Preliminary results of tests facing with the controlled retting

of hemp

M. Di Candilo

a, P. Ranalli

a,*, C. Bozzi

b, B. Focher

b, G. Mastromei

caIstituto Sperimentale per le Colture Industriali,Via di Corticella,133-40129Bologna,Italy bStazione Sperimentale Cellulosa,Carta,Fibre tessili

6egetali ed artificiali,Piazza L.da Vinci,26-20133Milano,Italy

cDipartimento di Biologia Animale e Genetica,Uni

6ersita` di Firenze,Via Romana,17-50125Firenze,Italy

Accepted 8 October 1999

Abstract

An important component of the implementation of the hemp crop management is the microbiological retting of the straw. At the Experimental Institute for Industrial Crops, research has been focused on this topic and in 1997 trials of retting performed in tanks placed in the laboratory or in open field were carried out. Cultivar ‘Fibranova’ was employed, harvested at the time of full flowering. For the laboratory tests, 12 plastic tanks containing well water were used. One of these was taken as the control and each of the remaining 11 tanks were inoculated with different strains ofClostridium felsineum. Four different retting times were experienced (3, 6, 9 and 12 days). The fibre was assessed for the morphological, chemical and physico-mechanical properties. The retting in open field was performed in four concrete tanks; (1) in pond water in an open tank, (2) in pond water in a tank covered with a transparent plastic film (to raise the temperature of the water), (3) in well water in an open tank and with the addition of a culture ofC.

felsineum, and (4) in well water in an open tank, without the addition ofC.felsineum. Six increasing retting durations were adopted (2, 4, 6, 8, 10 and 12 days). The fibre obtained was evaluated taking into account colour, softness and fineness. The results obtained indicated that the water type, the temperature of retting water and the bacterial inoculum all influenced the duration of the process and the quality of the fibre. Retting was completed in 6 days in pond water and in 12 days in well water. Raising the temperature of water from 24 to 28°C reduced the duration of the process from 6 to 4 days. It was found that the bacterial strains ‘L1 – 6’ and ‘C1 – 6’ ofC.felsineumreduced the duration of the retting process from 12 to 6 days (with a water temperature of 20°C), leading to a clearer, softer and finer fibre. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Hemp; Retting;Clostridium felsineum; Bacterial strain; Fibre quality

www.elsevier.com/locate/indcrop

1. Introduction

One of the main reasons for the decline of hemp-cultivation in Italy is because it is labour intensive, particularly the retting process. The tra-ditional manner of water retting involves pulling

* Corresponding author. Tel.:+39-51-631-6811; fax:+ 39-51-631-6847.

E-mail address:[email protected] (P. Ranalli)

the hemp by hand or machine, tying it into sheaves and soaking it in retting tanks filled with water for a period of up to 14 days. During water retting, naturally occurring organisms, predomi-nantly Clostridia species, break down the pectic compounds of the middle lamellae binding the plant cells together (Avrova, 1975; Donaghy et al., 1990). When the optimum degree of retting has been achieved the fibre can readily be ex-tracted from the partly decomposed straw by the scutching process after the straw has been dried. Hemp required between 1300 and 1350 h per hectare, therefore, its cultivation was coupled with the existence of large patriarchal families, capable of withstanding the labour of harvesting, retting and scutching (Bignardi, 1987).

Attempts at reintroducing hemp-growing are based on finding an alternative to this traditional water retting. In addition it is essential to fully mechanise all the operations involved, with partic-ular emphasis on harvesting, and on the

introduc-tion of industrial retting. In other words, the cultivation stage should end with the harvesting of the straw or with the green decortication. The product thus obtained should then be delivered to the industrial unit of retting.

The development of a flexible processing unit must include industrial retting facilities, able to serve all the growers in the area. Moreover, at this level, hemp could be processed alongside flax, by setting up retting systems using the same struc-tures, with the appropriate technical adjustments for each species (Ranalli and Casarini, 1997). Due to the seasonal variation in supply, a highly or-ganised logistic chain needs to be set-up.

