Industrial Crops and Products 11 (2000) 129 – 137

Integrated utilisation of green biomass in the green

biorefinery

Margrethe Andersen *, Pauli Kiel

Centre for Agro-Industrial Biotechnology,Uni6ersity of Southern Denmark,Esbjerg,Industri6ej11,6870Ølgod,Denmark

Accepted 8 October 1999

Abstract

Grass, clover and alfalfa are used for production of fodder pellets. In the green crop drying factories in the northern countries the drying is combined with pressing of the green crops resulting in production of large volumes of plant juices, green and brown juice. In order to get rid of these enormous amounts of plant juice, representing an environmental threat, it is our aim to convert the simple drying industry to a whole crop utilisation factory, a green biorefinery, where the plant juice can be used as raw material in a fermentation process. As the plant juice is very unstable, it has been necessary to develop a method for both conservation and utilisation of the juice. The plant juice is converted to a nice universal fermentation medium by lactic acid bacteria. A number of lactic acid producing strains have been tested. Among the most productive strains,Lactobacillus paracaseissp. paracasei P4155 is found to be the most effective in utilising fructans and citric acid. Most carbohydrates and organic acids in the juice can be converted to lactic acid by two homofermentative lactobacilli. The highest lactic acid yield and productivity is reached when using not-heat sterilised brown or green juice as the fermentation medium. The amount of free amino acids in the juice is increased and the content of vitamins and other important growth factors kept unspoiled by the lactic acid fermentation. The fermented juice can be stored as it is or evaporated to a concentrated form and used in fermentation industries for production of amino acids, organic acids, enzymes etc. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Lactic acid; Plant juice; Fermentation; Whole crop utilisation; Biorefinery

www.elsevier.com/locate/indcrop

1. Introduction

The green crop drying industry uses grass, clover and alfalfa as raw materials for production

of green pellets and solves their energy-economi-cal problems by pressing the green crop prior to drying.

The produced side stream, green or brown juice, has until now been spread on the fields as fertiliser. Problems with pollution of the ground water with nitrate, especially in the late autumn have, however, led to stringent regulations for the use of plant juice as fertiliser in many countries.

* Corresponding author. Tel.: +45-752-46533; fax: + 45-752-46540.

E-mail addresses: [email protected] (M. Andersen), [email protected] (P. Kiel)

In Denmark, from year 1999, plant juice will only be allowed spread on green fields in the autumn and not in the period between October 1st and February 1st.

The technology used at the green crop drying factories is in fact a first stage biorefinery with wet separation of green crops for multipurpose use as described by Carlsson (1998).

The green pellet factories can very well be

transformed to green biorefineries (Kiel, 1998), where the juice may be used for production of proteins, many different phyto-chemicals and fer-mentation products.

Until today this has however not happened. The problem with the plant juice can be solved by storing the juice in large lagoons from October 1st or by using the juice for other purposes. As storage can easily result in bad smelling waste

Table 1

Chemical composition in g kg−1of dry matter in green juice from first cut of different crops, and in one sample of brown juice from Dangrønt Products A/S Ringkøbing, Denmarka

Green juice from

Chemical composition of Green juice from Green juice from Brown juice dry matter (g kg−1) alfalfa 10/6–98 clover grass 27/5–98 Italian rye-grass 2/7–98 9/6–98

462.191.3 449.493.6

Water soluble carbohydrates, 137.091.3b 330.891.9 WSC

135.891.0 219.592.7 283.191.9 355.098.8 Free carbohydrates

107.1910.1 166.395.5

111.394.6

‘Fructan’ 0

3.290.1 5.790.2 15.290.4 5.690.01

Succinic acid

53.590.8 5.790.2

Malonic acid 17.790.2 6.590.2

16.390.1 8.990.1

14.690.2

Citric acid 8.390.1

33.790.8 36.990.9

Malic acid 42.891.0 24.390.01

0 0 0 5.090.1

Acetic acid

0 0

Lactic acid 3.390.1 63.191.0

Formic acid 0 0 4.590.2 0

98.791.8 120.891.4

Total organic acids 62.991.5 92.492.0

174.091.2 215.0916.7 264.2915.3

Protein (N×6.25) 349.096.8

Dry matter (%) 6.0290.005 5.9490.01 5.3890.001 3.3890.01

aAll samples were taken in May/June/July 1998. bDeterminations in triplicate.

