FLEXURAL TEST OF UNTREATED ELAIS GUINEESIS

POLYMER COMPOSITES

Saiful Adli Bin Yaman

'fA

Bachelor of Engineering with Honours

455

(Mechanical Engineering and Manufacturing Systems)

5132

2006 2006

UNIVERSITI MALAYSIA SARA W AK

RI3a BORANG PENGESAHAN STATUS TESIS

Judul: FLEXURAL TEST OF UNTREATED ELAIS GUlNEESlS POLYMER COMPOSITES

SESI PENGAJIAN : 2005/2006

Saya SAIFUL ADLI BIN YAMAN

(HURUF BESAR)

mengaku membenarkan tesis* ini disimpan di Pusat Khidmat Maklumat Akademik, Universiti Malaysia Sarawak dengan syarat-syarat kegunaan seperti berikut:

I. Tesis adalah hakmilik Universiti Malaysia Sarawak.

2. Pusat Khidmat Maklumat Akademik, Universiti Malaysia Sarawak dibenarkan membuat salinan untuk tujuan pengajian sahaja.

3. Membuat pendigitan untuk membangunkan Pangkalan Data Kandungan Tempatan.

4. Pusat Khidmat Maklumat Akademik, Universiti Malaysia Sarawak dibenarkan membuat salinan tesis ini sebagai bahan pertukaran antara institusi pengajian tinggi.

5. ** Sila tandakan ( '" ) di kotak yang berkenaan.

D

SULIT (Mengandungi maklumat yang berdarjah keselamatari atau kepentingan Malaysia seperti yang termaktub di dalam AKTA RAHSIA RASMI 1972).D

TERHAD (Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasilbadan di mana penyelidikan dijalankan).TIDAK TERHAD

(TANDATANGAN PENULlS) Alamat tetap : NO.86 TAMAN SRI SENA 2 JALAN SEMARIANG 93050

KUCHING SARAW AK PUAN MAHSHURI YUSOF

Nama Penyelia

~

C_C_ __

Tarikh : _ _.J_

c

_

1_1_?---'-'O_-b

_

_ _ _ __

Tarikh :_

t-(----,b

{_

'

Catatan * Tesis dimaksudkan sebagai tesis bagi Ijazah Doktor Falsafah, Sarjana dan Sarjana Muda.

** Jika tesis ini SULIT atau TERHAD, sila lampirkan surat daripada pihak berkuasalorganisasi berkenaan dengan menyatakan sekali sebab dan tempoh tesis ini perlu dikelaskan sebagai SULIT dan TERHAD.

This Final Year Project attached here:

: Flexural Test of Untreated Elais Guineesis Polymer Composites

Title

Author's Name : Saiful Adli Bin Yaman Matric Number : 9191

Has been read and approved by:

Date

P.I<HIDMAT MAI<LUMAT AI<ADEMII< UNIMAS

1/111111 "IIIIII"

1111111111

1000165780

FLEXURAL TEST OF UNTREATED ELAIS GUINEESIS

POLYMER COMPOSITES

SAIFUL ADLI BIN YAM AN

This project is submitted in partial fulfillment of the requirements for the degree of Bachelor of Engineering with Honours

(Mechanical Eo.gineering & Manufacturing System}

Faculty of Engineering

UNIVERSITI MALAYSIA SARA W AK

2006

ACKNOWLEDGEMENT

I would like to express my gratitude to my supervisor, Madam Mahshuri Bt. Yusof for her guidance and advice to accomplish this final year project. Your support and kindness is greatly appreciated. I would like to thank to the mechanical laboratory technicians for their cooperation and valuable support. I also would like to thanks the Timber Research

Laboratory for their environment and facilities. All your cooperation is highly appreciated. Last but not least, a special thanks to my family for their continuous moral

support. Finally, thanks to my entire friend who have given advices and suggestions on completing this report. Thanks everyone.

!

ABSTRACT

The empty fruit bunch (EFB) fibre, natural fibre was combined with unsaturated polyester resin matrix, to produce advance structural composite. The composites were fabricated using random lamination with different fibre volume fraction of 40%, 50%, and 60%. An experimental investigation has been carried out to measure the behavior of empty fruit bunch (EFB) reinforced unsaturated polyester composites when subjected to flexure or three-point loading. A number of tests were carried out and the result was obtained according to the load deflections data. The largest fibre volume fraction demonstrates a high flexural stress and flexural modulus value.

