Analisis Sediaan Farmasi

Analisis Sediaan Farmasi

Henry K.S.,M.Si.Apt,

Henry K.S.,M.Si.Apt,

Jadwal Kuliah

Jadwal Kuliah

Minggu

Minggu Bahan kajianBahan kajian

II Validasi metode analisisValidasi metode analisis II

II Validasi metode analisisValidasi metode analisis III

III Pemisahan Pemisahan komponen aktif dari komponen aktif dari bahan pembantu sediaan bahan pembantu sediaan obat, serta pemobat, serta pemilihan metodeilihan metode

analisis analisis

IV

IV Analisis kuantitatif sediaan obat monokomponen (padat & semi padat) secaraAnalisis kuantitatif sediaan obat monokomponen (padat & semi padat) secara

spektrofotometri, spektrofluorometri dan elektrokimia spektrofotometri, spektrofluorometri dan elektrokimia

V

V Analisis kuantitatif sediaan obat monokomponen (cair dan steril) secara spektrofotometri,Analisis kuantitatif sediaan obat monokomponen (cair dan steril) secara spektrofotometri,

spektrofluorometri dan elektrokimia spektrofluorometri dan elektrokimia

VI

VI Analisis kuantitatif sediaan obat multikomponen (padat & semi padat) secaraAnalisis kuantitatif sediaan obat multikomponen (padat & semi padat) secara

spektrofotometri dan spektrofluorometri spektrofotometri dan spektrofluorometri

VII

VII Analisis kuantitatif sediaan obat multikomponen (Cair dan Steril) secara spektrofotometriAnalisis kuantitatif sediaan obat multikomponen (Cair dan Steril) secara spektrofotometri

dan spektrofluorometri dan spektrofluorometri

VIII

VIII Penentuan dan Identifikasi permasalahan dalam hal Penentuan dan Identifikasi permasalahan dalam hal analisisanalisis IX

IX Analisis kuantitatif Analisis kuantitatif sediaan obat sediaan obat multikomponen multikomponen secara KCKTsecara KCKT X

X Analisis kuantitatif sediaan Analisis kuantitatif sediaan obat multikomponen secara obat multikomponen secara KLKLT dan KGT dan KG XI

XI Analisis Sediaan KosmetikaAnalisis Sediaan Kosmetika XII

XII Analisa Sediaan Makanan dan minumanAnalisa Sediaan Makanan dan minuman XIII

XIII Analisa dalam Sampel BiologisAnalisa dalam Sampel Biologis XIV

Daftar Pustaka:

Daftar Pustaka:

•• United States PharmacopoeiaUnited States Pharmacopoeia

•• Horwitz, W., and Latimer, Horwitz, W., and Latimer, G.W., 2005, Official MethodsG.W., 2005, Official Methods of Analysis, AOAC International, Maryland

of Analysis, AOAC International, Maryland

•• Robert V Smith, et. Al, Textbook of BiopharmaceuticRobert V Smith, et. Al, Textbook of Biopharmaceutic Analysi

Analysis,1981.s,1981.

•• Cahyadi Cahyadi W. W. , , 2006,2006, Analisi Analisis dan Aspek Kess dan Aspek Kesehatanehatan Bahan Tambahan Pangan

Bahan Tambahan Pangan, Bumi Aksara: Jakarta, Bumi Aksara: Jakarta •• Rohman A., dan I.G. Gandjar, 2007,Rohman A., dan I.G. Gandjar, 2007, MetodeMetode

Kromatografi untuk Analisis Makanan

Kromatografi untuk Analisis Makanan, Pustaka Pelajar:, Pustaka Pelajar: Yogyakarta

Yogyakarta

•• Mitra S., 2003,Mitra S., 2003, Sample Preparation Techniques inSample Preparation Techniques in Analytica

Analisis Sediaan Farmasi

Analisis Sediaan Farmasi

Analisis = ??

Analisis = ?????

???

Sediaan Farmasi = ????

Sediaan Farmasi = ????

C

Validation

Proses penilaian terhadap parameter

analitik tertentu, berdasarkan percobaan

laboratorium, untuk membuktikan bahwa

parameter tersebut memenuhi syarat

The Validation Process

Validation

Method

Validation

System

Suitability

Hardware

Software

Validation (4M)

• Man

• Machine

• Material

• Method

Qualification

Qualification

•• Qualification is a subset of the validation

Qualification is a subset of the validation

process that verifies module and system

process that verifies module and system

performance prior to the instrument being

performance prior to the instrument being

placed on-line.

placed on-line.

