-SPECIFIC AGREEMENT BETWEEN THE GOVERNMENT OF THE REPUBLIC OF INDONESIA AND THE GOVERNMENT OF THE KINGDOM OF BELGIUM ON THE IMPLEMENTATION OF THE

PROJECT : Bdevelopmeセt@ OF PAL-SHIPYARD".

The Government of the Republic of Indonesia and the Gover ment of the Kingdom of Belgium,

Within the framework of the General Agreement on Technica Cooperation of June 16, 1969,

Considering the importance of the development of the ship! building industry in Indonesia and desiring to co-operate in エィゥセ@

field,

Have agreed as follows

ARTICLE 1. Description of the project.

The Government of the Republic of Indonesia and the Gover ment of the Kingdom of Belgium decide to co-operate in the imple ' mentation of the project : "Development of PAL-Shipyard",

hereinafter referred to as "the Project".

The Project is described in the Terms of Reference (T.O.R.) attached to this Specific Agreement and forming an integral part of it.

ARTICLE 2. Executing Agency.

The Government of the Republic of Indonesia designates P.T. PABRIK KAPAL INDONESIA (Persero) (P.T. PAL INDONESIA) as its Executing Agency.

. .

I .

.

-2.

The Government of the Kingdom of Belgium designates the General Administration for International Co-operation and Deve-lopment (G.A.C.D.) as its Executing Agency. The G.A.C.D. is represented in Indonesia by the Development Co-operation Section of the Belgian Embassy in Jakarta.

For reasons of efficiency, the G.A.C.D. will entrust the implementation of its contribution to an experienced sub-contractor.

ARTICLE 3. Contribution of the Government of the Kingdom of Belgium.

Within the limits of the budgetary means of the Belgian Government, the Belgian contribution allocated to the Project will not exceed B.F. 100.000.000. This amount covers the

following inputs :

a) The total cost of a team of eight experts for a total

period of 108 manmonths. These experts will be respectively specialized in the following fields

two all-round specialists; two wooden hull specialists;

two engineroom and ship's outfit specialists; two electricians.

and be acceptable to the Government of the Republic of

Indonesia. The travel expenses to and from Surabaya will be borne by the Belgian Government.

b) The training of twenty Indonesian shipyard technicians in Belgium for a total duration of 120 manmonths, the travel expenses of these trainees to and from Belgium and the necessary allowances for lodging and health insurance during their stay in Belgium.

c) Establishing of training facilities and supply of necessa-ry equipment for the training facilities at PAL including the dispatching of this equipment to Surabaya.

3.

I

d) Maintenance and operational training in Belgium for the user as detailed in the T.O.R. for a total duration of 48 man-months.

The Government of the Kingdom of Belgium will bear their tra-vel expenses to and from Belgium as well as the necessary allowances for board and lodging and health insurance during their stay in Belgium.

ARTICLE 4. Contribution of the Government of the Republic of Indonesia.

The Government of the Republic of Indonesia, in accordance with the prevailing laws and regulations, shall grant the Projec with sufficient means to reach the objectives described in the Terms of Reference.

More particularly the Government of the Republic of Indo-nesia shall

- appoint the Indonesian counterparts as well as the appropriate administrative and technical personnel required for the imple-mentation of the Project;

- select the candidates for training in Belgium;

- place at the disposal of the Belgian experts the shipyard's infrastructure and equipment as well as the off ice accomoda-tion necessary for the implementaaccomoda-tion of the Project;

- do its utmost so that the Indonesian counterparts be in a posi tion to fully devote themselves to the Project;

- provide the Belgian experts who will be appointed in Indonesia for the Project with the exemptions and privileges mentioned in article 7 of the General Agreement on Technical Co-operati-on of June 16, 1969.

- grant exoneration from all duties, other restricting rights and taxes on the equipment which will be delivered by the

Government of the Kingdom of Belgium as agreed upon in Article 10 of the said General Agreement.

. .

I .

.

-I

-4.

provide furnished accomodation and a service car for the Bel-gian experts mentioned in Article 3.a. during their stay in Indonesia.

ARTICLE 5. Control and evaluation.

At any time both Governments may supervise and/or control the state of progress of the Project.

Where necessary and after consultation, both Governments may evaluate the Project or part of its implementation aspects.

ARTICLE 6. Settlement of dispute.

Any dispute arising out of the interpretation or imple-mentation of this Specific Agreement, shall be settled amicably by consultation or negotiation between the two Governments.

ARTICLE 7. Modification.

Alterations and additional clauses to this Agreement can be made after consultation by exchange of letters between both Governments.

ARTICLE 8. Validity.

This Specific Agreement comes into force on the date of signing and remains valid until the full completion of the Project.

In witness whereof, this Specific Agreement was signed

at Jakarta on November /.5th by

For the Government of

the Republic of Indon esia,

Signed

Prof. Dr. Ing. B.J. Habibie Minister of State for

Research and Technology.

1981, in duplicate

For the Government of the King<lom of Belgium,

Signed

Jacques I. D'HONDT Ambassador.

'

)

.('

TERMS OF REFERENCE.

l

..

I,,

-·.

•.I

.

'

TABLE OF CONTENT

. ; !. ... .. .

I.:

1. . Justification of the Project

2. nセBGャB・@ of the Project

..

• \ ; "\ •• • I:- • ·••·

3 . Institutional Frcr.ework . .. .. . ... . .. . -. ... -..

4. Content of the Technical Assistance

NNセ@ ...

...

·-··

a. : · Training of PAL Personnel at PAL ·· .,.. . -... • ..,.. - · ; ᄋセ@ • - - · ·--(",(' ... -·. ' •' セ Mr . - · - J . . - -·- .• :..-· - -•

b . Training of PAL Personnel .at Belgian Yards · ... ·· ·-· ·· · , . ... .

_ _ M ᄋ Mセ ᄋ MMMᄋ MMᄋ MM cLM M MMMセウ ⦅エセャゥウィゥョァ@ __ of_ TJ::ai.ning _ fas:ili_ties M セョ、@ __ Supply_. C?:f ... セMM NLNNセ M MMM

·s .

6.

-. .

Necessary Equir.nY"J1t at PAL

I

a.

:!Vlai.ntenanceana

.Oferational Training . for G エィセ@ セuウ・イ N ⦅@ .' : ·- ..

..

'ᄋセN@ ·

..

·Belgian Input . · :-.

.... . ...

·--

. . -· ··· ... · . . : ....Indonesian Inout . . ' .

. • .. . MN セ@..

1 .. . .

. t:. - ·· .

. -:·. . . . . .. . . ....

: .. ·: ... · ...

セ MZ@f

•'

. ...

: • • • • ·-' . __ .. . . . - ; _ _ • • · - - - · ' ¥ : , . - •• Zセᄋ@ セMᄋ@

• • .1 • •

.

'

.

.. ! .. • . -:- ·-:· .... · • . :.:--· .- .

.. .• _ .·.·:i": • : •

... ! · ·

·-.::: ZNセZN@ Mセ@

..

j

1

キセ@

--2.

1. Justification of the Project

Due to its geographical situation, maritime transport plays an

important role in Indonesia's economic life.

Consequently, the government of the Republic of Indonesia intends

the further expansion and development of a local shipbuilding

in-dustry.

Partnership with existing foreign yards is one of the ways to attain

above mentioned goal .

On 15th of January 1980 a Beleian joint venture of three shipyards

(Belgian Shipbuilders Corporation) concluded an agreement with

PAL shipyard, the latter represented by its President Director,

Prof. Dr. Ing. B.J. HABIBIE.