ABSTRAK

Gentian yang diperolehi daripada hampas kelapa sawit teJah diperkukuhkan dengan resin poliester yang tidak tepu untuk menghasilkan komposit gentian semulajadi. Komposit ini telah dibuat dengan menggunakan campuran gentian secara ram bang, pada berIainan pecahan isipadu gentian, iaitu 40%, 50%, dan 60%. Eksperimen telahpun dijalankan bagi rnenentukan sifat-sifat komposit gentian kelapa sawit bersama poliester tidak tepu ini berdasarkan kepada ujian pelenturan atau ujian pada bebanan tiga titik. Sebilangan eksperimen telah dijalankan dan hasil eksperimen yang diperolehi adalah berdasarkan kepada data daya pemesongan. Pecahan isipadu gentian yang paling besar menunjukkan nilai tekanan dan modulus pelenturan yang paling tinggi.

j

l

Pusat Kbidmat MakJumal ~ademl UNlVERSJTI MALAYSlA SARAWAK.

LIST OF

CONTENTS

CONTENTS DEDICATION ACKNOWLEDMENTS ABSTRACT LIST OF CONTENT LIST OF TABLE LIST OF FIGURE NOMENCLATURE CBAPTERONE INTRODUCTION 1.1 Introduction1.2 Scope and Objective

PAGE 11 iii v IX XI Xlll 2 v

CHAPTER TWO

LITERATURE REVIEW

2.1 Natural Fibres

2.2 Polymers Matrix Composite 2.2.1 Thermosets

2.2.2 Unsaturated Polyester Resins 2.3 Flexural Testing

2.3.1 Flexural Test Usages and Advantages 2.3.2 Testing Configuration (ASTM 0790) 2.3.3 Flexural Properties 2.3.3.1 Stress-Strain Behavior 2.3.3.2 Flexural Strength 2.3.3.3 Flexural Modulus 2.3.3.4 Failure Modes

CHAPTER THREE

METHODOLOGY

3.1 3.2 3.3 Introduction Fibre Extraction Fibre Volume Fraction3 4 5 6 8 9 10 12 13 18 22 25 27 27 29 VI

