UNIVERSITI TEKNIKAL MALAYSIA MELAKA

AN INVESTIGATION OF THE EFFECT OF VARIOUS HEAT

TREATMENT PROCESSES ON MICROSTRUCTURE AND

STRESS CORROSION CRACKING (SCC) OF ALUMINIUM

ALLOY 7075

This report submitted in accordance with requirement of the Universiti Teknikal Malaysia Melaka (UTeM) for the Bachelor Degree of Manufacturing Engineering

(Engineering Materials)

by

LENG SIONG CHENG B050710018

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

BORANG PENGESAHAN STATUS LAPORAN PROJEK SARJANA MUDA

TAJUK: An Investigation of the Effect of Various Heat Treatment Processes on Microstructure and Stress Corrosion Cracking (SCC) of Aluminium Alloy 7075

SESI PENGAJIAN: 2010/11 Semester 2

Saya LENG SIONG CHENG

mengaku membenarkan Laporan PSM ini disimpan di Perpustakaan Universiti Teknikal Malaysia Melaka (UTeM) dengan syarat-syarat kegunaan seperti berikut:

1. Laporan PSM adalah hak milik Universiti Teknikal Malaysia Melaka dan penulis. 2. Perpustakaan Universiti Teknikal Malaysia Melaka dibenarkan membuat salinan

untuk tujuan pengajian sahaja dengan izin penulis.

3. Perpustakaan dibenarkan membuat salinan laporan PSM ini sebagai bahan pertukaran antara institusi pengajian tinggi. atau kepentingan Malaysia yang termaktub di dalam AKTA RAHSIA RASMI 1972)

(Mengandungi maklumat TERHAD yang telah ditentukan oleh organisasi/badan di mana penyelidikan dijalankan)

Alamat Tetap:

PT 292, Jln Kotaville Indah 9,

Tmn Kotaville Indah, Wakaf Bharu,

DECLARATION

I hereby, declared this report entitled “An Investigation of the Effect of Various Heat Treatment Processes on Microstructure and Stress Corrosion Cracking (SCC)

of Aluminium Alloy 7075” is the results of my own research except as cited in references.

Signature : ……….

Author’s Name : LENG SIONG CHENG

APPROVAL

This report is submitted to the Faculty of Manufacturing Engineering of UTeM as a partial fulfillment of the requirements for the Degree in Bachelor of Manufacturing Engineering (Engineering Materials). The member of the supervisory committee is as follow:

i

ABSTRAK

Kajian menyeluruh telah dilakukan terhadap aloi aluminium 7075 kerana keunggulannya dalam sifat-sifat mekanikal hasil daripada process penguatan penuaan serta kegunaannya yang meluas dalam struktur kapal terbang. Walaupun dengan kaedah T6, aloi tersebut mampu mencapai kekuatan bahannya yang tinggi, tetapi ketahanannya terhadap SCC adalah rendah. Dengan kaedah T73, ketahanan AA-7075 terhadap SCC dalam aloi ini mampu ditingkatkan , tetapi kekuatan bahannya tidak mampu diperlihara seperti dalam kaedah T6. Kaedah retrogression

dan re-aging (RRA) pula dikatakan mampu meningkatkan ketahanan bahan terhadap

ii

ABSTRACT

iii

ACKNOWLEDGEMENT

iv

DEDICATION

To my beloved father Mr.

Leng Kok Oarand mother Mdm.

Teoh Ling Siau, my beloved eldest sister Pn.

Nur Atiqah Shuhaily Lengand family,

my beloved second sister Mdm

Leng Siek Ping, brother-in-law Mr.

