36

6.

REFERENCES

Aasen, I. M., T. Moreto, T. Katla, L. Axelsson, and I. Storro. (2000). Influence of Complex Nutrients, Temperature and pH on Bacteriocins Production by Lactobacillus sakei CCUG 42687. Journal of Microbiology. Vol 53 : 159-166.

Alemu, M., P. Laemkom, K. Doi, S. Ohmono, M. Yajima and S. Nitisinprasert. (2006) Characterization of Bacteriocin-Producing Lactic Acid Bacteria Strain N1-33 Isolated from Edible Fermented Bamboo Shoot. Kasetsart J. (Nat. Sci.). Vol 40 : 486-498.

Atlas, R. M. (2006). 2nd Handbook of Microbiological Media for the Examination of Food. Taylor & Francis Group.

Chen, H. and D.G. Hoover. (2003): Bacteriocins and Their Food Applications. Comprehensive Reviews in Food Science and Food Safety. Vol 2: 82–100.

_____, Y., H. Wu, C. Liu, H.Chen, and F. Yanagida. (2010). Isolation and Characterization of Lactic Acid Bacteria from Jiang-sun (Fermented Bamboo shoot), a Traditional Fermented Food in Taiwan. J. Sci Food Agric. Vol 90: 1977-1982.

Choudhury,D., J.K. Sahu, and G.D. Sharma. (2012). Bamboo Shoot: Microbiology, Biochemistry and Technology of Fermentation. a Review. Indian J. of Traditional Knowledge. Vol 11(2): 242-249.

Cleveland, J., T.J. Montville, I.F. Nes, and M. L. Chikindas. (2001). Bacteriocins: Safe, Natural Antimicrobials for Food Preservation. International Journal of Food Microbiology. Vol 71: 1-20.

Con, A.H. and N. Karasu. (2009). Determination of Antagonistic Starter Cultures for Pickle and Olive Fermentation Process. Czech J. Food Sci. Vol 27 (3): 185-193.

Cotter, P. D., C. Hill and R. P. Ross. (2005). Bacteriocins: Developing Innate Immunity for Food. Nature Reviews: Microbiology. Vol 3(10) : 777-788.

Dufrenne, J., E. Delfgou, W. Ritmeester, and S. Notermans. (1997). The Effect of Previous Growth Conditions on the Lag-Phase Time of Some Foodborne Pathogenic Mircroorganisms. International Journal of Food Microbiology. Vol 34 (1) : 89-94.

Eddleman, H. (1999). www.disknet.com/indiana_biolab/. (Accessed on February 22 2016; 07:15 p.m.).

Enan, G., A. A. Essawy, M. Uyttendaele, J. Debevere. (1996). Antibacterial Activity of Lactobacillus plantarum UG1 Isolated from Dry Sausage: Characterization, Production and Bactericidal Action of Plantaricin UG1. International Journal of Microbiology. Vol 30 : 189-215.

Ennahar, K., Sonomoto, and A. Ishizaki. (1999). Class IIa Bacteriocins from Lactic Acid Bacteria: Antibacterial Activity and Food Preservation. Journal of Bioscience and Bioengineering. Vol 87 (6) : 705-716.

Han, B., Z. Yu, B. Liu, Q. Ma and R. Zhang. (2011). Optimization of Bacteriocin Production by Lactobacillus plantarum YJG, Isolated from the Mucosa of the Gut of Healthy Chickens. African Journal of Microbiology Research. Vol 5 (10) : 1147-1155.

Hata, T., R. Tanaka, and S. Ohmono. (2010). Isolation and Characterization of Plantaricin ASM1: A New Bacteriocin Produced by Lactobacillus plantarum A-1. International Journal of Food Microbiology. Vol 137 : 94-99.

Hutkins, R. W. (2006). Microbiology and Technology of Fermented Foods. Blackwell Publishing Ltd.

Iranmanesh, M., H. Ezzatpanah, N. Mojgani, and T. Mak. (2015). Characterization and Kinetics of Growth of Bacteriocin Like Substance Produced by Lactic Acid Bacteria Isolated from Ewe Milk and Traditional Sour Buttermilk in Iran. Journal of Food Processing and Technology. Vol 6 (12) : 529-534.