l

r

3.4 Composite Specimen Production

3.5 Specimen Dimension and Testing Configuration (ASTM 0790)

CHAPTER FOUR

RESULT AND DISCUSSION

4.1 Introduction

4.2 Loads at Break and Deflection

4.3 Deflection at Break

4.4 Loads, deflection, and Strain at Yield

4.5 Stresses at Break 4.6 Stress-Strain 4.7 Flexural Properties

4.8 Flexure Failure

CHAPTER FIVE

CONCLUSION AND RECOMMENDATION

5.1 Conclusion 5.2 Recommendation VII

j

29 31 36 37 38 39 41 42 44 45 47 4951

54 REFERENCES

APPENDICES

LIST OF TABLE

Table Page

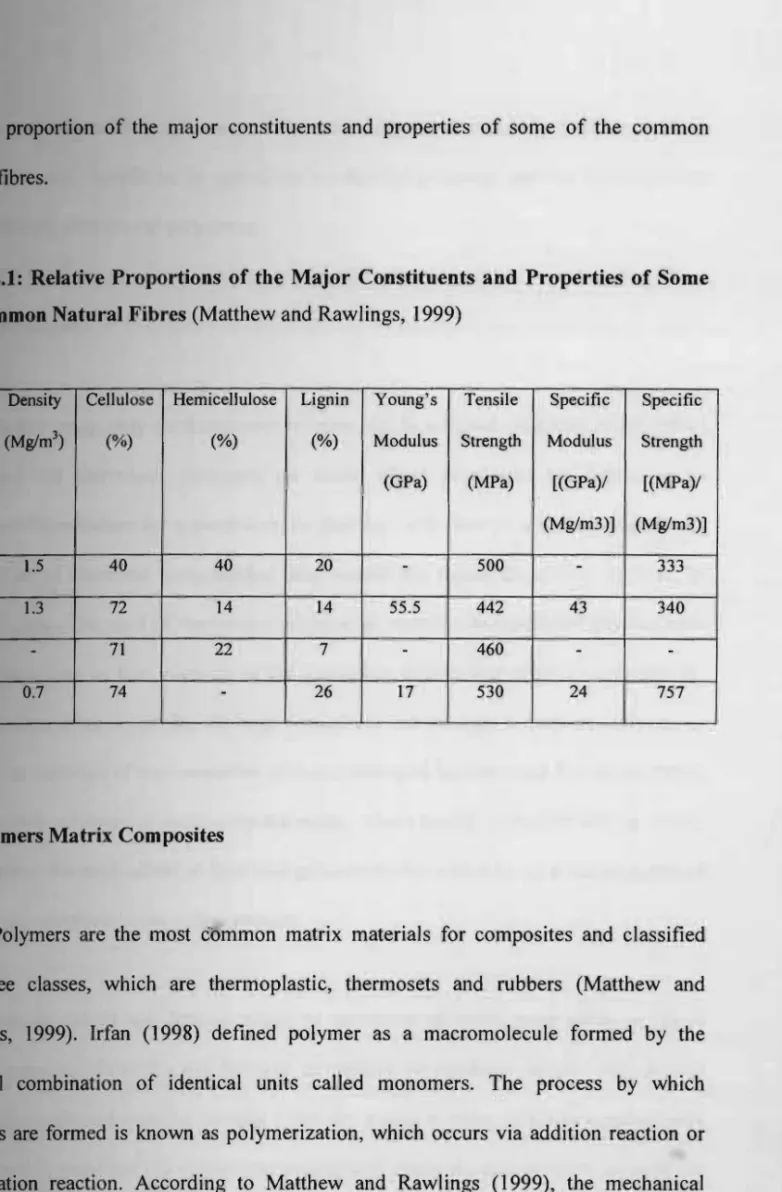

2.1 Relative Proportions of the Major Constituents and 4 Properties of Some the Common Natural Fibres

3.1 Possibilities for Dimensional, Support & Loading 32 Nose Radii, Span-to-Thickness Ratios & Loading

Rate for Flexure Specimens in Several Specifications

3.2 Dimensions and Testing Configuration of Random Orientation 33 for Flexure Test as specified by ASTM 0790

4.1 Result Summaries of Load, Deflection, and Strain at Yield 40 5. J Flexural Properties of 40%,50%, and 60% Fibre Volume Fraction 48

5.

2

Mechanical Properties of 40%,50%, and 60% Fibre Volume Fraction . 48 Al Collected Experimental Data and Stress Value for 40% Fibre 54Volume Fraction

A2 Collected Experimental Data and Stress Value for 50% Fibre 55 Volume Fraction

A3 Collected Experimental Data and Stress Value for 60% Fibre 55 Volume Fraction

BI

Collected Experimental Data and Modulus Value for 40% Fibre 56 Volume Fraction82 Collected Experimental Data and Stress Value for 50% Fibre 57

Volume Fraction

83 Collected Experimental Data and Stress Value for 60% Fibre 57

Volume Fraction

LIST OF FIGURE

Figure Page

2.1 Three-Point Flexure Loading Configuration

to

2.2 Normal Stress

«(J'

xx) Distribution in Various Layers of 13(a) [90/0/ (90)60/90] and (b) [0°/90°/ (0°) J90 0/0 0]

2.3 Variation in Normal Stress and Shear Stress in a Flexure Test 14 2.4 Stress in a Beam Subjected To Three-Point Flexure 16 2.5 Three-Point Flexure Test Shear Force and Bending Moment 17

Diagrams

2.6 Flexural Stress-Strain Response of [Oh2 CarbonlEpoxy Test 20 Specimen

2.7 Face Involved in Bending a Simple Beam 21

2.8 Load Deflection Diagrams for Various 0° Unidirectional 24

~.

Laminates in Three-Point Flexure Tests

2.9 Schematic of Possible Failure Modes in Three-Point Flexure 26 Tests

3.1 The Empty Fruit Bunch (EFB) Fibres 28

3.2 The Composite Specimen Surface after the Hot Pressing and 30 Hot Curing

3.3 The Test Specimen Cut from Composite Board 31

3.4 Schematic Diagram of Rectangular Test Specimen 33 Dimension as Described in ASTM 0790

3.5 Testometric Machine 34

3.6 The Three point Bending Heads with The Adjustable Span 34 for Flexure Test

4.1 Load Deflection Curves of 40%, 50%, and 60% EFB 37 Reinforced Unsaturated Polyester Composite

4.2 Stress Break of Random Laminated EFB Unsaturated 40 Polye ter Composite

4.3 Stress-Strain Curves of 40%, 50%, and 60% EFB-Reinforced 42 Unsaturated Polyester Composite

4.4 Flexural Stress and Flexural Modulus of Random Laminated 43 EFB Composites

4.5 The Flexure Failure of Random EFB-Reinforced Unsaturated 46 Polyester Composite

NOMENCLATURE

b pecimen width

D Deflection of the beam

Er Flexural modulus Fs Shear force h Thickness L Span length m Initial slope M Bending moment N Newton p ForcelLoad pr Fibre density

Pm

Fibre matrixVr

Fibre volume fraction...

