 6.81 MPa and from 13.61 to 18.37 MPa, whereas the CTM strength has reached 7.30 MPa and 27.92 MPa. However, with increasing age of hydration, the MBB strength increasesand it can achieve or even exceed the CTM strength. In fact, at the age of 90 days, the flexural tensile strength and the compressive strength of MBB can reach about 10.08 to 11.06 MPa and 49.69 to 54.17 MPa respectively. It is clearly noted that M2 and M3develop the highest flexural tensile strength and compressive strengthrespectively. In this period of hydration, the flexural tensile strength and the compressive strength of CTM are only 10.13 MPa and 49.00 MPa.

[image:4.595.65.531.349.518.2]Fig. 3. Flexural tensile strength and compressive strength development

The flexural tensile strength of mortar usingfly ash (M3) or waste of tile fragments (M5) develops rapidly in the first 28 days but tends to develop more slowlysubsequently. On the contrary, it is observed that theflexural tensile strength ofmortar using pumice or bottom ash (M1, M2 or M4)developsslowly atearly agebutmore quickly at long term hydration. Generally, the flexural tensile strength of MBB can exceed the flexural tensile strength of CTMafter 28 days of hydration, except for M3 that could realizeit only after 7 days.

The development of compressive strength in all mortar is relatively equal to the age of 28 days, but after that period, M2 and M3 show a fasterdevelopmentthanthe others. It is also noted that the compressive strength of MBB can generally exceed the compressive strength of CTMfrom 14 days of hydration.

Discussion. Test result shows that all of five pozzolan used in this study present a good pozzolanic reactivity. In fact, the five types of mortar that made by using a blend of 80% PC and 20% of pozzolan as a hydraulic binder can produce a strength that can reach or even exceed the strength of mortar made by using 100% PC. This indicates that silica (SiO2) and alumina (Al2O3) that exist in

each pozzolan are reactive and can bind free lime released during PC hydration to form additional binder compounds such as C-S-Hand C-A-H that contribute to strengthdevelopment.

The test result also shows that the development of strength as well as the strength at the age of 90 days vary depending on the type of pozzolan used. Thiscould be related to the fact that all of the pozzolan used are not derived from the same source as well as their chemical contents vary, therefore their pozzolanic reactivity are different.

Conclusion

• Five pozzolan used in this study showa good pozzolanic reactivity in terms of mechanical strength, so it is worth considering as an ingredient of PPC.

• The mechanical strength of mortar using blended binder is lower than the strengthof control mortarat early age but itincreasesand can achieve or exceed the control mortarstrengthat long term hydration.

• The different development of the mechanical strength of the mortar with blended bindercould bestrongly related to the chemical content of pozzolan used, especially, reactive silica and reactive alumina.

4 6 8 10 12

0 20 40 60 80 100

Fl ex ur al T en si le S tr en gt h (M P a) Age (days)

M1 M2 M3 M4 M5 M6

12 24 36 48 60

0 20 40 60 80 100

C om pr es si ve S tr en gt h (M P a) Age (days)

M1 M2 M3 M4 M5 M6

References

[1] Badan Standardisasi Nasional, Standar Nasional Indonesia Semen Portland Pozzolan SNI 15-0302-2004, 2004.

[2] F.M. Lea, The Chemistry of Cement and Concrete, Edward Arnold Ltd., London, 1970.

[3] P. K. Mehta,Properties of Concrete Structure, and Materials, Englewood Cliffs, New Jersey, 1986.

[4] A. M. Neville and J. J. Brooks,Concrete Technology, Longman, Singapore, 1998.

[5] Badan Standarisasi Nasional, Standar Nasional Indonesia Untuk Tata Cara Pembuatan Rencana Campuran Beton Normal SNI 03-2834-2000, 2000.