Ivanova, I., P. Kabadjova, A. Pantev, S. Danova, and X. Dousset. (2000). Detection, Purification and Partial Characterization of a Novel Bacteriocin Substance Produced by Lactoccous lactis subsp. lactis B14 Isolated from Boza-Bulgarian Traditional Cereal Beverage. Biocatalysis: Fundamentals & Applications. Vol 41(6) : 47-53.

Mortvedt, J. J., F. R. Cox, L. M. Shuman and R. M. Welch. (1991). Micronutrients in Agriculture. 2nd Edition, Soil Science Society of America. Madison.

Juneja, V. K and J. N. Sofos. (2002). Control of Foodborne Microorganisms. Marcell Dekker Inc.

Karthiyekan, V. and S. W. Santosh. (2009). Isolation and Partial Characterization of Bacteriocin Produced from Lactobacillus plantarum. African Journal of Microbiology Research. Vol. 3 (5) : 233-239.

Kato, T., T. Matsuda, E. Ogawa, H. Ogawa, H. Kato, U. Doi, R. Nakamura. (1994). Plantaricin 149, a Bacteriocin Produced by Lactobacillus plantarum NRIC 149. Journal of Fermentation. Vol 77 : 277-282.

Kelly, W. J., R. V. Asmudson, C. M. Huang. (1996). Characterization of Plantaricin KW30, a Bacteriocin Produced by Lactobacillus plantarum. Journal Application of Bacteriology. Vol 81 : 657-662.

Khay, E. O., M. Ouhsassi, A. E. Harsal, M. Idaomar, and J. Abrini. (2013). Optimization of Bacteriocin-Like Production by Enterococcus durans E204 Isolated from Camel Milk of Morocco. Research Articles in Microbiology and Biotechnology. Vol 1 (4) : 155-159.

Lee, H., H. Yoon, and Y. Ji. (2011). Functional Properties of Lactobacillus Strains Isolated from Kimchi. International Journal of Food Microbiology. Vol 145: 155– 161.

Lindayani, L. Hartayanie, and M. P. Murniati. (2015). Efek Probiotik dan Mikrostatik dari Bakteri Asam Laktat yang Berperan dalam Fermentasi Acar Rebung. Penelitian Unggulan Perguruan Tinggi. Universitas Katolik Soegijapranata, Semarang. (unpublished).

Mahrous, H., M. Abeer, M. Abd El-Mongy, A. I. El-Batal and H. A. Hamza. (2013). Study Bacteriocin Production and Optimization using New Isolates of Lactobacillus spp. Isolated from Some Dairy Products under Different Culture Conditions. Food and Nutrition Sciences. Vol 4 : 342-356.

Mohankumar, A. and N. Murugalatha. (2011). Characterization and Antibacterial Activity of Bacteriocin Producing Lactobacillus Isolated from Raw Cattle Milk Sample. International Journal of Biology. Vol 3 (3) : 128-143.

Mollendorff, J. W., S. D. Todorov, and L. M. T. Dicks. (2009). Optimization of Growth Medium for Production of Bacteriocins Produced by Lactobacillus plantarum JW3BZ and JW6BZ, and Lactobacillus fermentum JW11BZ and JW15BZ isolated from Boza. Trakia Journal of Sciences. Vol 7 (1) : 22-23.

Naufalin, R. (2013). Aktivitas Antimikroba Formula Kulit Buah Kecombrang (Nicolaia speciosa Horan) sebagai Pengawet Alami Pangan. Seminar Nasional PATPI.

Nithya, K., D, Senbagam, B. Senthilkumar, N. Udhayashree, and R. Gurusamy. (2012). Characterization of Bacteriocin Producing Lactic Acid Bacteria and Its Application as Food Preservative. African Journal of Microbiology Research. Vol 6 (6) : 1138-1146.

Ooi, M. F., N. Mazlan, H. L. Foo, T. C. Loh, R. Mohamd, R. A. Rahim, and A. Ariff. (2015). Effect of Carbon and Nitrogen Sources on Bacteriocin-Inhibitory Activity of Postbiotic Metabolites Produced by Lactibacillus plantarum I-UL4. Malaysian Journal of Microbiology. Vol 11 (2) : 176-184.