The agreement encloses :

a. Technical cooperation between state-owned PAL shipyard in

Sura-baya and above mentioned shipyards, for the construction of all

types of shallow-draught vessels for inland water navigation

and for coastal shipping .

b. Technical cooperation between same yards for the joint building

in Surabaya at PAL's yard, of 12 fast patrol boats for the

In-donesian Ministry of Finance.

The PAL shipyard in Surabaya have large premises and already existing

facilities, but the facilities have to be up-graded and the skill of

the personnel to be increased in order to meet necessary efficiency

levels.

Therefore, the government of the Republic of Indonesia applies for :

a. Training of PAL personnel by Belgian technicians, both in Belgium

. -.,.,

M セM

. i

.

-,.· ·:..

•).·

3 .· b. ····-Supply of m::x3.ern tools and equip.rent for the up-grading of

PAL shipyard .

..=.

I ' . · • - .

.

.

セ@ .. . --:.·.... .. ,

, ;

: _

..

·· : t

;-'..·

..

: .. :, .-. .'-·_ :;·- . : セᄋ@.. ; . . . . . . . ᄋ N セ ᄋ@ __ .. --· .. ··· ' -.. .:.

[Z [⦅ZMMセZNZNZᄋZ⦅@ ....:.:

... ,;. · .. '::

·:

.. ' :·-... セ@ .. :..

: . . M セMᄋMᄋ@ セM セ NLLZ@ _ ... -.

'. . .. .. N MMᄋMNセZMN@ -. -...

セNN@ . ,. ...·•. -. --": _., ·• .·· . : ... セᄋ@ .. Zセ@

.. ;_ · ... .. . ·"': .. : ··.··-·

--:·:·

7 -:-:

.. "'.

セM セ@ Mセ ᄋ セNᄋNZNZᄋ⦅ZZ@. ..:: .

NMZイセ セ Mセ セエセセM[セ⦅[[N@': -.

• • セ@ ' I • ' • • ;... • :

. -·-:: -·

..

., .. · · . i t '

- ···' r •· . ..

-·-

...

..._., . ,. ... ,..

セᄋMᄋMGZセZMM セMセ[NM[NNNN@ '·...

:---.. . ,....; :. ... セ@ N⦅NZ⦅NL⦅セ MセMNNNN⦅ZNセᄋM ᄋᄋ セᄋᄋ@ .. li..,.r .. イセZ@ _.,.. .... セ@ ... セ M...

-":.-·-.. .· ... MNM セMM .. _ ... NZNM MセZ@ ..• --: ,,, MMAMセ M ·-·.

-

__ _ ...- -

---

·---

M[Mセ@ セMMMセ@---

·----·

, - .. .-

.. --... ---GᄋMMMMMMZMM N MセMMBBGMM Mセᄋ@ . -... ...

· · .. :... . """ ---:·-·· . ·.-···-:·.. ... ...

-.-,· .. •'•

..

. ' ,: . M セ@ : . · .. . . セ@ ...

.

,• ; · ..··' -.. . セ ᄋM - . J

· . '

• ' .<'

. :

-

-.. 1

.. . " .,.

. .. ··-- .I_

N. '

J

-4.

Name of the Proiec t

The Project will be known and referred to as

5.

3.

Institutional frameworkBeneficiary of the technical assistance will be PAL shipyard, in

full :

PABRIK KAPAL

P.T. PAL I NDONESIA (PERSERO)

UJUNG - SURABAYA

INDONESIA.

Property and management

- The Indonesian State, through its Ministry of Finance is the

only and 100

%

shareholder of above mentioned company.- The Government of Indonesia through the President Director who

is responsible to the Minister of Finance, has the management

of the PAL shipyard in hand.

...J , r ._.

..

c

I . l .. . , '\ 4 . 6Content of the 'Technical Ji.ssistance

Tne technical assistance will consist of . four major parts

' .

... .

. . . . "..

"'-;.,, -...a . TraiD:ing of PAL personnel. at PAL. · · ;

·-. ·-.·-.·-. ,,

b . Training of PAL :p2rsonnel at Belgian yards. · · ·

c . Establishing . of tra ining facilities and supply of necessary

d.

セゥ セ イ・Nョエ@ foi: the t rain:ing facilities at PAL . ·

:tv'..ainten ance and Of>2ra t i onal training for the . user'.·· ..

' ; · · . ;,

セ@ • • • • 1

-· .... ... . ... · .. .• .. ·, ....

...

. . . . :. .. セ@ - ...-

.:.... .. • . . . l ...

.. , , . ,.. · . .

.

... .·

. •.

• r ! • • ' • • _ , ,.._ • •

·.:

'.

· -

..

.,. . .. .... .... ...--

.-. :-: ··-= , ... セ@ .. セᄋN@ Zセ@ -; ... · .... ᄋセ M MZ@ Mセ ᄋᄋZ@ : .... ..

c . . . .

: j ' セ ᄋ@ •::: : ..• -セ@... . . ...

f .: • : ·.

-. ... -. ....

- -- - ----:"'-.,._,..

___

,__ ...-

.... - --..-

--I .

l'T'-· - .. - -. . ... -· --L ,#_,:. •.. , .. __ . ,...:_. ____ ___ セMM L⦅@.... :•.I ''"-· -

.

. ... " _ ,, "...

. .:..., ... ._, _,,

• < •

. '

.. ... -セ@ . .;. ... セ@ ·-·

-

-

...-·

.. _.- --··---· - --- ----... - ---- --.... --·---- -·:-- --- -. - ·-. - -"P"--=--:...·

..

:.. ,..

· · ••': . ... . ·-···:··• !"

... ··

: . セ@. .

···. •. :·

. : . ;a..

. ... __ . ..

,

·. ... __ , .. . ·• セ@ .'

. '-

- - - ·-. • . ""

----·- --

MMMM M MMMMM M MMMMMMM MMMセMMMMMMMMMMM.. ·· ... ·

-4/f.I., ,

- - . . . - _ ... _ .. セ NNN@

.

---

-

-

-----

--

- . . _ . ( - MMMMMMMセ M M MMM セ@ - .a. Training of PAL personnel at PAL

1. Scope

Because of lack of practical marine construction experience

especially in the field of fast patrol boats, Indonesia is in

need for specialists to assist and conduct the technicians and

skilled labourers initially trained in Belgium.

Specifically to assemble and build fast patrol boats, which

are supplied in components from Belgian yards.

Furthermore, it is for economic reasons essential for the

Re-public of Indonesia to have these boats at their disposal, in

operating conditions, at the shortest possible time.

Belgian experts, supervising the assembly and construction of

fast patrol boats at PAL and assuring a follow-up of all skilled

Indonesian labourers and technicians already trained in Belgium,

will be sent to Indonesia.

Minimal following specialists will be necessary during the

as-sembly period :

2 All-round specialists (Spipbuilding and Maintenance)

2 Wooden-hull specialists (Carpenters)

2 Engine room and ship's outfit specialists (Engine fitter and

Pipe fitter).

2 Electricians.

Duration of the stay in Indonesia will be 12 months for each of

the specialists. However one specialist will have to stay in

Indonesia for 12 months after putting the boats in service, in

order to establish maintenance procedures .

2. Timing.

One specialist of each trade must be available when building

8

one or two months in advance, in order to prepare the work

and to settle.

This will enable them to start assembling as soon as the first

components arrive at PAL.

The global period for assembly of 12 fast patrol boats is

esti-mated to last 18 months.

3.

QualificationsAll experts are to be specialists in their セー・」ゥヲゥ」@ field and

to possess a ample experience in shipbuilding and

shipmainte-nance.

