ABSTRACT

this project. Aluminium alloy 7075-T73 possesses lowest yield strength, ultimate tensile strength, and Rockwell hardness among all types of aluminium alloy 7075 in this project. However, aluminium alloy 7075-T73 possesses higher impact strength compare to aluminium alloy 7075-T6 and aluminium alloy 7075-RRA.

ABSTRAK

Walaubagaimanapun, kekuatan hentaman aloi aluminium 7075 (yang telah melalui proses pengerasan larutan) adalah paling tinggi banding dengan semua jenis aloi aluminium 7075 dalam projek ini. Aloi aluminium 7075-T73 memiliki kekuatan alah, kekuatan tegangan muktamad, dan kekerasan yang paling rendah banding dengan semua jenis aloi aluminium 7075 dalam projek ini. Walaubagaimanapun, aloi aluminium 7075-T73 memiliki kekuatan hentaman yang lebih tinggi banding dengan aloi aluminium 7075-T6 dan aloi aluminium 7075-RRA.

DEDICATION

ACKNOWLEDGEMENT

I am grateful for the help and guidance of Madam Intan Sharhida Othman and Dr. Mohd Warikh bin Abd Rashid throughout this project. Their ability to remain unruffled in the face of apparent catastrophe has helped to maintain the project on an even keel.

The encouragement and support from my academic advisor, Mr. Jeefferie Abd. Razak, has also been of the highest value.

TABLE OF CONTENT

CHAPTER 2: LITERATURE REVIEW 5

2.1 Heat Treatment of Aluminium Alloy 5

2.1.1 Temper Designation of Aluminium Alloy 6

2.1.2 Solution Heat Treatment 8

2.1.3 Quenching 10

2.1.4 Artificial Aging 13

2.1.5 Overaging 14

2.1.6 Retrogression and Reaging (RRA) Treatment 15

2.2 Aluminium Alloy 7075 17

2.3 Mechanical Properties Test 20

2.3.1 Tensile Test 20

2.3.2 Rockwell Hardness Test 23

2.3.4 Effect of RRA Treatment on Hardness of Aluminium Alloy 25 7075-T6

2.3.5 Effect of RRA Treatment on Tensile Strength of Aluminium 26 Alloy 7075-T6

2.4 Microstructure Evolution of Aluminium Alloy 7075 27

2.4.1 Microstruture Evolution of Aluminium Alloy 7075-T6 Temper 28 2.4.2 Microstructure Evolution of Aluminium Alloy 7075-T73 28

