A NA LYSIS O F THE O PTIMUM PERC ENTA G E O F A DMIXTURE O F SIKA MENT- 163, WHIC H C A N BE A DDED INTO C O NC RETE MIXTURE TO A C HIEVE THE MA XIMUM

O F C O NC RETE C O MPRESSIO N STRENG TH

G id io n Turu’ a llo *

A b stra k

Pe ne litia n ini b e rtujua n untuk m e nd a p a tka n p ro se nta si o p tim um d a ri b a ha n ta m b a ha n Sika m e nt-163 ya ng d a p a t d ita m b a hka n ke d a la m c a m p ura n b e to n untuk m e m p e ro le h kua t te ka n b e to n m a ksim um . Pro se nta si d a ri Sika m e nt-163 ya ng d ita m b a hka n ke d a la m c a m p ura n b e to n b e rva ria si d a ri 0 % (b e to n no rm a l), 0,75 %, 1 %, 1,25 %, 1,5 %, 1,75 %, 2 %, d a n 2,5 % d a ri b e ra t se m e n. Pe ne litia n ini d ila ksa na ka n d e ng a n m e ng g una ka n 9 b e nd a uji untuk se tia p p ro se nta si p e na m b a ha n Sika m e nt-163 d a n p e ng e te sa n d ila kuka n p a d a wa ktu um ur b e to n m e nc a p a i 28 ha ri. Ha sil p e rc o b a a n m e nunjukka n b a hwa p ro se nta si o p tim um d a ri Sika m e nt-163 ya ng d ita m b a hka n ke d a la m c a m p ura n b e to n untuk m e nd a p a tka n kua t te ka n b e to n m a ksim um a d a la h 1,5 %. Ha l ini d ise b a b ka n p e na m b a ha n Sika m e nt-163 le b ih d a ri 1,5 % ke d a la m c a mp ura n b e to n a ka n m e nye b a b ka n jum la h a ir ya ng d ig una ka n kura ng d a ri jum la h a ir ya ng d ip e rluka n untuk b e rla ng sung nya p ro se s hid ra si ya ng se m p urna . Se b a g a i ha silnya , b e to n ya ng d iha silka n m e m p unya i kua t te ka n ya ng le b ih re nd a h.

Ka ta kunc i: b a ha n ta m b a ha n, b e to n, d a n kua t te ka n b e to n

Abstrac t

This re se a rc h a ims to find o ut the o p timum p e rc e nta g e o f a d mixture o f Sika me nt-163, whic h c a n b e a d d e d into c o nc re te mixture to a c hie ve the ma ximum o f c o nc re te c o mp re ssio n stre ng th. The p e rc e nta g e s o f Sika me nt-163, whic h a re a d d e d in c o nc re te mixture , a re 0 % (no rma l c o nc re te ), 0.75 %, 1 %, 1.25 %, 1.5 %, 1.75 %, 2 % a nd 2.5 % b y c e me nt we ig ht. The re se a rc h is c o nd uc te d using nine te st sp e c ime ns fo r e a c h p e rc e nta g e o f Sika me nt-163 with the sa me slump . The te sts we re c o nduc te d, whe n the c o nc re te ’ s a g e re a c he d 28 d a ys. The re sults o f te st sho w tha t the o p timum p e rc e nta g e o f Sika me nt-163, whic h is a d d e d into c o nc re te mixture to a c hie ve the ma ximum o f c o nc re te c o mp re ssio n stre ng th is 1.5 %. This is c a use d the a d d ing a d mixture Sika me nt-163 into c o nc re te mixture mo re tha n 1.5 % b y c e me nt we ig ht c a n re d uc e mo re o f use d wa te r fo r the sa me slump ; the re fo re , the use d wa te r le ss tha n tha t is ne e d e d to p e rfo rm c o mp le te d hyd ra tio n p ro c e ss. As the re sult, the c o mp re ssio n stre ng th o f c o nc re te wa s p ro d uc e d , b e c o me lo we r.