M.Andersen,P.Kiel/Industrial Crops and Products11 (2000) 129 – 137 131

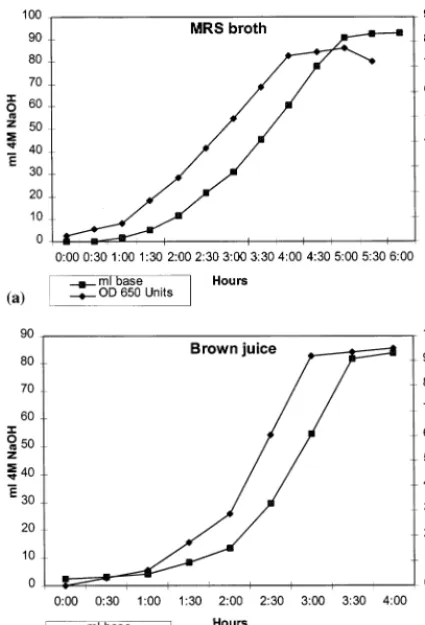

Fig. 2. (a) Growth curve and base-titration curve for a batch fermentation of MRS broth by L. sali6arius BC 1001. (b)

Growth curve and base-titration curve for a batch fermenta-tion of brown juice byL.sali6ariusBC 1001. The brown juice

was added glucose to reach the same sugar concentration as in the MRS broth.

Lier, 1994; Mu¨ller and Steller, 1995). The aim of this study is to find a way of simultaneous preser-vation and utilisation of plant juice for fermenta-tion purposes.

2. Materials and methods

2.1. Sources of juice

Italian rye-grass (Lolium multiflorum) cultivar Bofur, clover grass consisting of 50% of each of perennial ryegrass (Lolium perenne) cultivar Chantal and white clover (Trifolium repens) cultivar Milkanova, and alfalfa (Medicago sati6a)

cultivar Daisy were grown, harvested and cut by Borris Experimental Station, Danish Insti-tute of Plant and Soil Sciences. The fresh crops were pressed in a screw press, Kent Ma-chines type 164 Innopro AB. Sweden, and sepa-rated in juice and press cake. The juice was used fresh or kept in a freezer at −20°C for up to one year.

Brown juice was received at regularly intervals from an industrial green pellet plant, Dangrønt Products, Ringkøbing, Denmark. The samples were placed in a freezer at the laboratory, at

−20°C, immediately after receiving them. The brown juice is produced when the green biomass is heated to 80°C by steam, followed by pressing in a screw press.

2.2. Dry matter

The dry matter content of the juice was deter-mined after drying at 105°C for 20 h, in an Heraeus Type 6060 laboratory oven.

2.3. Sugar analyses

Content of mono-, di-, and trisaccharides were determined after centrifugation of the sample and the content of water soluble carbohydrates (WSC) was determined after mild acid hydrolysis. The increase in the total amount of sugars after hy-drolysis was ascribed to the content of fructans. products, other possibilities are now studied

M

.

Andersen

,

P

.

Kiel

/

Industrial

Crops

and

Products

11

(2000)

129

–

137

Table 2

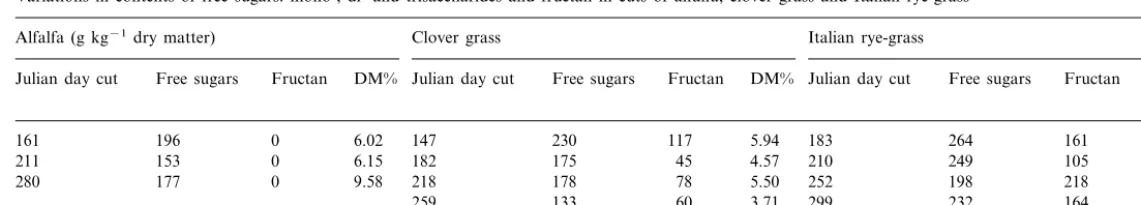

Variations in contents of free sugars: mono-, di- and trisaccharides and fructan in cuts of alfalfa, clover grass and Italian rye-grassa

Alfalfa (g kg−1dry matter) Clover grass Italian rye-grass

Julian day cut Free sugars Fructan DM% Julian day cut Free sugars Fructan DM% Julian day cut Free sugars Fructan DM%

