CHAPTER 6

CONCLUSION AND SUGGESTION

6.1. Conclusion

After doing all development for break schedule and work pattern by creating

program in Microsoft Excel, the conclusion of this research are drawn:

a. The algorithm generated to build new break schedule is explained in

Algorithm 1.

b. The criteria for selecting the best break schedule among several scenarios

are:

1) Working hour should not be more than five consecutive hours and

followed by rest period that should not be less than one hour (Thailand’s

Ministry of Labour, 1998).

2) The greatest value of maximum line can be handled by one stagger

among other scenarios with same total break time.

3) The least number of stagger team needed among other scenarios with

same total break time.

4) Total working hour for stagger that assigned in maximum capacity of line

teams can be handled is at least 8 hours.

5) Break time frame must be on multiplication of quarter hour.

6) Check all break duration for stagger team whether has same length or

not.

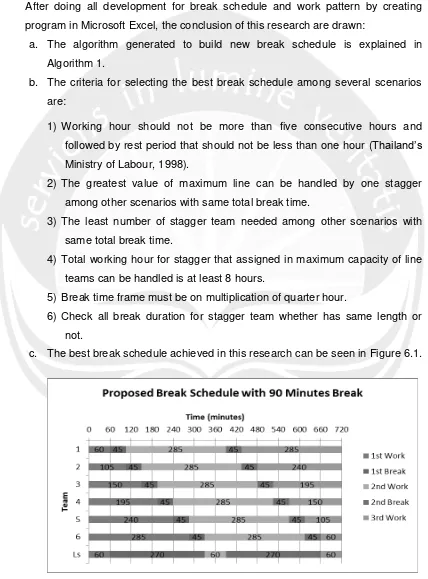

[image:1.595.88.516.160.739.2]c. The best break schedule achieved in this research can be seen in Figure 6.1.

58

d. The best break schedule achieved in this research assigns one stagger team

to handle 6 line teams.

e. The algorithm generated to build work pattern is explained in Algorithm 2.

f. The criteria for selecting the best work pattern among several scenarios are:

1) Workweek should not be more than 60 hours (EICC, 2014; Apple, 2013).

2) There must be two crews assigned on one day as there are three crews

in the company and two shift works in one day.

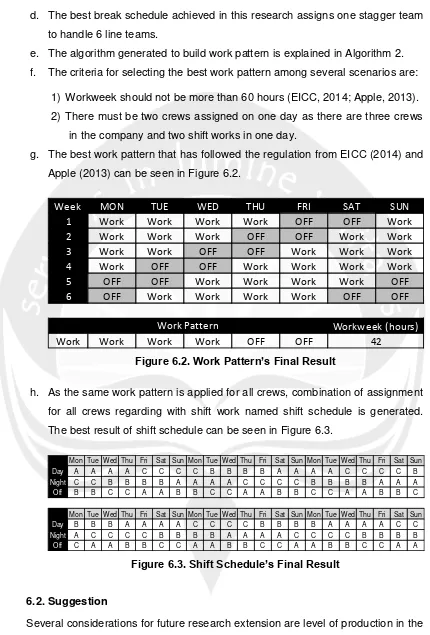

g. The best work pattern that has followed the regulation from EICC (2014) and

Apple (2013) can be seen in Figure 6.2.

Week MON TUE WED THU FRI SAT SUN

1 Work Work Work Work OFF OFF Work

2 Work Work Work OFF OFF Work Work

3 Work Work OFF OFF Work Work Work

4 Work OFF OFF Work Work Work Work

5 OFF OFF Work Work Work Work OFF

6 OFF Work Work Work Work OFF OFF

Work Work Work Work OFF OFF

Workweek (hours) 42

[image:2.595.87.517.76.711.2]Work Pattern

Figure 6.2. Work Pattern’s Final Result

h. As the same work pattern is applied for all crews, combination of assignment

for all crews regarding with shift work named shift schedule is generated.

The best result of shift schedule can be seen in Figure 6.3.

Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun

Day A A A A C C C C B B B B A A A A C C C C B

Night C C B B B B A A A A C C C C B B B B A A A

Off B B C C A A B B C C A A B B C C A A B B C

Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri Sat Sun

Day B B B A A A A C C C C B B B B A A A A C C

Night A C C C C B B B B A A A A C C C C B B B B

Off C A A B B C C A A B B C C A A B B C C A A

Figure 6.3. Shift Schedule’s Final Result

6.2. Suggestion

Several considerations for future research extension are level of production in the

company, cost incurred, and number of headcount. Level of production in the

can be created based on level of production. If there is a change for the

schedule, current schedule and proposed schedule can be compared considering

the cost incurred and number of headcount. The program also needs to be

developed for analysis as this research analyzes the schedule manually. By

60 REFERENCES

Alfares, Hesham K. (2001). Efficient Optimization of Cyclic Labor Days-Off

Scheduling. OR-Spektrum, 23 (2), 283-194.