A carefull selection is necessary and all retained candidates

'

9b. TRAINING :oF " P A L " personnel at Belg.ianyards

1. SCOPE.

People of following trades will be trained _in Bel_gium

1 technical supervisor 4 carpenters

3 aluminium welders 3 boilermakers Z aluminium workers 2 pipefitters

2 engine fitters 2 electricians

1 technician for mechanica l workshop.

Duration of training period will be 6 months for each of the 20 participants.

2. TIMING.

The training .will start 1

.before October

セ@

1981.

3. SELECTION OF THE CANDIDATES. , '

The curriculum vitae of tne candidates will be forwarded by the Indonesian

--

·-- - . -- __ , ---

-·-

authorities . - - ·-· - -·- - - -- · ___ - - - · - -- -- _ ___ _For each of the trades specific qualifications are イセアオ・ウエ・、@ and mentioned

below. セセ@

4. SPECIFIC QUALIFICATIONS AND TRAINING PROGRAM FOR EACH TRADE. TECHNICAL SUPERVISOR (1 man)

a. ァセセAセセセセセAセセセセセ@

The candidates should have a t e chnical s chool forma tion of higher degree or a practical experience of ten .years in a ssembling and rrechan ics.

It is for training purposes also necessary to have a good command of English and/or Dutch.

b . AセセセセセセセM・セセセセセセセセ@

As the technical ウセー・イカゥウッイ@ will be in ch arge of all other エセ」ィョゥ」ゥ 。ョ ウ@

he will be given a cl e ar insight into the training t echniqu es for his fellow-trainees.

Furthermore, his trnining will consist in closely ass isting the

\

'

BOA18UILDERS - CARPENTERS (4 men)

a. ァセセセセセセセセセセセセセセM

10

The candidate Chief boatbuilder (and/or foreman) should have a basic technical knowledge of carpentry, acquired either at school (with .·

minimum a primary school certificate) , either through practical experience. For the candidates 「ッ。エ「セゥャ、・イウ@ a basic piimary schoo l formation is

highl y desirable but not absolutely necessary. The nature of the work requires a good health.

The group must have at le as t one candidate with good command of English and/or Dutch, to act as int erpreter for the ッエィ・セ@ candidates, if necessary. The candidate Chief - boatbuilders (and/or for eman) must ィ。カセ@ a good command of English · and/or Dutch.

b. AセセセセセセセM・セセqセセセセ@

To get acquainted with wooden boatbuilding practices in general and particularly with glueing techniques for the construction. of keel, stem and transom and furthermore with the ーャ。ョォゥョセ@ process for the hull, following t r aining programm is fo resee n

Theoret ical training (6 weeks)

- Knowl edge of ma t er ials, wood, different ty pes of giue , fastenings and

ᄋセ@

f astening methods . セ@

Buying a nd selec ting of timber .

- Knowl edge of tools and machines ( sawing, pla.ning, e tc.) Sawing of logs.

Drying of wood .

Workshop organisation and l a y-out. Safety precautiops.

Practical training . (20 weeks)

Necessa ry jigs for glue ing of kee l, s t ern and tr ansom sec tions. Acquisitiion of good ski ll in manufacturing kee l and ste rn sections. How to work with machines .

Making scarf j oint s . Glue ing p:ITicesses . Planking proces se s.

Marking , mak i ng , shaping and fi tt i ng セ ヲ@ woode n se ctions .

An addi ti ona l th eoret i ca l and practical traini ng will be given to the cand i date Chief-bcatbuilder ( and/6 r ヲッ イ・セ。 ョI@

dオイゥセァ@ this tr a ining special attention wil 1 be tive n to spec ific technj ca l

probl ems that might occur when assembl i ng the vesse l. Training will be given in !"3elgiurn .. ⦅MM⦅LNᄋセMセ@ · ·--,--, .:·_ .. ..

\

ALLJ;·HNIUM WELDERS ( 3 me n ) a . ァセセAセセセセセセセセセセM

11

The candidatesChie f-we lder (and/or foreman) should have a basic

technical knowledge acquired either in school (with minimum a prima ry school certificate) either throuah ッイ。セエゥ」。ャ@ exoerience . '

For the candidate we lders a bas ic primary schoo l leveL is highly desirable but not absolu tel y necesaary .

Due to the nature of the work a good hea lth is required .

The group must have a t l eas t one cand id ate with good command of English and/or Dutch, to ac t as interpreter for the othe r candidates if necessary. The cand id ate Chi e f-welder ( and/or fore man) must have a good command of English and/or Dutch.

. セ@

b. Aセ セセセセ セq⦅・セセセセセセMセ@

To be ab le to construct and assemb le sections of new ships and later execute all kindsof maintenance and repair work , following training programm wil l be for esee n :

Theoretical training (6 キ・・ォウセ@ ___ - - - -··----Knowledge of materials .

- Knowledge of tools and we lding equ i pmen t. Knowledge of welding codes .

Safety precautions 2nd rules. Prac tical training (20 weeks)

Handling of welding equipme nt. Fla t we ldi ng techniq ues .

Flat horizontal weld ing techniques . Vertica l welding techniques .

Overhead welding techniques . Gauging (Arc-Air )

An addi tional theoretica l and practica l training will be given to the candidate Chief-welde r (and/or foreman) .

Extra at t entio n will be qiven to specia l LJelding problems that mig ht occJ To rraierialize above ment i oned progr;:;iT.m , insiruciors aS' L1ell as a ll

n2ceasary docum2ntation , ・アオゥセセウョエ@ and materials wil l t2 put at disposal

..

.\

.

12 .!

TECHNICIANS FOR ASSEMBLING - bo ile rmセers@ (3 men ) - ALUMINIUM WOR..£,ERS (2 men )

セセNYセセAAイAセセAAセセセセM

The candidates should have at least a technical school level of lower degree or a practical experi ence of five year in assembling in the steel working industry.

It is also necessary that they have a good command of English セセ、Oッイ@

Dutch.

b. iセセAセAセセM・セセYセセセセセM

Theoretica1 training (6 weeks) Reading of drawings.

- Knowledge of materials .

=sa fety precautions and rules.

セ@ Use of portable machines TIG/MTG welding machines Drilling machines

Grind ing machines· Gauging machines Woodworking machines .

- - - · - - _ _ . t . . . - _ __ _ .. _ _ _ -

-Practical training (20 weeks ) for steel ships.

Practical experience in assembling . Oxy-flame cutting .

Tack welding for assembling.

Straightening of sections and joints after welding . For wooden and alu . vessels.

- Keellaying and straightening . Alu. sections assembling in keel.

Adaptation if necessary by heat or cold input. Steel sections of engine room assembling by means Frame adaptation and connection to sections .

- - - -

- - - ----

--

-

\

13

ENGINE FITTERS (2 men) a. Qualifications.

--- The candidates shou ld have at l eas t a technical school level of l owe r degree or a practical e xperience of five year in marine mechanics and/or marine propulsion systems .

In view of the required spec iali sat ion, experience is i mperat ivE. A good coITTTiand of English and/or Dutch is necessary .

b. AセセセセセセセM・セセセセセセセセ@

Theoret ical training (6 week s) セ@ . Reading of drawings .

- Knowledge of materials.

..

Additional . course to c omplete Safet y precautions and rules .

mechanica l ォョッセゥ・、ァ・N ⦅@ ..

Practica l training. (20 weeks )

Installation and alignment of mai n engines . --·----·-- - - ·- :- In sta llation ·or propeller shafts -. - - ,

Install ation of auxiliary pump sets , etc . Insta llation of rudders and steering gear. Installation of windlass.

Maintenance of engines .

PIPEFITTERS (2 men) セ@

a. Qualifications .

--- --- --- --- --- ---

MMMMᄋセMMMMMMThe candidates shou ld at least have a technical school l evel.of lower degree or a practical exper ience of five year in pipe construction.and installation.