Low Ah Kian, my lovely niece

Celine Low, and the new-born nephew

v

2.1.1 Aluminium Alloys Designation for Wrought Alloys 8 2.1.2 Temper Designation of Wrought Aluminium Alloys 9 2.1.3 T- designation for Aluminium Alloys 7075 11 2.2 Heat Treatment of Aluminium Alloy 7075 15

2.2.1 Solution Heat Treatment 16

2.2.2 Quenching 16

2.2.3 Precipitation Hardening 17

2.2.4 Heat Treatment to Overcome the SCC Problems in AA-7075

19

vi

2.2.6 Retrogression and Re-aging 21

2.27 Microstructure of Aluminium Alloy 7075 22

2.3 Stress Corrosion Cracking (SCC) 26

2.3.1 Mechanism of SCC 27

2.3.2 SCC Occurrence and Environments 29

2.3.3 Environment Causing SCC 30

2.3.4 The Effect of Electrode Potential 31

2.3.5 Alloy Dependence 32

2.3.6 Stress Effect 33

2.3.7 Stress Corrosion Cracking Problem in Aluminium Alloy 7075

3.4 Heat Treatment Processes 40

3.4.1 T6 Tempering 41

3.4.2 T73 Tempering 43

3.4.3 Retrogression and Re-Aging (RRA) 46

3.5 Direct Tensile Stress Corrosion Cracking Test (DTSCC) 48

3.6 Tensile Test 50

3.7 Hardness Test 50

3.8 Microstructure Observation 51

4. RESULTS AND DISCUSSIONS 53

4.1 Material Characterisation 53

4.2 Microstructure Observation 54

4.3 Tensile Test 58

vii

5. CONCLUSION AND RECOMMENDATIONS 64

5.1 Conclusions 64

5.2 Recommendations 65

REFERENCE 66

APPENDIX A 68

APPENDIX B 69

APPENDIX C 70

APPENDIX D 73

APPENDIX E 74

APPENDIX F 75

viii

LIST OF TABLES

PAGE

Table 2.1 Aluminium Alloys Code Designation 9

Table 2.2 Temper Designations 10

Table 2.3 List of T-temper Designations 12

Table 2.4 Results of Mechanical Tests Done on AA -7075 which are Heat Treated via Tempering Methods T6, T73 and RRA

20

Table 2.5 Examples of SCC Environments 29

Table 3.1 Specification of the Test Specimen (ASTM E8-04) 39

ix

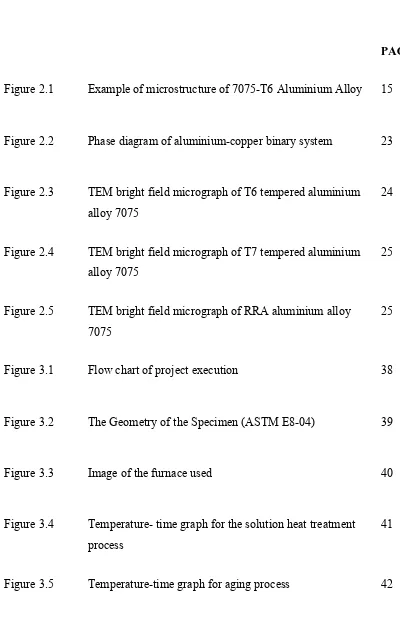

LIST OF FIGURES

PAGE

Figure 2.1 Example of microstructure of 7075-T6 Aluminium Alloy 15

Figure 2.2 Phase diagram of aluminium-copper binary system 23

Figure 2.3 TEM bright field micrograph of T6 tempered aluminium alloy 7075

24

Figure 2.4 TEM bright field micrograph of T7 tempered aluminium alloy 7075

25

Figure 2.5 TEM bright field micrograph of RRA aluminium alloy 7075

25

Figure 3.1 Flow chart of project execution 38

Figure 3.2 The Geometry of the Specimen (ASTM E8-04) 39

Figure 3.3 Image of the furnace used 40

Figure 3.4 Temperature- time graph for the solution heat treatment process

41

x

Figure 3.6 Temperature-time graph for T6 tempering 42

Figure 3.7 Temperature-time graph for T73 over-aging (Stage 1) 43

Figure 3.8 Temperature-time graph for over-aging (Stage 2) 44

Figure 3.9 Temperature-time graph for T73 tempering 45

Figure 3.10 Temperature-time graph for retrogression 46

Figure 3.11 Temperature-time graph for RRA 47

Figure 3.12 Universal Testing Machine Used 48

Figure 3.13(a) DTSCC test setup 49

Figure 3.13(b) DTSCC test setup, where the NaCl solution is contained in the green rubber tube, with the specimen soaking in the solution