Ke yword: Ad mixture , C o nc re te , a nd C o nc re te C o mp re ssio n Stre ng th, p e ng ung sia n

* Sta f Pe ng a ja r Jurusa n Te knik Sip il Fa kulta s Te knik Unive rsita s Ta d ula ko , Pa lu

1. Intro d uc tio n

C o nc re te is m a d e fro m a p ro p e rly p ro p o rtio ne d m ixture o f hyd ra ulic c e m e nt, w a te r, fine a nd c o a rse a g g re g a te s, a nd o fte n, c he m ic a l o r m ine ra l a d m ixture s. The m o st c o m m o n hyd ra ulic c e m e nt use d in c o nstruc tio n to d a y is p o rtla nd c e m e nt. The suc c e ssful

o f its c o m p o ne nts. Be c a use c e m e nt is the m o st a c tive c o m p o ne nt o f c o nc re te a nd usua lly ha s the g re a te st unit c o st, its se le c tio n a nd p ro p e r use a re im p o rta nt in o b ta ining m o st e c o no mic a lly the b a la nc e o f p ro p e rtie s d e sire d fo r a ny p a rtic ula r c o nc re te m ixture .

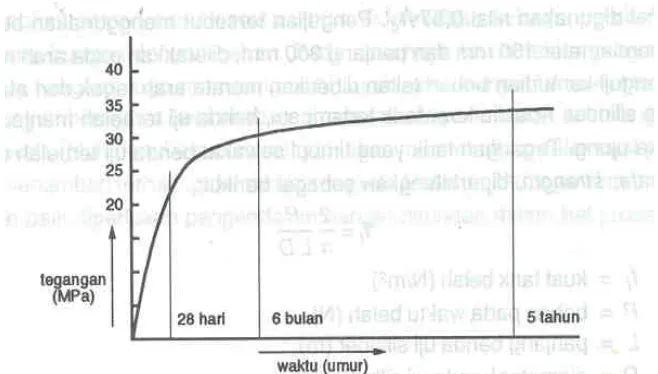

The c o nc re te c o m p re ssio n stre ng th will inc re a se b y inc re a se o f its a g e a s the Fig ure 1 sho wn b e lo w. The inc re a sing o f c o nc re te c o m p re ssio n stre ng th is a lso a ffe c te d b y so m e fa c to rs suc h a s wa te r c e m e nt ra tio , c uring te m p e ra ture , e tc . The hig he r o f its wa te r c e m e nt ra tio the lo we r o f its inc re a sing stre ng th.

Typ e I / II Po rtla nd c e m e nts, whic h c a n p ro vid e a d e q ua te le ve ls o f stre ng th a nd d ura b ility, a re the m o st p o p ula r c e m e nts use d b y c o nc re te p ro d uc e rs. Ho we ve r, so m e a p p lic a tio ns re q uire the use o f o the r c e m e nts to p ro vid e hig he r le ve ls o f p ro p e rtie s. The ne e d fo r hig h-e a rly strh-e ng th c h-e m h-e nts in p a vh-e m h-e nt re p a irs a nd the use o f b le nd e d c e m e nts with a g g re g a te s susc e p tib le to a lka li-a g g re g li-a te re li-a c tio ns li-a re e xli-a m p le s o f suc h a p p lic a tio ns.

It is e sse ntia l tha t hig hwa y e ng ine e rs se le c t the typ e o f c e m e nt tha t will o b ta in the b e st p e rfo rm a nc e fro m the c o nc re te . This c ho ic e invo lve s

the c o rre c t kno wle d g e o f the re la tio nship b e twe e n c e m e nt a nd p e rfo rm a nc e a nd , in p a rtic ula r, b e twe e n typ e o f c e m e nt a nd d ura b ility o f c o nc re te .

The m a nufa c ture a nd c o m p o sitio n o f Po rtla nd c e m e nts, hyd ra tio n p ro c e sse s, a nd c he m ic a l a nd p hysic a l p ro p e rtie s ha ve b e e n re p e a te d ly stud ie d a nd re se a rc he d , with innum e ra b le re p o rts a nd p a p e rs writte n o n a ll a sp e c ts o f the se p ro p e rtie s.