•• If the instrument is not qualified prior to

If the instrument is not qualified prior to

use and a problem is encountered, the

use and a problem is encountered, the

source of the problem will be

source of the problem will be difficult to

difficult to

identify.

The Validation Timeline

The Validation Timeline

Vendor’s Site

Vendor’s Site

User’s

User’s

Site

Site

User’s

User’s

Site

Site

Structural

Structural

and

and

Software

Software

Qualification

Qualification

Qualification

Qualification

IQ

IQ

OQ

OQ

PQ

PQ

Calibration

Calibration

and

and

Maintenance,

Maintenance,

System

System

Suitability

Suitability

BeforeInstallation Qualification (IQ)

Installation Qualification (IQ)

•• The IQ process can be divided into two

The IQ process can be divided into two

steps: preinstallation and physical

steps: preinstallation and physical

installation.

installation.

•• During the preinstallation, all the

During the preinstallation, all the

information pertinent to the proper

information pertinent to the proper

installation, operation, and maintenance of

installation, operation, and maintenance of

the instrument is reviewed.

the instrument is reviewed.

•• Site requirements and the receipt of all of

Site requirements and the receipt of all of

the parts, pieces, manuals, etc., necessary

the parts, pieces, manuals, etc., necessary

to perform the installation are confirmed.

•• During the physical installation, serial

During the physical installation, serial

numbers are recorded, and all of the

numbers are recorded, and all of the

fluidic, electrical, and communication

fluidic, electrical, and communication

connections are made for components in

connections are made for components in

the system.

the system.

•• Documentation describing how the

Documentation describing how the

instrument was installed, who

instrument was installed, who performed

performed

the installation, and other miscellaneous

the installation, and other miscellaneous

details should be archived.

details should be archived.

Installation Qualification (IQ)

Operational Qualification (OQ)

• The OQ process ensures that the specific

modules of the system are operating

according to the defined specifications for

accuracy, linearity and precision.

• This process may be as simple as

verifying the module’s self diagnostic

routines, or it may be performed in more

depth by running specific tests, for

example, to verify detector wavelength

accuracy, flow rate, or injector precision.

Performance Qualification (PQ)

• The PQ process verifies system performance.

• PQ testing is conducted under actual running

conditions across the anticipated working range.

• In practice, however, OQ and PQ are frequently

performed together, particularly for linearity and

precision (repeatability) tests, which can be

conducted more easily at the system level.

• For HPLC, the PQ test should use a method with

a well-characterized analyte mixture, column,

and mobile phase. A system suitability must be

performed.

• Proper documentation supporting the PQ

process should be archived.

Validation

• Process Validation

– Prospective Validation – Ongoing Validation

– Re-Validation: After change, Periodic, – Retrospective Validation

• Analytical Method Validation

– Specificity, Linearity, Precision, Accuracy/Recovery, Ruggedness

• Cleaning Validation

• Utility System Validation • Computer Validation

What is not Analytical Method Validation?

• Calibration

The Process of Performing Tests on Individual System Components to Ensure Proper function

• System Suitability

Test to verify the proper functioning of the operating system, i.e., the electronics, the equipment, the

HPLC Detector calibration

• Wavelength Accuracy

• Linear Range

• Noise Level

• Drift

Typical System Suitability Test

• Minimum Resolution of 3.0 between

the analyte peak and internal

standard peaks

• Relative Standard Deviation of

replicate standard injections of not

more than 2.0%

Method Life Cycle

Validation

Verification vs. Validation

• Compendial vs. Non-compendial Methods

– Compendial methods-Verification – Non-compendial methods-Validation

Today’s Validation Requirements

ICH/USP

GMPs

GMP Validation Parameters

• Accuracy

• Specificity

• Sensitivity

FDA Validation Parameters

• Accuracy

• Precision

• Linearity

(& Range)

• Specificity

(& Determination Limit)

• Recovery

• Ruggedness

ICH/USP Validation Requirements &

Parameters

• Specificity • Linearity • Range • Accuracy • Precision – Repeatability – Intermediate Precision – Reproducibility • Limit of DetectionICH

I nter national Conf er ence on H armoni zation

Specificity Linearity and Range Accuracy Precision Limit of Detection Limit of Quantitation Ruggedness Robustness

USP

USP Data Elements Required For Assay

Validation

* May be required, depending on the nature of the specific test.

