TECHNOLOGY INNOVATION ADOPTION TO IMPROVE THE PERFORMANCE OF DAIRY SMALL-MEDIUM ENTERPRISES:

CASE STUDY IN PANGALENGAN-BANDUNG REGENCY, WEST JAVA, INDONESIA

NUNI NOVITASARI

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

DECLARATION

I, Nuni Novitasari, hereby declare that the thesis entitled Technology Innovation Adoption to Improve the Performance of Dairy Small-Medium Enterprises: Case Study in Pangalengan-Bandung Regency, West Java, Indonesia, submitted for the award of Master of Science from Bogor Agricultural University Indonesia and Master of Applied Innovation and Entrepreneurship from The University of Adelaide in the framework of international double degree program between both universities, is my work through the guidance of my academic advisors and to the best of my knowledge it has not been submitted for the award of any degree in any other academic institutions. This thesis does not contain any pieces of work of other person, except those are acknowledged and refrain herein.

SUMMARY

NUNI NOVITASARI. Technology Innovation Adoption to Improve the Performance of Dairy Small-Medium Enterprises: Case Study in Pangalengan-Bandung Regency, West Java, Indonesia. Supervised by TITI CANDRA SUNARTI and NASTITI SIWI INDRASTI.

SMEs have an important role as the backbone of the economy in Indonesia. SMEs contribute significantly to the GDP, which amounts approximately to 60 percent and the number of workers absorbed by the sector stood at 97 percent of the total available workforce. However, there are several challenges faced by the SMEs in developing countries, such as sourcing financial capital, human resource competency and technology adoption. The majority of SMEs in Indonesia still apply traditional practices in terms of production processes and marketing, which indicates the low level of technology adopted. This condition is also observed in the Indonesia dairy sector.

Pangalengan is a sub-district of Bandung Regency that serves as the centre of milk production in West Java. There are many establishments of SMEs of dairy products producing milk caramel, milk nougat, milk dodol, and milk crackers. Initially, the smallholder dairy farmers’ motivation was to utilize the fresh milk that could not be absorbed by the milk processing plant due to quality issues. Most of dairy SMEs in Pangalengan were lack of technology adoption and GMP implementation, with resulting inconsistency in the quality of the product and limited area of product distribution. This has resulted in the product’s low marketability when compared with the milk candy found in the national market which consists of mainly imported products.

This study intends to explore the conditions and the problems of the production and quality of the product faced by the Small Medium Enterprises (SMEs) of dairy products in Pangalengan-Bandung Regency and to propose the technology that might be accepted and adopted to address the problem in the framework of Good Manufacturing Practices (GMP). The outputs of this study are recommendations on the technology adoption to improve the quality of the products and identification of factors that may influence the adoption of technology innovation by the dairy SMEs. The conceptual frameworks that are used in this study consist of Good Manufacturing Practices (GMP) and the perceivable attributes of innovation in the theory of innovation adoption by Rogers (2003).

This research takes the form of an exploratory case study because it aims to explore the condition of SMEs of dairy products in Pangalengan-Bandung Regency with the conceptual framework of Good Manufacturing Practices and technology innovation adoption theory. The data were collected by doing literature study, field observations in the SMEs of dairy products and conducting interviews with the five respondents.

sanitation; (2) Introduction of processing machinery for key processing stage, such as manual mixing to be replaced by the mechanically operated mixer, moulding and cutting machines, and the use of boiling pans equipped with the thermocouple; (3) Improvement of the product’s packaging to enhance protection of the product thus will extend the shelf life. It is suggested to modify the secondary packaging using standing pouch aluminium foil.

Factors that may influence the adoption of technology by the SMEs have been identified. The positive factors are the motivation and efforts to improve the quality and performance of the product; consumers’ demand for quality and good manufacturing practices; government or regulatory enforcement; and increasing production volumes. The negative factors are limited knowledge and educational background of the SMEs’ human resources; the reluctance of the SMEs to change their current traditional practices; and financial cost.

This study also evaluates the perceived attributes of innovation / technology of GMP. The SMEs perceived that the relative advantage of GMP implementation is low due to the cost that arises as a result of facilities and equipment improvement. Implementation of GMP and the new technology embodied in it are perceived as complicated by the SMEs. This is caused by their limited knowledge of the concept of GMP and the new technology itself. However, the SMEs perceived that GMP implementation is compatible with their values, needs, consumer’s demand, and government regulatory.

RINGKASAN

NUNI NOVITASARI. Technology Innovation Adoption to Improve the Performance of Dairy Small-Medium Enterprises: Case Study in Pangalengan-Bandung Regency, West Java, Indonesia. Dibimbing oleh TITI CANDRA SUNARTI dan NASTITI SIWI INDRASTI.

Industri Kecil Menengah (IKM) memiliki peranan penting sebagai tulang punggung ekonomi di Indonesia. IKM berkontribusi signifikan terhadap PDB, sebesar 60 persen dan jumlah tenaga kerja yang terserap oleh sektor ini mencapai 97 persen dari total tenaga kerja yang tersedia. Namun, ada beberapa tantangan yang dihadapi oleh IKM di negara-negara berkembang, seperti permodalan, kompetensi sumber daya manusia dan adopsi teknologi. Mayoritas IKM di Indonesia masih menerapkan praktek-praktek tradisional dalam hal proses produksi dan pemasaran, yang menunjukkan rendahnya tingkat teknologi yang diadopsi. Kondisi ini juga diamati di sektor peternakan susu Indonesia.

Pangalengan adalah suatu kecamatan di Kabupaten Bandung sebagai pusat penghasil susu sapi di Jawa Barat. Sebagai daerah penghasil susu, maka di Pangalengan banyak berdiri IKM produk olahan susu yang menghasilkan produk caramel susu, noga susu, dodol susu dan kerupuk susu. Pada awalnya, pendirian IKM susu ini didorong oleh motivasi para peternak susu untuk memanfaatkan kelebihan susu segar yang tidak dapat diserap oleh Industri Pengolah Susu (IPS) karena masalah kualitas. Tingkat adopsi teknologi dan implementasi Good Manufacturing Practices (GMP) sebagian besar IKM produk susu di Pangalengan masih tergolong rendah sehingga kualitas produk yang dihasilkan tidak konsisten dan terbatasnya daerah jangkaun distribusi produk. Hal ini mengakibatkan daya saing dan tingkat pemasaran produk lebih rendah bila dibandingkan dengan permen susu di pasaran yang sebagian besar berasal dari produk impor.

Penelitian ini bertujuan untuk mengeksplorasi kondisi dan masalah produksi dan kualitas produk yang dihadapi oleh IKM produk susu di Pangalengan-Kabupaten Bandung dan untuk merekomendasikan teknologi yang bisa diterima dan diadopsi untuk mengatasi masalah tersebut dalam kerangka teori Good Manufacturing Practices (GMP). Output dari penelitian ini adalah rekomendasi adopsi teknologi untuk meningkatkan kualitas produk dan identifikasi faktor-faktor yang dapat mempengaruhi adopsi inovasi teknologi oleh IKM produk susu. Penelitian ini dilakukan melalui metode studi kasus eksplorasi dengan kerangka konseptual GMP dan teori Adopsi Inovasi/Teknologi (Rogers, 2003). Pengumpulan data dilakukan dengan studi literatur, observasi lapangan di IKM produk susu dan wawancara dengan lima responden.

untuk meningkatkan perlindungan terhadap produk sehingga dapat memperpanjang masa simpan. Disarankan untuk mengubah kemasan sekunder menggunakan standing pouch aluminium foil.