Alfares, Hesham K. (2002). Optimum Workforce Scheduling Under The (14, 21)

Days-Off Timetable. Journal of Applied Mathematics & Decision Sciences,

6 (3), 191-199.

Alfares, Hesham K. (2006). Compressed Workweek Scheduling with Days-Off

Consecutivity Weekend-Off Frequency, and Work Stretch Constraints.

INFOR, 44 (3), 175-189.

Apple. (2013). Apple Supplier of Conduct. Accessed on March 3rd, 2014 from

https://www.apple.com/supplier-responsibility/pdf/Apple_Supplier_Code_of

_Conduct.pdf.

Brunner, Jens O., Bard, Jonathan F. & Kolisch, Rainer. (2009). Flexible Shift

Scheduling of Physicians. Health Care Management Science, 12 (3),

285-305.

Brusco, Michael J. & Jacobs, Larry W. (2000). Optimal Models for Meal-Break

and Start-Time Flexibility in Continuous Tour Scheduling. Management

Science, 46 (12), 1630-1641.

Department of Labour. (1998). Labour Protection Act B.E. 2541 (1998), 2541

(44), 12-14, 76.

EICC. (2014). Electronic Industry Citizenship Coalition Code of Conduct.

Accessed on December 2nd, 2014 from http://www.eiccoalition.org/media/

docs/EICCCodeofConduct5_English.pdf.

Elshafei, Moustafa & Alfares, Hesham K. (2008). A Dynamic Programming

Algorithm for Days-Off Scheduling with Sequence Dependent Labor Costs.

Journal of Scheduling, 11 (2), 85-93.

Kaluzny, B. L., & Hill, A. (2011). Scheduling Security Personnel for the Vancouver

2010 Winter Olympic Games, INFOR, 49 (3), 221–231.

Keller, Simone M., RN, BSN. (2009). Effects of Extended Work Shifts and Shift

Work on Patient Safety, Productivity, and Employee Health. AAOHN

Labour Standard Development Bureau. (2008). Labour Protection Act (No. 2)

B.E. 2551 (2008). (2), 3.

Laporte, G & Pesant, G. (2004). A General Multi-Shift Scheduling System.

Journal of The Operational Research Society, 55 (11), 1208-1217.

Rekik, Monia, Cordeau, Jean-françois, & Soumis, François. (2010). Implicit Shift

Scheduling with Multiple Breaks and Work Stretch Duration Restrictions.

Journal of Scheduling, 13 (1), 49-75.

Tucker, Philip, Smith, Lawrence, Macdonald, Ian & Folkard, Simon. (1999).

Distribution of Rest Days in 12 Hour Shift Systems-Impacts on Health,

Wellbeing, and on Shift Alertness. Occupational and Environmental

Medicine, 56 (3), 206-214.

Unite The Union, (2013). Shift Work and Night Work. Accessed on May 20th,

2014 from http://www.unitetheunion.org/uploaded/documents/ShiftandNight

Work%2011-4950.pdf

Yuniartha, D. R. (2012). Shift Pattern in Cyclic Scheduling with Between-Days

Break-Time Constraint. Proceedings of the Asia Pacific Industrial

62 APPENDIX 1

USER GUIDE FOR BREAK SCHEDULE PROGRAM

Overview

This program is used for building break schedule automatically. However, this

program works as calculator only as the program cannot choose the best break

schedule over several scenarios created. In the input section, this program will

generate several scenarios based on possible values of break schedule

components. The output of this program is break schedule for all scenarios

generated in input section. This program is built on one of feature in Microsoft

Excel, VB Program.

Operating Break Schedule Program

1. Open Microsoft Excel’s file named Final Project DONE.xlsm

2. Make sure to enable Macro feature

3. Choose worksheet named Input

4. Look at break schedule section in Input sheet

5. Click command button named Input below break schedule’s input data

6. Fill in shift length in hour, number of line assigned, and break time in

minutes on user form showed

7. If there is mistype, click button named Clear to clean out data inputted in

user form

8. If cancelling to fill in break schedule’s input, click button named Cancel

and user form will be closed

9. If button named OK is clicked after fill in all input, several scenarios will be

generated automatically based on possible values from input data

10. After all scenarios are generated, click command button named RUN

Break Schedule and break schedule over all scenarios will be built in

worksheet named Break Schedule. If the value in break schedule is

greater than 5 hours or 300 minutes, it will be displayed by red colored

number. Break schedule that has red colored number cannot be

considered as good break schedule. If there are some break schedule

Editing Break Schedule Program

1. Open Microsoft Excel’s file named Final Project DONE.xlsm

2. Click on Developer tab. If there is no Developer tab, click File, select

Options, choose Customize Ribbon, Give check mark for Developer on

Main Tabs, and Click OK.

3. On Developer tab, click Visual Basic

4. Double click in Sheet1 (Input). In this sheet, there are several private sub

there.