Temper

2.4.3 Microstruture Evolution of Aluminium Alloy 7075-T6 After 29 RRA Treatment

2.5 Relevant Studies or Researches 32

CHAPTER 3: METHODOLOGY

3.1 Introduction 34

3.1.1 Project Flow Chart 35

3.1.2 Materials Preparation 36

3.1.2.1 Aluminium Alloy 7075 Preparation 36

3.2 Heat Treatment Process 37

3.2.1 Solution Hardening 37

3.2.2 T6 Temper 37

3.2.3 T73 Temper 37

3.2.4 RRA Heat Treatment 38

3.3 Mechanical Testing 39

3.3.1 Tensile Test 39

3.3.2 Rockwell Hardness Test 41

3.3.3 Charpy Impact Test 41

CHAPTER 4: RESULT AND DISCUSSION

4.1 Introduction 43

4.2 Observation of Heat Treatment of Aluminium Alloy 7075 43

4.3 Mechanical Testing of Aluminium Alloy 7075 44

4.3.1 Tensile Test for Aluminium Alloy 7075 44

4.3.1.1 Analysis of Tensile Test Graph of Different Heat 49 Treated Aluminium Alloy 7075

4.3.1.2 Analysis of Tensile Test Graph of All Aluminium 51 Alloy 7075-RRA

4.3.2 Rockwell Hardness Test for Aluminium Alloy 7075 52 4.3.3 Charpy Impact Test for Aluminium Alloy 7075 55

CHAPTER 5: CONCLUSION AND RECOMMENDATION

5.1 Conclusion 58

5.2 Recommendation 59

REFERENCES 63

LIST OF TABLE

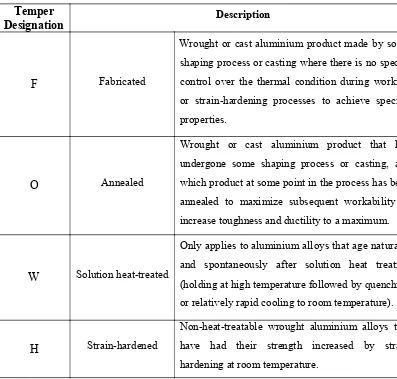

Table 2.1 Basic temper designation (Kaufman, 2000). 6

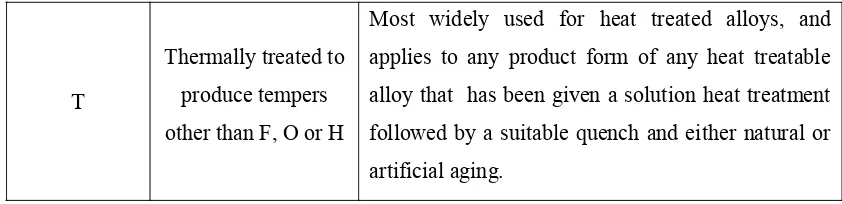

Table 2.2 Subdivisions of “T” temper heat treatable alloys (Kaufman, 7 2000).

Table 2.3 Chemical composition of aluminium alloy 7075 (ASTM, 18 B211M-03).

Table 2.4 General properties of aluminium alloy 7075, aluminium alloy 18 7075-T6, and aluminium alloy 7075-T73.

Table 2.5 Standard dimensions of 12.5 mm tensile specimen. 22 Table 2.6 Experimental parameter of solution heat treatment, aging, 32

overaging and RRA treatment of relevant studies or researches. Table 3.1 Label of specimens at various heat treatment processes. 38 Table 3.2 Standard dimensions of 12.5 mm tensile specimen. 40 Table 3.3 Quantity of specimen needed for each experiment. 44 Table 3.4 Quantity of specimen needed for whole project. 44 Table 4.1 Result of tensile test (ultimate tensile strength) for all specimens 47

of aluminium alloy 7075.

Table 4.2 Result of hardness test (Rockwell hardness scale B) for all 55 specimens of aluminium alloy 7075.

Table 4.3 Result of Charpy impact test for all specimens of aluminium 58 alloy 7075.

LIST OF FIGURES

Figure 2.1 DTA curves at 20oC/min heating for aluminium alloy 7075 9 (Hatch, 1983).

Figure 2.2 Schematic representation of temperature effects on factors that 12 determine precipitation rate (Hatch, 1983).

Figure 2.3 Tensile strength of eight alloys as a function of average 13 cooling rate during quenching (Hatch, 1983).

Figure 2.4 Instron 5585 universal tensile testing machine. 20 Figure 2.5 Important points in stress-strain curve of ductile material. 21 Figure 2.6 Important material properties prediction based on the shape of 22

stress-strain curve of a material.

Figure 2.7 Standard 12.5 mm round tension test specimen (ASTM, E8M- 22 04).

Figure 2.8 Mitutoyo HR-522 series Rockwell type hardness test machine. 23

Figure 2.9 Gunt W400 Charpy impact tester. 24

Figure 2.10 Precipitation sequence of aluminium alloy 70775-T6 (Reda et 26 al. 2007).

Figure 2.14 TEM microstructure after RRA (retrogression at 180oC) 31

(F. Viana et al. 1999).

Figure 3.1 Flow chart of whole project. 35

Figure 3.2 Instron 5585 universal tensile testing machine. 40 Figure 3.3 Standard 12.5mm round tension test specimen (ASTM, E8M- 40

04).

Figure 3.4 Mitutoyo HR-522 series Rockwell type hardness test machine. 42

Figure 4.1 Effect of retrogression period (5 minutes, 10 minutes, and 15 48 minutes) on ultimate tensile strength of aluminium alloy 7075-RRA.

Figure 4.2 Effect of different heat treatment process on ultimate tensile 49 strength of aluminium alloy 7075.

Figure 4.3 Tensile test graphs of aluminium alloy 7075 from different 51 heat treatment process.

Figure 4.4 Tensile test graphs of all aluminium alloy 7075-RRA. 53 Figure 4.5 Effect of retrogression period (5 minutes, 10 minutes, and 15 56

minutes) on hardness of aluminium alloy 7075-RRA.