On the basis of these considerations, as part of the research project ‘‘Induction of Phenotypic Markers and Improvement of Common Hemp’’ granted by Ministry of Agricultural Policies, ret-ting experiments were carried out using water from different origins, with and without the addi-tion of micro-organisms in order to (1) reduce the

Table 1

Retting in tanks in the laboratory, supplemented with different strains ofC.felsineum; retting times, fibre softness, fineness and coloura

Fibre softness Retting time

Retting treat- Water temperature Fibre fineness Fibre colour

(days)

C.felsineum 0.037 b

C1–6

4.0 b 0.062 a

Control 20.2 12 Grey

aMeans followed by different letters in each column are significantly different forP50.01 (Duncan’s test). bS, visual scores (1–5).

Table 2

Retting in tanks in open field; retting times, fibre softness and coloura

Fibre softness (S)b

Retting treatment Water temperature (°C) Retting time (days) Fibre colour

In pond water:

4

28.2 5.0 a

In covered tank Ivory white

In open tank 24.1 6 5.0 a Ivory white

In well water:

24.0 10 4.0 b Grey

Supplemented withC.felsineum

24.0 12

Not supplemented with microrganisms 4.0 b Grey

Fig. 1. Cross section micrography (×462) of hemp fibres (L1 – 6) after 3 (top) and 12 (bottom) days of retting.

Fig. 2. Cross section micrography (×2300) of hemp fibres (L1 – 6) after 3 (top) and 12 (bottom) days of retting.

duration of retting, (2) improve the quality of the fibre, (3) increase the possibility of controlling the retting process and thus obtaining a product with a constant quality, (4) reduce the cost of retting. This report provides results gained in the first trials of retting performed in 1997 in the open in special concrete tanks, and in the laboratory in small plastic tanks.

2. Materials and methods

2.1. Plant material

Hemp (Cannabis sati6a L. cv. Fibranova)

grown in Anzola E. (Bologna) was pulled :1

Table 3

Modulus, degree of polymerization and pentosans content of hemp samples after 3 and 12 days of retting in tanks supple-mented with different strains ofC.felsineum

DPv Pentosans (%)

Retting Modulus treatment (g/den)

L1–6/3 332 3050 4.90

380 2690 2.10

L1–6/12

282

C1–6/3 3085 3.52

326 1.74

C1–6/12 3054

4.28 3035 Control/3 206

285 3.69

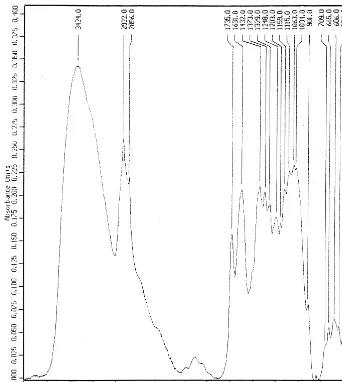

Fig. 3. FTIR spectra of hemp fibres (L1 – 6) after 3 days of retting.

week after the mid point of flowering. The green hemp was allowed to dry in the field until the straw moisture content was near 10% and then made into bales. After a period of 2 months

storage undercover indoors, the bales were

opened and used as experimental material.

2.2. Isolation of bacterial strains

With the aim to improve the hemp retting process, we concentrated our research on the identification ofClostridium felsineumstrains with high levels of pectinolytic activity. From different

pecti-nolytic activity higher than the reference strainC.

felsineum NCIMB 10690.

2.3. Retting in tanks in the laboratory

For the laboratory tests, 12 plastic tanks filled with well water were used. One of these was taken as the control. Each of the remaining 11 tanks

were inoculated with different strains of C.

felsineum anaerobic bacteria which are the main pectin degrading bacteria involved in water-ret-ting of hemp.

Each tank was filled with four bundles of stalks (each formed of four stems) and these were ex-tracted after 3, 6, 9 and 12 days of retting. After this operation, the stems were manually scutched and the fibre combed. Subsequently, the fibre was assessed for the morphological, chemical and physico-mechanical properties.

2.4. Retting in tanks in open field

Concrete tanks were buried in the soil. Retting was carried out submerging the dried stalks of plants cv Fibranova, harvested during full bloom. The following retting methods were com-pared:

1. in pond water in an open tank,

2. in pond water in a tank covered with a trans-parent plastic film (to raise the temperature of the water),

3. in well water in an open tank with the addition

of a culture of C. felsineum to the retting

liquor,

4. in well water in an open tank without the addition of micro-organisms to the retting liquor.

Six increasing retting times (2, 4, 6, 8, 10 and 12 days) were used for each tank, the aim being to compare the progress of the retting methods and establish the optimal retting time for each one.