117 5.94 183 264 161 5.38

161 196 0 6.02 147 230

45 4.57 210 249 105

175 4.62

6.15 182

211 153 0

178

177 0 9.58 218 78 5.50 252 198 218 5.07

280

259 133 60 3.71 299 232 164 6.59

M.Andersen,P.Kiel/Industrial Crops and Products11 (2000) 129 – 137 133

2.3.1. Sample pre-treatments

Hydrolysis of the grass juice samples were car-ried out by adding 2.5 ml of a 1 M H2SO4 to 20 ml grass juice. The solution was diluted to 50 ml and placed in a boiling water bath for 15 min. After cooling, the solution was neutralised with diluted ammonia. The hydrolysed samples as well as the untreated samples were centrifuged at 6000×gin a Heraeus Sepatech Contifuge 17 RS. Before the sugar analyses, the ions in the samples were eliminated by an ion exchange treatment in a mixed bed resin consisting of Amberlite CG 120 and Dowex 1×4 both from Fluka Chemie AG, Switzerland, and passed through a 0.45 microme-ter Sartorius filmicrome-ter membrane.

2.3.2. High performance liquid chromatography

For sugar analyses a high performance liquid chromatography (HPLC) system consisting of a Perkin – Elmer isocratic LC pump 250, a Perkin – Elmer Series 200 RI detector and a Perkin – Elmer Model 1020 integrator were used. The pre treated samples were injected through a Rheodyne model 7125 injector into a Bio-Rad Aminex HPX-87C column. The column was provided with a Bio-Rad IG Carbo C micro guard column. The column was kept at 85°C and the sugars were eluted with demineralised water with a flow rate

of 0.6 ml/min. Identification of the sugars were accomplished by comparing the retention times with those for known standards. For control of the method test samples were simultaneously analysed by means of an enzyme test method (Boehringer Mannheim no. 716260).

2.4. Analyses for organic acids

An HPLC system consisting of a 410 series LC pump (Perkin – Elmer), a RI detector Series 200 (Perkin – Elmer) and a PC integrator model 1022 (Perkin – Elmer) were used. The system was equipped with two Aminex HPX-87 H cation-ex-change columns (Bio-Rad), connected in series. To protect the column a Bio-Rad 1G cation H micro guard column was inserted. The first and the second column were operated at 35 and 85°C, respectively as described by Blake et al. (1987). After centrifugation and filtration as described earlier, 1 ml of the sample was injected through a Rheodyne model 7125 Injector with a 20 ml loop.

The eluent was a 5 mM sulphuric acid and the flow rate was 0.5 ml min−1. The organic acids were identified by comparison with known standards. Control of the results was done by comparison with results from enzymatic meth-ods.

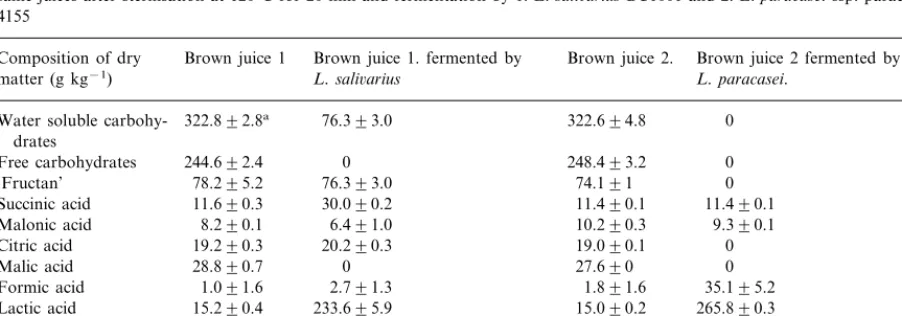

Table 3

Chemical composition of two different brown juice samples (1 and 2) in g kg−1of dry matter, and the chemical composition of the same juices after sterilisation at 120°C for 20 min and fermentation by 1:L.sali6ariusBC1001 and 2:L.paracaseissp. paracasei P

4155

Composition of dry Brown juice 1 Brown juice 1. fermented by Brown juice 2. Brown juice 2 fermented by L.sali6arius