Figure 4.6 Effect of different heat treatment process on hardness of 57 aluminium alloy 7075.

Figure 4.7 Effect of retrogression period (5 minutes, 10 minutes, and 15 58 minutes) on impact strength of aluminium alloy 7075-RRA.

Figure 4.8 Effect of different heat treatment process on impact strength 59 of aluminium alloy 7075.

LIST OF ABBREVIATIONS

AA - Aluminium alloy

GP - Guinier-Preston

RRA - Retrogression and reaging

SCC - Stress corrosion cracking

T6 - Temper assignation for aluminium alloy that has been solution heat treated and artificially aged to achieve precipitation hardening. T7 - Temper assignation for aluminium alloy that has been solution

CHAPTER 1

INTRODUCTION

1.1 Background of Project

Pure aluminium is too soft for most of the structural applications. Therefore, it is usually alloyed with other elements to improve its mechanical properties. Optimum strength of aluminium can be achieved by alloying and heat treatments, which greatly promote the formation of small and hard precipitates that interfere with the motion of dislocations.

Aluminium alloy 7075 is an aluminium alloy with zinc as the major alloying element. It possesses good mechanical properties with good fatigue strength and average machinability, but it is not weldable and has less resistance to stress-corrosion cracking than many other aluminium alloys. It is widely used for aircraft structural materials because it possesses a high strength with low density (Li, J. F. et al., 2007). However, this material has a problem where it is highly susceptible to stress corrosion cracking (SCC), especially when it aged to the maximum strength, T6 temper. Therefore, over-aging treatment such as T73 has been developed. However, the strength of the aluminium alloy 7075 with these over-aging treatments is decreased.

A heat treatment method called retrogression and reaging (RRA) treatment was devised some time ago by Cina and Ranish (1973), and Cina (1974). Retrogression and reaging (RRA) is an intermediate heat treatment that able to increase dramatically the SCC resistance of the aluminium alloy 7075-T6 without sacrificing its maximum strength. RRA treatment consists of two main stages, retrogressing the aluminium alloy 7075-T6 structure at high temperature within the two-phase field for

a short period, then, follow by reaging the retrogressed aluminium alloy 7075-T6 at its original T6 temper condition.

In this project, experiment is conducted in order to study the effects of the RRA heat treatment process on the mechanical properties and microstructure evolution of aluminium alloy 7075-T6.

1.2 Problem Statement

In aerospace application, aluminium alloy 7075 is frequently used due to its high strength to weight ratio. This aluminium alloy prior to be used for structural such as aerospace applications is typically aged up to T6 temper. The aluminium alloy 7075 in the T6 temper possesses high strength properties but unfortunately it also known to be highly susceptible to stress corrosion cracking (SCC). The aluminium alloy has to be over-aged (T73) to solve the SCC resistance problem, however, this over-aging process reduces the strength of the aluminium alloy by 10-15% compared to the T6 temper. In order to overcome this material properties problem, a heat treatment known as retrogression and reaging (RRA) will be use to replace the over-aging process (T73). RRA is an intermediate heat treatment that able to enhance stress- corrosion cracking resistance without any sacrifice of yield or tensile strength in aluminium alloy 7075-T6.

1.3 Objective

The objective of this Projek Sarjana Muda, PSM are:

i. To study the influent of retrogression and reaging, RRA treatment on aluminium alloy 7075.

1.4 Scope of Study

The project can be divided into three main stages:

i. Material preparation stage ii. Material properties testing stage

iii. Material microstructure evolution review stage

The first stage of this project will covers the preparation of raw material, aluminium alloy 7075 to become aluminium alloy 7075-T6 through solution heat treatment, quenching, and artificial aging by using several experimental parameter. Besides that, it also covers the retrogression and reaging, RRA treatment with several experimental parameters of respective aluminium alloy 7075-T6 in order to optimize its mechanical properties.

The second stage of this project will covers material mechanical properties testing through several testing method. The material mechanical properties testing methods that are cover in this project are Rockwell hardness test, fracture toughness test, and tensile test. All of these material mechanical properties testing will be conduct based on ASTM standard.

Lastly, the third stage of this project will cover review of microstructure evolution of aluminium alloy 7075 from relevant journals.