Wr

Fibre weight Wm Matrix weight 0 Centre deflection t Shear stress (J Normal stress xiiiCHAPTER!

INTRODUCTION

1.1 Introduction

There are various kinds of natural fibres that suitable and easily can be found, such as wool, silk, cotton, hemp, jute, sisal, and flax. All these fibres are in fact comes from animal or plant product, which are widely used for textiles, twine, rope and clothes nowadays.

The natural fibres from the local plant will be extracted and used in this study. The oil palm crop waste is the type of plant that has been identified as a potential fibre for particle reinforced composite. ··Oil palm, or its scientific name Elais guineensis, is originated from West Africa and introduced to Malaysia in 1987 as an ornamental plant (Gurmit et. all 1999). The oil palm empty fibre bunch (EFB) is the one of the fibre sources from the oil palm crops that will be used in this study. These empty fruit bunches are obtained at first stages of the milling process and the strand from the empty fruit bunches are preferred because it can be obtained during regular harvest and oil palm processing.

According to Sirim Berhad Malaysia, the empty fruit fibres (EFB) was identified as the first series of standards on oil palm fibres because the EFB has the highest fibre yields and is the only material commercially utilised for fibre extraction. Compare with the other fibres from other wood species, the EFB fibres are characteristically compatible,

clean and biodegradable. These EFB fibres are suitable for the manufacture of mattress, insulation, particleboard, car seat, and composite panel product.

1.2 Scopes and Objective

Objectively, the flexural test is a test method for measuring behaviour of materials that subjected to three-point loading. To perform the flexural test in this study, the untreated Elais guineensis were used as a materials test specimen. The fibres from Elais

guineensis or specifically known as oil palm empty fruit bunch (EFB) are extracted

through a few processes before performing the flexural test without treated them with chemical solution. To achieve the objective mentioned before, ASTM D790-00 will be utilized to obtain the data regarding to flexural test properties of these natural fibres reinforced polymer composites.

CHAPTER 2

LITERATURE REVIEW

2.1 Natural Fibres

According to Ghosh (2004), the natural fibres are basically classified into three

groups of their origin: vegetable origin, animal or insect origin, and mineral origin.

Among these, natural fibres are important in terms of production volume, industrial

activity, and usage patterns. The fibres that were used in this study were the natural fibres

ofthe local plant; oil palm empty fruit bunch (EFB) fibres.

The EFB fibres that were used in this study are the natural structure made of

cellulose fibres. The strands of cellulose fibres in different plants are associated with

different amounts of other natural substances such as hemicelluloses, lignin, pectinous

matter, waxes, and gums (Ghosh, 2004). According to Matthew and Rawlings (1999),

the fibres extracted from plants are essentially micro-composites consisting of cellulose

fibres in an amorphous matrix of lignin and hemicelluloses and often have a high length

to diameter ratio, called the aspect ratio, of greater than 1000. Table 2.1 shows the

relative proportion of the major constituents and properties of some of the common

natural

fibres.Table

2.1: Relative Proportions of the Major Constituents and Properties of SomeCommon Natural Fibres (Matthew and Rawlings, 1999)

Density Cellulose Hemicellulose Lignin Young's Tensile Specific Specific

(Mglm3) (%) (%) (%) Modulus Strength Modulus Strength

(GPa) (MPa) [(GPa)/ [(MPa)/

I (Mg/m3)] (Mglm3)] Wood 1.5 40 40 20

-

500-

333 Jute 1.3 72 14 14 55.5 442 43 340 Hemp-

71 22 I 7-

460-

-I

Sisal 0.7 74-

26 17 530 'I 24 7572.2 Polymers Matrix Composites

Polymers are the most common matrix materials for composites and classified

into three classes, which are thermoplastic, thermosets and rubbers (Matthew and

Rawlings, 1999). lrfan (1998) defined polymer as a macromolecule formed by the

chemical combination of identical units called monomers. The process by which

polymers are formed is known as polymerization, which occurs via addition reaction or

condensation reaction. According to Matthew and Rawlings (1999), the mechanical

properties of polymers are generally inadequate for many structural purposes. The

strength and stiffness of polymers are lower than metals and ceramics. This means there

is

B considerable benefit to be gained by reinforcing polymers and the reinforcementwithout having exceptional properties.

