!"#$%&'(#)*#+*,-.'#/#.(0#1-&&2-"($31*+"#,*&-11-4-*&%.'(4-"*

KUNING

Nanik Rahmani, Ade Andriani, Yopi and Sri Hartati

Research Center for Biotechnology, Indonesian Institute of Sciences (LIPI) Jl. Raya Bogor Km. 46, Cibinong, Bogor 16911, Indonesia

Phone (021) 8754587/Fax (021) 8754588

!"#$%&'()*+,%-)$.**/0*#

(Diterima 20-02-2015; Disetujui 30-11-2015)

ABSTRACT

Characteristic the physic-chemical of Indonesia cassava starch from four cultivated varieties has been conducted for maltooligosaccharide production. Result of proximate analysis of the extracted starch indicated that the extracted starch was quite pure. The purity of the

!"#$%&#!'()#%$&*(+%)(,-).%//0(&123$4!'(50(4-&$1)&16-&(%2%/0)-)(50(.)-27(89:(4-&$17$%6*)(%#(;<==>(4%72-3&%#-12)()*1+(#*%#(#*!(

integrity of the granules starch as intact. Based on the amylopectin and amylase content showed that one of cultivated variety of cassava, cultivated variety Kuning contain the amylopectin higher than amylase was compared with the other cultivated variety. The next focus research was analysis potential of starch from cultivated variety Kuning for maltooligosaccharide production by enzymatic

*0'$1/0)-)(50(?@%40/%)!(A$14(4%$-2!(5%&#!$-.4(Brevibacterium sp. The optimum hydrolysis condition for cultivated variety Kuning was obtained substrate concentration 4.5% (b/v), comparison of substrate: enzyme 1:2, temperature reaction 30oC with reducing sugars concentration of 13.359 ppm. The hydrolysis products of cassava starch cultivated variety Kuning were maltooligosaccharides mixture, yielding maltose, maltotriose, maltotetraose, maltopentaose. This result showed that cassava starch of cultivated varieties Kuning potential for maltooligosaccharides production.

Key words: Tuber, cassava, starch, phisic-chemical, maltooligosaccharides

ABSTRAK

Nanik Rahmani, Ade Andriani, Yopi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning.

B%$%C#!$-)#-C(3)-C1(C-4-%(C%$51*-'$%#('%$-(!46%#(,%$-!#%)(C./#-,%$(%)%/(D2'12!)-%('-/%C.C%2(.2#.C(4!/-*%#(61#!2)-20%()!5%7%-(5%*%2(

baku untuk produksi maltooligosakarida. Analisa proksimat karbohidrat hasil ekstraksi dari keempat varietas kultivar ubi kayu

4!27-2'-C%)-C%2(5%*+%(C%$51*-'$%#(0%27('-*%)-/C%2(&.C.6(4.$2-E(B!4.$2-%2('%$-(C%$51*-'$%#(#!$)!5.#(#!$/-*%#()!#!/%*('-C123$4%)-(

dengan analisa mikrokospis dengan menggunakan mikroskop electron SEM dengan pembesaran 2500X yang menunjukkan bahwa granulanya utuh. Berdasarkan kadar amilopektin dan amilosa menunjukkan bahwa salah satu varietas kultivar ubi kayu yaitu varietas Kuning mengandung amilopektin lebih tinggi dibandingkan kadar amilosanya jika dibandingkan dengan tiga varietas kultivar lainnya. Fokus penelitian selanjutnya adalah analisa potensi karbohidrat varietas kultivar Kuning tersebut untuk produksi maltooligosakarida dengan hidrolisis enzimatis oleh 1"$#)&$2!(dari Brevibacterium sp. Kondisi optimum hidrolisis dari varietas kultivar Kuning diperoleh pada konsentrasi substrat 4.5% (b/v), perbandingan substrat dan enzim 1:2, suhu reaksi 30oC dengan kadar gula reduksi yang diperoleh 13.359 ppm. Produk hidrolisis dari ubi kayu varietas kultivar Kuning adalah berupa campuran maltooligosakarida yang terdiri atas maltose, maltotriose, maltotetraose, maltopentaose. Hasil ini menunjukkan bahwa karbohidrat ubi kayu dari varietas kultivar Kuning mempunyai potensi untuk digunakan sebagai bahan baku untuk produksi maltooligosakarida.

Kata kunciF(.45-@.45-%2G(.5-(C%0.G(C%$51*-'$%#G(3)-C1(C-4-%G(4%/#11/-71)%C%$-'%

Hak cipta © 2015 BB-Pascapanen

four cultivated four cultivated starch indicated that indicated%2%/0)-)(50(.)-27(

%2%/0)-)(50(.)-27( amylopectin amylopectin amylopectin higher amylopectin higher of starch from cultivated of starch from cultivated

Brevibacterium Brevibacterium (b/v), comparison (b/v), comparison hydrolysis products hydrolysis products

otetraose, maltopentaose. otetraose, maltopentaose. potential for maltooligosaccharides production.

potential for maltooligosaccharides production.

, cassava, starch, phisic-chemical, maltooligosaccharides , cassava, starch, phisic-chemical, maltooligosaccharides

Andriani,

Kampus Penelitian Pertanian Cimanggu

cultivated varieties cultivated varietiested that the extracted ted that the extracted

.)-27(89:(4-&$17$%6*)(

.)-27(89:( amylopectin and amylase amylopectin and amylase higher than amylase higher than amylase

of starch from cultivated variety Kuning for maltooligosaccharide of starch from cultivated variety Kuning for maltooligosaccharide

evibacterium evibacterium sp. The sp. comparison of substrate: comparison of substrate: products of cassava products of cassava

maltopentaose. maltopentaose. potential for maltooligosaccharides production.

potential for maltooligosaccharides production.

, cassava, starch, phisic-chemical, maltooligosaccharides , cassava, starch, phisic-chemical, maltooligosaccharides

Andriani, Yopi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning. Andriani, Yopi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning.

C-4-%(C%$51*-'$%#(

C-4-%(C%$51*-'$%#(

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

varieties has beenvarieties has been extracted starch extracted

89:(4-&$17$%6*)(4-&$17$%6*)( amylase content amylase content amylase was amylase was

variety Kuning for maltooligosaccharide variety Kuning for maltooligosaccharide sp. The optimum

sp. The optimum of substrate: enzyme substrate: cassava starch cultivated cassava starch

maltopentaose. This result maltopentaose. This result

, cassava, starch, phisic-chemical, maltooligosaccharides , cassava, starch, phisic-chemical, maltooligosaccharides

opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning. opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning.

C%$51*-'$%#(

C%$51*-'$%#( maltooligosakarida. maltooligosakarida.

5%*+%(C%$51*-'$%#(

5%*+%(C%$51*-'$%#( mikrokospis mikrokospis utuh. Berdasarkan utuh. Berdasarkan mengandung mengandung Fokus penelitian selanjutnya Fokus penelitian

dengan hidrolisis dengan hidrolisis pada konsentrasi pada konsentrasi 13.359 ppm. 13.359

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

been conductedbeen conducted extracted starch was starch was

4-&$17$%6*)(%#(;<==>(

4-&$17$%6*)(%#(;<==>( content showed content showed was compared was compared

variety Kuning for maltooligosaccharide variety Kuning for maltooligosaccharide

optimum hydrolysis optimum hydrolysis substrate: enzyme 1:2, enzyme 1:2,

starch cultivated cultivated This result showed result showed

, cassava, starch, phisic-chemical, maltooligosaccharides , cassava, starch, phisic-chemical, maltooligosaccharides

opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning. opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning.

C%$51*-'$%#('%$-(!46%#(

C%$51*-'$%#('%$-(!46%#( maltooligosakarida. Analisa maltooligosakarida.

C%$51*-'$%#(0%27(

C%$51*-'$%#(0%27( mikrokospis dengan menggunakan mikrokospis dengan

Berdasarkan kadar Berdasarkan kadar mengandung amilopektin mengandung amilopektin penelitian selanjutnya selanjutnya

hidrolisis enzimatis hidrolisis enzimatis konsentrasi substrat konsentrasi substrat 13.359 ppm. Produk 13.359 ppm. Produk maltose, maltotriose, maltose, maltotriose,

mempunyai potensi untuk digunakan sebagai bahan baku untuk produksi maltooligosakarida. mempunyai potensi untuk digunakan sebagai bahan baku untuk produksi maltooligosakarida.