2.2.1 The Effe c t o f Wa te r / C e m e nt Ra tio to C o nc re te C o m p re ssio n Stre ng th.

The stre ng th o f ha rd e ne d c e m e nt d e p e nd s o n the num b e r o f wa te r use d fo r the hyd ra tio n p ro c e ss ta ke s p la c e s. The hyd ra tio n p ro c e ss b a sic a lly, ne e d s wa te r o f a b o ut 25 % o f c e m e nt we ig ht (Tjo kro d im ulyo , 1996). Ab ra m s’ La w sta te s tha t a ssum ing full c o m p a c tio n, a nd a t a g ive n a g e a nd no rm a l te m p e ra ture , stre ng th o f c o nc re te c a n b e ta ke n to b e inve rse ly p ro p o rtio na l to the wa te r/ c e m e nt ra tio a s the fo rm ula b e lo w,

wcr

B

A

c

f

'

=

………..(1)whe re , f’ c a nd wc r a re the c o nc re te

c o m p re ssio n stre ng th a nd wa te r/ c e m e nt ra tio re sp e c tive ly; while A a nd B a re c o nsta nts. The hig he r the ra tio , the g re a te r the wa te r c o nse q ue ntly, the c o nc re te a ssum e s le ss c o m p re ssive stre ng th. Also , m o re d a ys o f we t c uring a re re q uire d to o b ta in the ha rd ne ss ne c e ssa ry to ha rd o ff m o isture m ig ra tio n. Fo r e xa m p le , the id e a l ra tio is 0.40 to 0.45, whic h wo uld re q uire se ve n d a ys o f we t c ure . The num b e r o f wa te r use d in c o nc re te m ix is stro ng ly re la te d to the slum p va lue o f c o nc re te fre sh. The m o re wa te r use d in the c o nc re te m ix, the hig he r the slum p .

The re la tio nship b e twe e n c e m e nt a nd wa te r c o nte nt is c ruc ia l im p o rta nc e to the c o nc re te d ura b ility. C a p illa ry p o ro sity fo rm e d fro m re sid ua l sp a c e s o c c up ie d b y m ix wa te r inc re a se s with hig he r w/ c ra tio within o rd ina ry Po rtla nd c e m e nt. In this m a nne r, inc re a se d wa te r c o nte nt within the o rig ina l mix ind ic a te s

a lo we r stre ng th a nd a p o te ntia l d e c re a se in d ura b ility.

2.2.1 The e ffe c t o f Ad mixture s to C o nc re te C o m p re ssio n Stre ng th.

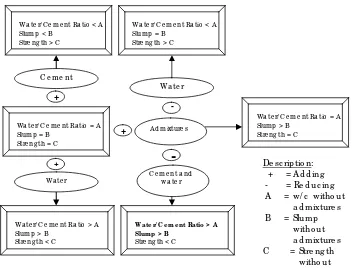

The concept of using admixtures in

concrete mixture can be seen in the Figure 2

below. As can be seen from the figure; the

adding of admixture into concrete mixture

at the same slump with normal concrete by

reducing used water can increase the

concrete compression strength. The concrete

compression strength also can be increase

by adding cement as the picture shows;

however adding cement will reduce

workability of concrete due to reduce of

concrete slump. Even using cement exceed

from the needed amount will generate a new

problem in concrete itself, i.e. it will

generate shrinkage and creep in concrete at

earlier time; therefore it will reduce

concrete compression strength (Haidar,

2002).