Pandey, A.K., V. Ojha and S.K. Choubey. (2012). Development and Shelf-life Evaluation of Value Added Edible Products from Bamboo shoot. American J. Food Tech.7(6): 363-371.

Parada, J. L., C. R. Caron, A. B. P. Medeiros, and C. R. Soccol. (2007). Bacteriocins from Lactic Acid Bacteria: Purification, Properties and use as Bipreservatives. International Journal of Brazilian Archives of Biology and Technology. Vol. 50 (3) : 521-542.

Rahayu, E.S. (2003). Lactic Acid Bacteria in Fermented Foods of Indonesian Origin. Journal of Agritech. Vol. 23 (2): 75-84.

Rattanachaikunsopon, P. and P. Phumkhachom. (2000). A Bacteriocin Produced by Lactobacillus lactis subsp. lactis Isolated from Thai Fermented Foods. Science Asia Research Article. Vol 26 : 195-200.

Rawal, K., N. Bhavsar, G. Raol, B. V. Raol, and J. D. Patel. (2013). Bacteriocin: Production and Optimization by Lactobacillus species. Journal of Microbiology and Biotechnology Research. Vol 3 (6) : 64-76.

Sifour, M., I. Tayeb, H. O. Haddar, H. Namous, and S. Aissaoui. (2012). Production and Characterization of Bacteriocin of Lactobacillus plantarum F12 with Inhibitory Activity Against Listeria monocytogenes. The Online Journal of Science and Technology. Vol 2 (1) : 55-61.

Soomro, A. H., T. Masud, and K. Anwar. (2002). Role of Lactic Acid Bacteria (LAB) in Food Preservation and Human Health. Pakistan Journal of Nutrition. Vol 1 (1) : 20-24.

Tagg, J. R., A. S. Dajani, and L. W. Wannamaker. (1976). Bacteriocins of Gram-positive bacteria. Bacteriological Reviews. Vol 40 (3) : 7222-756.

Tamang, J.P. and P.K., Sarkar. (1996). Microbiology of Mesu, a Traditional Fermented Bamboo Shoot Product. International Journal of Food Microbiology., Vol 29: 49-58.

Thirumurugan, A., Ramachandran, S. and Gobikrishnan, S. (2015). Optimization of Medium Components for Maximizing the Bacteriocin Production by Lactobacillus plantarum ATM11 using Statistical Design. International Food Research Journal. Vol 22 (3) : 1272-1279.

Todorov, S. D. and L. M. T. Dicks. (2006). Effect of Medium Components on Bacteriocin Production by Lactobacillus plantarum strains ST23LD and ST341LD, Isolated from Spoiled Olive Brine. Journal of Microbiological Research. Vol 161 : 102-108.

___________________________. (2005). Growth Parameters Influencing the Production of Lactobacillus rhamnosus Bacteriocins ST461BZ and ST462BZ. Journal of Microbiology. Vol 55 (4) : 283-289.

___________________________. (2005). Effect of Growth Medium on Bacteriocin Production by Lactobacillus plantarum ST194BZ, a Strain Isolated from Boza. Food Technology and Biotechnology Journal. Vol 43 (2) : 165-173.

_______, A., B. Gotcheva, X. Dousset, B. Onno, and I. Ivanova. (2000). Influence of Growth Medium on Bacteriocin Production in Lactobacillus plantarum ST31. Journal of Biotechnolgy. Vol 14 :50-55.

______, S. and N. Richana. (2011). Potensi Bakteriosin dari Lactobacillus sp. galur SCG 1223 sebagai Biopreservatif pada Daging Segar. Buletin Teknologi Pascapanen Pertanian. Vol 7 (2) : 65-77.

www.biomerieux-usa.com. (Accessed on February 24 2016; 08:00 p.m.).

www.fda.gov/Food/ScienceResearch/LaboratoryMethods/BacteriologicalAnalyticalman ualBAM/default.htm. (Accessed on January 22 2016; 12:58 p.m.).