Faktor-faktor yang dapat mempengaruhi adopsi teknologi oleh IKM produk susu telah diidentifikasi. Faktor-faktor positif adalah motivasi dan upaya perbaikan kualitas dan kinerja produk; perrmintaan konsumen akan kualitas dan praktek produksi yang baik; penegakan peraturan oleh pemerintah; dan adanya peningkatan volume produksi. Faktor-faktor negatif adalah keterbatasan pengetahuan dan latar belakang pendidikan sumber daya manusia IKM; keengganan IKM untuk mengubah praktik tradisional mereka saat ini; dan biaya keuangan.

Penelitian ini juga mengevaluasi atribut inovasi/teknologi GMP yang dipersepsikan oleh para responden. IKM mempersepsikan bahwa keuntungan relatif dari pelaksanaan GMP rendah bila dibandingkan dengan biaya yang harus dikeluarkan untuk perbaikan peralatan dan fasilitas produksi. Pelaksanaan GMP dan teknologi baru yang terkandung di dalamnya masih dianggap sebagai rumit oleh UKM. Hal ini disebabkan oleh pengetahuan mereka yang terbatas mengenai konsep GMP dan teknologi baru itu sendiri. Namun, IKM mempersepsikan bahwa pelaksanaan GMP sesuai dengan nilai-nilai yang dianut, kebutuhan, permintaan konsumen, dan peraturan pemerintah.

Copyright 2015 of Bogor Agricultural University

All Rights Reserved

1. No part of or entire of this thesis maybe excerpted without inclusion and

mentioning the sources.

a. Excerption only for research and education use, writing for scientific papers,

reporting, critical writing or reviewing of a problem.

b. Excerption does not inflict a financial loss in the proper interest of Bogor

Agricultural University.

2. No part of or entire of this thesis maybe translated and reproduced in any form

A thesis

Submitted to the Graduate School in Partial Fulfillment of the Requirement for

Master of Science Degree in Agroindustrial Technology

TECHNOLOGY INNOVATION ADOPTION TO IMPROVE THE

PERFORMANCE OF DAIRY SMALL-MEDIUM ENTERPRISES:

CASE STUDY IN PANGALENGAN-BANDUNG REGENCY,

WEST JAVA, INDONESIA

SEKOLAH PASCASARJANA INSTITUT PERTANIAN BOGOR

BOGOR 2015

Thesis title : Technology Innovation Adoption to Improve the Performance of Dairy Small-Medium Enterprises: Case Study in

Pangalengan-Bandung Regency, West Java, Indonesia Name : Nuni Novitasari

Registration No. : F351137101

Approved Advisory Committee

Dr. Ir. Titi Candra Sunarti, MSi Chairman

Prof. Dr. Ir. Nastiti Siwi Indrasti Member

Agreed

Coordinator of Major Agroindustrial Technology

Prof. Dr. Ir. Machfud, MS

Dean of the Graduate School

Dr. Ir. Dahrul Syah, MScAgr

ACKNOWLEDGEMENTS

First and foremost, I am deeply grateful to Allah SWT for giving me tremendous blessings and protections. My deepest appreciation to my advisers, Dr. Ir. Titi Candra Sunarti , Prof. Dr. Ir. Nastiti Siwi Indrasti, Dr. Barry Elsey and Dr. Wendy Lindsay for their critical and valuable insights, guidance and encouragement through the whole process of my thesis writing. My appreciation also to Dr. Hartrisari Hardjomijojo, DEA as an external examiner for her valuable inputs and suggestions.

I would also like to acknowledge individuals who have helped me through the process although it does not make them responsible for the final text. Ir. Agus Sudibyo, MP and Drh. Asep Rahmat Hoerudin who were willing to share their knowledge, insights and time for this study as expert respondents. Ateng Zailani, Nusep Rohmat, and Ucup Tosin who were willing to share their knowledge, insights and time for this study as respondents. Ms. Amina Omarova & Ms. Nicole Rizzo-Gray for their assistance and guidance during my study in University of Adelaide.

My sincere thank further to all my fellow friends in double degree program of TIP-IPB and University of Adelaide for their support, cooperation and assistance during my study: Anindita, Dwi, Yani, Arum, Nur Aini, Chicha Dena, Farda, Karim, Tri, Dickie, Iwan, Danang, Andar, Benny, Koko, Rudh, and Ardy.

Finally I would like to thank my parents, Bapak Nana Suryana and Ibu Mintarsih; my husband, Nindya Malvins Trimadya, and my daughter, Lira Nesya Kamila for their love & support for me. To them I dedicate this piece of work.

TABLE OF CONTENT

TABLE OF CONTENT v

LIST OF TABLES vi

LIST OF FIGURES vi

LIST OF APPENDICES vi

1 INTRODUCTION 1

Background and Need 1

Problem Statement 2

Objectives of the Research 3

Research Questions 3

Significance to the Field 3

Limitation 4

2 LITERATURE REVIEW 5

Quality Assurance 5

Good Manufacturing Practices (GMP) 6

Technology Innovation Adoption 9

Summary 11

3 METHODOLOGY 12

Setting 13

Participants 13

Measurement Instrument and Protocols 13

Data Analysis 14

4 FINDINGS AND DISCUSSIONS 15

Description of Dairy SMEs’ Profile in Pangalengan 15 Identification of Current Processing Technology 16 Evaluation of the GMP Implementation by the SME 17 Problems of Production and Quality of the Product faced by the Dairy

SMEs in Pangalengan 19

Identification of Technology Innovation might be Accepted and

Adopted by the SMEs in Implementing GMP to Address the Problems 20 Factors that may Influence the Adoption of Technology by the Dairy

SMEs in Pangalengan 25

Implications of Research 29

5 CONCLUSION AND RECOMMENDATION 30

Summary 30

Recommendation 30

REFERENCES 31

APPENDICES 33

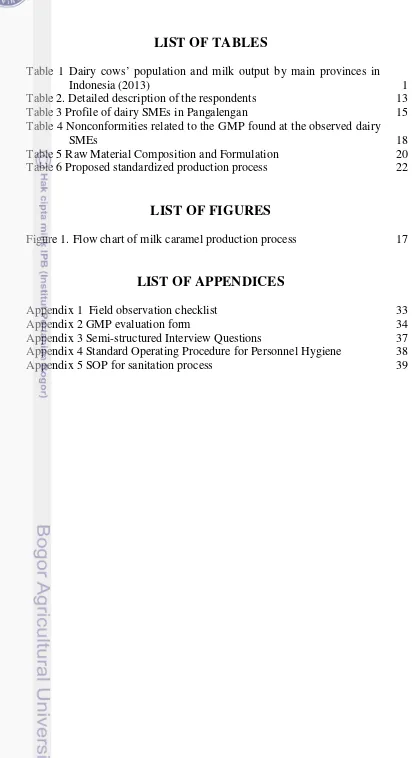

LIST OF TABLES

Table 1 Dairy cows’ population and milk output by main provinces in

Indonesia (2013) ... 1

Table 2. Detailed description of the respondents ... 13

Table 3 Profile of dairy SMEs in Pangalengan ... 15

Table 4 Nonconformities related to the GMP found at the observed dairy SMEs ... 18