Fig ure 2. C o nc e p t o f Using Ad mixture s

Wa te r/ C e m e nt Ra tio < A Slump < B

Stre ng th > C

C e m e nt

Wa te r/ C e m e nt Ra tio = A Slump = B

Stre ng th = C

Wa te r

Wa te r/ C e m e nt Ra tio > A Slump > B

Stre ng th < C

Ad mixture s Wa te r/ C e m e nt Ra tio < A Slump = B

Stre ng th > C

Wa te r/ C e m e nt Ra tio = A Slump > B

Stre ng th = C

Wa te r

+

+

-

-Wa te r/ C e m e nt Ra tio > A Slum p > B

Stre ng th < C C e m e nt a nd

w a te r

+

De sc rip tio n: + = Ad d ing - = Re d uc ing A = w/ c witho ut

a d m ixture s B = Slum p

witho ut a d m ixture s C = Stre ng th

36,04 37,53

42,49 43,51 45,83

39,36

33,43

25,04

20 24 28 32 36 40 44 48 52

0 0,25 0,5 0,75 1 1,25 1,5 1,75 2 2,25 2,5 2,75

Persentase sikament - 163 (%)

K

u

a

t t

ek

a

n

ra

ta

-r

a

ta

(M

P

a

)

3. Exp e rim e nta l Pro g ra m

3.1 Ma te ria ls Te sting

The m a te ria ls use d to p ro d uc e c o nc re te in this re se a rc h sho uld b e fulfilling the re q uire d sp e c ific a tio n b e fo re use d ; o the rwise , the m a te ria ls c a nno t b e use d . Tho se m a te ria ls a re b o th fine a nd c o a rse a g g re g a te s, c e m e nt a nd wa te r. The c o a rse a g g re g a te in fro m sto ne c rushe d wa s ta ke n fro m Ta ip a rive r, while fine a g g re g a te w a s ta ke n fro m Pa lu rive r. The use d c e m e nt se le c te d fro m typ e I b ra nd To na sa .

The a g g re g a te s’ te sting , whic h a re d o ne ; a re sie ve a na lysis, a g g re g a te s wa te r c o nte nt, a g g re g a te s so il c o nte nt, sp e c ific b ulk g ra vity, o rg a nic c o nte nt a nd we a ring o ut te st b y Lo s Ang e le s m a c hine .

3.2 Mix De sig n

The c o m p o sitio n o f m a te ria ls,

whic h use d in the c o nc re te m ix, is c a lc ula te d b a se d o n the Ind o ne sia c o d e fo r No rm a l C o nc re te Mix De sig n (SK SNI T-15-1990-03). The a ve ra g e o f c o nc re te c o m p re ssio n stre ng th is c a lc ula te d b y fo llo wing e q ua tio n.

f’ c r = f’ c + 1.64 S ………..(2)

o r f’ c r = f’ c + M ………(3)

whe re , f’ c r = the a ve ra g e o f c o nc re te c o m p re ssio n stre ng th f’ c = re q uire d c o nc re te c o m p re ssio n

stre ng th.

S = Sta nd a rd d e via tio n va lue (ta ke n 7 MPa if the p re vio us e xp e rie nc e d d a ta no t a va ila b le ).

M = Ad d itio na l va lue , Ma rg in; It is ta ke n 12 MPa if the p re vio us d a ta no t a va ila b le .

3.3. Sa m p le Te st

The te st sp e c im e ns m a d e o f c o nc re te c ub e o f 150 m m x 150 m m x 150 m m size . Te sts o f the sa m p le c ub e s we re d o ne whe n tho se a g e s we re 28 d a ys. The num b e r o f sa m p le s use d in the te st c a n b e se e n in the Ta b le 1 b e lo w.

4. The Exp e rim e nta l Re sults a nd

Disc ussio n.

4.1 The Exp e rim e nta l Re sults.

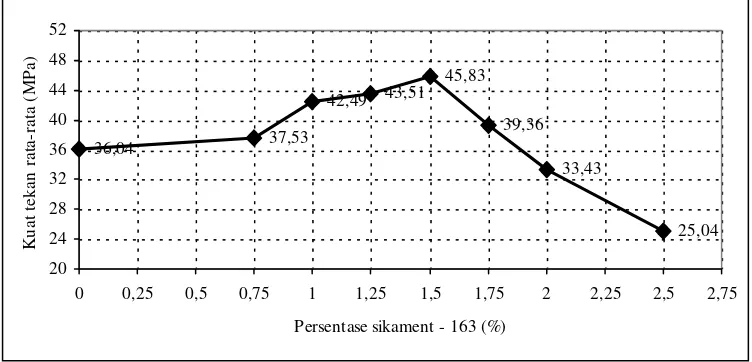

The c o nc re te c o m p re ssio n te st re sults a t e a c h c o nc re te ’ s a g e is p re se nte d in the Fig ure 3 b e lo w.