Free carbohydrates 248.493.2 0

‘Fructan’ 78.295.2 76.393.0 74.191 0 Formic acid 1.091.6

233.695.9

Lactic acid 15.290.4 15.090.2 265.890.3

40.890.9

34.692.4 66.892.5

Acetic acid 34.690.7

388.498.2 119.692.9

331.098.3 117.694.2

Total organic acids

Fig. 3. (a) Contents of free sugars, fructans and lactic acid in brown juice, before sterilisation (light grey bars), after fermentation withL.sali6ariusBC 1001 of sterilised brown juice, (dark grey bars) and after fermentation with the same strain in not sterilised

brown juice (open bars). (b) Contents of free sugars, fructans and lactic acid in brown juice, before sterilisation (light grey bars), after fermentation withL.paracaseissp. Paracasei P 4155 of sterilised brown juice, (dark grey bars) and after fermentation with the same strain in not sterilised brown juice (open bars).

2.5. Micro-organisms and culti6ation media

Lactobacillus sali6arius BC 1001 was isolated

from grass juice at our laboratory Lactobacillus paracasei ssp. paracasei P4155 was kindly sup-plied by Dr Marina Mu¨ller, Centre for Agricul-tural Landscape and Land Use Research, Institute for Microbial Ecology, Paulinenaue, Germany.

The lactic acid bacteria were grown in MRS broth for 6 h at their optimum temperature, which is 40°C for L. sali6arius and 35°C for L.

paracasei ssp paracasei before inoculation of the plant juice.

M.Andersen,P.Kiel/Industrial Crops and Products11 (2000) 129 – 137 135

2.6. Lactic acid fermentations

Where nothing else is stated, the fermentation experiments were carried out with fresh, unsterile plant juice. The juice was inoculated with a fresh grown culture of L. sali6arius BC 1001 or L. paracasei ssp paracasei P4155. The amount of inoculum used was 5% (v/v) in the plant juice. The fermentations were carried out in double in 2-l fermentors with a working volume of 1 l. The fermentors were equipped with controllers for pH, temperature and agitation. The pH was main-tained at 6.25 by automatic addition of 4 M NaOH. The agitation speed was 92 rpm and the temperature was maintained at optimum.

The medium and the product were analysed for sugars and organic acids. All analyses were made in triple.

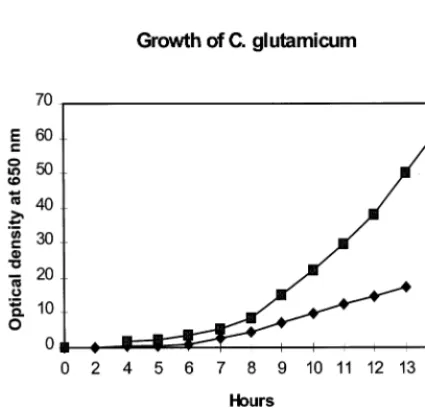

2.7. Growth experiments with Corynebacterium glutamicum V5

The lactic acid fermented juice of alfalfa was used in growth experiments with the strain ATCC 700235 of Corynebacterium glutamicumV5.

The growth in alfalfa juice was compared with growth in the traditional soy hydrolysate medium described in Section 2.5. In the new medium 2% soy hydrolysate was replaced by 46% lactic acid fermented alfalfa juice with a dry matter content of 12.3%. The growth was carried out in a 100-l fermentor with a 40-l working volume. The medium was sterilised at 121°C for 20 min. After cooling to 30°C and adjustment of pH to 7.0, the inoculum, 1% was added. The agitation was in-creased with the increase in growth and varied from 400 to 1000 rpm. PH was kept constant with 25% ammonia and dissolved oxygen was kept at 20% of saturation.

Every hour, a sample was taken to determine the optical density at 650 nm of the medium. Both fermentations were repeated.

3. Results

3.1. Chemical composition of plant juice

The total annual amount of brown and green juice produced by Dangrønt Products Ltd, Den-mark is about 100.000 m2

.

Table 1 shows the composition of green juice from different crops as well as one sample of brown juice derived from pressing of mixed crops. Italian rye-grass shows the highest amount of water soluble carbohydrates. The juices also con-tain some amounts of organic acids, especially malic acid and citric acid. The content of lactic acid in the brown juice probably derives from spontaneous lactic aid fermentation in the grass before pressing.