Kata kunci

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

conducted for maltooligo conducted for maltooligowas quite pure. was quite pure.

;<==>(4%72-3&%#-12)(

;<==>(4%72-3&%#-12)( showed that one

showed that compared with the compared with the variety Kuning for maltooligosaccharide variety Kuning for maltooligosaccharide

hydrolysis condition hydrolysis condition 1:2, temperature 1:2, temperature cultivated variety Kuning cultivated variety

showed that showed that

, cassava, starch, phisic-chemical, maltooligosaccharides , cassava, starch, phisic-chemical, maltooligosaccharides

ABSTRAK ABSTRAK

opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning. opi and Sri Hartati. 2015. Produksi maltooligosakarida dari ubi kayu varietas kuning.

!46%#(,%$-!#%)(

!46%#(,%$-!#%)( maltooligosakarida. Analisa proksimat maltooligosakarida. Analisa

0%27('-*%)-/C%2(

0%27('-*%)-/C%2( dengan menggunakan menggunakan

kadar amilopektin kadar amilopektin amilopektin lebih tinggi amilopektin lebih selanjutnya adalah selanjutnya adalah enzimatis oleh

enzimatis oleh 1"$#)&$2!( substrat 4.5%

INTRODUCTION

Tubers become one of the alternative source developments of carbohydrate than rice and maize. One of tuber groups is cassava (Manihot esculenta) that most popular especially at the most rural areas in Indonesia either consumed directly or as a main raw material (starch) in various industry. Indonesia is the fourth country which largest producer cassava in the world after Nigeria, Brazil and Thailand in 2010 1. Starch from cassava is the main ingredient in a number of industrial textiles, paper, pharmaceuticals and food.

The utilization and processing of tuber become foodstuffs depends on starch characteristic that contained in each of the tuber. There are many advantages of utilizing cassava for starch production. Cassava offers a relatively cheap source of raw material containing a high concentration of starch (dry matter basis) that can match or better the properties offered by other starches (maize. wheat, sweet potato and rice). Cassava starch is easy to extract using a simple process (when compared to other starches) that can be carried out on a small-scale with limited capital. In addition cassava starch has a high level of purity due to the low levels of proteins and lipids found in cassava roots2.

Today people are becoming more health conscious and they are looking for foods with special health-promoting functions. Oligosaccharides are attracting increasing interest as prebiotic functional food ingredients. They can be extracted or obtained by enzymatic hydrolysis from a variety of biomass sources or synthesized from simple oligosaccharides by enzymatic transfer reactions3. Analysis characteristics of physic-chemical of starch from cassava was important to develop processing of foodstuff product and its derivatives that potential for food functional application. Starch from tubers can be used as a material for maltooligosaccharides production. The use of cassava as a material for maltooligosaccharide production is one of the current challenges for increasing both of the value of cassava and human nutrition.

Maltooligosaccharides potential were used for functional food, such as symbiotic health-food products &12#%-2-27( 51#*( 6$15-1#-&( 5-3'15%&#!$-%( %2'( 6$!5-1#-&( maltooligosaccharides4,5. The purpose of this study is to determine the characteristic of physico-chemical of Indonesia cassava starch from four varieties cultivar (FEC 25, Adira I, Kuning and Roti) and analysis their potential for maltooligosaccharide productions.

METODOLOGY

,567895:;

Samples of cassava which harvested in nine months were provided by Laboratory of Plant Molecular Genetics and Biosynthetic Pathway Alteration, Research Center for Biotechnology-LIPI.

,76<=>;

Starch extraction

The starch was extracted through the stages of the process, such as stripping, washing, grater, extraction, 3/#$%#-12G( 6$!&-6-#%#-12G( '$0-27G( %2'( )-!,-27E( H$!)*( cassava tuber from four varieties cultivar were peeled and washed by using manually to clean tubers from soil and the other dirt. The tuber was shredded using grater machine and then starch extracted by added water with a ratio of material and water was 3.5: 1. Furthermore, #*!( 3/#!$-27( *%)( 5!!2( '12!( #1( )!6%$%#!( #*!( )#%$&*( A$14( the residue. Residue obtained from the screening process again extracted 5 times with the same ratio of the water addition and precipitation on night. After precipitation, the supernatant were removed until the only remaining part of the wet starch deposition. Furthermore, drying starch obtained using the sun. Starches continue were crushed with mortar and then continue to the sifting 6$1&!))( #1( 15#%-2( %( .2-A1$4( 6%$#-&/!( )-I!( .)-27( %( 3/#!$( pore size of 50 meshes. Finally, starch obtained from four varieties cultivar were weighed and subsequently for next analyzed.

Proximate analysis

:1-)#.$!G(6$1#!-2G(/-6-'G(%)*(%2'(&$.'!(35!$(&12#!2#)( of the isolated starches were determined using the approved methods of AOAC6.

Physico-chemical analysis

Physic-chemically analysis consist of carbohydrate content (by different), amylose, amylopectin, viscosity, starch digestibility, water and oil absorptions. The amylose content was determined by using the iodine blue complex method using a solution of 0.2% iodine in 2% potassium iodide7. The digestibility of starch was performed by in vitro using methods developed by8. The principle of this method, the sample is hydrolyzed using ?@%40/%)!( !2I04!( -2#1( )-46/!( .2-#)( ).&*( %)( 4%/#1)!E( The amount of maltose hydrolysis enzyme was measured using spectrophotometric method.

Hak cipta © 2015 BB-Pascapanen

starchesstarches starch is starch is (when compared (when compared on a small-scale on a small-scale cassava starch has a cassava starch has

of proteins and of proteins

becoming more health becoming more health foods with special with special Oligosaccharides are Oligosaccharides are prebiotic functional prebiotic functional or obtained or obtained

biomass

3/#$%#-12G( cassava tuber cassava tuber and washed and washed and the and the machine machine a

Kampus Penelitian Pertanian Cimanggu

comparedsmall-scale small-scale has a high has a high proteins and lipids proteins and lipids

health conscious health conscious special health-promoting special health-promoting are attracting

are attracting functional food ingredients. functional food

obtained by enzymatic obtained by

biomass sources biomass sources oligosaccharides by enzymatic oligosaccharides by enzymatic

characteristics of

characteristics

Kampus Penelitian Pertanian Cimanggu

6$!&-6-#%#-12G(6$!&-6-#%#-12G(

tuber from four tuber from washed by using washed by using the other dirt. the other dirt. machine and machine and a ratio of a ratio of #*!( 3/#!$-27(

#*!(

the the

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

lipidsconscious and conscious and health-promoting health-promoting attracting increasing attracting increasing food ingredients. food ingredients. by enzymatic enzymatic sources or synthesized sources or

by enzymatic enzymatic characteristics of physic-chemical characteristics of physic-chemical

important to important product and its derivatives product and its

functional application. functional application.

material for material for use of cassava of cassava production is one production is

both of the value of cassava and human nutrition. both of the value of cassava and human nutrition.

Maltooligosaccharides Maltooligosaccharides

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

extracted through the through stripping, washing, stripping, washing, 6$!&-6-#%#-12G( '$0-27G(6$!&-6-#%#-12G( '$0-27G(

from four varieties four varieties using manually using manually other dirt. The tuber dirt. The

and then starch and then starch ratio of material of mater

3/#!$-27( *%)(

3/#!$-27( *%)(

the residue. the residue. again extracted again extracted addition addition the

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

andhealth-promoting health-promoting increasing increasing ingredients. They ingredients. They enzymatic hydrolysis enzymatic hydrolysis

or synthesized synthesized enzymatic transfer enzymatic transfer physic-chemical physic-chemical important to develop to develop

its derivatives derivatives application. Starch application. Starch

for maltooligo for maltooligo cassava as a material cassava as a material

is one of the one of the

both of the value of cassava and human nutrition. both of the value of cassava and human nutrition.