5. Look at Private Sub Command_input_Click(). This private sub is used for

giving instruction when command button named Input for break schedule

is clicked.

3. Double click on UserForm_BreakSchedule. This forms display how user

form for break schedule would like to showed including instruction for

command button in user form.

4. Double click on user form. There are several private subs regarding with

the display on user form. Private Sub UserForm_initialize() is used for

displaying no values showed on textboxfor all input. Private Sub

Command_ok_Click(), it is used for generate the input on scenarios after

clicking command button named OK. The value on Work1_cont

represents initial first work. Currently value of Work1_cont is 15 with

increment 15. The value of Work1_cont will be tried by do loop command

until equal to 120. If there is change on value of Work1_cont, three parts

regarding with Work1_cont can be changed manually. The value for first

stagger break also can be changed manually. Currently minimum value

for b1 or break1 is 40 with increment 5 to find possible value for

combination of break. Those two values can be changed depend on the

needs. Private Sub Command_clear_Click() is used for clean out any

values in input after command button named Clear is clicked. Private Sub

Command_cancel_Click() is used for closing user form as canceling input

data in user form after command button named Cancel is clicked.

1. Double click on Sheet1 (Input). Look at Private Sub

RUNBreakSchedule_Click(). That is used for generate break schedule

based on scenarios created in Input sheets after clicking command button

64

2. Double click on Modules folder. There are two modules for break

schedule. Those are BreakScheduleScn1 and BreakScheduleScnOther.

Both modules there work as function to calculate break schedule that are

called in when command button named RUN Break Schedule is clicked.

BreakScheduleScn1 Module is used for calculating break schedule for

scenario 1 only. constraint_10AM is used for giving limitation when line

team gets long break. Currently, the value for constraint_10AM is 3. If 3

hours is too long to be the limitation, value for constraint_10AM can be

changed manually. BreakScheduleScnOther Module is used for

calculating break schedule for all scenarios generated in input except

APPENDIX 2

USER GUIDE FOR WORK PATTERN PROGRAM

Overview

This program is used for building work pattern automatically. However, this

program works as calculator only as the program cannot choose the best work

pattern over several scenarios created. In the input section, this program will

generate several scenarios based on possible values of placement of first day

work on work cycle. The output of this program is work pattern for all scenarios

generated in input section. This program is built on one of feature in Microsoft

Excel, VB Program.

Operating Work Pattern Program

1. Open Microsoft Excel’s file named Final Project DONE.xlsm

2. Make sure to enable Macro feature

3. Choose worksheet named Input

4. Look at work pattern section in Input sheet

5. Click command button named Input below work pattern’s input data

6. Fill in shift length in hour, break time in minutes, day-off in day, and work

cycle in day

7. If there is mistype, click button named Clear to clean out data inputted in

user form

8. If cancelling to fill in work pattern’s input, click button named Cancel and

user form will be closed

9. If button named OK is clicked after fill in all input, several scenarios will be

generated automatically based on possible values from input data

10. After all scenarios are generated, click command button named RUN

Work Pattern and work pattern over all scenarios will be built in worksheet

named Work Pattern. If the value of workweek is greater than 60 hours, it

will be displayed by red colored number. Work pattern that has red

colored number cannot be considered as good work pattern. If there are

some work pattern that pass the regulation, those will be evaluated later

66 Editing Work Pattern Program

1. Open Microsoft Excel’s file named Final Project DONE.xlsm

2. Click on Developer tab. If there is no Developer tab, click File, select

Options, choose Customize Ribbon, Give check mark for Developer on

Main Tabs, and Click OK.

3. On Developer tab, click Visual Basic

4. Double click in Sheet1 (Input). In this sheet, there are several private sub

there.

5. Look at Private Sub Input1_Click(). This private sub is used for giving

instruction when command button named Input is clicked.

6. Double click on UserForm_WorkPattern. This forms display how user form

for work pattern would like to showed including instruction for command

button in user form.

7. Double click on user form. There are several private subs regarding with

the display on user form. Private Sub UserForm_initialize() is used for

displaying no values showed on textboxfor all input. Private Sub

Command_ok_Click(), it is used for generate the input on scenarios after

clicking command button named OK. Private Sub Command_clear_Click()

is used for clean out any values in input after command button named

Clear is clicked. Private Sub Command_cancel_Click() is used for closing

user form as canceling input data in user form after command button

named Cancel is clicked.

8. Double click on Sheet1 (Input). Look at Private Sub

RUNWorkPattern_Click(). That is used for generate work pattern based

on scenarios created in Input sheets after clicking command button

named RUN Work Pattern.

9. Double click on Modules folder. Double click on WorkPattern Module. The

module works as function to generate work pattern that is called in when

command button named RUN Work Pattern is clicked. Currently, this

program generates work pattern only for 6 days and 7 days’ work cycle. If

there is any option of work cycle beside those values, the assignment for

work and day off on each week and each crew must be added manually.