Table 5 Raw Material Composition and Formulation ... 20

Table 6 Proposed standardized production process ... 22

LIST OF FIGURES

Figure 1. Flow chart of milk caramel production process ... 17LIST OF APPENDICES

Appendix 1 Field observation checklist ... 33Appendix 2 GMP evaluation form ... 34

Appendix 3 Semi-structured Interview Questions ... 37

Appendix 4 Standard Operating Procedure for Personnel Hygiene ... 38

1

1

INTRODUCTION

This study intends to explore the conditions and the problems of the production and quality of the product faced by the Small Medium Enterprises (SMEs) of dairy products in Pangalengan-Bandung Regency and to propose the technology that might be accepted and adopted to address the problem in the framework of Good Manufacturing Practices (GMP). The outputs of this study are recommendations on the technology adoption to improve the quality of the products and identification of factors that may influence the adoption of technology innovation by the dairy SMEs. The conceptual frameworks that are used in this study consist of Good Manufacturing Practices (GMP) and the perceivable attributes of innovation in the theory of innovation adoption by Rogers (2003).

This research takes the form of an exploratory case study because it aims to explore the condition of SMEs of dairy products in Pangalengan-Bandung Regency. The data were collected by doing literature study, field observations in the SMEs of dairy products and conducting interviews with the five respondents.

Background and Need

Dairy is an important subsector of agriculture that contributes to the development of the economy in Indonesia. In 2013, Indonesia’s dairy cattle population was 636,000 head involving approximately 192,160 dairy farmers managing about 3 cows each on average. Over the last five years, Indonesia’s dairy cow population and milk production has increased annually by an average of 7.4% and 14.6% respectively. Approximately 90% of dairy farms are concentrated in West, Central and East Java with a small proportion of around 2% in Sumatra. As can be seen in Table 1, East Java is Indonesia’s largest dairy production base accounting for 57.09% of all milk production. West Java is the second biggest producer of milk in Indonesia, with the amount of 281,438 tonnes and 293,107 tonnes in 2012 and 2013 and contributed about 30% of national milk production (Daryanto 2014). Bandung Regency is the largest producer of milk in West Java, thus it becomes the potential location for the establishment of dairy product’s SMEs.

2

(Morey 2011). The quality of raw milk is not stable because of poor milking hygiene practices and lack of milking technology, both on-farm and post-farm gate. Milk is categorized as a perishable, high-risk product that can easily become deteriorated. It needs to be immediately processed to avoid spoilage. These conditions have stimulated the establishment of SMEs of dairy processed products in the centre area of fresh milk production (Elvita 2003). They utilize the fresh milk as a raw material for varied innovative new milk products such as milk caramel candy, milk crackers, milk tofu, milk nougat and milk jam.

Pangalengan is a sub-district of Bandung Regency that serves as the centre of milk production in West Java. There are many SMEs of dairy products producing milk caramel, milk nougat, milk dodol, and milk crackers. Initially, the smallholder dairy farmers’ motivation was to utilize the fresh milk that could not be absorbed by the milk treatment plant due to quality issues. Therefore, they were urged to innovate by processing the excess fresh milk to become more

Pangalengan has a wide range of traditional dairy products that have been known and appreciated by consumers for years. The main product they produce is milk caramel which amounts to 80 % of total products. These SMEs in Pangalengan produce milk caramel with production capacity ranging between 150 – 1000 l of milk per day involving 10 – 65 workers per each SME. These SMEs contribute to the economy of the region by creating the added value of the fresh milk (thus increasing income) and absorbing the workforce (thus reducing unemployment). Such a contribution is significant in rural areas where farming is the main economic activity. The farmers use their harvested commodity, including dairy products, by consuming it locally to fulfil the basic nutritional needs or by selling it in neighbouring urban markets to get the income, that enable them to fulfil other needs not available in the surroundings area (Benkerroum and Tamime 2004).

Milk caramel is a typical milk product of Pangalengan and is sought after as a souvenir by tourists who visit Pangalengan area or Bandung Regency. Milk caramel is a processed dairy product with a soft chewy texture and brown colour identical to the result of the caramelisation process, and has a distinctive taste of milk.

The problems of quality in the SMEs can be addressed by implementing the quality assurance system. The simplest and most suitable quality assurance system for the SMEs is implementing GMP. However, there is still limited information and research regarding the technology adoption and GMP implementation in the dairy SMEs, especially for the product of milk caramel.

Problem Statement

3

amounts approximately to 60 percent and the number of workers absorbed by the sector stood at 97 percent of the total workforce available (Anggadwita and Mustafid 2014). However, there are several challenges faced by the SMEs in developing countries, such as sourcing financial capital, human resource competency, and technology adoption. (Subrahmanya 2005). According to Anggadwita and Mustafid (2014), the majority of SMEs in Indonesia still apply traditional practices in terms of production processes and marketing, which indicates the low level of technology adopted. This condition is also observed in the Indonesia dairy sector.

Most of dairy SMEs in Pangalengan lack of technology adoption and GMP implementation, with resulting inconsistency in the quality of the product and limited area of product distribution. This has resulted in the product’s low marketability when compared with the milk candy found in the national market which consists of mainly imported products.

Objectives of the Research The objectives of this research are:

1. To recommend the adoption of technology in implementing GMP in the SMEs of dairy products (milk caramel) that may improve the quality of the products.

2. To identify the positive and negative factors that may influence the adoption of this new technology by the SMEs of dairy products.

Research Questions

The research questions in this research are identified as follow:

1. What are the problems of production quantity and quality of the product? 2. What type of technology innovation might be acceptable and adopted to

address the problems?

3. What are the positive and negative factors that may influence the adoption of technology by the SMEs of dairy products?

Significance to the Field

4

Limitation

5

2

LITERATURE REVIEW

Quality Assurance

Quality is a diverse concept and may be defined in different ways depending on the interest of the manufacturers or the consumer’s point of view. The widely known concept of quality introduced by Juran (1988) defines quality as “fitness for use” which means that the product or services should meet the requirement and expectation of the consumers (Vasconcellos 2003). Industry defines quality as

“A measure of purity, strength, flavour, color, size, maturity, workmanship and condition, or any other distinctive attribute or characteristic of the product” (Vasconcellos 2003: 12).

According to Vasconcellos (2003), there are four common standards of referring the quality, they are as follow:

1. Legal standard (mandatory government regulation) 2. Company or voluntary label standard

3. Industry standard

4. Consumer’s grade or standards

Quality assurance describes and manages the activities of control, evaluation, audits and regulatory aspects of food processing system to assure that the product being produced conforms to the standards. Nowadays the quality assurance systems that can be implemented by the food SMEs are those in the ISO Series (ISO 9001:2008, ISO 22000:2005), Hazard Analysis Critical Control Point (HACCP), and Good Manufacturing Practices (GMP) (Karipidis et al. 2009; Vasconcellos 2003).