Maltooligosaccharides Maltooligosaccharides functional food,

functional food, &12#%-2-27(

&12#%-2-27(

maltooligosaccharides maltooligosaccharides to determine to

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

through the stages the stageswashing, grater, washing, grater, '$0-27G( %2'( )-!,-27E(

'$0-27G( %2'(

varieties cultivar varieties cultivar manually to clean manually to The tuber was The tuber was starch extract starch extract material and water ial and water 3/#!$-27( *%)( 5!!2( '12!(*%)( 5!!2(

residue. Residue residue. Residue again extracted 5 extracted addition and addition and the supernatant the supernatant part of part of starch starch crushed

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

TheyThey hydrolysis hydrolysis synthesized from synthesized from transfer reactions transfer reactions physic-chemical of starch physic-chemical of

develop processing develop processing derivatives that potential derivatives that

Starch from Starch from maltooligosaccharides maltooligosaccharides

material for material for the current the current

both of the value of cassava and human nutrition.

both of the value of cassava and human nutrition.

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

cultivar cultivar to clean tubers to clean tubers was shredded was shredded extracted by extracted by and water was water was 5!!2( '12!( #1(5!!2( '12!(

Residue obtained Residue obtained extracted 5 times with extracted 5 times

and precipitation and precipitation supernatant were supernatant were part of the wet of the wet starch obtained starch obtained crushed crushed 6$1&!))(

6$1&!))(

Scanning electron microscopy (SEM) analysis

Granula of the isolated starch was additionally checked by scanning electron microscopy (SEM)9.

Optimation of hydrolysis condition starch Kuning variety cultivar for maltooligosaccharide production

Enzymatic hydrolysis was carried out under various conditions, such as diverse substrate concentrations (w/v) 1.5, 3, 4.5, 6 and 7.5%, comparison of substrate (mL) with enzyme (mL) ratio (v/v) 1:10 (1 mL substrate : 23 U amylase), 1:5 (1 mL substrate : 11.5 U amylase), 1:2 (1 mL substrate : 4.6 U amylase), and 1:1 (1 mL substrate : 2.3 U amylase) and temperature reaction (30, 40 and 50oC). Amylase enzyme was used in this analysis from marine bacterium, Brevibacterium sp. with enzyme activity 2.3 U/mL. Reactions were carried out in 100 mL 9$/!24!0!$(J%)C)(&12#%-2-27(;=(4K(1A($!%&#-12(4-"#.$!)( in a rotary shaker (Stuart orbital incubator S1500, Staffordshire, United Kingdom) at room temperature. Samples were taken at regular intervals (after 1, 2, 4, 6, and 8h), reactions were stopped by heating the samples in boiling water.

Reducing sugar analysis

Product hydrolysis was analyzed by calculating the reducing sugars. Reducing sugars were determined by the DNS method10.

Thin Layer chromatography (TLC) analysis

TLC analysis of maltooligosaccharides products was carried out by the ascending method (three time development) on silica gel 60F254 plates (Merck Art20-20 cm, Darmstadt, Germany). All samples were applied

in equal quantities (4 µL) and then resolved by two runs with a solvent mixture of n-Butanol/aceticacid/water (12:6:6, by volume). Spots were visualized by spraying #*!().7%$(&1/1$(L=E<(7(?@'-6*!20/%4-2!G(;<(4K(%&!#12!G( 2.5 mL phosphate acid, 0.5 ml aniline) and subsequent heating at 100oC for 15 min.

RESULT AND DISCUSSIONS

1685?<*87?=@78A*B8=C*B=D8*@5897697;*?D:69@58*?5;;5@5

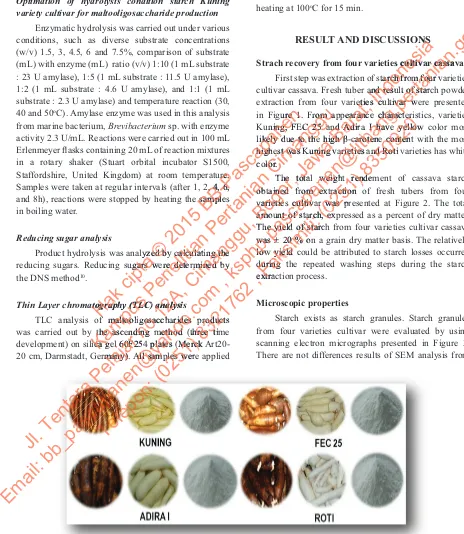

First step was extraction of starch from four varieties cultivar cassava. Fresh tuber and result of starch powder extraction from four varieties cultivar were presented in Figure 1. From appearance characteristics, varieties Kuning, FEC 25 and Adira I have yellow color most /-C!/0('.!(#1(#*!(*-7*(M@&%$1#!2!(&12#!2#(+-#*(#*!(41)#( highest was Kuning varieties and Roti varieties has white color.

Starch exists as starch granules. Starch granules from four varieties cultivar were evaluated by using scanning electron micrographs presented in Figure 3. There are not differences results of SEM analysis from

Figure 1. Photo of fresh cassava tubers, cassava tuber after peeled and starch powder from four varieties (Kuning, FEC 25, Adira I and Roti)

Gambar 1. Foto ubi kayu segar, ubi kayu setelah dikupas dari kulitnya dan tepung karbohidrat dari empat varietas kultivar (Kuning, FEC 25, Adira I dan Roti)

Hak cipta © 2015 BB-Pascapanen

temperature.temperature. 1, 2, 4, 6, 1, 2, 4, 6, the samples the samples

analyzed by analyzed by Reducing sugars were sugars were

Thin Layer chromatography (TLC) analysis Thin Layer chromatography (TLC) analysis

of

of

Hak cipta © 2015 BB-Pascapanen

extraction

Kampus Penelitian Pertanian Cimanggu

samplessamples

by calculating by calculating were determined were determined

Thin Layer chromatography (TLC) analysis Thin Layer chromatography (TLC) analysis

of maltooligosaccharides of maltooligosaccharides by the ascending

by the ascending silica gel

silica gel

Kampus Penelitian Pertanian Cimanggu

from four1. From appearance From appearance FEC 25 and

FEC 25 and /-C!/0('.!(#1(#*!('.!(#1(#*!(

highest was Kuning highest was color. color.

The obtained obtained

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

calculating thecalculating the determined by determined

Thin Layer chromatography (TLC) analysis Thin Layer chromatography (TLC) analysis

maltooligosaccharides maltooligosaccharides

ascending method ascending gel 60F254 gel 60F254 Germany). All Germany).

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

AND DISCUSSIONS

AND DISCUSSIONS

*@5897697;*?D:69@58

*@5897697;*?D:69@58

of starch from starch from tuber and result tuber and result varieties cultivar varieties cultivar appearance

was Kuning varieties Kuning varieties The total

The total obtained from obtained

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

determined bydetermined by

Thin Layer chromatography (TLC) analysis

maltooligosaccharides products maltooligosaccharides

ascending method (three method 60F254 plates (Merck 60F254 plates Germany). All samples Germany). All samples

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

*@5897697;*?D:69@58*?5;;5@5

*@5897697;*?D:69@58*?5;;5@5

from four varieties from four varieties result of starch result of starch cultivar were cultivar were appearance characteristics, appearance characteristics,

Adira I have Adira I have M@&%$1#!2!(

M@&%$1#!2

Kuning varieties and Kuning varieties

total weight total weight from extraction from extraction varieties cultivar

varieties cultivar amount of starch,

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

maltooligosaccharides products productsmethod (three time (three time plates (Merck Art20-plates (Merck samples were samples were

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

characteristics,varieties and Roti varieties varieties and Roti

Figure 2. Yield of cassava starch from four varieties cultivar

Gambar 2. Berat rendemen karbohidrat dari empat varietas kultivar ubi kayu

four varieties cultivar cassava. The purity of the extracted )#%$&*( +%)( ,-).%//0( &123$4!'( 50( 89:( 4-&$17$%6*)( %#( ;<==>( 4%72-3&%#-12)( +-#*( )&%/!( N=( O:( )*1+( #*%#( #*!( integrity of the granule starches as intact and the granule size of starches from four varieties cultivar small oval shaped (Figure 3).

!8=E9C567*5F5:A;9;

Proximate analysis of extracted cassava starch were presented in Table 1. The raw starch from four varieties cultivar employed in this study (Kuning, Adira I, FEC 25 and Roti) differs in proximate analysis properties each other with respect to water content, ash content, protein &12#!2#G(A%#(&12#!2#(%2'(&$.'!(35!$E(P%)!'(12(6$1"-4%#!( analysis showed that protein and fat content were law, these values indicated that the extracted starch was quite pure, so we can used this starch for next analysis.