[6] NF EN 196-1, Méthodes d’essais des ciments - Partie 1 : détermination des résistances mécaniques, Avril 2000

Mechanical Strength of

Hydraulic Binder Made by

Blending Type I Portland

Cement and Pozzolan

by

Alit Salain

FILE

TIME SUBMITTED 01-FEB-2016 08:59AM

SUBMISSION ID 626104403

WORD COUNT 2059

CHARACTER COUNT 9980

16

%

SIMILARITY INDEX

6

%

INTERNET SOURCES

14

%

PUBLICATIONS

6

%

STUDENT PAPERS

1

2

%

2

2

%

3

2

%

4

2

%

5

Mechanical Strength of Hydraulic Binder Made by Blending

Type I Portland Cement and Pozzolan

ORIGINALITY REPORT

PRIMARY SOURCES

Submitted to Prince of Songkla University

Student Paper

Sugita, I. Ketut Gede, and I. Gusti Ngurah

Priambadi. "The Effect of Solidification on

Acoustical of Tin Bronze 20Sn Alloy", Applied

Mechanics and Materials, 2015.

Publication

Ahmed, Mohd., Khalid Mohammad El Hadi,

Mohammad Abul Hasan, Javed Mallick, and

Akil Ahmed. "Evaluating the co-relationship

between concrete flexural tensile strength

and compressive strength", International

Journal of Structural Engineering, 2014.

PublicationXu, De Jin, Chuan Qing Fu, Xian Yu Jin, Ye

Tian, and Nan Guo Jin. "Experimental Study

on Strength and Abrasion-Resistance

Enhancement Admixture", Advanced

Materials Research, 2011.

Publication

1

%

6

1

%

7

1

%

8

1

%

9

1

%

10

1

%

Pavoine, Gérard Platret, Adélaïde

Feraille, and Amina Alaoui. "Effect of

gypsum content on sulfoaluminate mortars

stability", European Journal of Environmental

and Civil engineering, 2010.

Publication

Technologies for Environmental Cleanup

Toxic and Hazardous Waste Management,

1994.

Publication

Solikin, Mochamad, and Budi Setiawan.

"Mechanical Properties of Class C High

Volume Fly Ash Concrete with Lime Water as

Mixing Water", Applied Mechanics and

Materials, 2014.

Publication

Submitted to South Bank University

Student PaperDuran Atis, C.. "Strength properties of

high-volume fly ash roller compacted and

workable concrete, and influence of curing

condition", Cement and Concrete Research,

200506

Publication

Chandra, S.. "Influence of presaturation and

freeze-thaw test conditions on length

changes of portland cement mortar", Cement

and Concrete Research, 199207

11

1

%

12

1

%

13

1

%

14

<

1

%

15

<

1

%

16

<

1

%

17

<

1

%

Submitted to Higher Education Commission

Pakistan

Student Paper

jurnal.sttgarut.ac.id

Internet SourceSubmitted to Universiti Sains Malaysia

Student Paper

Fisher, A.. "The durability of cellulose fibre

reinforced concrete pipes in sewage

applications", Cement and Concrete

Research, 200104

Publication

Turu'allo, Gidion. "Sustainable Development

of Concrete Using GGBS: Effect of Curing

Temperatures on the Strength Development

of Concrete", Applied Mechanics and

Materials, 2015.

PublicationYew, Ming Kun Mahmud, Hilmi Bin Ang, Bee.

"Influence of different types of polypropylene

fibre on the mechanical properties of

high-strength oi", Construction and Building

Materials, August 15 2015 Issue

Publication

Sawsen, Chafei Fouzia, Khadraoui

Mohamed. "Effect of flax fibers treatments

on the rheological and the mechanical

18

<

1

%

19

<

1

%

20

<

1

%

EXCLUDE QUOTES OFF

EXCLUDE

BIBLIOGRAPHY OFF

EXCLUDE MATCHES OFF

and Building Materials, March 15 2015 Issue

PublicationPacheco-Torgal, F.. "Investigations about the

effect of aggregates on strength and

microstructure of geopolymeric mine waste

mud binders", Cement and Concrete

Research, 200706

PublicationMascolo, G.. "Hydration products of synthetic

glasses similar to blast-furnace slags",

Cement and Concrete Research, 197303

Publication

Hwang, Myung Goo, Gin Ho Kim, Han Ju

Park, Yong Gon Lee, Cheol Min Yang, Jae

Kyoo Lim, and Hee Yong Kang. "Fracture

Parameters of Short Carbon Fiber Reinforced

Polycarbonate Composite Fabricated by