' l

It i s 。ャウ ッ⦅ N セ ・」・ウウ。 イケ@ to have a good c ommand of Engli s h and/or Dutch.

b. AセセセセセセセM・セセセ セ セセ M

Th 2oretica1· training_(6 w2eks ) Reading of drau..1i11gs , diagrams , Kn0tt.1ledge of materials (pipes , - Knowledge of tools .

l

plans , isorn2trics . joints , valves , etc .) Additional course to complete mechanical knowl edge . Safety precautions and rules •

. Practical training . (20 weeks ) Bending of ーゥーセウ N@

Basic knowl edge of welding and oxy-flame cutt ing. In sta llation of pipes .

Tes ting of pipes and piping systems .

--..

-...

-\

14..

ELECTRICIANS (2 men) a. Qualifications.

---The candidates should have at l eas t a technical school level of lower degree or a practical experience of 5 year in electrical installations. A good command of English and/or.Dutch is necessary.

b. AセセセセセセセM・セセァセセセセ@

Theoretical training . (6 weeks ) Reading of drawings and plans. - Knowledge of materia ls.

Knowledge of tools.

Additiona l course to complete mechanical knowledge. Sa f et y precautions an d rul es .

Practica1 ·training.

Electrical installations on board of ウィセーウᄋN@

TECHNICIAN FOR 1-'C:CHANICAL WOW.SHOP (1 man) . a. Qualifications.

---The candidate shou ld at l eas t have a technical sc hool level of lower

.

.

degree or a practical experience of five year in a mechanical work shop . A good command of English and/or Dutch is also necessary .b. A セセセセセセセ M・セセァセ セセセ セ@

Theoretica l training (6 weeks) Reading of drawings .

KNowledge of ュ。エ・イゥ。セ@

- Knowledge of machines an d tools .

Additional course to comp l ete mechanical knowledge . Safety precautions and rules .

pイセ」エゥ」。 ャ@ trainino . (20 wee ks)

Practical formation and training in operating 12the

milling machine planing machine drilling machi ne etc.

In order to ma t erialize above mentioned training programms , the instructors and all necessary documentation , equipment and materials will be put at di spose. of the trainees by セ@ 1 BELG I AN · · yards .

0./.

-

_Jo/'

c. ESTABLISHING Of TBAINING. FACILITIES AND . SUPPLY OF

...

NECESSARY EQUIPMENT TO PAL.]]]]]]]]]]]]]]]]]]]]]]」]]]]]]」]]]]]]」セセセセ」」」」」」q セ@

. .

: Complementary to the エイセゥョゥョァ@ giv e n in Belgium, a セー・」ゥ。ャ@

· theoretical and practical training course will be organised. In order to materi a lize this p rogra m, ョ・」・ウウゥセケ@ equipment

for the エイ。ゥセゥョァ@ an d for the construction of. セQセセ・ョエウ@

of the boats , will be put at the disposal of

PAL

shipyard in Surabaya .The supplies for these faci l i t ies consist of : 1. Wood drying oven

2. Air conditioning system for the workshops . 3. Overhead bridge crane.

. 4 • Ship transport system.

----5.

キセッッ M エゥM[セ」ゥQゥョ MY@

system·.-6.

Supporting pillars 7. Hydr a ulic jacks.8. Wood working machines

9. Machines and too l s for assemb ly and preassembl y of

wood parts . ...

10. WG セ 。」ィ ゥョ ・ウ@ for assembly of aluminium sections .

11 . Machines for building the sections .

12 . イ ᄋ セ。」ィゥョ・ウ@ for the pipe fitters . '

13. r<a c hines for the fitters .

11 . Mac hin e s for the el e ctricians . 15 . Moc hines for finishing .

16. Ma c hines for plate shop .

..

'. ..

- - ---

---- -

---I

16

1. WOOD DRYING OVEM

Required for drying wood to assure correct adhesion of the glue to the following ·types of wood :

Teak.

Iroko (Kambala). Mahogany.

Thickness 14 to 65 mm (1/2" to 3") Begin dampness

.

.

100%

End dampness

.

.

12%

Drying capacity

.

.

50m3 pro month when filled to 80%

of capacity. Energy requirements :The drying oven

heating + 500.000 Kcal/hour.

2

damping steam at

o,s

Kg/cm , 60.000 Kcal/hour. should be fitted with :- access door.

electric air circulation ventilators

セ@

control box.

set of heat batteries with steam

fresh air inlet value in corrosion resistant material.

electric exhaust ventilator wet temperature regulation dry temperature regulation - wet temperature indicator - dry temperature indicator

- electric motor for operating the damp an d fresh air v alves.

- safety thermostat. - steam injection pipes.

- fully automatic operation Controled by the dampness of the wood.

damp air exhaust valve in corrosion resistant material.

セlイ@

Around the drying ' overi-.- i -s foreseen : '

Wagons and rails for transporting the wood loads.

The electrical connections for steam and condensate.

Boiler.

The starter.

- - ---

-

...-

--

- -

- ---

-·- ---.,--

..---·----セ@ ... - -. . . .. - · - - - ... - - - · · MセMMM - - - . : • " 4 • - MMMMᄋセセM

2. AIR CONDITIONING SYSTEM

Air conditioning system for a timber storage space an d for an assembly hall with adjacent wood-working machine-hall for the treatment of wood, as well as for the prefabrication and assembly of wooden components.

The desired conditions are :

- constant 60

%

relative humidity. - air change : twice per hour.Installation appropriate to the height, draught proofness and construction of the buildings.

Included in the installation are : cooling compressor and all required electric, hydraulic, and pneumatic セッョョ・」エゥッョウN@

The building is assumed to be well insulated so as to avoid condensation.

---

---- -------·

..

3. OVERHEAD CRANE.

Lifting capacity Controls

19

6,3 T

: Floor ccntrolled by push buttons.

Control box free to move along the length of the bridge.

Span According to the building.

Max. height of lift: According

to

the building with a minimum of 9m.Hoist speeds

Translation Bridge speeds

.

.

.

.

:

High speed :

Low speed

.

.

Speed.

.

High speed.

.

Low speed.

.

4,oo

m/mino,4o

m/min1.6 m/min en

4

m/min 25 m/min6,3 m/min

- The hoist セセアオゥRー・、@ with a load limiting switch. In case

---of an overload a red セ。イョゥョァ@ light under the hoist is switched on. The lifting operation is interrupted and only the lowering mode remains in operation.

- Crane equipped with travelling bridge according to the

pre-scriptions.

..

Necessary safety instructions in the English lan guage fixed to the bridge according to regulations.

- Instructions and spare parts book in English •

.

- Limit switches on all ュッカ・ュ・セエウ@ (bridge, hoist an hook).

- Bus bars and brushes for electric current. (length of bars ca 66 m)

...

204. SHIP TRANSPORT SYSTEM.

4.1. According to the possibilities of the yard. To be studied in conjunction with the planning of the yard and infra-structure. (Drawings to be made up by PAL)

.ternative 4.2. Hydraulic trailer with steerable fore and after wheels.

5. WOOD HANDLING SYSTEM .

Handcars with rubber tires.

- 2 pcs. 4m x 1m wide cap. 1,5 T - 4 pcs. 2m x 1m wide cap. 1,0 T

6. SUPPORTING PILLARS

--'---

- - - -

---8 pieces •

•

7. HYDRAULIC JACKS

..

8. WOOD WORKING MACHINES.'

One piece of each item unless otherwise indicate d.