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Adira I and Roti by using )&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==>

Gambar 3. Analisa mikroskopis karbohidrat dari empat varietas kultivar ubi kayu: Kuning, FEC 25, Adira I and Roti dengan menggunakan scanning electron microscopy (SEM) pembesaran 2500X

!<A;9?/?<7C9?5:*5F5:A;9;

Physic-chemical composition of extracted cassava starch were presented in Table 2.

Based on Table 2 showed that cassava starch from all varieties cultivar have similar content of carbohydrate total around 80%. The percent amylose content of the four varieties cultivar extracted starch varied from 13.0 to 16.4%, where is amylopectin content varied from 28.54 to 47.30%. Three varieties cultivar, such as FEC 25, Adira I and Roti contain amylopectin (30%) lower than amylose and Kuning variety cultivar has amylopectin higher (47%) than amylose. Fenema OR11 described that cassava starch is a good raw material for maltooligosaccharide production because it has a high content of amylopectin. The amylopectin content of the cassava starch was lower than amylose and high starch '-7!)#-5-/-#0G( +*-&*( &123$4!'( #*%#( #*!)!( )#%$&*( !%)-!$(

Hak cipta © 2015 BB-Pascapanen

endemen karbohidrat dari empat varietas kultivar ubi kayu endemen karbohidrat dari empat varietas kultivar ubi kayu

H

a

a

a

a

a

a

a

a

a

a

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25,

Kampus Penelitian Pertanian Cimanggu

endemen karbohidrat dari empat varietas kultivar ubi kayu endemen karbohidrat dari empat varietas kultivar ubi kayu

p

u

u

u

u

u

s

s

s

s

s

s

s

s

s

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25,

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==>

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==> Analisa mikroskopis karbohidrat dari empat varietas kultivar ubi kayu: Analisa mikroskopis karbohidrat dari empat varietas kultivar ubi kayu: dengan menggunakan scanning electr

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

varieties cultivar cassava. cultivar cassava.+%)( ,-).%//0( &123$4!'(

+%)( ,-).%//0(

;<==>( 4%72-3&%#-12)(4%72-3&%#-12)(

integrity of the integrity of the size of starches size of starches shaped (Figure 3).

shaped (Figure 3).

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

In

endemen karbohidrat dari empat varietas kultivar ubi kayu endemen karbohidrat dari empat varietas kultivar ubi kayu

1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25,

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==>

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==> oskopis karbohidrat dari empat varietas kultivar ubi kayu: oskopis karbohidrat dari empat varietas kultivar ubi kayu: dengan menggunakan scanning electr

dengan menggunakan scanning electr

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

cassava. Thecassava. The ,-).%//0( &123$4!'(&123$4!'(

4%72-3&%#-12)( +-#*(

4%72-3&%#-12)( +-#*(

the granule the granule starches from starches from shaped (Figure 3). shaped (Figure 3).

!8=E9C567*5F5:A;9;

!8=E9C567*5F5:A;9;

Proximate presented presented

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

endemen karbohidrat dari empat varietas kultivar ubi kayu endemen karbohidrat dari empat varietas kultivar ubi kayu

c

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25,

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==>

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==> oskopis karbohidrat dari empat varietas kultivar ubi kayu: oskopis karbohidrat dari empat varietas kultivar ubi kayu: dengan menggunakan scanning electr

dengan menggunakan scanning electr

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

cassava. The purity The purity&123$4!'( 50( 89:(

&123$4!'( 50( 89:(

+-#*( )&%/!(

+-#*( )&%/!(

granule starches granule starches

from four varieties

from four

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

1

Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25, Figure 3. Microscopic analysis of starch from four varieties cultivar cassava: Kuning, FEC 25,

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==>

)&%22-27(!/!&#$12(4-&$1)&160(L89:Q(+-#*(4%72-3&%#-12(;<==> oskopis karbohidrat dari empat varietas kultivar ubi kayu: oskopis karbohidrat dari empat varietas kultivar ubi kayu: dengan menggunakan scanning electr

Table 1. Proxymate components of starch from four varieties cultivar cassava Tabel 1. Komponen proksimat karbohidrat dari empat varietas kultivar ubi kayu

Proxymate components Komponen proksimat (%)

Cassava varieties cultivar/ Varietas kultivar ubi kayu

Kuning FEC 25 Roti Adira

Kadar air/ Moisture 15.56 11.39 11.5 11.29

Kadar abu/ Ash content 0.25 0.24 0.22 0.17

Protein kasar/ Crude protein 0.48 0.42 0.65 1.18

Lemak kasar/ Crude lipid 0.37 0.5 0.76 1.05

8!$%#(C%)%$R(S$.'!(35!$ 0.09 0.27 0.13 1.22 n = triple

#1( *0'$1/0)-)( 50( ?@%40/%)!E( T*-/!( &%))%,%( )#%$&*( A$14( Kuning variety cultivar contain amylopectin higher than amylose showed that this variety same with the characteristic of black potato starch from Indonesia contain amylopectin higher than amylose, 67.69%12.

Starches from all cassava variety cultivar were potential to be used for produce maltooligosaccharide. It showed by value of high digestibility assay (65-100%). Based on the amylopectin content show that Kuning variety can be used for maltooligosaccharde production linier type, different with the other variety cultivar. So, in this research we focus to analysis optimation hydrolysis condition of starch cassava Kuning variety cultivar for maltooligosacharide production.

#G69C569=F* <A>8=:A;9;* ?=F>969=F* =B* ;658?<* @58976A* ?D:69@58*HDF9FI*B=8*C5:6==:9I=;5??<589>7*G8=>D?69=F

The parameter analysis for optimation hydrolysis condition consist of substrate concentration, comparison of enzyme and substrate and temperature of hydrolysis. U*!(!2I04%#-&((*0'$1/0)-)((1A(()#%$&*((50((?@%40/%)!(/!%')(( to the formation of smaller maltosaccharide fragments. Every starch polysaccharide molecule possesses exactly one reducing end which can reduce dinitrosalicylic

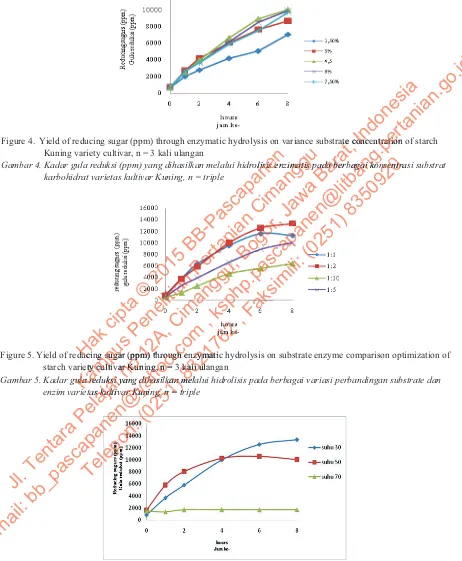

acid; therefore, the measurement of reducing sugars is a useful method to determine the molar concentration of starch molecules in solution13. So, we used measurement the reducing sugar as a parameter to decide the optimum condition for each parameter analysis. First step, we decide the optimum substrate concentration. Values of reducing sugars on some substrate concentration (1.5, 3, 4.5, 6 and 7.0 %) were shown at Figure 4. The value reducing sugar optimum at substrate concentration 4.5% and the lowest reducing sugar at substrate concentration 1.5%.