Ta b le 1.The num b e r o f te st sp e c im e ns

Concrete type

Pe rc e nta g e o f Sika m e nt- 163 (% ) To ta l0 0.75 1 1.25 1.5 1.75 2 2.5

Number of

test specimens

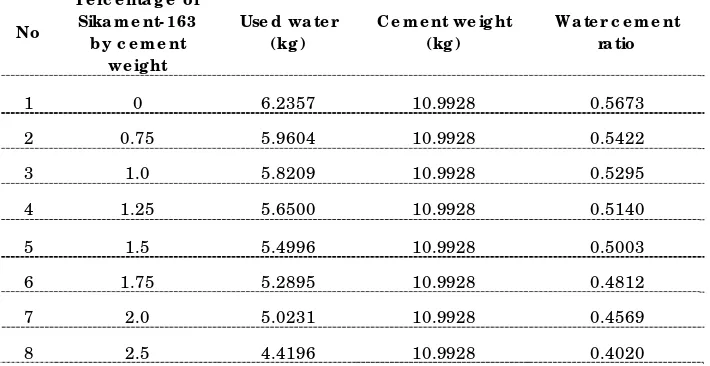

9 9 9 9 9 9 9 9 72Ta b le 2. Re la tio n b e twe e n the p e rc e nta g e o f Sika m e nt-163 with wa te r c e m e nt ra tio .

No

Pe rc e nta g e o f Sika m e nt- 163 b y c e m e nt

we ig ht

Use d wa te r (kg )

C e m e nt we ig ht (kg )

Wa te r c e m e nt ra tio

1 0 6.2357 10.9928 0.5673

2 0.75 5.9604 10.9928 0.5422

3 1.0 5.8209 10.9928 0.5295

4 1.25 5.6500 10.9928 0.5140

5 1.5 5.4996 10.9928 0.5003

6 1.75 5.2895 10.9928 0.4812

7 2.0 5.0231 10.9928 0.4569

8 2.5 4.4196 10.9928 0.4020

The te st re sults a b o ve sho w tha t the m a xim um c o nc re te c o m p re ssio n stre ng th is a c hie ve d whe n the p e rc e nta g e o f Sika m e nt-163 whic h wa s a d d e d into c o nc re te mixture is 1.5 % b y c e m e nt we ig ht. The g ra p h a lso sho ws tha t a d d the Sika m e nt-163 m o re tha n 1.5 % will re d uc e the c o m p re ssio n stre ng th fro m the o b ta ine d m a xim um va lue ; e ve n a d d it m o re tha n 2 % will p ro d uc e c o nc re te with c o m p re ssio n stre ng th lo we r tha n no rm a l c o nc re te . Ano the r re sult o f this re se a rc h suc h a s the re la tio n b e twe e n the p e rc e nta g e s o f Sika m e nt-163 with wa te r c e m e nt ra tio is sho wn in Ta b le 2 b e lo w. The ta b le sho ws tha t the hig he r p e rc e nta g e o f Sika m e nt-163 p ro d uc e s the lo we r wa te r c e m e nt ra tio o f c o nc re te m ixture .

4.2 Disc ussio n

Fig ure 3 a b o ve sho ws tha t using o f Sika m e nt-163 a s m uc h 1.5 % b y c e m e nt

e xp e c te d to ha ve hig he r stre ng th. Ho we ve r, it g ive s re ve rse re sults; it is c a use d the use d wa te r b y a d d ing Sika m e nt-163 m o re tha n 2 % into c o nc re te m ixture le ss tha n a m o unt wa te r tha t is ne e d e d to p e rfo rm a c o m p le te d hyd ra tio n p ro c e ss e ve n tho ug h it re sults c o nc re te with lo we r wa te r c e m e nt ra tio o r inc re a se d wo rka b ility.