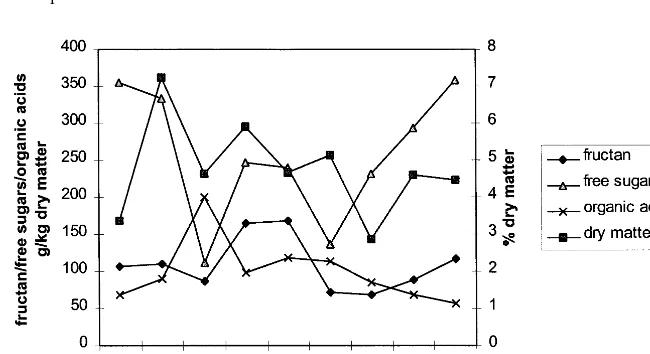

The content of mono, di- and tri-saccharides and fructans have been analysed in juices deriving from 3 – 4 cuts of alfalfa, clover grass and Italian rye-grass, as well as the dry content of the juices has been examined. Table 2 shows the variations in the examined samples.

The highest amount of fructans and total sug-ars are found in Italian rye-grass about Julian day 250, first week of September, where we found a total amount of carbohydrates of 40% of the dry matter, where 50% of this is fructans. Alfalfa contains no fructans.

Samples of brown juice were analysed for con-tent of dry matter, free and fructan bound sugars and organic acids.

From Fig. 1, it can be seen, that the dry matter in the brown juice varies between 3 and 7%, with an average on 4.8%. The amount of free sugars varies between 100 and 360 g kg−1 dry matter, the fructans between 70 and 170 g kg−1. The highest total amount of carbohydrates is found to be 47% in dry matter in June. A remarkable drop in the content of free sugars is seen at day number 211 and day number 280. As alfalfa is harvested only in short periods around these days, it is likely to assume that the drop in the content of fructan and free sugars in the brown juice is caused by a considerable increase of juice derived from alfalfa in the mixed brown juice.

The composition of the brown juice is not only influenced by the variation in the amounts of the different species of crops. The weather conditions, temperature, the fall of rain and the time after harvest where the crops are left on the field, before processing influence the final composition of the brown juice. It is thus reasonable to believe that low content of free sugars at the 211 Julian day is partly caused by lactic acid fermentation, before pressing, as the amount of organic acid (and particularly lactic acid) is shown to increase at the same time as the amount of free sugars drops.

3.2. Lactic acid fermentation of plant juice

Two strains giving the highest yield of lactic acid have been selected and compared concerning productivity and utilisation of carbohydrates and organic acids.

The highest growth rate and lactic acid produc-tivity is found with Lactobacillus sali6arius in

sterile brown juice. Growth in sterile MRS broth, normally used for cultivation of lactic acid bacte-ria and sterile brown juice with the same content of WSC are compared in Fig. 2(a and b), where it can be shown, that the growth rate is higher in brown juice than in MRS broth.

The chemical composition of brown juice be-fore and after sterilisation and lactic acid fermen-tation shown in Table 3 documents that the two

strains have very different abilities to utilise sug-ars and organic acids in the juice. Lactobacillus paracasei ssp. paracasei P4155 is found to utilise all available free carbohydrates as well as fruc-tans, citric acid and malic acid, whereas Lacto

-bacillus sali6arius BC 1001 is not able to utilise

fructans and citric acid.

Lactobacillus paracasei ssp. paracasei P4155 produces more formic acid and more acetic acid than Lactobacillus sali6arius BC 1001.

When unsterile brown juice is fermented by the two different lactobacilli as shown in Fig. 3(a and b), the same tendency is seen. The only difference is that we reach a higher yield with both strains, presumably because other micro-organisms and enzymes in the brown juice take part in the degra-dation of the different carbon sources.

The fermented juice has been stored for up to half a year under approximately anaerobic condi-tions in a 8 m3circular tank with just enough air space above the liquid to allow an UV lamp to be placed.

The juice has also been concentrated by evaporation.

3.3. Growth experiments with lactic acid fermented juice

Both evaporated and stored juice have shown to be excellent growth media for par example

Corynebacterium glutamicum, used for amino acid production. If peptone, yeast extract or hy-drolysed soy protein in a general growth medium is substituted with fermented brown or green juice with the same content of protein a very high growth rate can be obtained as shown in Fig. 4, where Corynebacterium glutamicum V5, ATCC 700239 is grown in lactic acid fermented green juice from alfalfa.