Next step was to decide the comparison between substrate and enzyme amylase concentration used in the hydrolysis. We used substrate concentration 4.5% from the previously result. Comparison between substrate and enzyme concentration were made in v/v in hydrolysis $!%&#-12E(U*!(,1/.4!(1A().5)#$%#!(+!$!(4%'!(3"(LN(4KQG( whereas enzyme concentration were made in variance 1 mL, 2 mL, 5 mL, 10 mL with each activity 2.3 U, 4.6 U, 11.5 U and 23 U. Yield of reducing sugar produced by enzymatic hydrolysis on variance comparison substrate %2'(!2I04!(+!$!()*1+2(%#(H-7.$!(<E(P%)!'(12(#*-)(37.$!( shown that optimum comparisons between substrate and enzyme was 1:2 with the highest value of reducing sugar. Table 2. Physic-chemical characteristics of starch from four varieties cultivar cassava

3$4!&(5/(6$7$89!7%29%8(:2%8*(8%#%$(8$74*.%;7$9(;$7%(!#+$9(<$7%!9$2(8=&9%<$7(=4%(8$)=

Physic-chemical characteristics of starch Cassava varieties cultivar/ Varietas kultivar ubi kayu

Kuning FEC 25 Roti Adira I

M@&%$1#!2(R(M@C%$1#!2(L664Q 7.2 5.9 8.5

-Carbohydrate content / Kadar pati (by different) 75.7 85 85.6 85.0

Amylopectin / Amilopektin (%) 47.3 30.9 28.5 30.5

Amylose /Amilosa (%) 28.4 54.1 57.1 54.5

Viscosity /Viskositas (Cp) 16.4 14.4 14.8 13.0

Starch digestibility / Daya cerna karbohidrat (%) 97.5 83.4 64.7 88.2

Water absorption / Penyerapan air (g/g) 0.6 1.3 0.8 0.9

Oil absorption / Penyerapan minyak (g/g) 1.1 1.1 1.2 1.2

n = triple

Hak cipta © 2015 BB-Pascapanen

?@%40/%)!E( T*-/!(

?@%40/%)!E( T*-/!(

cultivar conta cultivar conta showed that showed that

black black

$4!&(5/(6$7$89!7%29%8(:2%8*(8%#%$(8$74*.%;7$9(;$7%(!#+$9(<$7%!9$2(8=&9%<$7(=4%(8$)=

$4!&(5/(6$7$89!7%29%8(:2%8*(8%#%$(8$74*.%;7$9(;$7%(!#+$9(<$7%!9$2(8=&9%<$7(=4%(8$)=

Hak cipta © 2015 BB-Pascapanen

Hak cipta © 2015 BB-Pascapanen

Hak cipta © 2015 BB-Pascapanen

Hak cipta © 2015 BB-Pascapanen

Hak cipta © 2015 BB-Pascapanen

Cassava varieties cultivar/ Cassava varieties cultivar/

FEC 25 FEC 25

75.7 47.3 47.3 28.4 28.4

Starch digestibility / Daya cerna karbohidrat (%) Starch digestibility / Daya cerna karbohidrat (%)

Oil absorption / Penyerapan minyak (g/g) Oil absorption / Penyerapan minyak (g/g)

Kampus Penelitian Pertanian Cimanggu

T*-/!( &%))%,%(

T*-/!( &%))%,%(

contain amylopectin contain amylopectin that this variety that this variety black potato

black potato

contain amylopectin higher than amylose, 67.69% contain amylopectin higher than amylose, 67.69%

from all cassava

from all

Kampus Penelitian Pertanian Cimanggu

Kampus Penelitian Pertanian Cimanggu

Kampus Penelitian Pertanian Cimanggu

Kampus Penelitian Pertanian Cimanggu

Kampus Penelitian Pertanian Cimanggu

Kampus Penelitian Pertanian Cimanggu

Cassava varieties cultivar/ Cassava varieties cultivar/FEC 25 FEC 25

5.9 5.9 85

16.4 16.4 97.5 97.5 0.6

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

1.05 1.05 1.22 1.22

&%))%,%( )#%$&*(

&%))%,%( )#%$&*(

amylopectin amylopectin variety same variety same potato starch from starch contain amylopectin higher than amylose, 67.69% contain amylopectin higher than amylose, 67.69%

all cassava cassava used for produce for produce value of high digestibility value of high

the amylopectin amylopectin can be used for can be used type, different type, different this research we this research condition of condition

maltooligosacharide production.

maltooligosacharide production.

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Cassava varieties cultivar/ Varietas kultivar ubi kayu Cassava varieties cultivar/ Varietas kultivar ubi kayu85 30.9 30.9 54.1 54.1

0.6 1.1 1.1

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

)#%$&*( A$14(

)#%$&*( A$14(

amylopectin higher amylopectin higher

same with same with starch from Indonesia from Indonesia contain amylopectin higher than amylose, 67.69% contain amylopectin higher than amylose, 67.69%

cassava variety cassava variety

produce maltooligosaccharide. produce maltooligosaccharide. high digestibility digestibility

amylopectin content amylopectin content used for maltoolifor maltooli ferent with the ferent with research we focus we focus condition of starch of starch

maltooligosacharide production. maltooligosacharide production.

#G69C569=F*

#G69C569=F*

?D:69@58

?D:69@58

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

arietas kultivar ubi kayu arietas kultivar ubi kayu

Roti Roti

8.5 8.5

54.1 14.4 14.4 83.4 83.4

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

higherhigher with the with the Indonesia Indonesia contain amylopectin higher than amylose, 67.69% contain amylopectin higher than amylose, 67.69%1212.

variety cultivar variety cultivar maltooligosaccharide. maltooligosaccharide. digestibility assay

digestibility assay content show content show maltooligosaccharde maltooligosaccharde with the other

with the other focus to analysis focus to analysis starch cassava starch cassava maltooligosacharide production.

acid; acid; a

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

arietas kultivar ubi kayu arietas kultivar ubi kayu

8.5 85.6 85.6 28.5 28.5 57.1

Figure 4. Yield of reducing sugar (ppm) through enzymatic hydrolysis on variance substrate concentration of starch Kuning variety cultivar, n = 3 kali ulangan

Gambar 4. Kadar gula reduksi (ppm) yang dihasilkan melalui hidrolisis enzimatis pada berbagai konsentrasi substrat karbohidrat varietas kultivar Kuning, n = triple

Figure 5. Yield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of starch variety cultivar Kuning, n = 3 kali ulangan

Gambar 5. Kadar gula reduksi yang dihasilkan melalui hidrolisis pada berbagai variasi perbandingan substrate dan enzim varietas kultivar Kuning, n = triple

Figure 6. Yield of reducing sugar (ppm) through enzymatic hydrolysis on variance of temperature hydrolysis of starch variety kultivar Kuning, n = 3 kali ulangan

Gambar 6. Kadar gula reduksi yang dihasilkan pada berbagai suhu hidrolisis dari varietas kultivar Kuning, n = triple

Hak cipta © 2015 BB-Pascapanen

eduksi (ppm) yang dihasilkan melalui hidrolisis enzimatis pada berbagai konsentrasi substrat eduksi (ppm) yang dihasilkan melalui hidrolisis enzimatis pada berbagai konsentrasi substrat

k

ci

ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of

Kampus Penelitian Pertanian Cimanggu

olisis enzimatis pada berbagai konsentrasi substrat olisis enzimatis pada berbagai konsentrasi substrat

us

ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of starch variety cultivar Kuning, n = 3 kali ulangan

starch variety cultivar Kuning, n = 3 kali ulangan

Gambar 5. Kadar gula reduksi yang dihasilkan melalui hidr Gambar 5. Kadar gula reduksi yang dihasilkan melalui hidr

enzim varietas kultivar Kuning, n = triple enzim varietas kultivar Kuning, n = triple

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

ield of reducing sugar (ppm) through enzymatic hydrolysis on variance substrate concentration of starch ield of reducing sugar (ppm) through enzymatic hydrolysis on variance substrate concentration of starcholisis enzimatis pada berbagai konsentrasi substrat olisis enzimatis pada berbagai konsentrasi substrat

12A

ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of starch variety cultivar Kuning, n = 3 kali ulangan

starch variety cultivar Kuning, n = 3 kali ulangan

eduksi yang dihasilkan melalui hidr eduksi yang dihasilkan melalui hidr enzim varietas kultivar Kuning, n = triple enzim varietas kultivar Kuning, n = triple

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

ield of reducing sugar (ppm) through enzymatic hydrolysis on variance substrate concentration of starch ield of reducing sugar (ppm) through enzymatic hydrolysis on variance substrate concentration of starcholisis enzimatis pada berbagai konsentrasi substrat olisis enzimatis pada berbagai konsentrasi substrat

com

ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of starch variety cultivar Kuning, n = 3 kali ulangan

starch variety cultivar Kuning, n = 3 kali ulangan

eduksi yang dihasilkan melalui hidr eduksi yang dihasilkan melalui hidr enzim varietas kultivar Kuning, n = triple enzim varietas kultivar Kuning, n = triple

a

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

olisis enzimatis pada berbagai konsentrasi substrat olisis enzimatis pada berbagai konsentrasi substrat