セセセセMAセセセセセセセセAセR⦅eャ。セセセM

Width of plane Thickness of plane Cylinder

Blades Motor

,

630 mm

200 mm

preferably with 4 blades. from widia steel·s, 4 sets 7,5 HP

Machine supplied with dust extraction outlet, dia 120 mm

S pe ed of feed : 6 to 16 m/min With jig for the adjustment of blades. - cッョヲ・イセ@ to the Belgian safety ウエ。ョ、。イ、セ@ •

..

. ,.

セAセAMセセセAセセセMセセセセセセセ@

Plane width 500 mm

Cylinder Motor

: preferably with 4 blades : 7,5 HP

Blades from widia steel, 4 sets

With jig for the adjustment of blades.

Feeder Automatic fe e der with the following

characteristics

8 speeds from 2 to 33 m/min - 3 fe e der rolls

fitted to stand on the planer - power of motor :

o,7

KW22

distance between column and rollers 580 mm Dust extraction with outlet of' dla セRP@ mm.

Conform to the Belgian safety standards.

-..

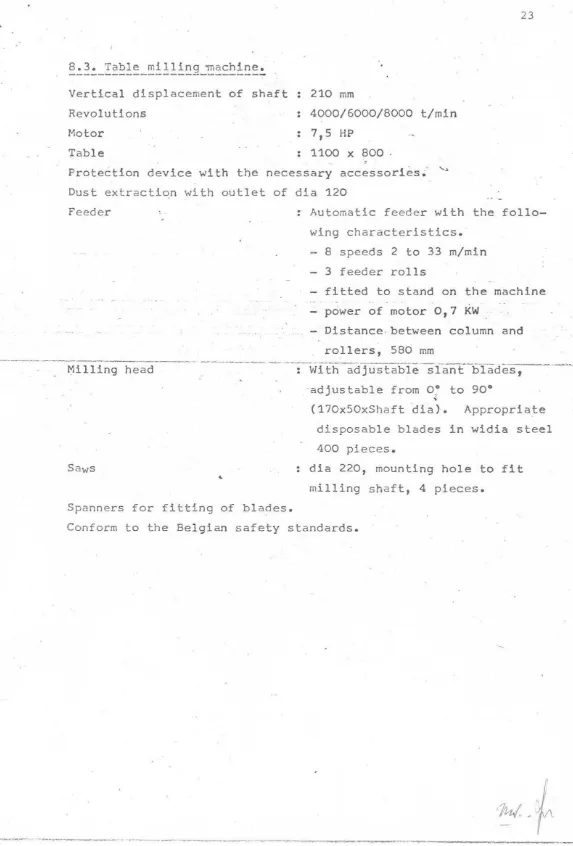

23Vertical displacement of shaft 210 mm

Revolutions 4000/6000/8000 t/min

Motor : 7

,s

HPTable 1100 x 800 .

Protection device with the necessary accessories.- Gセ@ Dust extractiqn with outlet of dia 120

Feeder : Automatic fe eder with the

follo-wing characteristics. 8 speeds 2 to 33 m/min

3 feeder rolls

fitted to stand on the machine power of motor o,7 KW

Distance .between column and ro.llers, 580 mm

Milling head - --- -: - wft-h adjustablesfant - blades,

Saws

..

Spanners for fitting of blades.

adjustable from ッセ@

..

to 90°(170x50xShaft dia). Appropriate disposable blades in widia steel 400 pieces.

dia 220, mounting hole to fit milling shaft, 4 pieces.

Conform to the Belgian safety standards .

[image:29.620.19.592.3.849.2]...

セセセAMセセセAセセセR⦅RAセセセMセセセセセセセセMセセセセMセセセセセᄋ@

\Shafts : 6

Plane width Plane height

Surface plane shaft Side plane shaft

Horizontal shaft

.

.

Vertical moulqing shaft Universal moulding shaft:

210 mm

125 mm

7,5 HP

5,5 HP

7,5 HP

s,s

HP7,5 HP

(1 shaft)

(1 shaft)

(1 shaft)

(1 shaft)

(2 shafts)

Rセ@

G セ@

Feeding mechanism Feeding speeds

: through driven upper and lower rollers.

o,75 HP with stepless adjustment from

6 to 36 m/min. _

Shafts fitted with spacers for clamping of tools. I

Blades consisting of : 6 ーャ。ョセョァ@ heads, one for each shaft.

/

Fitting jig for blades.

per head 4 sets of widia blades

2 fraises for grooyes, セゥ、エィ@ v a riable from 3 to 6 mm.

Sets of tools for fitting blades, upkeep and lubrification. Technical handbook • ...

- Dust extraction outlet dia 150 mm on each shaft. Conform to the ' Belgian safety st a ndards.

-- Mセ@ ... r----·

8.5. Circular cut off saw .

---Cut off saw with pneumatic operation and handgrip for manua l operation.

- Travel : 600 mm.

- Saw

. .

: dia 400 mm , hub compatible wit h machine shaf t, widia teeth, 2 pieces.

Equipped with side table and measuring scale.

Equipped with dust extraction outlet : dia 120 mm

..

25

I ...

i

'

I

I

t.

·

.

,.

26Max. distance between sawblades

.

.

270 mm •Chain width

.

.

290 mm •Max. thickness of wood

.

• 110 mm • Max. diameter of sawblades.

.

275 mm •'

-Min. distance from swanneck to

outer sawblade 780 mm.

Shaft revolutions

.

.

2850 RPMMotor fTlin. 40 HP

Feeding speed

.

.

7 to 55 m/min. stepless.Feeding motor

.

.

3 HP- Equipped with robust non return device and necessary safety fittings.

Delivered with _ 10_ special _ sa'!'.Jblades, 350 dia, with widia teeth

·- --

---- -

.

-·-

----

----

---for sawing moulmain teak.

- Apertaining spacers for cutting planks on ウエイゥーウセッヲ@ 120 mm and 20 mm width.

- Apertaining set of spacers, various sizes between 20 and 120 mm.

8.7. Band saw.

Saw wheels Band saw Table Motor

;·

Dia 800 mm

Max. width 45 mm : 1200 x 800

· : 5, 5 HP

Saws : 10 pieces

Dust · extraction outlet Dia 120 mm

Conform to the Belgian safety standards •

..

27

-

.

28

8.8. Scarfing machine.

---,--Machine adapted by a specialized Belgian yard for making scarf joints on planks upto 25 mm thick.

Basi c machine : Heavy duty moulding machine with spindle in-clination variable to 45° and very slow turning spindle 2400 R.P.M.

Modifications

Included

- fitting of appropriate dust extraction outlet. - fitting of sawblade, dia 560 with 48 widia

t e eth, inclination WLセSᄚN@

セゥエエゥョァ@ of sliding table with plank 」ャ。ュセゥョァ@

mechanism.

: - 2 saws , dia 560, widia teeth.

Mobile upper table, lower table fixed. - Table surface, 2,55 x 1,30 m.

Complete with two heated pressure platep.

. 2

Pressure variab_le from 2_, 4 _to _3, _5 __ }\g/cm セ@

Total セャッウゥョァ@ force, maximum 20 T. - Opening betwee n tables 450 mm.

Lo a ding width

2,so

m.,...-- セ@ ·-,_

-- He ating, by means of closed circuit circulation of el e ctrically heated fluid.

29

-..

8.10. Panel saw.

---Diameter sawblade : 400 mm.

Max. depth of vertical cut : 125 mm. Saw inclination

Saw revolutions Motor

Sliding table Saws

: 45°

: 3000/6000 rセpNmN@

S,S HP

3750 mm.

Dia 400 mm - 4 pieces. Toois for fitting sawblades and upkeep.

Dust extraction outlet : Dia 120.

Conform to the Belgian safety regulations.

- - - -- - - ---

--

---..