There have been numerous studies of factors that influence the implementation and adoption of quality assurance systems by the SMEs. Karipidis and others (2009) reviewed that the influencing factors can be grouped into four categories, which are:

1. Internal benefits or advantages (e.g. improve company’s confidence to produce quality product)

2. External benefits or advantages (e.g. improve market share and competitiveness)

3. Internal barriers or disadvantages (e.g. limited trained human resources and limited financial)

4. External barriers or disadvantages (insufficient quality tools and lack of training or education).

There are four basic factors that may encourage SMEs to adopt QAS, which are: their positioning in the marketplace when compared to the competition, the effect of poor quality, the quality culture, and the effectiveness of activities aiming to achieve quality goals (Karipidis et al. 2009).

6

Elvita (2003) studied the implementation of the quality control system in the product of milk caramel in a dairy SME in Bandung-Indonesia. The result suggested that the problems faced by the SME in relation to milk caramels encompass the raw materials quality, processing quality control, human resources management, as well as the product marketing and distribution. However, this study did not clearly evaluate the implementation of GMP as a quality assurance system that is more practical and suitable for the food SMEs in Indonesia (Pursito 2014). Thus, it needs further study about the technology that can be accepted and adopted by the milk caramel SMEs to solve the quality problems and improving the implementation of GMP.

Good Manufacturing Practices (GMP)

Good Manufacturing Practices (GMP) is a guidance for food production which is aimed to produce food products with quality, that are safe to be consumed and in accordance with consumers’ requirements. Fardiaz (1996) as cited by Herlinawati (2012) states that the objectives of GMP application in the food industry are to:

1. Encourage the food processing industry to be responsible for the quality and safety of products produced.

2. Improve the competitiveness of the food processing industry.

3. Improve the productivity and efficiency of the food processing industry. GMP forms the basis of a foundational platform for a quality assurance program upon which other systems such as food safety system (e.g. ISO 22000, HACCP) could be built to produce consistent quality and safety of the food. GMP provides the basic requirement to assure good practices related to the workers, the facility and environment, the machinery or equipment and also process control (Chandan et al. 2009; Dewanti-Hariyadi 2010). The benefits of GMP implementation in small dairy factory as pointed out by Cusato et al. (2013) are related to food safety, longer product shelf life, reduced losses, better working environment, and consumer satisfaction.

The GMP standard in this study refers to the Regulation of Head of The National Agency for Food and Drug Control (NADFC) Republic of Indonesia No. HK.03.1.23.04.12.2206 year 2012 about Good Manufacturing Practices for household and small scale industry (Pursito 2014). The scope of GMP covers the following aspects:

1. Location and production environments

7

2. Building and facility

Building and facility should assure that during the production process, food will not be contaminated by the physical, biological, and chemical hazards, as well as easy to clean and sanitize.

3. Production equipment

The layout of the production equipment ought to be designed to avoid cross contamination. The equipment coming contact with food should be designed and constructed to ensure the quality and the safety of the food produced. Production equipment and containers should be made of materials with no toxic effect, durable, and easy to clean and sanitize in its intended use.

4. Water supply and facility

An adequate supply of potable water with appropriate facilities for its storage, distribution and temperature control, should be available and meet the requirement of clean water or drinking water quality standards.

5. Hygiene and sanitation facility and activity

Hygiene and sanitation facility and activity are needed to assure that the building and equipment are in clean condition and to prevent the cross-contamination from the workers. Cleaning facility for washing of food, equipment, supplies and building (floors, walls and others) should be available and well maintained. Employee hygiene facilities such as hand washing and toilet should be available in sufficient quantities and in a clean state to ensure the hygiene of employees in order to prevent contamination to food.

6. Personnel health and hygiene

An appropriate degree of personal cleanliness and health can assure that the workers or food handlers are not the sources of food contamination. Food handlers should maintain a high degree of cleanliness, where appropriate, wear suitable protective clothing, head covering, and footwear. Food handlers should avoid the non-hygienic practices that could result in contamination of food, for example: smoking, spitting, chewing or eating, and sneezing or coughing over unprotected food. Food handlers should not wear accessories such as jewellery, watches, pins or other items that could contaminate the food safety and quality.

7. Maintenance and sanitation hygiene program

Maintenance and sanitation program for production facilities (buildings, machinery/equipment, pest control, waste handling and other) shall be done periodically to ensure avoiding cross contamination to the processed food. Cleaning should remove food residues and dirt that may be a source of contamination.

8. Storage

8

9. Process control

The production process shall be controlled properly to produce good quality and safe food product. Process control in food home industry or food SME can be done through the following steps:

a. Establish the raw material specification

b. Establish the raw material composition and formulation

c. Establish the standard operating procedure for the production process of

food

d. Establish the type, size, specification of the packaging

e. Establish the detailed product information, including product’s name,

production date, expiry date. 10. Food labelling

Food should be labelled with clear information and instruction to enable consumers to choose, store, handle and consume the food. The food label should contain the following minimum required information:

a. Product’s name

b. List of raw materials and ingredients c. Nett weight

d. Producer’s name and address e. Expiry date

f. Production code g. Food licence number

11. Supervision by the person in charge

A person in charge is required to supervise all stages of the production process and control to assure the food product quality and safety.

12. Product recall

The owner of the food factory must recall the product if suspected to cause illness/food poisoning/ and or not meet the requirements of food legislations and regulations.

13. Records and documentation

Appropriate records and documentation are needed to facilitate traceability of problems related to production and distribution process, to prevent the distribution of products that exceed the expiry date, and to improve the suitability and effectiveness of the food safety and quality management system.

14. Training of employees

Managers and employees must have basic knowledge and competency regarding the principles and practices of food hygiene, sanitation and food processing in order to produce good quality and safe food.

9

Amoa-Awua et al. (2007) confirmed that GMP implementation is an effective system for ensuring the quality and safety in the traditional processing of maize in Ghana. In such traditional operations, GMP can be implemented at a minimal cost by relying on simple techniques and instruments such as visual inspections, using pH strips, thermometers, and timing of unit operations (Amoa-Awua et al. 2007).

Yuwono et al. (2012) identified internal and external factors that influence the continuity of GMP application in the fish fillet processing plants. The internal factors are lack of education and lack of experience, while the external factors are lack of government policies in socialisation and training of GMP, lack of potable water and ice supply, lack of law enforcement, and market demand.

Addressing the issues of GMP implementation in food SMEs, government plays a significant role, such as supporting and providing the infrastructure for the SMEs (e.g. potable water, cold supply chain), providing training related to the sanitary production process and good manufacturing process for SMEs and conducting regular monitoring of GMP implementation (Herlinawati 2012; Suhartono 2009).

Technology Innovation Adoption

The introduction of quality assurance concepts to the SMEs that is embodied in the implementation of GMP and the processing technology included can be regarded as new technology or innovation concept for the SMEs. The implementation of GMP and technology included in it is aimed to improve the product’s quality and competitiveness.