17

7

7

6

6

6

6

6

ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of ield of reducing sugar (ppm) through enzymatic hydrolysis on substrate enzyme comparison optimization of starch variety cultivar Kuning, n = 3 kali ulangan

starch variety cultivar Kuning, n = 3 kali ulangan

eduksi yang dihasilkan melalui hidr eduksi yang dihasilkan melalui hidr enzim varietas kultivar Kuning, n = triple enzim varietas kultivar Kuning, n = triple

U*!( 32%/( )#!6( +%)( #1( '!&-'!( #*!( #!46!$%#.$!( 16#-4.4( A1$( *0'$1/0)-)( ).5)#$%#!( 50( ?@%40/%)!( A$14(

Brevibacterium sp to produce maltooligosaccharide from variety cultivar Kuning. We used substrate concentration 4.5% and comparison substrate and enzyme 1:2 (v/v) in three variance temperature hydrolysis, such as 30, 50 and 70oC. The values of reducing sugars from three variance temperature hydrolysis were shown at Figure 6. From this data showed that temperature 50oC was optimum for production maltooligosaccharide with the highest value of reducing sugars from varity cultivar Kuning.

Based on the value of reducing sugars were shown at Figure 4, 5, and 6, respectively showed that optimum hydrolysis condition for maltooligosachharide production from Kuning variety cultivar were substrate concentration 4,5% (b/v), comparison of substrate: enzyme 1:2, and temperature hydrolysis 30oC with the reducing sugars 13.359 ppm.

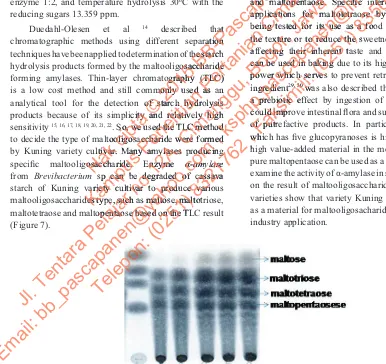

Duedahl-Olesen et al 14 described that chromatographic methods using different separation techniques have been applied to determination of the starch hydrolysis products formed by the maltooligosaccharide forming amylases. Thin-layer chromatography (TLC) is a low cost method and still commonly used as an analytical tool for the detection of starch hydrolysis products because of its simplicity and relatively high sensitivity 15, 16, 17, 18, 19, 20, 21, 22. So, we used the TLC method to decide the type of maltooligosaccharide were formed by Kuning variety cultivar. Many amylases producing )6!&-3&( 4%/#11/-71)%&&*%$-'!E( 92I04!( 1"$#)&$2!( from Brevibacterium sp can be degraded of cassava starch of Kuning variety cultivar to produce various maltooligosaccharides type, such as maltose, maltotriose, maltotetraose and maltopentaose based on the TLC result (Figure 7).

Figure 7. Chromatogram of TLC for enzymatic hydrolysis produce Kuning variety cultivar. S was standard mix (maltose, maltotriose, maltotetraose and maltopentaose); 0, 2, 4, 6 and 8 showed time of enzymatic hydrolysis (hours)

Gambar 6. Kromatogram TLC hasil hidrolisis pada kondisi optimum varietas kultivar Kuning. S adalah standar

0$#+=7$>()$>?(9!7;%7%($9$2(#$&9*2!@(#$&9*97%*2!@(#$&9*9!97$*2!($>;(#$&9*+!>9$*2!A(B@(5@(C@(D@($>;(E(

menunjukkan waktu hydrolysis enzimatis dalam jam

Based on the TLC data on Figure 7 showed that Kuning variety cultivar can produce variance maltooligosaccharide from 0 hour until 8 hour reaction, with the dominant product was maltotriose, maltotetraose and maltopentaose. This result was similar to 23 described

#*%#(61#%#1()#%$&*(*0'$1/0)-)(50(#*!$416*-/-&(?@%40/%)!( from B. megaterium VUMB109 produced higher quantity of maltopentaose and maltotriose 24 also reported amylase from Pseudomonas stutzeri AS22 produce high maltotetraose (G4).

Result analysis from variety Kuning was very interested, because cassava starch from Kuning variety can produce mainly maltotriose, maltotetraose and maltopentaose that have properties are compatible for use in the food industry26. Many report the application of maltooligosaccharide, such as maltotriose, maltotetraose %2'( 4%/#16!2#%1)!E( 86!&-3&( -2#!$!)#( +%)( 4%20( C-2'( applications for maltotetraose by25. Maltotetraose is being tested for its use as a food additive to improve the texture or to reduce the sweetness of foods without %AA!&#-27( #*!-$( -2*!$!2#( #%)#!( %2'( J%,1$27, 28. It’s also can be used in baking due to its high moisture retention power which serves to prevent retrogradation of starch ingredient29, 30 was also described that maltotetraose has a prebiotic effect by ingestion of maltotetraose syrup &1./'(-46$1,!(-2#!)#-2%/(J1$%(%2'().66$!))(#*!(A1$4%#-12( of putrefactive products. In particular, maltopentaose +*-&*(*%)(3,!(7/.&160$%21)!)(-)(*-7*/0('!4%2'!'(%)(%( *-7*(,%/.!@%''!'(4%#!$-%/(-2(#*!(4!'-&%/(3!/'()-2&!(#*!( pure maltopentaose can be used as a diagnostic reagent to !"%4-2!(#*!(%&#-,-#0(1A(?@%40/%)!(-2()!$.418, 31, 32, 33. Based on the result of maltooligosaccharide type from Kuning varieties show that variety Kuning have challenge used as a material for maltooligosacharides and used for food industry application.

that that separation separation of the starch of the starch maltooligosaccharide maltooligosaccharide chromatography (TLC) chromatography

commonly used commonly n of starch n of starch simplicity and simplicity and . So, we used . So, we used maltooligosaccharide maltooligosaccharide cultivar. Many cultivar. 4%/#11/-71)%&&*%$-'!E(

4%/#11/-71)%&&*%$-'!E(

sp

maltopentaose maltopentaose use in the food in the food maltooligosaccharide, maltooligosaccharide, %2'( 4%/#16!2#%

%2'( 4%/#16!2#%

applications applications being

Kampus Penelitian Pertanian Cimanggu

starchmaltooligosaccharide maltooligosaccharide chromatography (TLC) chromatography (TLC) commonly used as an used as starch hydrolysis starch hydrolysis and relatively and relatively we used the TLC used the maltooligosaccharide maltooligosaccharide

. Many amylases Many amylases 4%/#11/-71)%&&*%$-'!E( 92I04!(

4%/#11/-71)%&&*%$-'!E(

sp can be sp can Kuning variety cultivar variety cultivar maltooligosaccharides type, maltooligosaccharides type,

maltopentaose

Kampus Penelitian Pertanian Cimanggu

maltopentaose that thatfood industry food industry maltooligosaccharide, maltooligosaccharide,

4%/#16!2#%

4%/#16!2#%

applications applications being tested being tested the texture the %AA!&#-27(

%A

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

as an anhydrolysis hydrolysis relatively high relatively high the TLC method the TLC method maltooligosaccharide were formed maltooligosaccharide were

amylases producing amylases

92I04!(

92I04!(

can be degraded be degraded cultivar to cultivar type, such as type, such maltopentaose maltopentaose

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

AS22 produce AS22 producevariety Kuning variety Kuning starch from starch from maltotriose, maltotriose, have properties have properties industry

industry2626. Many . Many

maltooligosaccharide, such maltooligosaccharide, such

4%/#16!2#%1)!E( 86!&-3&(

4%/#16!2#%1)!E( 86!&-3&(

applications for maltotetraose applications for

tested for tested for the texture or texture %AA!&#-27( #*!-$(A!&#-27(

can be used can be used power power ingredient

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

methodmethod were formed formed amylases producing producing 1"$#)&$2!(

1"$#)&$2!(

degraded of cassava degraded of cultivar to produce to produce

such as maltose, as maltose, maltopentaose based on maltopentaose based

e

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

higher higher reported reported produce high produce highKuning was Kuning was from Kuning from Kuning se, maltotetraose se, maltotetraose properties are compatible properties are