When the hemp was extracted from the tanks, the stalks were rinsed then dried in the open air. The fibre was extracted from the stalks by

scutch-ing. These samples were evaluated taking

into account the characteristics as in the previous test.

2.5. Morphological, chemical and physico-mechanical properties

The fibre bundle samples obtained from both experiments were evaluated taking into account the colour, the degree of separation of the fibres and the softness of the fibre. The fineness of the fibre was also assessed according to the weight/

length ratio.

For Scanning Electron Microscopy (SEM), the fibre was prepared by making cross sections of a Teflon tube filled with fibre bundles. The sections were sputter-coated with gold under vacuum and scanned using a Philips 515 SEM operated at 9.0 – 12.5 kV.

Fourier-transform infrared spectroscopy

(FTIR) spectra were performed with a Bruker IFS 66-FTIR spectrometer on samples dispersed in KBr pellets. For each sample, 32 scans were accu-mulated with a resolution of 4 cm−1.

Pentosans content was determined according to the TAPPI T 223 hm 84 methods. The degree of cellulose polymerization (DPv) was determined in

cupriethylenediamine (CED) after delignifying the material with sodium chlorite according to UNI 8282.

Fibre modulus — the tensile properties of se-lected technical fibres were determined with an Instron 1122 (load cell 19.6 N) at the cross-head

speed of 5 mm/min with a temperature of 209

2°C and a relative humidity of 6592%.

The modulus (g/den) was measured by the

slope of the stress – strain curves taking the dis-tance between grips as the gauge length (10 cm).

Technological fibres, previously conditioned

(2092°C and 6592% R.H.) and weighed, were

used. A minimum of 50 measurements were taken for each sample.

3. Results and discussion

3.1. Retting in tanks in the laboratory

temperature (20°C), degrade the non-cellulosic polysaccharides (pectic compounds of the middle lamellae) and the bark could be extracted from the woody core in only 3 days, thus giving an optimal degree of retting within 6 days. The other strains gave results which fell halfway between the two mentioned above and the control, and the retting took place at the 12th day only (Table 1).

Scutching was easier with the stems retted with the addition of the bacterial strains ‘L1 – 6’ and ‘C1 – 6’ than with the control and led to lighter, softer and finer fibre (Table 1).

3.2. Retting in tanks in open field

Retting was much faster in pond water and especially in the tank covered with transparent plastic film, where the average water temperature was 4°C higher than in the open tanks (28 versus 24°C). Retting was achieved (1) in 4 days in the covered tank and in 6 days in the uncovered tank, both filled with pond water, (2) in 10 days in the

tank containing well water inoculated with C.

felsineum, and (3) in 12 days in well water without inoculum (Table 2).

Retting in well water with the addition of bac-teria was very similar to that of the control, probably because the inoculum was prepared us-ing a mixture of two uncharacterisedC.felsineum, since the strain described in the tank laboratory experiment were not yet available when the open field experiment was performed.

As far as quality is concerned, it should be pointed out that the fibre obtained with retting in pond water were markedly lighter and softer than those obtained with well water. The latter, despite the longer retting time, were coarser and rather rough, opaque and darker in colour (Table 2).

3.3. Morphological, chemical and physico-mechanical properties

The SEM micrographs of the cross sections of hemp fibre after different retting treatments showed no significant differences. At the lowest magnification (×462) the cross sections of the

hemp samples (Fig. 1) retted for different times (3 – 12 days) showed that the cortical fibres are multiple cellular systems found as aggregates (bundles) of single cells, called ‘ultimates’ or ‘ele-mentary fibre’ that are bound by pectin sub-stances (Centola, 1954; Garcia-Jaldon, 1997). For long retting times the samples showed fibre bun-dles with small numbers of ‘ultimates’.

At higher magnification (×2300; Fig. 2) the same sample shows that the hemp elementary fibre has a large average diameter and a greater variation in diameter (diameter 10 – 50 mm, i.e. an

average of 18 – 23 mm).

The physico-mechanical data suggest that ret-ting the sample in water containing a bacterial strain resulted in higher modulus values than retting in plain water (Table 3). The sample treated with the bacterial strain ‘L1 – 6’ showed the highest values. In fact the higher the modulus values the higher is the cellulose content in the fibre, thus increasing the time of retting increases the modulus of the samples. The lignocellulose fibres are polymer composite systems made up mostly of cellulose, hemicellulose and lignin, and there is not a clear relation between their tensile properties, the morphological structure and chem-ical composition (Rials and Wolcott, 1997). Moreover the experimental conditions, above all the cross-head speed, can strongly modify the tenacity values.