49

Figure 3.14 Image of hardness testing machine used 50

Figure 3.15 Image scanning electron microscope used 51

Figure 4.1 Microstructure of heat treated of aluminium alloy 7075 57

Figure 4.2 Tensile strength of non corroded heat treated aluminium

alloys 7075

xi

Figure 4.3 Tensile strength of corroded heat treated aluminium alloy

7075. 60

Figure 4.4 Comparison of tensile strength between the corroded and

non corroded specimens. 61

Figure 4.5 Reduction of tensile strength of heat treated aluminium

alloy 7075 62

Figure 4.6 Hardness results for heat treated specimens of aluminium

xii

LIST OF ABREVIATION

Al - Aluminium

AA - Aluminium alloy

AH - Age hardening

ASM - American Society of Materials

ASTM - American Standard for Testing of Materials BCC - Body-centre cubic

FCC - Face-centre cubic

HT - Heat treatment

Nd-YAG - Neodymium-doped Yttrium Aluminium Garnet PH - Precipitation hardening

PHT - Precipitation heat treatment RRA - Retrogression and re-aging SCC - Stress Corrosion Cracking SEM - Scanning Electron Microscope SHT - Solution heat treatment

1

CHAPTER 1

INTRODUCTION

1.1 Project Background

Aluminum alloy 7075 is a well known type of aluminum alloy used as structural materials of aerospace, transportation, and sports, where the need of lightweight and high strength are needed. Aluminum alloy 7075 is one of the 7000-series aluminum alloys, which captured its reputation in the aeronautical industries due to their attractive comprehensive properties, such as low density, high strength, ductility, toughness and resistance to fatigue (Li et. al, 2007). However, like other 7000-series aluminium alloy, aluminium alloy 7075 is sensitive to localized corrosion such as intergranular corrosion, exfoliation corrosion and stress corrosion. Further enhancement is necessary in order to extend its further applications.

Li et. al (2007) and Reda et al. (2008) stated that the corrosion resistance is

2

corrosion. Besides of T73, another process named retrogression and re-aging or RRA is another heat treatment process which is well known to enhance the corrosion resistance of aluminum alloy.

This project is done to study the effect of various heat treatment processes on the microstructure and stress corrosion cracking of aluminum alloy 7075. Heat treatment is applied on the material specimens to enhance their corrosion resistance against the stress corrosion cracking. Two different types of heat treatment processes, namely T73 tempering and RRA are applied on the aluminum alloy 7075, with T6 tempering as the reference. Direct tensile stress corrosion cracking test is done on the specimens, where later tensile test is done to determine the residual stress of the material after it undergone DTSCC. Besides, the tensile strength of the materials after DTSCC is then compared to the tensile strength of the materials which are not corroded under DTSCC, at which the difference of strength, indicates the occurrence of SCC within the materials. This cause of such properties is explained by relating with the microstructure appearance of specimens.

1.2 Problem Statement

In modern day transportations, as well as aerospace applications, the demand for lighter materials that possess good mechanical properties have become the direction for researches and developments, with the hope to find the best possible material for the structural components that suits the all requirements. Besides the aspect of light weight and mechanical properties, one other important concern in the structural components for these applications is their susceptibility to corrosion, especially when the materials are alloys.

3

corrosions cracks are mostly microcracks, where the cracks normally occur at the grain level. This phenomenon happens in all alloys, depending on the environment and stress level, at which the effect and consequence can be catastrophic compared to mechanical cracking. The corrosion takes place on the surfaces of the material, forming surface discontinuities that eventually becomes the stress raiser or notch to crack propagation at microstructural level, but the mechanism of crack propagation in such phenomenon is not merely caused by the atomic dislocation due to the stress, but it is also caused by the chemical attack on the crack tip, causing inter-granular cracks along the grain boundaries of the material. As the cracking happens within the grain boundaries, it is invisible to naked eyes. These inter-granular cracks will then become a mechanical crack when the crack growth achieves a certain crack size that is quite visible to naked eyes. SCC can happen in also all type of environment, but the corrosion rate maybe faster is the material is subjected to its susceptible environment.