Many report Many report such as maltotriose, such as maltotriose, 86!&-3&( -2#!$!)#(

86!&-3&(

maltotetraose maltotetraose for its use as for its use as or to reduce or to reduce A!&#-27( #*!-$( -2*!$!2#(#*!-$( -2*!$!2#(

be used in baking be used in power which power which ingredient ingredient a prebiotic a prebiotic &1./'(

&1./'(

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

producingproducing 1"$#)&$2!(

1"$#)&$2!(

of cassava of cassava produce various produce various maltose, maltotriose, maltose, maltotriose, based on the TLC based on the TLC

e

e

e

e

e

e

e

e

e

e

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

: (

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

report the application report the

maltotriose, maltotetraose maltotriose,

86!&-3&( -2#!$!)#( +%)(

86!&-3&( -2#!$!)#(

maltotetraose by maltotetraose by25

use as a food use as a food reduce the sweetness reduce the

-2*!$!2#( #%)#!(

-2*!$!2#(

in baking due in baking which serves which serves ingredient

ingredient29, 30 29, 30 was was

prebiotic effect prebiotic ef &1./'(-46$1,!(

&1./'(-46$1,!(

of putrefactive of putrefactive +*-&*(

+*-&*(

CONCLUSIONS

Based on the phisic-chemical characterization showed that starch from all of cultivated varieties casaava can be used for maltooligosaccharides production, especially for Kuning variety has ability to produce variance maltooligosaccharide. The optimum hydrolysis condition for maltooligosachharide production from cultivated variety Kuning were substrate concentration 4,5% (b/v), comparison of substrate: enzyme 1:2, and temperature hydrolysis 30oC with the reducing sugars 13.359 ppm. The dominant product hydrolysis was maltotriose, maltotetraose and maltopentaose. These maltooligosaccharides was important for many kind application in industry.

ACKNOWLEDGEMENTS

U*!( %.#*1$)( 7$%#!A.//0( %&C21+/!'7!( #*!( 32%2&-%/( support of DIPA PN UMBI 2011-2012 granted to Puslit Biologi-LIPI. We also thanks to Dicky Gustiawanto for cassava carbohydrate extraction.

REFERENCES

1. Angelucci F. Analysis of incentives and disincentives for cassava in Ghana. Technical notes series, MAFAP, FAO, Rome. © FAO 2013.

2. FAO Corporate document repository. 1999. Global cassava market study: cassava starch.

3. Rastall RA. Functional Oligosaccharides: Application and ManufactureAnnu. Rev. Food Sci. Technol. 2010. 1:305– 39. doi: 10.1146/annurev.food.080708.100746

4. Crittenden RG, Playne MJ. Production, properties and applications of food grade oligosaccharides. Trends FoodSci. Technol. 1996; 7:353-361.

5. Barreteau H, Delattre C, Michaud P. Production of oligosaccharides as promising new food additive generation.Food Technol. Biotechnol. 2006; 44:323-333.

VE( WXWSE( XA3&-%/( :!#*1')( 1A( W2%/0)-)E( W$/-27#12G( YWF( W))1&-%#-12( 1A( XA3&-%/( W2%/0#-&%/( S*!4-)#)ED2&E(

Washington D.C. 1984; 14th Edn.

ZE(81+5*%70%(S:G(P*%##%&*%$0%(B[E(8-46/-3!'('!#!$4-2%#-12(

of amylose in milled rice. Starch. 1979; 31:159-163. 8. Muchtadi D. 1992. Metode Kimia, Biokimia, dan Biologi

dalam Evaluasi Nilai Gizi Pangan Olahan. Bogor (ID): Pusat Antar Universitas Pangan dan Gizi. Institut Pertanian Bogor.

9. Tharanathan RN and Ramadas Bhat U. Scanning electron microscopy of chemically and enzymatically treated black gram (Phaseolus mungo) and ragi (Eleusine coracana) starch granules. Starch. 1988; 40:378-382.

10. Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. J Anal Chem. 1959; 31:426-428.

11. Fennema OR (Ed.). Food Chemistry, third ed. Marcel Dekker, Inc., New York, USA.1996.

12. Rahmani N, Rohanah, Sukarno, Ade andriani, Yopi. Production of maltooligosaccharides from black potato (Coleus tuberosusQ( )#%$&*( 50?@%40/%)!( A$14( %( 4%$-2!(

bacterium (Brevibacterium sp.). Microbiology Indonesia. 2013; 7(3):129-136.

13. Hiromi K, Ogawa K, Nakanishi N, Ono S. A kinetic method for the determination of number-average molecular weight of linear high polymer by using an exo-enzyme. J. Biochem. 1966; 69:439-449.

14. Lene Duedahl-Olesen, Lars Haastrup Pedersen, Kim Lambertsen Larsen. Suitability and limitations of methods for characterisation of activity of maltooligosaccharide-forming amylases. Carbohydrate Research. 2000; 329:109-119.

N<E( [150#( \HG( [\( W&C!$4%2E( D)1/%#-12G( 6.$-3&%#-12G( %2'(

characterization of a maltotetraose-producing amylase from Pseudomonas stutzeri. Arch. Biochem. Biophys. 1971; 145(1):105-114.

16. Kainuma K, S Kobayashi, T Ito, S Suzuki. Isolation and action pattern of maltohexaose-producing amylase from Aerobacter (Enterobacter) aeroges. FEBS Lett. 1972; 26: 281-285.

17. Takasaki Y. An amylase producing maltotriose from Bacillus subtilis. Agric. Biol. Chem. 1985; 49: 1091-1097. 18. Saito N. A Thermophilic Extracellular alpha-Amylase from

Bacillus licheniformis Archives. Biochem. Biophys. 1973; 155:290-298.

N]E(U%2-7.&*-(^G(S:(\%!G(_(`1)*-7-G(`(:%$.0%4%E(a.$-3&%#-12( 1A(P%&-//.)(&-$&./%2)(H@;(%40/%)!(b(-#)(7!2!$%/(6$16!$#-!)E(

Agric. Biol. Chem. 1983; 47:511-519

20. Hayashi T, Teruhiko Akiba, Koki Horikoshi. Production

%2'( a.$-3&%#-12( 1A( _!+( :%/#1*!"%1)!@A1$4-27( A$14(

Alkalophilic Bacillus sp. H-167. Agric. Biol. Chem. 1988a; 52 (2):443-448.

21. Hayashi T, T Akiba, K Horikoshi. Properties of new alkaline maltohexaose forming amylases. Appl. Microbiol. Biotechnol. 1988b; 28: 281-285.

22. Okemoto H, S Kobayashi, M Monma, H Hashimoto, K Hara, K Kainuma. 1986. Isolation and cultivation of a novel microorganism producing a maltopentaose-forming enzyme. Appl. Microbiol. Biotechnol. 1986; 25:137-142. 23. Jana M, Chiraujit MB, Saptadip SB, Bikos RPB. Syed

Sirajul IC, Prodeep KDM, Keshab CM. Salt-independent

#*!$416*-/-&( ?@%40/%)!( A$14( Bacillus megaterium

Yc:PN=]F( W2( !A3&%&0( #!)#-27( A1$( 6$!6%$%#-12( 1A( 4%/#11/-71)%&&*%$-'!E( D2'.)#$-%/( &$16)( b( a$1'.&#)E( ;=Nde(

41:386-391. Doi:10.1016/j.indcrop.2012-04.048.

Hak cipta © 2015 BB-Pascapanen

32%2&-%/(

32%2&-%/(

to Puslit to Puslit Gustiawanto for Gustiawanto for

incentives and incentives echnical notes series, echnical notes

document repository document repository market study: cassava starch. market study: cassava starch.

Functional

J. Biochem. 1966; 69:439-449. Lene Duedahl-Olesen, Lene Duedahl-Olesen, Lambertsen

Lambertsen for characterisation for

forming

Kampus Penelitian Pertanian Cimanggu

forand disincentives and disincentives notes series, MAFseries, MAF

repository. 1999. repository. market study: cassava starch. market study: cassava starch.