Rogers (2003) defines innovation as an idea, practice, or object that is perceived as new by an individual or other unit of adoption. In this perspective, the newness of an innovation is measured subjectively by the adopters and more emphasizing in the usefulness and novelty. In the context of a developing country, technological innovation is characterized as the process where a company creates and/or applies the new design and/or new production process of goods and services regardless of whether they are new to their competitors, their customers or the world (Subrahmanya 2013). According to Subrahmanya (2013), innovation will emerge only when a technically competent firm is able to identify and respond to customer requirements by developing or improving products/processes.

Technology innovation can be classified into hardware technology and software technology. Hardware technology refers to the physical or material objects such as tools, machinery, or equipment, while software technology refers to information base or systems underlying the hardware technology (Rogers 2003). GMP can be classified as the software technology that underlying the usage of hardware technology needed to improve the implementation of the concept.

10

1. Relative advantage. This is the degree to which innovation is perceived as better than the existing one. It can be measured by the economic perspective, convenience, and satisfaction. The relative advantage correlates positively with the rate of adoption.

2. Compatibility. This is the degree to which an innovation is perceived as being consistent with the existing values, past experiences, and the needs of the adopters. The compatibility correlates positively with the rate of adoption.

3. Complexity. This is the degree to which an innovation is perceived as difficult to be understood and to be applied. The complexity correlates positively with the rate of adoption.

4. Trialability. This is the degree to which an innovation can be trialled prior to full implementation in the real situation. The trialability correlates positively with the rate of adoption.

5. Observability, it is the degree to which the result of an innovation can be observed by others. The observability correlates positively with the rate of adoption.

This study focuses on the relative advantage, compatibility, and complexity of GMP and relevant technology needed as technological factors because according to Rogers (2003b), these three factors have consistently influenced in adoption behaviour of technical innovation than other factors.

In addition, Ram and Sheth (1989) argued there are five barriers that weaken the adoption of innovation and may lead to the innovation resistance, which are: usage barrier, value barrier, risk barrier, tradition barrier and image barrier. The usage barrier happens when an innovation is not compatible with existing workflows, practices or habits. It is the most probable cause for resistance to innovations. The value barrier arises if the innovation does not offer significant performance-to-price compared to its substitutes. Risk barrier refers to the degree of risks an innovation entails (physical, economic and function). Tradition barrier related to the changes an innovation may cause in daily routines and deviate from established traditions. The image barrier arises due to a stereotyped thinking and perception of an innovation.

Benkerroum and Tamime (2004) studied the technology transfer of some Moroccan traditional dairy products to improve the traditional fermentation process. The study proposed the schemes of standardized production stages, in which the processing steps are basically the same as those used in traditional method with the required adjustments for standardization and enhancement of safety and quality of the final products. They included three main criteria as follow: (1) Pasteurization of the raw milk due to its poor hygienic quality; (2) Mechanization of some key processing stages; and (3) Improvements of the product’s conditioning and packaging.

11

rejected product. They also perceived that GMP is compatible with their values and customer’s values (requirements of the customer and regulation of the export destination countries). They have received education, training, and manual guidance from the government thus they do not perceive GMP as complex. On the other hand, the respondents who decided to stop the GMP implementation perceived that the GMP implementation did not give them relative advantages, not compatible, and difficult to apply.

Summary

The problems of quality in the SMEs can be addressed by implementing the quality assurance system. The simplest and most suitable quality assurance system for the SMEs is implementing Good Manufacturing Practices. There are several studies that have been conducted to analyze factors affecting the SMEs to adopt the quality assurance system and GMP as well as the new technology to solve the problems of quality. Furthermore, the technology adoption rate is also influenced by the perceivable characteristics of innovations.

12

3

METHODOLOGY

The exploratory case study methodology is applied in this study, with the unit of analysis being the SMEs of dairy products in Pangalengan. An exploratory case study is used to explore those situations in which the intervention being evaluated has no clear, single set of outcomes (Yin 2013). For the novice researcher, a case study is an excellent opportunity to gain useful insight into a case. It enables the researcher to gather data from a variety of sources and to converge the data to clarify the issues under investigation (Baxter and Jack 2008).

This research was conducted through four stages as follow: 1. Identification of the dairy SMEs profile in Pangalengan.

The data of dairy SMEs profile in Pangalengan were collected from the documentation of the SMEs report, doing field observation and semi-structured interview. The data covered the number of SMEs, the production capacity, the number of workers, the competency of the human resources, the legal status, and monthly income. There were three SMEs in Pangalengan included as respondents and being observed in this study, they are: AA Enterprise, BB Enterprise and CC Enterprise. The detailed description of the respondents can be seen in Table 2.

2. Identification of current conditions and processing technology of the dairy SMEs.

This stage covers identification of current processing technology being used, evaluation of the GMP implementation by the SMEs, and identification of the problem of production and quality of the product. The data were collected by doing field observation and semi-structured interview with the owners and workers of the SMEs. The data covered production flow process, the raw materials and equipment being used, the quality control process, and the implementation of 14 elements of GMP (conformities and non conformities).

3. Identification of technology adoption that might be acceptable and applied to address the problem.

The information was collected by doing field observation and semi-structured interview with the expertise of dairy processing technology and the SMEs’ owner. Literature study was conducted to enhance the data related with the Good Manufacturing Practices, milk candy processing technology and dairy processing technology. The expert respondents involved in this study consist of Ir. Agus Sudibyo, MP as a senior researcher from Center for Agro-based Industry and Drh. Asep Rahmat H. as a processing unit manager from Cooperatives of Bandung Regency Dairy Farmers (CBRDF).

4. Identification of factors that may influence the adoption of new technology by the SMEs.

13

Setting

This study was conducted from May 2014 until May 2015. The interviews and field observations were done in June 2014 and January 2015. The study took place in the SMEs of dairy products in Pangalengan-Bandung Regency, West Java, Indonesia.

Participants

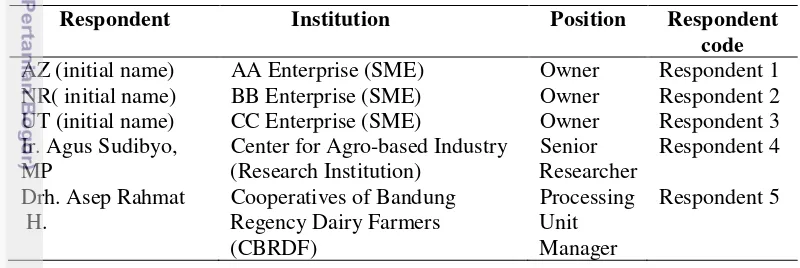

The participants involved in this study were selected by using the purposive sampling method. There were three SMEs of dairy products in Pangalengan and two experts selected as respondents based on their expertise in the dairy processing technology and Good Manufacturing Practices in the small scale food industry. The SMEs respondents were selected based on the size of the SMEs which were indicated by the production capacity and the sales volumes. The selected respondents were the three biggest establishment SMEs in Pangalengan. The details of the participants in this study can be seen in the following Table 2.