Analytical Performance Parameter Assay Category 1 Assay Category 2 Assay Category 3 Quantitative Limit Tests

Accuracy Yes Yes *

Precision Yes Yes No Yes Specificity Yes Yes Yes

LOD No No Yes

LOQ No Yes No

Linearity Yes Yes No *

Range Yes Yes * *

USP Categories

• Category 1: Quantitation of major components or active ingredients

• Category 2: Determination of impurities or degradation products

• Category 3: Determination of performance characteristics

ICH Validation Characteristics vs. Type of

Analytical Procedure

Type of Analytical Procedure Identification Impurity testing Assay Quantitative Limit TestsAccuracy No Yes No Yes Precision

Repeatability No Yes No Yes Interm. Prec. No Yes No Yes Specificity Yes Yes Yes Yes

LOD No No Yes No

LOQ No Yes No No

Linearity No Yes No Yes Range No Yes No Yes

Method Validation for USP

• Method validation, according to the United

States Pharmacopeia (USP), is performed to

ensure that an analytical methodology is

accurate, specific, reproducible, and rugged

over the specified range that an analyte will be

analyzed.

• Method validation provides an assurance of

reliability during normal use and is sometime

described as the proces of providing

documented evidence that the method does

what it is intended to do.

KAPAN DILAKUKAN?

1. Pengembangan metode analisis (MA) yang

telah ada misalnya untuk:

- Matriks sampel yang spesifik

- Memperbaiki “Analytical Performance” MA

dengan adanya instrument atau teknik baru

- MA yang terlalu mahal, memakan banyak

waktu & energi

2. Terhadap MA yang dibuat dari

modifikasi metode resmi (standard

yang telah dipublikasi secara

internasional, regional atau nasional;

jurnal ilmiah yang relevan)

TUJUAN

1. Hasil analisis absah/valid, dapat

dipercaya dan dapat dipertanggung

jawabkan secara ilmiah

2. Hasil analisis dapat menunjukkan

Accuracy vs precision

What you

would like

Accuracy vs precision

•

Poor accuracy

•

Good precision

Accuracy vs precision

•

Poor precision

•

Good accuracy

Accuracy vs precision

•

Totally hopeless!

•Poor precision

•

Poor accuracy

What would you

call this?

So what definitions do these

concepts lead us to in the

ACCURACY (1)

• The accuracy of an analytical

procedure expresses the closeness of

agreement between the value which is

accepted either as a conventional true

value or an accepted reference value

and the value found. This is

ACCURACY (2)

Assay of Drug Substance:

a) application of an analytical procedure to an

analyte of known purity (e.g. reference

material);

b) comparison of the results of the proposed

analytical procedure with those of a second

well-characterized procedure, the accuracy

of which is stated and/or defined

(independent procedure)

c) accuracy may be inferred once precision,

linearity and specificity have been

ACCURACY (3)

Assay of Drug Product:

a) application of the analytical procedure to synthetic mixtures of the drug product components to which known quantities of the drug substance to be

analysed have been added;

b) in cases where it is impossible to obtain samples of all drug product components, it may be acceptable either to:

– add known quantities of the analyte to the drug product or – to compare the results obtained from a second, well

characterized procedure, the accuracy of which is stated and/or defined (independent procedure)

c) accuracy may be inferred once precision, linearity and specificity have been established.

ACCURACY (4)

Impurities (Quantitation):

• Accuracy should be assessed on samples (drug substance/drug product) spiked with known

amounts of impurities.

• In cases where it is impossible to obtain samples of certain impurities and/or degradation products, it is considered acceptable to compare results obtained by an independent procedure.

• It should be clear how the individual or total

impurities are to be determined e.g., weight/weight

or area percent, in all cases with respect to the major analyte.

The Matrix Effect

• The matrix effect problem occurs when the unknown sample

contains many impurities.

• If impurities present in the unknown interact with the analyte to change the instrumental response or

themselves produce an

instrumental response, then a calibration curve based on pure analyte samples will give an

Analytical Method Development

• Accuracy: Application of the method to synthetic mixtures of the drug product components to which known quantities of the

analyte have been added • Recovery reduced

by ~10 – 15%

From: Analytical Method Validation and Instrument Performance Verification, Edited by Chung Chow Chan,Herman Lam, Y.C. Lee and Xue-Ming Zhang, ISBN 0-471-25953-5, Wiley & Sons

Recommended Data

• Accuracy should be assessed using a

min.

of

9 determinations over a min. of 3

concentration levels

covering the specified

range (e.g. 3 concentrations/3 replicates

each of the total analytical procedure).