セセセセセMAセセAセMAセZZ⦅RAセAセRMセセᆪセARセセMQセAセセセMセAセセMセeRᆪセeᆪセセAセ@

セセセセeセᄋ@

8*11.bis Assemb ling jig for transom with appropriate

--- Pattern o f stern profi le made from plate steel, minimum 8 mm .

- Clamps wit h depth a dju stme nt for successive cl ampi ng of layers.

セセセセセMセセセAセ 。 エAセR⦅ゥAR⦅セセセMセeRZZセeZZAセセセMセAセセRセMヲセセMセセセAセR@

セセZZAセRセZZセN@

.

Shape according to lines p l a n . -- Made from HEA profiles or we ld e d profiles.

Cl amps for clamping every 25 cm.

Pneumatic pres s jig oyer 39 sections.

31

1. Consisting of 78 pneumat ic pistons (working pressure 10 bar, bore 100 , stroke 70, with built-in spring.)

2 . Including the necessary piping, non return valves and valves with speed regulation.

3. Includin g a piston compressor (working pressure 10 bar, power 2 KW, air reservoir 250 1.)

4. Including a n air regulation unit.

8.16. Saw dust extraction.

MMMMMMMMMMMMMMMMMMセMMMMMM

セpゥー・キッイォ@ according to positioning of machines with :

a. connections to :

8.1 Thickness planer dia ·120

8.2 Surf ace planer dia 120

セ@ セ@

8.3 Table milling machine dia 120

8.4 Moulding plane machine dia 150 (x 6)

8.s·cut off saw dia 120

8.6 Multiple circular saw dia 150

8.7 Band saw dia 120

8.8 Scarfing machine dia 150

8.10 Panel saw dia 120.

I

I

b. connection of ventilator -·air filters silo.

transport system

Ventilator with motor 25 HP.

- Air filters with small dust box connected tp ventilator, driven by a motor 7,5 HP.

- Silo with separator, 200 m3 with possibility to empty into a truck •

33

8.17. Tap making machine.

--- Pneumatic column boring machine RPM 3-2/4 {1400/2800 RPM) Motor : 1,9 KW at 1400 RPM

2,2 KW at 2800 RPM Vertical Travel : 150 mm max.

Double acting cylinder with control valve. Foot control valve.

2 clamping セケャゥョ、・イウL@ dia 40. - Safety equipment.

Appropriate fraises (dia . 11, 5 pieces) (dia 13, 5 pieces) {dia 16, 5 pieces)

for tap drills.

(dia 20, 5 pieces) {dia 22, 5 pieces)

Machine mounted on stable framework.

- Automatic sharpening of widia blades for moulding plane machine, surface and thickn ess plane should be possible . In case that the sharpening of tools cannot be

subcon-tracted the purchase of such an a utomaticshar pening machine

...

would be necessary for PAL.

34

Mセ@

-9. MACHINES AND TOOLS FOR ASSEMBLY AND PREASSEMBLY OF WOOD PARTS.

9.1. Electric handtools.

electric angle drilling machine FEIN - heavy duty slow running hand drill FEIN

electric hand drill FEIN angle sanding machine FESTO

accessory dust collection unit FESTO - belt sanding machine light model

FESTO with frame impact wrench FEIN screwdrivers FEIN - jig saw FEIN

_ _ ______ -_ router_ SCHEER __ _ -- planes : heavy type ELU

light type ELU circular saw FESTO :

light type cutting depth 60 mm heavy type cutting depth 100 mm

Accessories.

sanding discs for FESTO sanders for wood fine grain P100

- sanding belts for FESTO sanders for wood fine grain P100

- socket spanner sets for impact wrenches from M6 to M20

angle drive piece for impact wrenches - screwdrivers from 4 to 10 mm

saw blades for aluminium

circular saw for router in high speed steel

.

.

.

.

.

5 pieces.

'-2 pieces 40 pieces

.

5 pieces.

5 pieces

.

.

8 pieces.

15 pieces.

.

15 pieces.

.

15 pieces.

! .-. 2 pieces

-.

5 pieces.

.

QPセーゥ・」・ウ@.

.

5 pieces.

.

1 piece.

1000 pieces

1000 pieces

15 sets

15 pieces 15 pieces 1000 pieces

;

.:

- groove fraise for router in high speed steel

.

.

¢ 4 5 pieces

セ@ 5 5 pieces

0

6 : 5 pieces¢ 7

.

.

'5 . pieces- 0

8.

0 5 pieces_..

0

10.

.

5 pieces0

14 5 piecesdisposable blades in widia steel

for . hand planing machines

.

.

.1000 piecesセ@ -· -· -·

Clamp span 20

..

.

100 piecesspan 40 span 60

: 800 pieces

M M Mᄋ セ MMMM M :- - 200- pl

ece's

.span 100Clamps with round handgrips.

Glueing clamp span 2500

..

50 pieces

..

20 pieces

セセセセMAセセAセセセセeMセセMセセセセセセセAセセeセMセセセセeセセセR⦅AセMAセセMセセAAセセセセセ@

list. 40 x

Saw Sandvik 50 cm.

Saw Sandvik nr. 5541

s,

length 300 mm. Tenon saw Sandvik nr. 5543, length 250 mm. Veneer saw Sandvik nr. 5552.- Sabre saw Sandvik nr. 5545.

- Halfround bastard rasp_ Nicholson 1on long. Jack plane length 600 x blade width 51 mm.

36

- Rebate plane, length 24 cm, made of beech blade width 30 mm : curved and flat.

Carpenters set square, cast iron foot, steel blade,

length 250 mm.

'

- Bevel gauge, steel

Awl with square point, chrome vanadium, plastic handle. - Dividers with clinch, length , 200 mm.

Pincers 200 mm. Pliers

- Drift ¢ 2/32

Carborundum stone, one side fine (grain 400) and one side rough (grain 120) dim : 150x50x25 mm.

Metal smoothing plane, Stanley type 5 blade width 51 mm x length 356 mm • .

- - - - # - . .. .

Wooden smoothing plane, curved and flat. Round hammer.

Scriber - widia point.

- Stanley knife.

Carpenters hammer with ash handle, ground and polished head, painted black, square 18 mm.

Carpenters hammer with ash handle, ground and polished head, painted black, square 25 mm. ·

Carpenters hammer, beech, glued together and with an oval handle wedged in place, length of head 140 mm, thickness 80 mm.

Scraper. - Hack saw.

Scraper stee l

. ;

Metal drill HSS cylindrical NWK 6 mm. - Metal drill HSS cylindrical NWK 7 mm. - Metal drill HSS cyli!"ldrical NWK 8 mm.

Drill jacket Stanley size 254 mm. Chisel with plastic handle 6 mm.

Chisel with _plastic handle 8 mm. セ@ --- --- ---·

-

... _ "-:. .Chisel with plastic

-

Chisel with plastic - Chisel with ' plastic Chisel with plastic - Chisel with plasticScrewdriver 4 mm. Screwdriver 6 mm. Screwdriver 8 mm. Screwdriver 10 . mm.

handle handle handle handle handle

- - · -- --·-- - Screwdriver--9 _ mm. _ _ _ Drill set.

Depth gange. Center punch Masons hammer

Folding measure (2 m) Tape measure. {2 ュIセ@

Spartules

- Flat paint brushes 100 x 15

10 mm.

16 mm.

20 mm. 30 mm. 40 mm.

Complete paint spraying installation - Breathing apparatus for painter

- Transportable ventilators

.

.

.

.

.

.

.

.

Industrial vacuum cleaner with flexible hose : at least 10 m

..