Table 2. Detailed description of the respondents

Respondent Institution Position Respondent

code

AZ (initial name) AA Enterprise (SME) Owner Respondent 1 NR( initial name) BB Enterprise (SME) Owner Respondent 2 UT (initial name) CC Enterprise (SME) Owner Respondent 3 Ir. Agus Sudibyo, done by visiting the three SMEs of dairy products in Pangalengan and observing all aspects related to the elements of GMP, the production process and quality of the product. A field observation checklist was used to implement the records of the field observations. Photographs were also taken as records and additional information to the field observation checklist. The detailed of field observation data checklist and GMP evaluation form are provided in the Appendix 1 and Appendix 2.

14

The interviews were conducted face to face with the five respondents at the site of their businesses. The interview question list was used as a guide, yet the researcher was allowed to ask questions outside the list to further pursue the respondent’s answer and explore more information or data. The detailed of interview questions list guide is provided in the Appendix 3. The interviews lasted for 1 – 2 hours. Sound recordings were taken of all of the conversations during the interviews.

Data Analysis

The data analysis applied in this study is descriptive analysis (field observation) and interpretive analysis (interview results). The collected data from interviews were analysed by using a case study data analysis technique (Yin 2013). It started by transcribing the interviews recording into a textual report. Since interviews were conducted in the Indonesian language, the transcription is also in the Indonesian language to have better understanding of the analysis and to avoid misinterpretation by the researcher. The data of the transcribed scripts were coded and grouped into more general themes. After that, the themes were identified referring to or related to the research questions. Finally, the analysed data were translated into English.

15

4

FINDINGS AND DISCUSSIONS

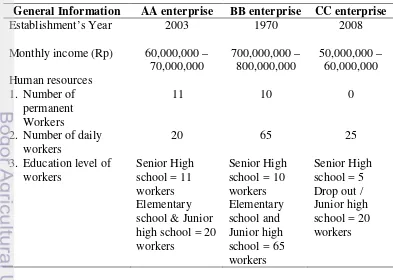

Description of Dairy SMEs’ Profile in Pangalengan

The AA enterprise was first established in 2003. The owner (Respondent 1) runs the business with the support of his family members, including his wife, brothers, and sisters. Currently, AA enterprise employs 21 freelance workers and processes 200 – 250 l of fresh milk per day with average monthly income reaches Rp 60 – 70 million per month.

The BB enterprise is the leading dairy product home industry in Pangalengan. It was the pioneer of dairy products’ SME in Pangalengan, established in 1970 by the owner, involving family members. Through the innovation and creativity process, since 1985 BB enterprise started to produce other dairy products, namely milk dodol, milk nougat and milk crackers. Currently, the company employs 75 workers and processes 1000 l of fresh milk for milk caramel candy products on a daily basis. Its monthly income reaches Rp 700 – 800 million per month. In 1992, the government awarded BB enterprise the Upakarti award as the small-medium scale entrepreneurs who had succeeded in business and surrounding community development.

The CC enterprise was established in 2008 by Respondent 3. Previously, Respondent 3 was an employee of AA enterprise and BB Enterprise. He was an experienced and skilled worker who has decided to establish his own enterprise. Currently, CC enterprise employs 23 freelance workers and processes 150 – 200 litres of fresh milk per day with average monthly income reaches Rp 50 – 60 million per month. The detailed profile of these SMEs can be seen in Table 3. Table 3 Profile of dairy SMEs in Pangalengan

General Information AA enterprise BB enterprise CC enterprise

Establishment’s Year 2003 1970 2008

16

In running their business, these dairy SMEs cooperate with the Cooperatives of Bandung Regency Dairy Farmers (CBRDF) as a supplier of the fresh milk. As mentioned before that Pangalengan is an area of milk producer. The dairy farmers in Pangalengan delivered their fresh milk to be collected and sold to the CBRDF. The CBRDF has members amount to 6462 (5,418 active members of dairy farmers and 1,044 non-active members) with the total population of cows reaching 12,797, and able to produce fresh milk at the average of 135,070.85 l per day. These figures can assure that the supply of raw materials for the SMEs can be sustainable if they want to increase their production scale or capacity. The dairy SMEs in Pangalengan is prioritized by the CBRDF because they are in the same area and the demand volume is far less than the amount of CBBRDF milk produce.

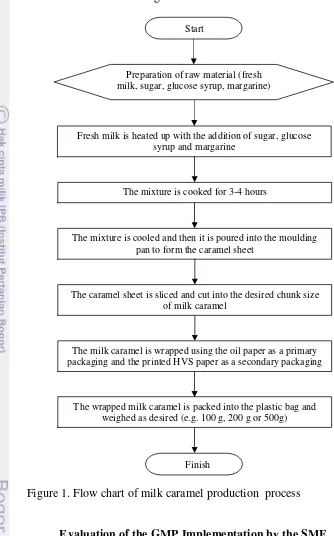

Identification of Current Processing Technology

Milk caramel is a processed dairy product with a soft chewy texture, brown colour and has a distinctive taste, flavour and aroma. The distinctive properties of milk caramel are the result of the reaction between sugar and milk proteins during the heating process (known as caramelisation and Maillard reaction). Milk fat decomposition during heating in the high-sugar environment also contributes to the distinctive taste of the product (Alikonis 1979; Elvita 2003).

Maillard reaction is a reaction between reducing sugars with amino acids. The most important influence the Maillard reaction has on confectionery is the formation of colour, aroma and taste during processing. Another color and flavor reaction in milk caramel making is caramelisation, which involves sugar pyrolysis and then the formation of sugar-sugar polymers. If proteins are present the intermediates from the caramelisation reaction may interact forming similar products to those isolated from Maillard reaction systems. Caramelisation occurs at a temperature above 80oC, while the typical cooking range for caramel confectionery is 240 0F- 270 °F (115 0C– 130 0C) (Davies and Labuza 2000).

Heating and cooking is the key processing stage to evaporate the water content of the milk. The cooking process should be done with the stirring along the process to distribute the heat evenly throughout the dough and to avoid the coagulation of the mixture. The First stage of heating is pasteurization that aims to kill the pathogenic bacteria. The original type of heat treatment was a batch process in which milk was heated to 63 °C in open vats and held at that temperature for 30 minutes (Bylund and Pak 2003).

The composition of raw materials and ingredients in the milk caramel consist of fresh milk, sugar, glucose syrup, and margarine. The packaging materials consist of oil paper and HVS paper (as a primary packaging) and printed plastic bag (as a secondary packaging).

17

milk caramels is shown in the Figure 1 below.

Figure 1. Flow chart of milk caramel production process

Evaluation of the GMP Implementation by the SME

The observed SMEs have applied several aspects of GMP in their daily operation and conformed to some requirements of GMP elements. The conformities found are for the element water supply and facilities, storage, food labelling, and product recall. On the other hand, there were also found nonconformities in several elements as described in the Table 4 below.

Start

Preparation of raw material (fresh milk, sugar, glucose syrup, margarine)

Fresh milk is heated up with the addition of sugar, glucose syrup and margarine

The mixture is cooked for 3-4 hours

The mixture is cooled and then it is poured into the moulding pan to form the caramel sheet

The caramel sheet is sliced and cut into the desired chunk size of milk caramel

The milk caramel is wrapped using the oil paper as a primary packaging and the printed HVS paper as a secondary packaging

The wrapped milk caramel is packed into the plastic bag and weighed as desired (e.g. 100 g, 200 g or 500g)

18

Table 4 Nonconformities related to the GMP found at the observed dairy SMEs

Elements Nonconformities

Building and facilities

The dairy SMEs utilize the existing building for the production building, and it was not designed earlier for food production that meets the requirements of GMP.