• Accuracy should be reported as:

–

% recovery

by the assay of known addedamount of analyte in the sample or as

– the difference between the mean and the accepted true value together with the

Example:

• Taken from:

ASEAN Operational Manual for

Implementation of GMP ed. 2000 p.405

• Nine solutions containing different

concentrations of ketotifen fumarate

reference standard added to ketotifen

tablet batch no. 2506VAMG were

Example (continued):

Conc. of ketotifen fumarate Areadetected Recovery (%) Acceptance Criteria mg/ml % 0.280 0.320 0.360 0.380 0.400 0.420 0.440 0.480 0.520 70 80 90 95 100 105 110 120 130 1473566 1677013 1904848 1905862 2091215 2180374 2293647 2518976 2670144 99.32 99.48 100.94 100.51 100.06 100.03 100.07 101.01 98.99 Mean (recovery) : 100.04 Standard deviation : 0.699 Relative standard deviation (RSD) : 0.699 %

98.0 – 102.0 %

Accuracy

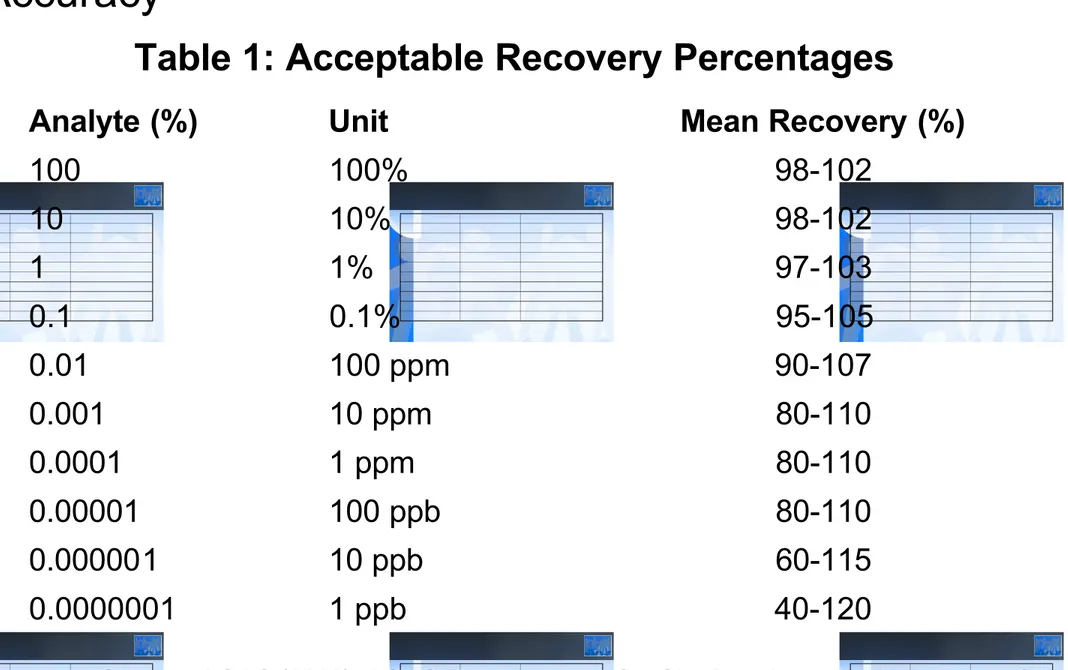

Analyte (%) Unit Mean Recovery (%)

100 100% 98-102 10 10% 98-102 1 1% 97-103 0.1 0.1% 95-105 0.01 100 ppm 90-107 0.001 10 ppm 80-110 0.0001 1 ppm 80-110 0.00001 100 ppb 80-110 0.000001 10 ppb 60-115 0.0000001 1 ppb 40-120

Table 1: Acceptable Recovery Percentages

Source: AOAC (2002). AOAC Requirements for Single Laboratory Validation of Chemical Methods. DRAFT 2002-11-07, \AOACI\eCam\Single-Lab_Validation_47.doc. http://www.aoac.org/Ag_Materials/additives/aoac_slv.pdf

PRECISION

• The precision of an analytical procedure expresses the closeness of agreement (degree of scatter)

between a series of measurements obtained from

multiple sampling of the same homogeneous sample under the prescribed conditions.