Functional Oligosaccharides: Functional Oligosaccharides: ManufactureAnnu. Rev. Food

ManufactureAnnu. Rev. Food 146/annurev

146/annurev

Kampus Penelitian Pertanian Cimanggu

J. Biochem. 1966; 69:439-449. J. Biochem. 1966; 69:439-449.

Duedahl-Olesen, Duedahl-Olesen, Lambertsen Larsen. Lambertsen Larsen. for characterisation characterisation forming amylases. forming

119. 119.

N<E( [150#(

N<E(

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

disincentives fordisincentives for MAFAP, FAO, MAFAP,

. 1999. Global . 1999. Global

Oligosaccharides: Oligosaccharides:

Food Sci. Technol. Food Sci.

146/annurev.food.080708.100746 146/annurev.food.080708.100746

Playne MJ. Playne MJ. of food grade of food grade echnol. 1996; 7:353-361. echnol. 1996; 7:353-361. Barreteau H, Delattre

Barreteau H, Delattre oligosaccharides oligosaccharides generation.Food generation.Food

VE( WXWSE(

VE( WXWSE(

W))1&-%#-12(

W))1&-%#-12(

W

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Microbiology Indonesia. Microbiology

N, Ono S. A kinetic Ono S. A number-average number-average polymer by using polymer by J. Biochem. 1966; 69:439-449. J. Biochem. 1966; 69:439-449. Duedahl-Olesen, Lars Duedahl-Olesen, Lars Larsen. Suitability Larsen. Suitability characterisation of characterisation of forming amylases. Carbohydrate amylases.

[150#( \HG(

[150#( \H characterization characterization from

from

1971; 145(1):105-1 16.

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

forFAO, AO,

Global cassava Global cassava

Oligosaccharides: Application Oligosaccharides: Application

Technol. 2010. echnol. .food.080708.100746 .food.080708.100746

MJ. Production, Production, grade oligosaccharides. grade oligosaccharides. echnol. 1996; 7:353-361.

echnol. 1996; 7:353-361. Delattre C, Delattre C, oligosaccharides as promising oligosaccharides as promising

generation.Food Technol. Biotechnol. 2006; 44:323-333. generation.Food Technol. Biotechnol. 2006; 44:323-333.

WXWSE( XA3&-%/(XA3&-%/(

W))1&-%#-12(

W))1&-%#-12(

Washington D.C. 1984; 14th Edn.ashington D.C. 1984; 14th Edn.

ZE(81+5*%70%(

ZE(81+5*%70%(

of amylose in milled rice. Starch. 1979; 31:159-163. of amylose in milled rice. Starch. 1979; 31:159-163. 8. Muchtadi

8.

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

potato potato4%$-2!(

4%$-2!( Indonesia. Indonesia.

kinetic method kinetic method -average molecular -average

by using an exo-enzyme. using an

Lars Haastrup Lars Haastrup Suitability and Suitability and

of activity of activity amylases. Carbohydrate amylases. Carbohydrate

\HG( [\( W&C!$4%2E(G( [\( W&C!$4%2E( characterization of characterization from Pseudomonas from Pseudomonas 1971; 145(1):105-1 1971; 145(1):105-1 16. Kainuma 16. Kainuma

action action

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

cassavacassava

Application and Application and 2010. 1:305– 2010. 1:305– .food.080708.100746

.food.080708.100746 Production, properties Production, properties

oligosaccharides. oligosaccharides. echnol. 1996; 7:353-361.

echnol. 1996; 7:353-361. C, Michaud Michaud promising promising

echnol. Biotechnol. 2006; 44:323-333. echnol. Biotechnol. 2006; 44:323-333.

:!#*1')(

:!#*1')(

XA3&-%/(

Telepon: (0251) 8321762 , Faksimili: (0251) 8350920

Haastrup Pedersen, Haastrup

and limitations and limitations

activity of activity of maltooligosaccharide-Carbohydrate Research.

Carbohydrate Research.

W&C!$4%2E( D)1/%#-12G(

W&C!$4%2E(

characterization of a maltotetraose-producing characterization of a maltotetraose-producing

Pseudomonas stutzeri. Pseudomonas stutzeri. 1971; 145(1):105-114. 1971; 145(1):105-1 Kainuma K, S Kobayashi, Kainuma K, S

24. Maalej H, Hanen Ben Ayed, Olfa Ghorbel-Bellaaj, Moncef Nasri, and Noomen Hmidet. Production and biochemical characterization of a high maltotetraose (G4) producing amylase from Pseudomonas stutzeri AS22. BioMed Reasearch International. 2014.

25. Trupti K, Sharma, Vaibhav A, Bhadane, Lalitha S, Kumar, Meenakshi V, Rele, Gajanan Bhawar and Imran Rahman. Optimization of the production of a maltooligosaccharides producing amylase from the alkalophilic Streptomyces lonarensis strain NCL 716 using SVR Modeling. Starch. 2013; 65:179-185. DOI 10.1002/star.201200094.

26. Byoung-Cheol Min, Sang-Hyeon Yoon, Jeong-Weon Kim, Yin-Won Lee,‡ Young-Bae Kim, Kwan Hwa Park. Cloning of Novel Maltooligosaccharide-Producing Amylases as Antistaling Agents for Bread. J. Agric. Food Chem. 1998; 46:779-782.

27. Rivero MU, A. Santamaria-Orleans. 2001. Oligosaccharides: application in infant food. Early Human Development. 2001; 65(2):S43-S52.

28. Aiyer PV. Amylases and their applications. African Jounal of Biotechnology. 2005; 4(13): 1525-1529.

29. Palacios HR, PB Schwarz, BL D’Appolonia. Effect of

?@%40/%)!)( A$14( '-AA!$!2#( )1.$&!)( 12( #*!( $!#$17$%'%#-12(

and recrystallization of concentrated wheat starch gels, relationship to bread staling. Journal of Agricultural and Food Chemistry. 2004; 52(19): 5978-5986.

30. Malabendu J, M Chiranjit, S Saptadip. Salt-independent

#*!$416*-/-&( ?@%40/%)!)( A$14( Bacillus megaterium

Yc:PN=]e( %2( !A3&%&0( #!)#-27( A1$( 6$!6%$%#-12( 1A(

maltooligosaccharides. Industrial Crops and Products. 2013; 41:386-390.

31. Pankratz T J. Process for producing soluble amylose. U. S. Patent 4 1977; 029,516.

32. Masao K, H Kanchin, M Takashi. Enzymatic manufacture of a-maltopentaose in waterhydrophobic solvent systems. Japan Kokai TokkyoKoho. JP 9180093 A2. 1991.

33. Takashi O, I Akihisa, H Kozo, H Hitoshi, K Shoichi. Manufacture of maltopentaose syrups with c-amylase. Japan Kokai Tokkyo Koho. JP 9245794 A2.1992.

Hak cipta © 2015 BB-Pascapanen

JounalJounal

Hak cipta © 2015 BB-Pascapanen

a-maltopentaos Japan Kokai Japan Kokai 33. Takashi 33. TakashiManufacture Manufacture Japan Kokai

Kampus Penelitian Pertanian Cimanggu

a-maltopentaos a-maltopentaosJapan Kokai TokkyoKoho. JP Japan Kokai TokkyoKoho. JP

akashi O, I Akihisa, akashi O, I Akihisa, Manufacture

Manufacture Japan Kokai Japan Kokai

Jl. Tentara Pelajar no 12A, Cimanggu, Bogor, Jawa Barat, Indonesia

Crops and Crops andproducing soluble amylose. producing soluble

Takashi. Enzymatic akashi. Enzymatic in waterhydrophobic waterhydrophobic okkyoKoho. JP 9180093 okkyoKoho. JP

Akihisa, H Akihisa, Manufacture of maltopentaose of maltopentaose Japan Kokai Tokkyo Koho. JP Japan Kokai Tokkyo Koho. JP

Email: bb_pascapanen@yahoo.com , ksphp.pascapanen@litbang.pertanian.go.id

megaterium megaterium6$!6%$%#-12( 1A(

6$!6%$%#-12( 1A( Products. Products.

soluble amylose. U. amylose.

Enzymatic manufacture Enzymatic

waterhydrophobic solvent waterhydrophobic okkyoKoho. JP 9180093 A2. 1991. 9180093

H Kozo, H H Kozo, maltopentaose maltopentaose okkyo Koho. JP okkyo Koho. JP