- The floors and the wall of cooking area do not have

smooth surfaces.

- Ceilings construction does not allow the minimization

of dirt and condensation, and the shedding of particles.

- Lack of screen against the entry of insects.

Production

- Absence of hand washing facility near the production

area.

- Hand washing facility not equipped with the soap and

hand dryer.

- Absence of competent person responsible for the

sanitation of equipment and production area.

- The dairy SMEs already have the cleaning program

but not documented properly.

- The cooking area and some plastic storage equipment

(e.g. plastic milk container) are not in a good state of cleanliness. It indicates that the effectiveness of the cleaning program should be evaluated.

Personnel

rings, bracelets, and watches that may harm the safety of the processed food.

- Food handlers do not always wash hands with soap

before start to work, after handling raw materials and dirty equipment, and after using the toilet.

- Failure in hygiene habits during food processing

(eating, drinking, and chatting while wrapping the product in the packaging room).

- Lack of awareness and knowledge of workers

19

Elements Nonconformities

Process control - Lack of established process control system. - Lack of inspection of raw materials at reception. - Lack of inspection and monitoring of process control

(temperature, end cooking point).

- Absence of standardized production procedure.

Supervision by the person in charge

- Owners play this role whereas they are also in charge

of other functions, such as purchasing, finance, and marketing.

Records and documentation

- Lack of appropriate record or documentation related to

the production and distribution process. Training of

employees

- Absence of continuous training program (GMP) and

records of such program that lead to inadequate knowledge and awareness of workers.

Problems of Production and Quality of the Product faced by the Dairy SMEs in Pangalengan

Based on the data collected through interviews and field observation, and the process of data analysis, there are several problems with production and quality the product faced by the dairy SMEs in Pangalengan, they are as follows: 1. Finished product quality is not consistent in terms of taste, texture, size, and the shelf-life of the product. As stated by respondent1,

”….by having a limited competency of workers and traditional production process management, the quality of the product becomes not stable and uniformity is difficult to achieve...”

They often found some defect products in the retailer store before reaching its expiry date. The problems of product’s texture & taste related to the production process control, especially in the heating and cooking stage (e.g. overcooking due to lack of time and temperature control).

2. The current secondary packaging, which is a transparent plastic bag, cannot protect the product properly from direct sunlight and high temperature when the product is being displayed in the retailer store. Under this condition, the fat content of milk caramel will seep into the wrapping paper, making it look defective, and the product texture is softened.

3. The causes of the problems are non-standardized production process, low level of GMP implementation and lack adoption of new technology. These SMEs do not have the process and quality control system established, thus the consistent quality of the product is difficult to achieve. In the view of respondent 5,

20

These SMEs still use simple, traditional and manually operated equipment in the production process. It indicates the lack adoption of new technology. 4. The GMP implementation evaluation shows that there are four main

elements that need to be improved by the SMEs and directly affected the product’s quality, these elements are: process control, personnel hygiene, hygiene and sanitation activities, and training of workers.

Identification of Technology Innovation might be Accepted and Adopted by the SMEs in Implementing GMP to Address the Problems

The problems of production and quality of the product faced by the dairy SMEs can be addressed by implementing the GMP properly and adopting new technology. Based on the interviews, field observations, and data analysis, the researcher has identified three types of technology in the framework of GMP that might be accepted and adopted to address the problems, they are as follow: 1. Process control system

According to the GMP standard, the process control system for the SMEs can be achieved and established by the following steps:

a. Establish the raw material specification

Raw material specification establishment is to ensure that only sound and suitable raw materials are being used. Raw materials or ingredients should, where appropriate, be inspected and sorted before processing. Under limited condition and competency of the SMEs, the raw material quality assurance can be achieved by asking Certificate of Analysis (CoA) from the supplier. For example, the fresh milk quality inspections are done by the Cooperatives of Bandung Regency Dairy Farmers (CBRDF) as the supplier and the SMEs can ask the CoA from them.

Raw material specification generally refers to the Indonesian National Standard. Fresh milk quality standard refers to SNI 3141.1:2011. Sugar quality standard refers to SNI 3140.2:2011. Glucose syrup quality standard refers to SNI 01-2978-1992.

b. Establish the raw material composition and formulation

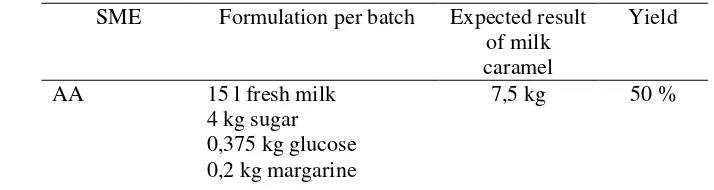

The raw material composition and formulation should be established to make sure the consistency of the finished product quality. Measurement and weighing of raw materials should be conducted for each batch production referring to the established composition or formulation. The detailed formulation is described in the Table 5. Table 5 Raw Material Composition and Formulation

21

SME Formulation per batch Expected result of milk caramel

Yield

BB 25 l fresh milk 5 kg sugar 0,25 kg glucose

8.5 kg 34 %

CC 20 l fresh milk 5 kg sugar

0,25 kg margarine 0,2 kg glucose

8 kg 40 %

c. Establish the standard operating procedure (SOP) of production process The SOP of production process is established as a guidance of production process. It ensures the production process is carried out through the same stages with standardized condition. The proposed standardized production process can be seen in the Table 6.

d. Establish the standard operating procedure (SOP) of personal hygiene The SOP of personal hygiene is established to ensure that food handlers who contact with food do not result in cross-contamination to the food. This is done by maintaining a good state of personal cleanliness, and ensuring correct behaviour when handling the food. The proposed SOP of personal hygiene is provided in Appendix 4. e. Establish the standard operating procedure for sanitation

Cleaning and sanitation programs should ensure that all parts of the establishment are appropriately clean. Cleaning programs should specify:

- Areas, items of equipment and utensils to be cleaned; - Responsibility for particular tasks;

- Method and frequency of cleaning; and - Monitoring arrangements.

22

Table 6 Proposed standardized production process

No Process stage Process quality control Description

1 Preparation of raw materials The composition of raw materials is referred to the formulation sheets

2 Fresh milk is heated up with the addition of sugar, glucose syrup, and margarine.

Milk is pasteurized in a temperature 63-700C for 30 minutes prior to addition of other ingredients.

3 The mixture is cooked in a temperature 115-1320C for 3-4 hours.

- The cooking process should be done by stirring the mixture throughout the process to distribute the heat evenly throughout the mixture and to avoid the coagulation of the mixture.

- Temperature is checked by using thermometer. - The end point of cooking stage is determined by

checking the mixture stickiness (expert

23

No Process stage Process quality control Description

4 The mixture is cooled until it reaches a temperature 450C and then it is poured into the molding pan.

The mixture is weighed in the molding pan to make sure the size consistency of each dough sheet .