42

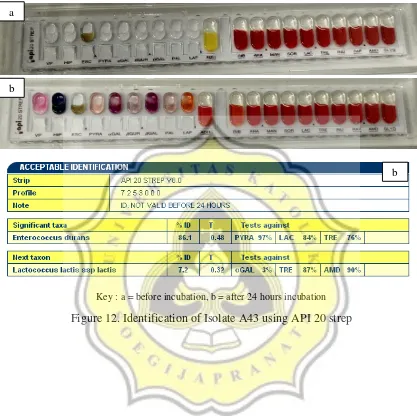

a

b

b

7.

APPENDICES

Appendix 1. Species Identification of LAB Isolates using API 20 strep

Key : a = before incubation, b = after 24 hours incubation

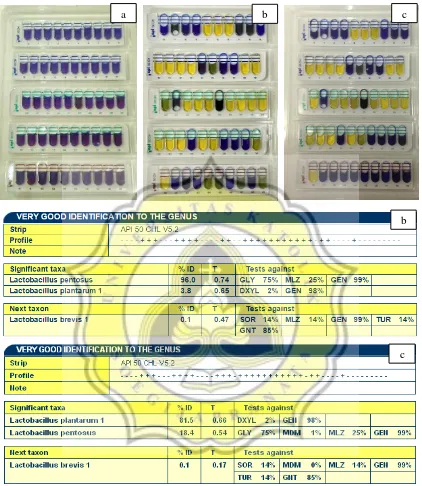

Appendix 2. Species Identification of LAB Isolates using API 50 CH

Key : a = before incubation, b = after 24 hours incubation, c = after 48 hours incubation

Figure 13. Identification of Isolate D44 using API 50 CH

a b c

b

Appendix 3. Media Used for Growth and Bacteriocin Inhibitory Activity Test of LAB Isolated from Yellow Betung Bamboo Shoot Pickle

3.1. MRS Broth Medium (Merck Brand)

MRS Broth medium was prepared by dissolving 52.2 grams of powdered MRS Broth into

1 liter of distilled water. Stir until the powder dissolve evenly. MRS Broth medium then

sterilized using an autoclave at 121°C for 15 minutes. Composition MRS Broth: 20 gL-1

D(+)-glucose, 10 gL-1 of casein/meat peptone, 8 gL-1 of meat extract, 5 gL-1 of sodium

acetate, 4 gL-1 of extract of yeast, 2 gL-1 of dipotassium hydrogen phosphate, 2 gL-1 of

di-ammonium hydrogen citrate, 1 gL-1 of tween 80, 0.2 gL-1 of magnesium sulfate, and 0.04

gL-1 of manganese sulfate.

3.2. Nutrient Broth Medium (Merck Brand)

Nutrient Broth (NB) medium was prepared by suspending 8 grams of powdered NB into

1 litre of distilled water. Stir until the powder dissolve evenly. NB medium then sterilized

using an autoclave at 121°C for 15 minutes. Composition NB: peptone from meat 5 gL-1,

meat extract 3 gL-1.

3.3. Nutrient Agar Medium (Merck Brand)

Nutrient Agar (NA) medium was prepared by dissolving 20 grams of powdered NA into

1 liter of distilled water. Stirred using a stirrer while heated until dissolved powder evenly

and boil first. Then sterilized using an autoclave at 121°C for 15 minutes. NA

Composition: 12 gL-1 of gelatin, 5 gL-1 of meat peptone, and 3 gL-1 of meat extract.

Appendix 4. Composition of Standard Solution McFarland No. 2 and 3

McFarland No. 2 standard solution was prepared by mixing 0.2 mL of BaCl2 1% with 9.9

mL of 1% H2SO4. McFarland No. 3 standard solution was prepared by mixing 0.3 mL of

BaCl2 1% with 9.7 mL of 1% H2SO4. McFarland No. 5 standard solution was prepared

by mixing 0.5 mL of BaCl2 1% with 9.5 mL of 1% H2SO4. McFarland No. 2 standard

solution equivalent to the number of bacteria 600 CFU (x106/mL), McFarland No. 3

standard solution equivalent to the number of bacteria 900 CFU (x106/mL) and

McFarland No. 5 standard solution equivalent to the number of bacteria 1500 CFU

(x106/mL). In this test, a solution of McFarland No.2 standard was used in the

identification of species, while McFarland No.3 and Mc Farland No. 5 were used in the