7000 series Al alloys have been widely used as structural materials in aeronautical and transportation purposes due to their attractive comprehensive properties, such as low density, high strength, ductility, toughness and resistance to fatigue. Perhaps due to its lower price and cost of manufacturing, 7000 series AA gains higher popularity as compared to a better but more expensive material known to be titanium alloys. 7075 Al alloy is one type of the 7000 series AA. Not only it possesses the same principle alloying element as other 7000 series AA, i.e. zinc, it is also sensitive to localized corrosion, such as inter-granular corrosion, exfoliation corrosion and stress corrosion cracking. (Li et al., 2007)

4

upon this problem in T6, over-aging treatments such as T73, T76 and T74 have been developed. However, the strength of these over-aging treated aluminium alloy 7075-T7 is relatively poorer than T6. Retrogression and re-aging, RRA is then developed as it produces a balance of properties for both strength and corrosion resistance for the 7000 series Al alloys. (Reda et. al., 2008) However, the RRA treatment cannot be used for large-section Al alloys due to its very short retrogression time.

5

1.2 Objectives and Aims

The objectives of the investigation include:

i. To relate the microstructure of the heat treated aluminium alloy 7075 with material’s stress corrosion behaviour.

ii. To study the effect of various heat treatment on the mechanical properties of aluminium alloy 7075.

1.4 Scope of Project

6

CHAPTER 2

LITERATURE REVIEW

2.1 Aluminium Alloy 7075

According to Budinski et al. (2005), aluminium and its alloys are the second only to steel in importance in our modern world. With steels, it is possible to make large structures and tools, but aluminium alloys made large structures possible with a lighter weight.

Aluminium alloys are essential engineering materials. The curious aspect of this material is that it is relatively new to our world. This “commodity metal” was made common for about 60 years. Pure aluminium was first produced in the laboratory in 1825, by the reduction of aluminium chloride, and its wide acceptance did not occur until World War II. Nowadays, aluminium alloys are mostly used in aerospace, marine, and transportation applications as the main material for the structural components.

7

mass. For example, a 10-mm-diameter aluminium wire will have the same resistivity as a 6-mm-diameter copper wire. The resistivity of the material is just the inverse of the conductivity of the material. However, the aluminium wire is still 13% lighter than the copper wire. This is a vital consideration for long distance power transmission cables.

Aluminium alloys, in some extent, are regarded as corrosion-resist material. However, the corrosion termed in the case of aluminium is regarded as atmospheric corrosion, rather than chemical corrosion. Aluminium is still subjected to electrochemical corrosion. (Budinski et al., 2005)

In overall, aluminium alloys are best described of having some noteworthy advantages like

i. One-third the weight of steel.

ii. Good thermal and electrical conductivity. iii. High strength-to-weight ratio.

iv. Can be given a hard surface by anodizing and hardcoating. v. Most alloys weldable.

xiii. One-third the stiffness of steel.

8

It is strong, with the strength comparable to many steels, and has good fatigue strength and average machinability, but has less resistance to chemical corrosion than many other aluminium alloys. Its relatively high cost limits its use to applications where cheaper alloys are not suitable. It is commonly produced in several heat temper grades, 7075-O, 7075-T6, and 7075-T651.

The first aluminium alloy 7075 was developed by Japanese company Sumitomo Metal in 1936. 7075 was used for the Zero fighter's air frame of the Imperial Japanese Navy in pre-war times. Aluminium alloy 7075 is often used in transport applications, including marine, automotive and aviation applications, due to their high strength-to-density ratio. Its strength and light weight are also desirable in other fields. Rock climbing equipment, bicycle components, and hang glider airframes are commonly made from aluminium alloy 7075. One interesting use for 7075 is in the manufacture of M16 rifles for the American military. It is also commonly used in shafts for lacrosse sticks.

Due to its strength, high density, thermal properties and its polishability 7075 is widely used in mould tool manufacture. This alloy has been further refined into other 7000 series alloys for this application namely 7050 and 7020.

2.1. 1 Aluminium Alloys Designation for Wrought Alloys