• Precision may be considered at three levels: –

repeatability,

–

intermediate precision and

–reproducibility

.• Precision should be investigated using

homogeneous, authentic samples. However, if it is not possible to obtain a homogeneous sample it may be investigated using artificially prepared samples or a sample solution.

• The precision of an analytical procedure is usually expressed as the variance,

standard deviation or

Repeatability (1)

• Repeatability expresses the precision

under the same operating conditions

over a short interval of time.

• Repeatability is also termed intra-assay

precision.

Repeatability (2)

• Repeatability should be assessed

using:

a) a minimum of 9 determinations

covering the specified range for the

procedure (e.g. 3 concentrations/3

replicates each) or

b) a minimum of 6 determinations at

100% of the test concentration.

Intermediate precision

• Intermediate precision expresses within-laboratories variations:

different days

,different analysts

,different equipment

, etc.• The extent to which intermediate precision should be established depends on the circumstances under

which the procedure is intended to be used.

• The applicant should establish the effects of random events on the precision of the analytical procedure. • Typical variations to be studied include days,

analysts, equipment, etc. It is not considered

necessary to study these effects individually. The use of an experimental design (matrix) is

Reproducibility

• Reproducibility is assessed by means

of an inter-laboratory trial.

• Reproducibility should be considered

in case of the standardization of an

analytical procedure, for instance, for

inclusion of procedures in

Recommended Data

• The

standard deviation

,

relative

standard deviation

(coefficient of

variation) and confidence interval

should be reported for each type of

precision investigated.

Example

• Taken from:

ASEAN Operational Manual for

Implementation of GMP ed. 2000 p.403

• The active ingredient, ketotifen

fumarate,

in tablets (batch no. 2506VAMG) was

assayed seven times using HPLC and

the reference standard

Example (continued)

Sample no. Concentration (mg/ml) Area detected 1 2 3 4 5 6 7 0.4 0.4 0.4 0.4 0.4 0.4 0.4 1902803 1928083 1911457 1915897 1913312 1897702 1907019 Mean : 1910896 Standard deviation : 9841.78 Relative standard deviation (RSD) : 0.515 %

Acceptance criteria: Relative standard deviation (RSD): not more than 2 %

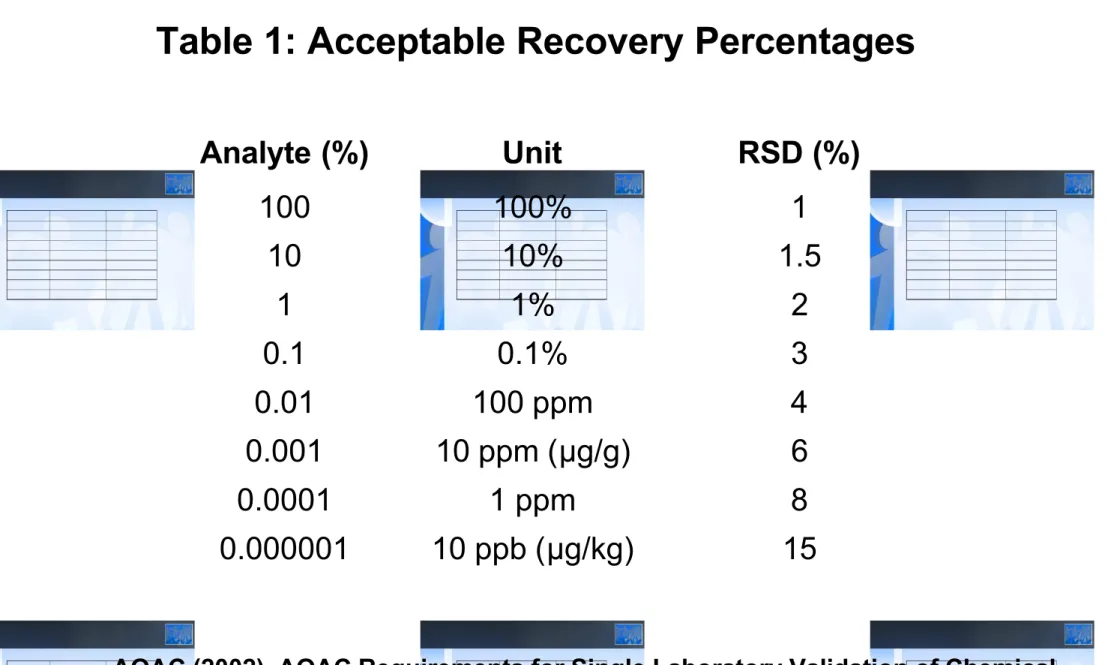

Kriteria

Secara umum:

- RSD < 1.0 % (Bahan baku obat)

- RSD < 2.0 % (Sediaan obat)

Analyte (%) Unit RSD (%) 100 100% 1 10 10% 1.5 1 1% 2 0.1 0.1% 3 0.01 100 ppm 4 0.001 10 ppm (μg/g) 6 0.0001 1 ppm 8 0.000001 10 ppb (μg/kg) 15

Table 1: Acceptable Recovery Percentages

AOAC (2002). AOAC Requirements for Single Laboratory Validation of Chemical Methods. DRAFT 2002-11-07, \AOACI\eCam\Single-Lab_Validation_47.doc. http://www.aoac.org/Ag_Materials/additives/aoac_slv.pdf.

Specificity/Selectivity

• Ability of an analytical method to measure the analyte free from interference due to other components.

• Selectivity describes the ability of an analytical method to differentiate various substances in a sample

Specificity: Impurities Assay

• Chromatographic Methods

– Demonstrate Resolution

• Impurities/Degradants Available

– Spike with impurities/degradants

– Show resolution and a lack of interference

• Impurities/Degradants Not Available

– Stress Samples

– For assay, Stressed and Unstressed Samples should be compared.

Forced Degradation Studies

• Temperature (50-60 • Humidity (70-80%)

• Acid Hydrolysis (0.1 N HCl) • Base Hydrolysis (0.1 N NaOH) • Oxidation (3-30%)

• Light (UV/Vis)

Intent is to create 10 to 30 % Degradation

Examples of pure and impure HPLC peaks

Source: LabCompliance (2007). Validation of Analytical Methods and Procedures: Tutorial. http://www.labcompliance.com/tutorial/methods/default.aspx?sm=d_d

Linearity

• Ability of an assay

to elicit a direct and

proportional

response to

changes in analyte

concentration.

Linearity Should be Evaluated

• By Visual Inspection of plot of signals vs. analyte concentration

• By Appropriate statistical methods

– Linear Regression (y = mx + b)

– Correlation Coefficient, y-intercept (b), slope (m)

• Acceptance criteria: Linear regression r 2 > 0.99

Cara penetapan

• Ditetapkan terhadap minimum

konsentrasi pada rentang minimum 50 %

- 150 % dari kadar analit

• Dihitung regresi liniernya dan didapat

persamaan regresi: Y = a + bx

RANGE

• The specified range is normally derived

from linearity studies and depends on the

intended application of the procedure.

• It is established by confirming that the

analytical procedure provides an

acceptable degree of linearity, accuracy

and precision when applied to samples

containing amounts of analyte within or at

the extremes of the specified range of the

analytical procedure.

Minimum Specified Ranges

• for the

assay

of a drug substance or a finished

(drug) product: normally from 80 - 120 % of the

test concentration

• for

content uniformity

, covering a minimum of

70 - 130 % of the test concentration

• for

dissolution

testing:

+/-20 % over the

specified range

; e.g., if the specifications for a

controlled released product cover a region

from 20%, after 1 hour, up to 90%, after 24

hours, the validated range would be 0-110% of

the label claim

Detection limit vs Quantitation

limit

‘Know that it’s there’

vs

Detection limit

(means)

Is any of it present?

Quantitation limit

How much of it is present???

Method Validation- LOD and LOQ

Sensitivity

• Limit of detection (LOD) – “the lowest content that can be measured with reasonable statistical certainty.”

• Limit of quantitative measurement (LOQ) – “the lowest concentration of an analyte that can be determined with acceptable precision (repeatability) and accuracy under

the stated conditions of the test.”

1. Based in Visual Evaluations

- Used for non-instrumental methods

2. Based on Signal-to Noise-Ratio

- 3:1 for Detection Limit

- 10:1 for Quantitation Limit

3. Based on Standard Deviation of the Response and the Slope

Analytical Method Development

Noise LOD Signal to Noise = 3:1 LOQ Signal to Noise = 10:19/23/2013 76

• Berdasarkan kurva kalibrasi analit

Menurut Miller:

LOD = 3.S

Y/X+ yb

yb = intersep

LOQ = 10.S

Y/X+yb

( ˆ) / 2

2

/ y y N