9.6. eアオゥーュセョエL M ヲッイ@ electrical 」ッョョ・」エゥッョウセ@

MMMMMMMMMMセMMMMMMMMMMMMMMMMMMMMMMMMMMMMMMM

- Electric plugs for welding machines appropriate to the installed wall plugs Electric plugs for hand tools

l'"

Wire for extension cables for hand

f'

tools (monophase 220 V + earth)' power capacity

o,s

KW- Distribution boxes with 6 outlets monophase 220 V an d fuse

- Cable between source and distribution box, type of cable according to existing voltage HRセP@ or 380); total power 3 KW

Portable lamps for lighting_ on board . :· ··-·-·-·· · Spare bulbs

Projectors

---

---

------·-

-9. 7. Fraises.

---Special f raises an d drills. All f raises i n high speed steel

• Fraises for taps 26 mm

Mセ ッ@ mm -13 mm 11 mm

.

Tap hole f raises 26 mm 20 mm 13 mm 11 mm Drill セ@ 6 mm 13 cm long• Drill セ@ 12 mm 24 cm long

Drill and countersink 45 ° in

or with widia

HSS

•

•

.

•38

5 pieces 100 pieces

: 1000

m

.

.

10 pieces.

300 m.

.

50 pieces.

• 50 pieces

.

セT@ .. . ..

-• 4 pieces

•

..

teeth

.

.

.

20 pieces.

.

20 pieces.

.

20 pieces.

: 20 pieces

.

20 pieces.

.

20 pieces.

.

.

20 pieces.

20 pieces.

.

20 pieces.

.

20 pieces.

.

20 pieces;

• Deburring fraise with collar - front side with small slope and with

center point 26 mm 20 mm 13 mm 11 mm

• 8 mm steel drill with countersink on adjustable collar.

• Adjustable fraise for marking grooves to 4 mm fitted for the moulding plane machine

• Widia saw ¢ 550 54 teeth with hub adjusted to the scarf joint machine

10. MACHINES FOR ASSEMBLY OF ALUMINIUM secセionsN@

.

.

.

.

39

20· pieces 20 pieces

.

.

20 piecesセ@ セ@ 20 pieces

.

.

.

.

.

.

20 pieces

4 pieces

2 pieces _

- - - - ---·---

4

piecesCurrent variable from 30 to 40 am p Utilisation capacity min. 80

%

Primary voltage 220 Y or 380 V Unit consisting of :

current source pulsed arc wire feed

- standard built-in water cooling

.

.

- water cool e d torch with gas ma ntle orifice¢ 1,7 mm and current guide ¢ 1,2 mm

- Earthing cable 10 m.

20 m extension kit between current source and wire feeder. - 3 m cable between wire feeder and watercooled torch .

supply cable 30 m - gas tubing 2 m

manometer

I

f lowmeterAmplitude and frequency of pulses 。、ェオウエ。「ャセN@

Base current amperes (wide speed) ad ju stable voltage

40

from wire feeding unit or by means of remote control .

Basic set of accessories and spare parts ー・セ@ welding unit. Supplementary ウー。セ・@ parts :

20 tef lon wire guides

• 40 current guides

0

1,2 mm • 4 gas orif lces• 10 Current guide holders.

Current source:max . current at 380 V - 43 A Possibility to adjust following functions · :

.

.

• function switch for normal welding, pulsed welding,

1 piece

セセセセセMMセセセセMZMMセセセセセセセセセMMセセセセセセセセセセMセセセMセ M MセMMセセM

spot welding •

• Potentio-meters for independent adjustment of セ@

セ@

starting current normal basic current pulsed curr en t

crater filling current

start and stop slope of current pulse frequency

Watercooled torch with cable of 20 m. Switch on torch for switching basic current on and off.

One box of parts for torch.

2 Tungsten electrodes length 195

0

1,6 mm40

"

"

"

"

0

2,4 mm40 II II

"

"

¢ 3,2 mm2 II

"

"

II0

4,0 mm2 II

,

·.

....-

·.

·....

.

·,.,

.- セ ᄋ Q@ ュ。ョッュ・セ・イ@

I

f i°c5wmeter'.

1· earthing cable

i

supply cablegas tube 2 m

• # ...

io

m- .;.: '·):

30 m

4!"'

, .... '

41 t,

·.

•. ZセLN@ ...

..

---,.

-.

-

.

-

.

Small size

pressure

.

- '

Working

s·et

of chisels....

--

..6 kg.·.

flat .! chisel

... _ ... ,,.-... ::...:.. ⦅[ZNLZZ⦅セ@ MMMMMエセMMMNZZNN[N@ - ...

.. : セ@ _ ... : .. :, - gouge chisel .

... \.,., !' ... セゥNN@ :.;_ • ..,._... Mセ@ ... ' ... - セ@•.

ᄋ セᄋ@ : L LNZMセ[LNNNLNNM .:;.• ... - .- curved · chisei

3 piec.es :

...

-

.

... .

... ."

. ZNセ@., ... : .... :;. :

I • .. .. I

.. - .. i Nセ@ セNNNN@ : . - "'

..

I 2, •<a, • •

セM セ@ .

...

---

_..._.

.,. .... セ@ .._

...Nセ[@ .\ :- ".t • .:.: ... :: ,. ....

. . _ _ _ , , . , . _ _ _ _ _ . . . . · · - - >#'_ ....

-• ;.4:.. - ... Mセ@ ... セBNZ ᄋ Qᄋ@ - セNZNNNNN⦅Z@ ... .

.

'

- ·- . Q MセLLN@ MM。セ@ ... - - .

• セ@ ... NLNセᄋセM[[NN⦅N@ ,-. -.h __ : , ,, ...

-. -. -. -. -. -. -. - . : · -4.1 ... MᄋセセNNNNNN@ c;.. セ@

·!'t - _ ... _ ... __ .,.._...,. - . . . - .... .;,. -.;'" GヲセLNMセN@ - ... ! J - . Mセ@ .i- .. , . . . ,_...., ... _ . _

_ _

.,

MMセ@ ᄋセGセM セ M セMMMM\ᄋᄋMMMᄋセセZ⦅セセ]MMセ[Nセ@

...

jᄆZqNセ

ᄋM [ヲZeセセゥZZNヲヲエ@

MMセセ[セᄋ

ᄋZZセjZャセZZ⦅ᄋZセセセセセセ[LNNNNセセセMセjセMZPセWN@

.

. . ' 1o"-4 Pneumatic ッイヲョ、ゥョァ NM ュ。」ィゥョ・ ᄋMMᄋGZᄋLセGN[ZLセ⦅LL⦅N[Z]セMセZZNZZNZMN[[ᄋGAZヲeZ⦅ MZ@ [|セ@ -·' 3 ーゥ・」・ウ ᄋᄋセNZセセ[ZNーNL[@ _

- ᄋセ@ MMANMANMMMMMMMMMMMz MMMMMMMMMMMMMMセ@ • ⦅[BBGサセセ@ ZZB[ セ@ .. ᄋMセQB ᄋ ᄋ M セMMZセセ@ [TGQ[セ[[セ[セZL[@

..

ᄋセMZL@.. : ..

セ@ ZセMZZᄋZLT@ セ@... " . . • • .. ... - - - - . -セ@ ... ⦅NL⦅[セM ... MNNMセ@ . . . ·..._ . . . ;...""" I.I""!<. LNNLNNNゥNNNNセ@ ,,_.,,,,... オZMセᄋ@ _.._,."'=-" - .... NNNLNNGHMセ@ .... ..,-!>, ... - "'·=--r.--(""""'" セ@

-- - - MセMMMMᄋNNMセ NZ@ Shank- V MM ュュ MᄋMZNセNセセセセセセセZZ⦅NセセセᄋMMZMᄋZ⦅[MMNN[セGM ... MMZMZNNBGBB[MMZZNNセNN@ . ... LLLNN 」Z Z[[ZMMセMZZZMセ@ ... ZZ[MセNN⦅NZLZセZMMZ@

MBB ᄋMMᄋセM ..;- lrii'':. • .. - -... ...-· ." .. ᄋ MZ[Z[O[セ@ ....