4. Discussion and conclusion

M.Andersen,P.Kiel/Industrial Crops and Products11 (2000) 129 – 137 137

adding more carbohydrates or for production of other organic acids or amino acids in a second stage fermentation. Experiments carried out on sterilised brown juice show, that the different lactic acid bacterial strains have different ability to utilise par example the fructans and citric acid in the juice. Fermentation experiments with the two strains in not-sterilised brown juice show that fructans as well as citric acid are converted to lactic acid, resulting in an increased yield with both strains. On the basis of this, it can be concluded, that fermentation in ‘not heat treated’ juice, where the content of naturally occurring plant enzymes is intact, is to be preferred. Of the tested strains, L. paracasei ssp. paracasei shows the highest yield of lactic acid (YLA/WSC=0.82) in sterile media, whereas L. sali6arius shows a yield

of 0.72. The same tendency is seen in not sterilised brown juice media. Here the yield (YLA/WSC) is1.1 for L. paracasei ssp. paracasei and 0.9 for L.

sali6arius. As the most effective and cheap way to

produce lactic acid (and lactic acid fermented brown juice) will be a continuous fermentation in not heat sterilised green or brown juice, it is important to choose a robust fast growing stain. In that respectL. sali6arius BC 1001 is until now

the most promising strain, as the strain grows very fast. Lactic acid fermented juice can be stored under anaerobic conditions without loss of contents of vital chemical compounds, at least in the winter period, and acidified, concentrated brown juice can be stored the whole year around. This, together with the fact that the acidified plant juice is an excellent medium for par example amino acid producing strains ofCorynebacterium glutamicum, leads us to the conclusion that green crop drying factories can be a good starting point for a green biorefinery, where organic acids and amino acids are to be produced in parallel with fodder pellets.

Acknowledgements

This research was sponsored by the program, ‘Increased Utilisation of Renewable Resources for Industrial Non-Food Purposes (1997 – 2001)’ un-der the auspices of the ministry of Food, Agricul-ture and Fisheries.

References

Andersen, M., Kiel, P., 1997. Agricultural residues and cereals as fermentation media. In: Campbell, G.M., Webb, C., McKee, S.L. (Eds.), Cereals: Novel Uses and Processes. Plenum Press, New York, pp. 229 – 232.

Blake, J.D., Clarke, M.L., Richards, G.N., 1987. Determina-tion of organic acids in sugar cane process juice by high-performance liquid chromatography: Improved resolution using dual aminex HPX-87H cation-exchange columns equilibrated to different temperatures. J. Chromatogr. 398, 265 – 277.

Carlsson, R., 1998. Status quo of the utilisation of green biomass. In: Soyers, K., Kamm, B., Kamm, M. (Eds.), Die Gru¨ne Bioraffinerie. Verlag Gesellschaft fu¨r o¨kologische Technologie, Berlin, pp. 39 – 45.

Cheeseman, C.G., 1976. The chemical composition of forage juice and its preservation. In: Wilkins, R.J. (Ed.), Green Crop Fractionation, The British Grassland Society, c/o Gras-land Research Institute, Hurley, Maidenhead, UK, pp. 39 – 46.

Kiel, P., 1998. Technology-development of the Green Biorefin-ery. In: Soyers, K., Kamm, B., Kamm, M. (Eds.), Die Gru¨ne Bioraffinerie. Verlag Gesellschaft fu¨r o¨kologische Technologie, Berlin, pp. 101 – 107.

McGrath, D., 1988. Seasonal variation in the water-soluble carbohydrate of perennial and Italian ryegrass under cut-ting conditions. Irish J. Agric. Res. 27, 131 – 139. Mu¨ller, M., Lier, D., 1994. Fermentation of fructans by

epiphytic lactic acid bacteria. J. Appl. Bacteriol. 76, 406 – 411.

Mu¨ller, M., Steller, J., 1995. Comparative studies of the degra-dation of grass fructans and Inulin by strains of Lacto-bacillus paracasei subsp. paracasei and Lactobacillus plantarum. J. Appl. Bacteriol. 78, 229 – 236.

Pollock, C.J., Cairns, A.J., 1991. Fructan metabolism in grasses and cereals. Annu. Rev. Plant Physiol. Plant Mol. Biol. 42, 77 – 101.