The FTIR data confirmed the strong activity of the bacterial strain ‘L1 – 6’. The signal intensity at

1734 cm−1 (Rau, 1963; Garcia-Jaldon, 1997) of

the non-cellulosic components (hemicellulose es-ters and pectic substances), normalized with the internal standard at 2916 cm−1(as), of the sample

subjected to 12 days of retting, was remarkably less than after 3 days (Fig. 3). The signal intensity

at 1373 cm−1

Furthermore the degree of polymerization (DPv) (Table 3) data are in agreement, confirming

the higher activity of the ‘L1 – 6’ bacterial strain.

4. Conclusions

Besides crop improvement and fibre extraction, processing into the final product further affects the performance of the fibre. Understanding the relation between the properties of a raw material and its production process is fundamental to the improvement of quality. The different stages of the production process have their influence on the end-product price and performance. The whole chain approach is necessary to be able to see where the most promising improvements can be made at the lowest costs. When, for example, fineness is an issue for the application of a fibre, genetic improvements may not yield the necessary results, when no adequate fibre extraction tech-nology is available. The production costs may become too high for a specific end-use even if the qualitative criteria are met. On the other hand, if an efficient fibre processing technology can be developed, which substantially upgrades the fibre quality for a specific end-use, irrespective of the variable properties of the input raw material, all the efforts for crop improvement are in vain.

The first indications obtained, besides confirm-ing the validity of rettconfirm-ing in water, also revealed the possibility of improving the technique, espe-cially by inoculating the retting liquor with bacte-ria capable of high biodegradation of pectic material. The use of bacterial strains specifically selected and the use of more suitable temperatures (without high energy costs) would certainly con-tribute to a marked reduction in the time required for retting and also standardise the process, ensur-ing a more constant product quality.

Imported products (especially from China) are criticised for the variability within and between the lots. On the other hand, the production costs

in Asian countries are very low, therefore quality is the key to making our product competitive.

Acknowledgements

Study performed within the Hemp research project of the Italian Ministry of Agricultural Policy.

References

Avrova, N.P., 1975. Synthesis of pectinolytic enzymes by Clostridium felsineum and their hydrolysis of the pectic substances of flax straw. Appl. Biochem. Microbiol. 9, 648 – 652.

Benedetti, R., Ciarrocca, R., Ciaralli, N., 1979. Chemicals characteristics of 7 hemp varieties. Cellul. Carta 30, 25. Bignardi, A., 1987. La canapa. Agrimont, p. 125.

Centola, G., 1954. L’influence du rouissage sur les proprie´te´s chimico-physiques de la fibre de chanvre. Teintex 19, 241. Donaghy, J.A., Levett, P.N., Haylock, R.W., 1990. Changes in microbial populations during anaerobic flax retting. J. Appl. Microbiol. 69, 634 – 641.

Garcia-Jaldon, C., 1997. Caracterisation morphologique et chimique du chanvre (Cannabis sati6a). Pretraitment a la Vapeur et Valorisation. These Universite Joseph Fourier-Grenoble I (Specialite: Chimie).

Lu¨dtke, M., 1955. U8ber die chemischen komponenten einiger bastfasern und ihre beziehungen zueinander. Meilland 40, 763.

Miller, G.L., 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426 – 428.

Petrescu, A., Nagy, G., Bugeac, H., 1979. Posibilitati de extindere a domeniilor de folesire a fibrei de cıˆnepa prin valorificare superiora. Text. Tricot. Confect. Text. 30, 480 – 484.

Ranalli, P., Casarini, B., 1997. La canapa: il ritorno di una coltura prestigiosa. L’Inf. Agrar. 39, 55 – 62.

Rau, J.H., 1963. Die infrarot-spektren der Textilfasern II/ Zel-lulosefasern. Meilliand Text. 44, 1197.

Rials, T.G., Wolcott, M.P., 1997. In: Rowell, R.M., Young, R.A., Rowell, J.K. (Eds.), Paper and Composites from Agro-Based Resources. Lewis, pp. 63 – 82.

Schliefer, K., 1975. Cellulosefasern, natu¨rliche. In: Hernst, B., Heinrich, H. (Eds.), Ulmmanns Encykl. Tech. Chem, 9, pp. 247 – 253.