MMMセセセ

セセ

MM s・エ⦅セゥ⦅⦅エオョァウエ・ョ

セ 」。イ「ゥ、セイゥョ、ャdNァ

セ ウ ⦅ エ ⦅ ッ ⦅ ョ⦅ ・セ ウMM

セセセセセセセセセセセMMMMMセセ@

...

__

.......

--... ... ________ ._ ... セᄋ@._

... ...:-. . ...:....... セNセ@ ' ... ...

.

•,... セ@ - ,.... •T- ...,. . . .,. . ; .

10.5. Sandblasting gun · for body workshop

---,. ... セN@

• . Complete with handle

. .... セ@

Bᄋセ Z@ ·- · Complete

,...\ • • .., -· ' - ,. L •· •

with sand .reservoir of + 'l kg

'

-- \ ...

- -.:-,,."4. ..• :f

.= ·---· ,. ·: ...

.

'.

... . .. .... . , . 3"I.; I

.

...

NNNセ⦅@ .... _,.

__

pieces

.·

..

Workihg _air. ーイ・セウオセセ M V@ ォァセ ⦅@ ... .. ...--=.. -- ...

' 6.

·.

10.6. Huck bolt machine.

---'.

,,

..

·l

..

-.,.2· LNNL⦅セ@

- \ ...

.

.

Suitable for steel and aluminium bolts

.

· ·' .-.

With 'choice of chucks of

0

8 mm and0

セo@ (2x) ·Work air press ure 6 kg.·

'

I

--,

-

.... -セᄋ@ -· ---M セMMセ@ : セセᄋ@.

-..

ᄋᄋセ@ ' I

...

.

...

.

..

..

• . ,_. •' I • ' セ@ ...• • 1 '

•:

.

.

...

'.

...

....

.

'l piece I ,. -'•'""

.

セN@.:

·- J

-

.... -:._...

'·

セ ᄋ M

-

,.

- 10 quick connection.: couplings for the pneumatic tools.

- 60

m

air hose and connecting pieces for above.セセセセセMセセᆪAAセMセAセMセセセeeセセセセセMセセMセセセセAセ⦅ャAセMセセセAAセᆪAセャMセAセセ@

-...セAA⦅セセセMセセセセセSセセeセセセセゥMセセセセeセセAセMセセセMeセセセセセセセMeセRセZ@

lation.

Working pressure 7 bar.

Power min. 38,3 KW with silencing (75db)

10.9. Burner unit. Consisting of :

-Trolly !or ァ。セ「ッエエャ・ウ@

Manometer

I

flowmeterセR@

セ M MMMᄋMMMMセM MMZSP M ュMョッウ・NMセセセセセセセセセセセセセセセセセセセセMMセセセMセ⦅Z⦅セセセセセ@

Burner with assorted nozzles.

10.10. Electric handtoold. Angled grinding machines

Profile saw

..

Circular saw

Heavy duty slow turning drill Necessary accessories

grinding discs

saw blades for aluminium drills

¢

8,¢

10reamers

¢

8,2;¢

10,2circular saw for plurninium

.

.

.

.

.

.

:

4 pieces 4 pieces 1 piece 1 piece

: 100 pieces : 200 pieces

.

.

.

.

10 pieces 10 pieces 3 pieces

•

I

"

10.11 Small ·tools.

-MMMMMMMMMセMMMMMMM

Stainless steel brushes Welding . cutting pliers Welding gloves

- Welding mask with spare smoked glass

- - - --

-for aluminium welding.

Safety mask for sand blasters

-

Safety glasses for burners-

Plate lifting clamps - American .tackles- Lifting strops 6 T length 4 m Lifting cab les 6 T length 4 m

-Shackles 6 T

Water hose 30 m 1/4" Plumline

ᄋ セ]Mウt・・ゥキゥイ・@ for centerI1ne--3om

- Huck bolt clipper - Tape messure 20 m

43

.

20 pieces.

.

5 pieces.

.

so pieces.

windows

セ@

GMセ@

.

8 pieces.

3 piec;es . 3 p ieces

.

8 pieces.

.

4 pieces.

.

4 pieces.

.

4 pieces.

.

4 pieces.

: 1. piece

.

5 pieces.

- - - -·

.

.

2 pieces.

1. piece•

..

.

1. piece

.

セセセセセMセセAセAセRMセセセセセセセセセセセMセセセMセMセAセセMセセセセセセセeAAセMセセeMセセAセセセR@

steel (cradle - frame steel motorfoundations etc. )

1.1. MACHINES FOR BUILDING ALUMINIUM SECTIONS. (if not available in steel plateshop ).

11.1. セセセᆪAセセMセセセセセセセ@

:

width 2 m. A1Mg5Mn 078 - max 10 mmSteel ..,. max 10 mm

11.2. セxセセセセAAセMセセARᆪセAAセセeセMeセセセセA⦅eセセセセMセセセMA@ equipped wi th necessary dies for pressing lightening holes in

the frames and longitudinals.

..

11.14. Pl.ate shear-: 2,5 m x 4 mm .

11.15. Eckhold butting machine for shaping the frames with

セイ。キ@ and 「オエエセョァ@ heads, for 4 mm material in 。ャオュゥョゥオュセ@

Appropriate dies. l

• "->.

11.16. Band saw for aluminium with at least 10 saws and saw welder.

11.17. Circular saw for aluminium type Kaltenbach.

11.18 •. Column drilling machine max. 16 mm diameter.

11.19. 4 Weldi ng transformers · : 350 A with necessary _ accessories.

QセNRPセ@ Mig/Mag pulsed arc welding machines, as

described in 10.1

11.21. Tig welding machine . as 、セウ」イゥ「・、@ in 10.2

QセNRRN@ Pneumatic chipping hammer

+ set chisels : flat, gouge, curved.

11.23. Pneumatic grinders with a セ・エ@ of tungsten carbide stones

11.24. Accessories for pneumatic tools - 8 quick connectors to fit tools

Air hose 100 m with terminals for quick connectors on tools.

11.25. Electric handtools Angled grinder ¢ 100 Profile saw

- Pl a ner with widia blades

.

.

.

.

•

.

: 15 pieces

:

.

.

.

.

1 piece

3 pieces

5 pieces

10 pieces

2 pieces

2 piec e s

11.26. Pneumatic clamping· tables for preassembly of

bulk

-heads and frames according to drawings.

11.27. Patterns for building sections according to drawings.

.4 5

11.28. Overhead SYJStem for wire feeding units according to drawings.

11.29. Small· tools.

•

4612. MACHINES FOR PIPE FITTERS

20 m shelves.

1 piece radial drilling machine max. 2" diameter.

3 pieces work bench with vice.

3 pieces tube vices.

'·

--

-1 piece tube bending machine for CON IRE tubes an d brass tubes as well as thin wall steel tubing, complete キゥエィ N セ@

all 「・ョ、ゥセァ@ equipment for tubes of ND32-ND125 .

1 piece tube bending machine for tubes µpto 2" . 1 piece handsaw cutting upto 150 mm diameter .

1 piece _circular saw cutting upto 135 mm diameter. 1 piece hacksaw cutting オセセッ@ 200 mm diameter.

1 piece column drilling machine : 12 mm.· ··

1 piece grindstone for pipes セーエッ@ 175 mm diameter. 1 piece grindstone for pipes upto 300 mm diameter.

1 piece testbench for pumps with watertank and necessary instruments for measur