In c o nc lusio n, the o p tim um p e rc e nta g e o f Sika m e nt-163, whic h c a n b e a d d e d into c o nc re te m ixture ; is 1.5 % with re d uc ing wa te r till 11.8 % fro m tha t is use d fo r no rm a l c o nc re te . The p ro d uc e d c o nc re te re sults the c o m p re ssio n stre ng th o f 27.16 % hig he r tha n no rm a l c o nc re te ’ s stre ng th. Mo re o ve r, using o f the Sika m e nt-163 whic h p ro d uc e d b y Sika C o m p a ny c a n a lso inc re a se c o nc re te wo rka b ility.

4.3 Sug g e stio n fo r the future wo rk

It is ne e d e d to a d va nc e d stud y the e ffe c ts o f Sika m e nt-163 a d m ixture to the d ura b ility c o nc re te e sp e c ia lly to c o rro sio n o f re info rc e d c o nc re te e m b e d d e d in c o nc re te to kno w whe the r the Sika m e nt-163 e ffe c t the p a ssive la ye r o f c o nc re te o r no t.

5 Re fe re nc e s

Ano nim , 2003, “ Ba ha n Pre se nta si Sika ”, PT Sika Ind o nse ia

C a lliste r Jr., W. D. 2003, Ma te ria ls Sc ie nc e

a nd Eng ine e ring —An

Intro d uc tio n, 6th e d . Ne w Yo rk: Wile y,

De p a rte m e n Pe ke rja a n Um um , Ta ta C a ra Pe mb ua ta n Re nc a na C a mp ura n Be to n No rma l (SK SNI

T-15-1990-03), Ya ya sa n LPMB,

Ba nd ung .

G a ni, M.S.J., 1997, C e me nt a nd

C o nc re te, C ha p m a n a nd Ha ll

Ja m e s M. d a n Ha rp e r, P.E., 1999, Effe c ts o f Ag g re g a te s o n C o nc re te

Pro p e rtie s, Jo urna l o f Ma te ria ls

Eng ine e ring , ASC E

Kha lil Ha id a r, 2002, Influe nc e o f Po ro sity o n Fra c ture C ha ra c te ristic s in

Mo rta r Struc ture s, 15th ASC E

Eng ine e ring Me c ha nic s C o nfe re nc e .

Me hta P.K. d a n Pa ulo Mo nte iro J.M., 2001, C o nc re te : Mic ro struc ture ,

Pro p e rtie s a nd Ma tria ls.

Murd o c k, L.J. d a n Bro o k, K.M. 1999,

Ba ha n d a n Pra kte k Be to n,

Erla ng g a . Ja ka rta .

Ne ville , A.M. d a n Bro o ks, J.J., 1998,

C o nc re te Te c hno lo g y, Lo ng m a n

Sing a p o re Pub lishe r.

Ra n Hua ng a nd C hung C hia Ya ng , 2000,

Effe c ts o f Ag g re g a te Vo lume Fra c tio n o n the Ela stic Mo duli a nd Vo id ra tio o f C e me nt Ba se d

Ma te ria ls,, Jo urna l o f Ma rine

sc ie nc e a nd Te c hno lo g y, Vo l.8, No , 1.

Ra ym o nd W.N. C ha n d a n Eric h P.W C ha n. 1999, Using Admixture s fo r

C o nc re te C o nstruc tio n, Jo urna l o f

Ma te ria ls Eng ine e ring , ASC E.

Sup a rto no , F.X, 1999, Ra nc a ng a n C a mp ura n Be to n Mutu Ting g i Be rda sa rka n Rumusa n Ab ra ms-FXS, Ind o c o nstruc tio n.

Tjo kro d im uljo , Ka rd iyo no . 1996, Te kno lo g i

Be to n, Jurusa n Te knik Sip il