5 The caramel sheet is sliced and cut into the desired size of milk caramel (1.5 cm x 1.5 cm).

The caramel chunk size is checked visually for its uniformity. SOP personel hygiene is referrred to as a process control of contamination from the foodhandlers.

6 The milk caramel is wraped. The first primary wrapping paper is the oil paper, the secondary wrapping paper is the printed HVS paper.

SOP personel hygiene SOP personel hygiene is referrred to as a process control of contamination from the foodhandlers.

7 Wrapped milk caramel is packed into the plastic bag and weighed as desired (e.g. 100 g, 200 g, or 500 g).

24

No Process stage Process quality control Description

8 The label sticker of expiry date is stamped on to the front side of the plastic bag.

25

2. Introduction of processing machinery for Mechanization of key

processing stage is desirable, such as manual mixing to be replaced by the mechanically operated mixer, the use of moulding and cutting machines, and the use of boiling pans equipped with a temperature monitoring devices (e.g. thermocouple).

3. Improvements in the product’s packaging to enhance protection of the

product thus extend the shelf life. It is suggested to modify the secondary packaging using standing pouch aluminium foil. Aluminium foil has a good tensile strength and an excellent barrier to light, liquid and foods (Coles and Kirwan 2011). Improvement in packaging design and materials will affect the consumer acceptance that might lead to the increase of product marketability.

Factors that may Influence the Adoption of Technology by the Dairy SMEs in Pangalengan

Factors that influence the adoption of technology fall into three categories, namely positive factors, negative factors, and the perceived attributes of the technology. Positive factors are those that encourage the SMEs to adopt the new technology. Negative factors are those considered to be barriers to technology adoption. While perceived attributes of technology are characteristic of technology innovation as perceived by the individuals.

1. Positive factors

a. Motivation and efforts to improve the quality and performance of the product

The respondents from SMEs realize that they have quality issues, and they need to improve the production process by implementing GMP and applying relevant technology. Respondent 1 said,

“...We realize that we still need to improve the quality of the product to be able to survive in this competitive business environment...”

Applying GMP and relevant technology are regarded as efforts of quality improvements and assurance of the products safety to gain consumers’ trust. This finding conforms with research by Fernando et al. (2014) and Karipidis et al. (2009).

b. Consumers’ demand for quality and good practices of manufacturing The increasing awareness of consumers regarding quality and good practices of manufacturing also encourage the respondents to adopt GMP. As stated by respondent 3,

“...When we exhibited in the exhibition, the consumers suggested we improve the packaging design and materials, and also the visitors who came to our place, they suggested improving the production building and facilities in relation with the GMP...”

26 c. Government or regulatory enforcement (e.g. home industry food licence)

The food licence for SMEs is issued by the local district government through the Bureau of Health. To get this licence, the food SMEs should be audited by the government official regarding the production facilities, production process, hygiene and sanitation requirements that are also included in the GMP. Therefore, the SMEs perceived that regulatory enforcement encourage them to implement GMP. This finding conforms with previous research by Karipidis et al. (2009), Yuwono et al. (2012).

d. The increase of production volumes

The SMEs recognize that they cannot rely on their current technology and working system if there is an increase of production volumes. Human power capacity will not be able to compensate for the increasing production volumes. Implementing quality assurance system such as GMP and adopting mechanized operating machines will become an urgent need to produce products that are safe and good quality.

2. Negative factors

a. Limited knowledge and educational background of the SMEs’ human resources

The workers’ education level is low because they had only limited secondary education. Consequently, the awareness and knowledge about food processing, hygiene and sanitation practices for the food industry is limited. This condition is also observed by the SMEs’ owner. Their knowledge about the quality assurance system, GMP concept and new relevant technology is also limited. They do not actively searching for the information for new and up-dated technology. They rely on the local government training event and some academics who visit their site to absorb the information on technology transfer. Respondent 5 said,

“...Technological changes relate with the educational background of the adopters. In my experience, the high-level education workers are more willing to adapt to the changing of technology...”

This is consistent with previous research (Cusato et al. 2013; Dewanti-Hariyadi 2010; Karipidis et al. 2009; Yuwono et al. 2012). b. Reluctance of the SMEs to change their current traditional practices

(mindset, experience)

Technology adoption also involves social changes. Changing a mindset, people’s attitude and ways of working are considered to be challenging by the SMEs. Respondent 5 said,

“...These SMEs are still trapped in the stigma or idea that they are producing a traditional product. It is difficult to change their practices to use the GMP concept, as well as introducing the new technology that is relevant...”

27

indicated by Ram and Sheth (1989). This finding also conforms with earlier research (Cusato et al. 2013; Dewanti-Hariyadi 2010).

c. Financial cost

Improving facilities and equipment to meet the requirements of GMP and adopting new technology such as mechanically operated machine would lead to additional cost that must be borne by the SMEs. Improving packaging design and material will increase the production cost that eventually affect the product’s selling price. Respondent 4 stated,

“...New technology adoption, whether hardware or software will involve cost to improve the current facilities or technology being used...”

This will be one of the challenges faced by the SMEs in adopting new technology; otherwise there is government support for them. This finding confirms previous research (Cusato et al. 2013; Dewanti-Hariyadi 2010; Karipidis et al. 2009; Yuwono et al. 2012).

Value barrier takes place in this case. Value is often related with the financial aspects. This is caused by the perception that the cost arise in adopting innovation is far higher than the benefit. This barrier might lead to the innovation resistance.

3. The technology perceived attributes a. Relative advantage improvement of product’s quality, assurance of food safety; reduced losses; better working environment; consumer satisfaction; and an extended shelf life for milk caramel. But there will be costs for improving the hygiene facilities, investing on mechanization of processing stages, and preparing the adequate personal hygiene facility. The SMEs still think that the cost of implementing GMP is too high. Thus, it will need government support, technically and financially, to accelerate the GMP implementation by the SMEs.

28 b. Compatibility

An innovation or technology can be compatible or incompatible with: (1) sociocultural values and beliefs; (2) previously introduced ideas; and (3) the needs for innovations (Rogers 2003a). The GMP implementation is compatible with the needs of the SMEs to address the problems of production and quality of the product. This fact is supported by the identified positive factor which is motivation and efforts to improve the quality and performance of the product.

The GMP implementation is perceived to be compatible with the needs of the customers. This has been identified in the positive factor which is consumer’s demand for quality and good practices of manufacturing. This fact is also supported by the statement of the respondent 5,

“…Yes, of course if the SMEs implement the GMP, they can give the assurance to the consumers that their products are safe and in good quality…”

The GMP implementation is also perceived compatible with the government and regulation enforcement. In order to get the food licence, the SMEs should be audited by the local government officer to examine the properness of the establishment, and that include aspects required by GMP.

c. Complexity

Implementation of GMP and the new technology embodied in it are perceived as complicated by the SMEs. This is caused by their limited knowledge regarding the concept of GMP and the new technology itself. Respondent 3 said,

“...About the GMP, I’m not familiar with that, I don’t think I have received the information or training about that. But as a food producer, of course, I implement some of the concepts, such as the cleanliness, and the hygiene practices...”