%.2.1

ThermosetsIn this study, only the thermosets polymer will be adopted. McGrum et. al. (1997)

mentioned that thermosets polymers are those whose precursors are heated to an

appropriate temperature for a short time, so that they will flow as a viscous liquid with

the reaction of chemical cross-linking then causes the liquid to solidifY to form an

infusible mass. The used of thermosets polymer as matrices in reinforced plastics have

some reason such as low viscosity at the precursors liquids that prior to cross-linking.

Economical forming is possible for large component and the high softening points can be

achieved in materials of only moderate cost. According to Matthew and Rawlings (1999),

thennosetting polymers or thermosets are resins, which readily cross-link during curing.

Furthermore, the application of heat and pressure or the additions of a curing agent or

hardener are involved in the curing,process.

Harper (2000) has defined reSInS as any class of solid, semi solid, or liquid

organic material, generally the product of natural or synthetic origin with a high

molecular weight and with no melting point. By gluing bundles of fibres together with

resin matrices, materials are made were strong, stiff fibres are able to carry most of the

stress whilst the matrix distributes the external load to all fibres as well as affording

According

protection and preventing fibre buckling under compressive forces (Hollaway, 1994).

to Harper (2000), the important beneficial factor lies in the inherent

enhancement of thermoset resins is in their physical, electrical, thermal, and chemical

properties when they are exposed to severe environmental conditions. There is various

kind of thermosets resin

such as epoxies, polyester, phenolics, polyurethanes, polyimides,bismaleimides and vinyl ester. Only the unsaturated polyester resin will be used for fibre

reinforcement polymer in this study.

2.2.2 Unsaturated Polyester Resins

Historically, the first polyester product produced by reacting tartaric acid with

glycerol in 1847 and then prepared with well-defined polymeric structure in 1920. The

commercial application of unsaturated polyester was made in 1941 and like many other

fields of research and development, the development of polyester accelerated during and

after the Second World War (Irfan, 1998). The thermosets polyester has been the most

popular family of polymers for many years. This polyester is versatile, inexpensive, used

extensively with glass fibre rejpforcement and often in substantial plastic component (McGrum et. al 1997).

According to McGrum et. al (1997), thermosetting polyester is derived from the

condensation effects of combining an unsaturated maleic anhydride or fumaric acid with

a polyhdric alcohol. When utilised as a molding compound, this unsaturated polyester

resin is dissolved in a cross linking monomer such as styrene with the addition of an

inhibitor such as phenolic derivatives to prevent cross linking until the compound is

ready for use in the molding process. The compounds are further enhanced with additives

and

use the free radical addition to polymerize the resin. The catalyst such as benzoylpen> ide and methylethyl ketone peroxide becomes the source for the free radical and

with

elevated temperature the heat decomposes the peroxide, producing free radicals.Irfan (1998) has stated that the cross linking of unsaturated polyester occurs via

free

radical polymerisation, after addition of vinyl monomer such styrene and catalyst.The catalyst is added in concentrations of 0.5%-2.0% to initiate formation of free

radicals, the amount depending on the temperature and the type of catalyst. In order to

obtain a high quality product, it is desirable that the styrene and fumerate radicals react

either alternately or in the proportion existing before cross-linking occurs. In

commercially available unsaturated polyester, 30% styrene or vinyl monomer is present.

The

curing reaction converts the viscous resin to a hard thermoset within a few hours. Inthe absence accelerator, oxygen in the air has an inhibiting effect on the curing process,

resulting in a softer surface on the product, despite the hardening of the inner portion.

The use of accelerator such as cobalt naphthenate eliminates such an effect.

Hollaway (1994) stated that the polyester resins are cured via a free radical co

polymerisation reaction, which can be initiated at room temperature with the organic

peroxides, by heat or radiation, such as ultra violet and visible light.

It

is able to cold-curepolyester resins from liquid that makes them more suitable than any other resin system

for the manufacture of very large structures. The catalyst system consists of organic