1.5 Importance of Study

Aluminium alloy 7075 is a material with high strength to weight ratio. Hence, it is commonly used by aerospace industry in aircraft’s structural construction (Li, J. F. et al., 2007). Therefore, study of microstructure evolution and mechanical properties of aluminium alloy 7075 is very important for aerospace industry in order to produce high strength and high stress corrosion cracking resistance properties by determine the optimum experimental parameter of its heat treatment processes. Moreover, it is

CHAPTER 2

LITERATURE REVIEW

2.1 Heat Treatment of Aluminium Alloy

The optimum strength of aluminium is achieved by alloying and heat treatments that promote the formation of small and hard precipitates, which interfere with the motion of dislocations. Aluminium alloys that can be heat treated to form these precipitates are considered heat treatable alloys. Pure aluminium is not heat treatable because no such particles can form while many heat treatable aluminium alloys are not weldable because welding would destroy the microstructure produced by careful heat treatment.

The initial strength of heat-treatable aluminium alloys is enhanced by the addition of alloying elements such as copper, magnesium, zinc, and silicon. Since these elements singly or in various combinations show increasing solid solubility in aluminium with increasing temperature, it is possible to subject them to thermal treatments that will impart pronounced strengthening.

Virtually all heat treatable aluminum alloys are strengthened by precipitation hardening. Precipitation hardening involves raising the temperature of the alloy into the single phase region so that all of the precipitates dissolve. The alloy is then rapidly quenched to form a supersaturated solid solution and to trap excess vacancies and dislocation loops which can later act as nucleation sites for precipitation. The precipitates can form slowly at room temperature (natural aging) and more quickly at slightly elevated temperatures, typically 100°C to 200°C (artificial aging). The degree of hardening obtained depends on the size, number and relative strength of

the precipitates. These factors are determined by the composition of the alloy and by the tempering temperature and tempering time.

2.1.1 Temper Designation of Aluminium Alloy

The temper designation system of aluminium alloy is used for all forms of wrought and cast aluminium and aluminium alloys, with the exception of ingot. The temper designation system is based on the sequence of basic treatments used to produce various tempers. The temper designation follows the alloy designation with the two separated by a hyphen. As shown in Table 2.1 below, basic designations consist of a letter while subdivisions of those basic tempers. Major subdivisions of basic temper designation are indicated by one or more digits following those letters.

Table 2.1: Basic temper designation (Kaufman, 2000).

Description

Wrought or cast aluminium product made by some shaping process or casting where there is no special Fabricated control over the thermal condition during working or strain-hardening processes to achieve specific properties.

Wrought or cast aluminium product that has undergone some shaping process or casting, and Annealed which product at some point in the process has been annealed to maximize subsequent workability or increase toughness and ductility to a maximum.

Only applies to aluminium alloys that age naturally and spontaneously after solution heat treating Solution heat-treated

(holding at high temperature followed by quenching or relatively rapid cooling to room temperature). Non-heat-treatable wrought aluminium alloys that Strain-hardened have had their strength increased by strain

Most widely used for heat treated alloys, and Thermally treated to applies to any product form of any heat treatable produce tempers alloy that has been given a solution heat treatment other than F, O or H followed by a suitable quench and either natural or

artificial aging.

“T” designation denotes a stable temper other that “F”, “O”, and “H”. The “T” designations are always followed by one or more digits. Each of the numeral is indicates a specific sequence of basic treatments. In Table 2.2, numerals 1 to 10 indicate specific sequences of the heat treatment process.

Table 2.2: Subdivisions of “T” temper heat treatable alloys (Kaufman, 2000).

Description

Aluminium alloy that has cooled directly from high temperature hot working process and then naturally aged to a substantially stable condition.

Aluminium alloy that has been cooled from high temperature hot working process and then cold worked before being naturally aged to a substantially stable condition.

Aluminium alloy that has been given a solution heat treatment following by hot working, quenching, cold working, and being naturally aged to a substantially stable condition.

Aluminium alloy that has been given a solution heat treatment and without any cold work, naturally aged to a substantially stable condition.

Aluminium alloy that has been cooled form a high temperature shaping process and then artificially aged without any intermediate cold work. Aluminium alloy that has been solution heat treated and without any significant cold working, artificially aged to achieve precipitation hardening.

Aluminium alloy that has been solution heat treated and without any significant cold working, aged in a furnace to an over-aged condition. Aluminium alloy that has been solution heat treated, cold worked for strain hardening, and then artificially aged.